Speed in decision-making. Speed in reducing cycle-times. Speed in operations. And, speed in continuous improvement. The use of Artificial Intelligence in the supply chain is here to stay and will make huge waves in the years to come.

According to Gartner, supply chain organizations expect the level of machine automation in their supply chain processes to double in the next five years.

At the same time, global spending on IIoT Platforms is predicted to grow from $1.67B in 2018 to $12.44B in 2024, attaining a 40% compound annual growth rate (CAGR) in seven years.

In today’s connected digital world, maximizing productivity by reducing uncertainties is the top priority across industries. Plus, mounting expectations of supersonic speed and operational efficiencies further underscore the need to leverage the prowess of Artificial Intelligence (AI) in supply chains and logistics.

Accelerating Supply Chain Success with AI in Supply Chains & Logistics

AI in supply chains can deliver the powerful optimization capabilities required for more accurate capacity planning, improved demand forecasting, enhanced productivity, lower supply chain costs, and greater output, all while fostering safer working conditions.

The pandemic and the subsequent disruptions has demonstrated the dramatic impact of uncertainties on supply chains and has established the need for smart contingency plans to help companies deal with these uncertainties in the right way.

But is AI the answer? What can AI mean for companies as they struggle to get their supply chain and logistics back on track? Let’s find out.

AI in Supply Chains – The Business Advantage

Accurate Supply Chain Inventory Management

Accurate inventory management can ensure the right flow of items in and out of a warehouse. Simply put, it can help prevent overstocking, inadequate stocking and unexpected stock-outs.

But the inventory management process involves multiple inventory related variables (order processing, picking and packing) that can make the process both, time consuming and highly prone to errors.

Here is where AI driven supply chain planning process and tools, with their ability to handle mass data, can prove to be highly effective. These intelligent systems can analyze and interpret huge datasets quickly, providing timely guidance on forecasting supply and demand.

Some of the AI systems are so advanced that they can even predict and discover new consumer habits and forecast seasonal demand. This level of AI application can help anticipate future customer demand trends while minimizing the costs of overstocking unwanted inventory.

Warehousing Efficienty

An efficient warehouse is an integral part of the supply chain. AI-based automation can assist in the timely retrieval of an item from a warehouse and ensure a smooth journey to the customer.

AI systems can also solve several warehouse issues, more quickly and accurately than a human can, and also simplify complex procedures and speed up work. Also, along with saving valuable time, AI-driven automation efforts can significantly reduce the need for, and cost of, warehouse staff.

Enhanced Safety

AI-based automated tools can ensure smarter planning and efficient warehouse management, which can, in turn, enhance worker and material safety.

AI can analyze workplace safety data and inform manufacturers about any possible risks. It can record stocking parameters and update operations along with necessary feedback loops and proactive maintenance.

This helps companies react swiftly and decisively to keep warehouses secure and compliant with safety standards.

Reduced Operations Costs

Here’s one benefit of AI systems for the supply chain that one simply can’t ignore. From customer service to the warehouse, automated intelligent operations can work error-free for a longer duration, reducing the number of human oversight-led errors and workplace incidents.

Additionally, warehouse robots can provide greater speed and accuracy, achieving higher levels of productivity – all of which will reflect in reduced operations costs.

On-time Delivery

As we discussed above, AI systems help reduce dependency on manual efforts, thus making the entire process faster, safer and smarter. This helps facilitate timely delivery to the customer as per the commitment.

Automated systems accelerate traditional warehouse procedures, removing operational bottlenecks along the value chain with minimal effort to achieve delivery targets.

Challenges of AI in Supply Chain

The potential of AI in supply chain and logistics is undisputed. However, to say that the path to become AI-powered is without challenges would be a lie.

To build successful AI-powered supply chains, you must also be aware of the challenges that you might encounter along the way.

System Complexities

AI systems are usually cloud-based, and require expansive bandwidth. Sometimes, operators also need specialized hardware to access these AI capabilities and the cost of this AI-specific hardware can turn out to be a huge initial investment for many supply chain partners.

The Scalability Factor

Since most AI and cloud-based systems are quite scalable, the level of initial start-up users/systems that may be needed to be more impactful and effective could be higher.

Since all AI systems are unique and different, this is something that supply chain partners will have to discuss in depth with their AI service providers.

The Cost of Training

Like any other new technology solution, adoption of AI and its effective use will require personnel training, which is another aspect that’ll need significant investment in terms of time and money.

This can impact business efficiency as supply chain partners will need to work closely with the AI providers to create a training solution that is impactful and at the same time, affordable during the integration phase.

The Operational Costs Involved

An AI-operated machine has an exceptional network of individual processors and each of these parts need maintenance and replacement from time-to-time.

The challenge here is that due to the possible cost and energy involved, the operational investment could be quite high. When the time comes to replace some of these parts, the utility bills could shoot up and could directly impact the overhead expenses.

Scouting for the Needle in the Supply Chain Haystack

Data was once the barrier to effective use of AI. Not anymore. There is no dearth of data at most organizations. Smart investments in technologies like Artificial Intelligence (AI) are helping companies capture huge amounts of previously disaggregated data, but there arises a bigger question:

Is there a way to detect business bottlenecks sooner, given this ever-exploding pile of mashed-up data?

To guarantee results, supply chain managers need to be able to cut through the data noise with a powerful tool. A tool that can make use of this vast amount of data with targeted operational analytics to detect, quantify and rank the bottlenecks building-up in business processes early on.

Day-to-day Benefits of AI-Powered Supply Chains

Studies suggest that AI and Machine Learning (ML) technologies can deliver unprecedented value to supply chain and logistics operations.

From cost savings, reduced operational redundancies, risk mitigation, to enhanced supply chain forecasting, speedy deliveries, more optimized routes and improved customer service, AI in the supply chain is being preferred by several top companies globally.

According to McKinsey, 61% of manufacturing executives report decreased costs, and 53% report increased revenues as a direct result of introducing AI in the supply chain.

Further, more than one-third suggested a total revenue bounce of more than 5%. Some of the high impact areas in supply chain management include planning and scheduling, forecasting, spend analytics, logistics network optimization and more, further discussed below.

Bolstering Planning and Scheduling Activities

Most often, supply chain managers struggle to establish an end-to-end process to plan for profitable supply network accounting, especially while being faced daily with increasing globalization, expanding product portfolios, greater complexity, and fluctuating customer demand.

Lack of complete visibility into existing product portfolios due to unplanned events, plant shutdowns, or transportation problems makes this task even more convoluted.

A typical smart supply chain framework includes multiple products, spare parts, and critical components, which are responsible for accurate outcomes. In many supply chain industries, these products or parts can be defined using multiple characteristics that take a range of values.

This can result in a high number of product configurations and applications. Also, in many cases, products and parts are also phased-in and phased-out regularly, which can cause proliferation leading to uncertainties and the bullwhip-effects up and down the supply chain.

By implementing AI in supply chain and logistics, supply chain managers can enhance their decision making by predicting building-up bottlenecks, unforeseen abnormalities, and solutions in order to streamline production scheduling that otherwise tends to be highly variable.

Furthermore, AI in supply chain can also lead to accurate predictions and quantification of expected outcomes across different stages of the schedule enabling the scheduling of more optimal alternatives as and when such interruptions occur during execution.

Inteligent Decision-making

AI-lead supply chain optimization software amplifies important decisions by using cognitive predictions and recommendations on optimal actions.

This can help enhance overall supply chain performance. It also uncovers possible implications across various scenarios in terms of time, cost, and revenue. Also, by constantly learning over time, it continuously improves on these recommendations as relative conditions change.

End-to-end Visibility

With the complex network of supply chains that exist today, it is critical for manufacturers to get complete visibility of the entire supply value chain, with minimal effort.

Having a cognitive AI-driven automated platform offers a single virtualized data layer to reveal the cause and effect, to eliminate bottleneck operations, and pick opportunities for improvement. All of this using real-time data instead of redundant historical data.

Additional Resources: Why Supply Chain Visibility is a Big Deal?

Actionable Analytical Insights

Several companies today lack key actionable insights to drive timely decisions that meet expectations with speed and agility. Cognitive automation that uses the power of AI has the ability to sift through large amounts of scattered information to detect patterns and quantify tradeoffs at a scale, much better than what’s possible with conventional systems.

Inventory and Demand Management

One of the biggest challenges faced by supply chain companies is maintaining optimum stock levels to avoid ‘stock-out’ issues. At the same time overstocking can lead to high storage costs, which on the contrary, don’t lead to revenue generation either.

Bringing in the perfect balance here is mastering the art of inventory and warehouse management.

When applied to demand forecasting, AI & ML principles create highly accurate predictions of future demand. For example, forecasting the decline and end-of-life of a product accurately on a sales channel, along with the growth of the market introduction of a new product, is easily achievable.

Similarly, ML & AI in supply chain forecasting ensures material bills and PO data are structured and accurate predictions are made on time. This empowers field operators to maintain the optimum levels required to meet current (and near-term) demand.

Boosting Operational Efficiencies

Besides the treasures still largely trapped in disaggregated data system silos at most corporations, IoT-enabled physical sensors across supply chains now also provide a goldmine of information to monitor and manipulate supply chain planning processes too.

With billions of sensors and devices, analyzing this pot of gold manually can create huge operational resource wastage and delayed production cycles. This is where intelligent analytics powered by AI in supply chain and logistics delivers immense value.

When supply chain components become the critical nodes to tap data and power the machine learning algorithms, radical efficiencies can be achieved. The value is realized through the application of machine learning in price planning.

The increase or decrease in the price is governed by on-demand trends, product life cycles, and stacking the product against the competition. This data is priceless and can be used to optimize the supply chain planning process for even greater efficiencies.

Unlocking Fleet Management Efficiencies

One of the most underrated aspects of the supply chain is the fleet management process. Fleet managers orchestrate the vital link between the supplier and the consumer and are responsible for the uninterrupted flow of commerce.

Along with rising fuel costs and labor shortages, fleet managers constantly face data overload issues. Managing a large fleet can easily seem like a daunting task more akin to an air traffic controller. If you can’t find the information you need quickly, or properly utilize the data you collect, you may find your data pool quickly turning into an unproductive swamp.

AI in supply chain and logistics provides real-time tracking mechanisms to gain timely insights including the optimal times by where, when, and how deliveries must and should be made.

Such powerful multi-dimensional data analytics further aids in reducing unplanned fleet downtime, optimizing fuel efficiencies, detecting and avoiding bottlenecks. It provides fleet managers with the intelligent armor to battle against the otherwise unrelenting fleet management issues that occur on a daily basis.

Additional Resource: What AI-powered Freight Management Software can Deliver?

Streamlining Enterprise Resource Planning (ERP)

A study by Panorama Consulting determined that “63% of manufacturing companies exceed their ERP budgets with average implementation costs overrun rising to $3 million.” Because supply chain managers deal with heterogeneous purchasing, procurement, and logistics across global supply chains, they tend to have more complex business processes than what a traditional software can handle.

AI in supply chain and logistics helps streamline the ERP framework to make it future-ready and connect people, processes, and data in an intelligent way. Finally, when AI is correctly implemented on ERP and related data systems, data becomes more receptive and event-driven over time, while processing greater amounts of data, to intelligently learn, quantify, rank, and prescribe remedies proactively and more frequently over time.

AI in Supply Chain: a Future Full of Promises

Gartner predicts that “The rise of IIoT will allow supply chains to provide more differentiated services to customers, more efficiently”.

As supply chain companies shift their focus from products to outcomes, traditional business models will become dated and then obsolete altogether, with the bodies and brands of the laggards and losers scattered along the way.

With global supply chains strengthening their roots, competitive pressures will force firms to extract every possible ounce of cost from their respective operations.

This is even more pronounced for local, regional, and national firms that are limited in their economies of scale, currency hedge capabilities, market concentration, with limited technology and operational budgets.

In such cases, looking at and embracing the winning SaaS and cloud solutions is a strategy for keeping up, and getting ahead of, the international conglomerates with massive IT and OT budgets, and greater margins of error in the near-term for making poor and expensive supply chain optimization technology mistakes with expensive consultants.

With all these influences coming to bear simultaneously, we are about to see a paradigm shift from simple reactive intelligence to predictive, adaptive and continuous learning systems that drive better decisions for continuous improvements using ML and AI in supply chain and ML on your existing data sources.

According to PwC, AI applications have the power to transform the way business is done and contribute up to $15.7 trillion to the global economy by 2030.

Today, AI can seed in the much needed agility and precision in supply chain optimization. It can also trigger a transformational increase in operational and supply chain efficiencies and a decrease in costs where repetitive manual tasks can be automated.

Readying Your Supply Chain for Artificial Intelligence: What You Need To Do First

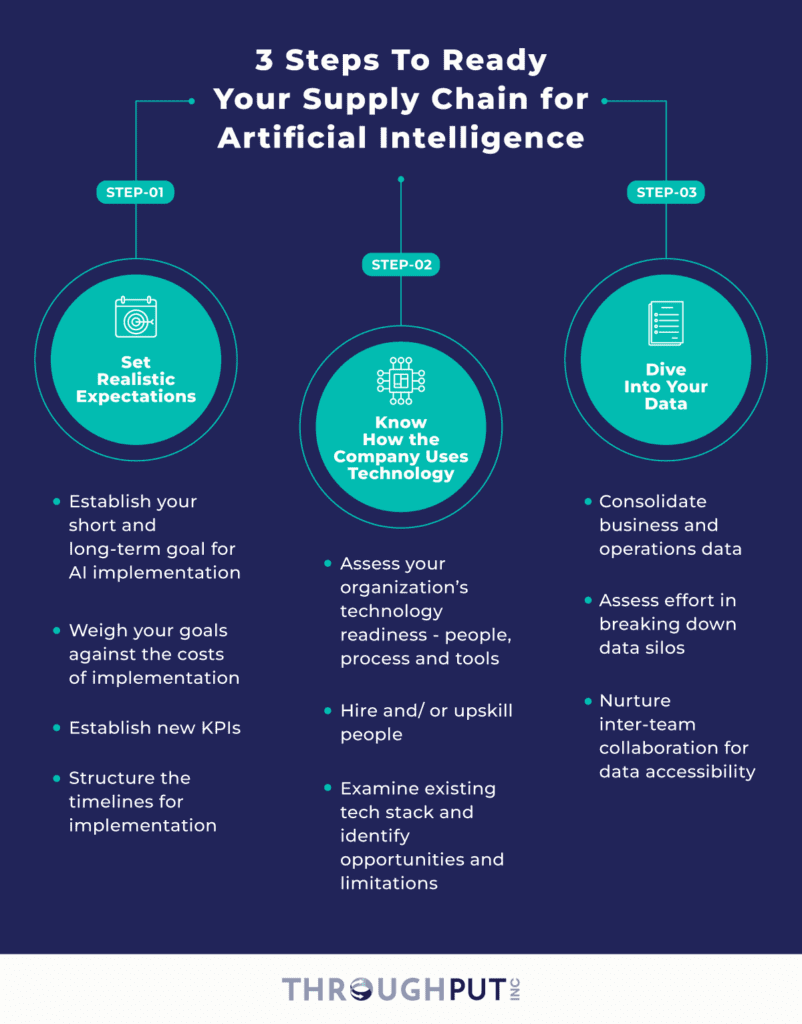

Before investing heavily in new technologies, you must first assess your state of digital readiness. This assessment involves three steps:

1. Set Realistic Expectations

Every organization must conduct a self-awareness test before committing to AI implementation. Gather key internal stakeholders and ask thoughtful questions that scrutinize the targets and goals of a proposed implementation.

If you haven’t yet had formal discussions about new technology integrations, decide what these integrations might help you achieve.

Quantify your broad expectations for the short and long term. Weigh those against the hypothetical costs of implementation — including technology-acquisition expenses; the effects of temporary productivity disruption; and the labor costs of installation, setup and training.

At this stage, it can be useful to establish new KPIs to measure the impact of integrating AI in supply chain management. These should be related to the company’s traditional high-level goals. At a more granular level, professionals should understand how AI and automation will contribute to specific company operations.

Digital transformation doesn’t occur in a vacuum —existing personnel and processes across the organization will be impacted, even if the implementation is on a relatively small scale.

Once you have (1) an idea of the expected ROI of AI, (2) the potential impacts of digital transformation and (3) an estimate of costs, start thinking about your project timeline. Here, your focus should be on long-term efficiency gains, rather than immediate fixes.

Your investment is not going to pay off right away. The benefits of AI-powered supply chain management are cumulative in nature, and you’ll likely have to make near-term sacrifices to achieve significant future advantages.

2. Know How the Company Uses Technology

After understanding what you hope to gain from AI in supply chain, from a broader operational standpoint, assess your organization’s technology readiness. That assessment should be focused on three components: people, skills and tools.

Start by consulting with human resources staff to gain an understanding of the potential personnel impacts of technological transformation. Chances are good that you’ll need to bring in specialized personnel to fill new roles in your organization, so you’ll need a plan for identifying and recruiting those people. You may also need to train existing employees and ensure they understand how their responsibilities and workflows will change during and after implementation.

Examine your existing technology stack and discuss its advantages and limitations with relevant stakeholders. Interoperability is a critical measure of tech readiness, so try to get a sense of how well your various technologies are working together now.

Do this by asking questions: What is the language used for this application, and is it used for any others? How efficient are the data collection and storage tools, and how easy is it to retrieve data on demand? To what extent are we leveraging open-source technologies?

Are our critical applications closed and dependent on vendor services and customization, or are they interoperable and application programming interface (API)-ready?

Looking ahead, you’ll also want to think about where your new tech stack will be located —on-site; in a data warehouse; in a private, hybrid or public cloud; or some combination of those.

Who will need access to it (and from where) to keep operations running smoothly and KPI benchmarks met? In sum, this assessment requires a combination of meticulous planning at the personnel and application levels, and big-picture thinking about the state of the entire enterprise.

3. Dive Into Your Data

Data is the fuel that feeds AI, and you’ll need a lot of it to maximize your returns. Most business leaders know this, and they assume that they don’t have enough data to make an AI investment worthwhile. This is a common misconception.

Within most organizations, there is usually an abundance of data being generated, stored and forgotten. For these companies, the challenge isn’t collecting new data — it’s locating, consolidating and analyzing existing data. Often, most of the company’s data is collected for compliance purposes or used during audits.

Companies will want to consolidate their business and operations data — regardless of the amount — to assess overall data readiness. And your organization probably has more data than you think.

When stakeholders claim there isn’t enough data, that it isn’t clean, or that they’re unsure which data is relevant, they are succumbing to a common fallacy. They assume scarcity when availability is the real issue. Siloed data isn’t helpful to most operations, so it might as well not even exist.

Before implementing ai in scm (supply chain management), organizations might have to spend considerable time and effort breaking down silos, which often are intertwined with company culture and deeply embedded business processes.

A lack of commonality between different personnel types, such as information technology, operations technology, and operations and business, is also a culprit. Each of these teams has a different core objective and looks at data differently.

What may be immensely valuable to one department is often just noise to another, and in many organizations, a lack of regular interaction among teams leads to a lack of communication about important things like data.

Digital transformations can force internal teams to overcome silos and even restructure to facilitate increased collaboration. Ideally, however, a company should remove silos before beginning a digital transformation.

Doing so will not only make the transition process easier and more effective, but provide insights on whether the business is ready for such a transformation. If you can’t compel teams to work together and share important business information as a matter of course, you might not be ready.

AI is already beginning to transform and revolutionize supply management. If your organization hasn’t yet begun its digital transformation journey, and you’re feeling left behind, don’t worry: Machine learning is still in its nascent stage, and AI won’t disappear.

That’s not to say you should wait for AI technologies to fully mature before exploring their usefulness to your organization. Instead, follow the steps above to determine your company’s digital readiness. That exercise should inform your next steps.

If you’re not ready for transformation, start by preparing a plan to implement artificial intelligence in supply chain. If you are ready already, start creating and executing your implementation plan.

What No one Tells You about Implementing AI Integration

Today’s supply chain executives are short on time, and having multiple meetings to discuss solution implementation is a burden they can’t afford. Integrated AI tools provide actionable insights that eliminate bottlenecks and unlock real-time value. That’s important because supply chain companies need more execution — not more analysis.

Implementing a full AI solution might seem daunting and cost-prohibitive, and it’s true that costs can range from millions to tens of millions of dollars, depending on the size of the organization. Businesses must first undergo a full digitization process and then implement an analytics program before they can integrate AI tools.

Oftentimes, companies waste significant resources in this process because they don’t incorporate the end user feedback and end up having to backtrack to address unanticipated problems.

But there is an alternative. An agile approach enables organizations to begin implementing AI in cost-effective ways. By integrating third-party vendors, they can start where they are, learn what works for their businesses, and scale up as needed.

This tactic allows for much faster AI integration than building a new platform from the ground up or building on top of legacy solutions.

Benefits Associated with Agile Cloud-based AI Strategies

1. Maximised Data

Supply chain companies excel at managing the flow of goods and services, and legacy platforms were designed to handle the data associated with these processes. But because they were built before AI and machine learning, they’re not equipped for the demands of today’s supply chain industries.

Newer platforms are built with technology stacks that can handle data capture, storage, processing, analysis, and visualization, and they’re designed for quick integration. Rather than wait for legacy vendors to build machine learning algorithms into their platforms, supply chain companies can take advantage of new tools immediately.

2. Automated Critical Analyses

Supply chain operations are complex, and it’s difficult for a human to recognizse patterns in inefficiencies, even with the aid of traditional business intelligence solutions.

Operations teams can reduce the amount of time it takes to analyze data by leveraging AI tools. AI works 24/7, and its sole job is to analyze inputs and highlight trends. Analysts can use those insights to identify potential areas of improvement, forecast demand and inventory levels, schedule maintenance and downtime activities, and predict potential equipment failures.

As an example of how this is working, consider AI’s role in agriculture. Weather forecasting and smart image processing enable growers to identify pests, weeds, and disease early on so they can protect their healthy crops.

Predictive analytics enable them to gauge how environmental factors will influence their crop yields, and real-time soil monitoring helps them adjust water levels to optimize growth. Supply chain companies can enjoy similar real-time and predictive benefits through AI solutions.

3. Enhanced Competitiveness

AI is not just a nice-to-have; it’s an imperative to stay competitive. These tools reduce processing time and facilitate smarter, faster decision-making.

AI provides a view into market trends and even weather patterns that might impact operations, and that data can make all the difference in maintaining strong customer relationships and industry credibility.

Having a view into when, where, and why bottlenecks occur can transform a company’s workflows and radically improve a supply chain company’s profitability.

By partnering with third-party AI vendors, supply chain businesses can move away from the cumbersome old model of waiting for legacy platforms to catch up with new technologies. The most successful businesses will be those that apply scalable, easily integrated solutions to their existing processes.

Additional Resources:

Top 3 Challenges an AI-enabled Supply Chain Can Solve

Supply Chain Analytics for Optimum Operational Planning and Efficiency

Supply Chain Planning & Optimization Software – An End-to-End Supply Chain Solution