AI in Transportation and Logistics: Steering Towards Smarter Operations

E-commerce has changed the transportation and logistics industry. So have the problems of the Suez and Panama Canal, geopolitical tensions, and economic fluctuations.

Many of the new technologies hitting the market are promising to make disruption and changes an “experience of resilience” for the logistics businesses. While we can’t vouch for all of them, artificial intelligence or AI in transportation and logistics definitely emerges as a promising option.

Amid this constant demand-supply flux in today’s global markets, AI can help predict scenarios and possible outcomes, facilitating proactive and smarter strategies. Many AI-powered tools now not only give you visibility into the supply chain, they can also recommend intelligent actions, facilitating optimized decisions.

Other than this, AI in transportation and logistics also helps in day-to-day activities like optimizing route planning, improving inventory management, and running operations smoothly even in the face of constant flux.

That said, many businesses still fail to leverage the true, full potential of AI in their distribution processes.

This blog will show you how AI is transforming the transportation and logistics landscape, highlighting its diverse applications and benefits. We will also showcase specific use cases, such as route optimization with examples of big global companies using AI to enable smarter, more efficient operations.

What is the Role of AI in the Transportation and Logistics Industry

The role of AI in the transportation and logistics industry is varied.

It has led to significant advancements in several operations, the most talked about of which has to date been warehouse automation.

Robots have helped efficiently sort, pick, and pack inventory, considerably speeding up order fulfillment. However, while this has dramatically improved efficiency in warehouse processes, it is only the tip of the iceberg when it comes to the potential applications of AI.

In reality, AI in transportation and logistics can increase efficiency across supply and distribution processes, starting from real-time tracking and monitoring of inventory in warehouses (or on the move), to demand-driven optimization of inventory and distribution to minimize wastage and transportation costs.

This, in turn, creates considerable new data that can be fed back into the system to further improve process efficiency. Thus, AI can transform warehouses into high-tech, highly efficient distribution centers that can not only keep up with the rapidly growing demand in today’s consumer environment but also help improve the overall customer experience.

In other words, the need to integrate AI in supply chains and logistics is no longer an opportunity but a necessity.

What Are the Benefits of AI in Transportation and Logistics

The benefits of AI in transportation and logistics are multi-fold including demand-driven traffic management, smart warehouse systems, OTIF deliveries and more.

Demand-driven, Optimized Traffic Management

AI-powered traffic management systems help businesses eliminate congestion and bottlenecks, optimize transportation routes, schedules, traffic flow, and capacity allocation, and minimize travel times based on real-time demand changes.

This, in turn, improves delivery times, optimizes fuel consumption, and reduces harmful emissions.

Smart Warehouse Systems

AI makes it possible to deploy smart warehouse systems that can rapidly adapt and respond to new scenarios and optimize operations across the entire logistics network.

As a result of streamlined, optimized warehouse operations, overall productivity goes up substantially.

On Time in Full (OTIF) Deliveries

Logistics operations are key to supply chain operations, right from procurement to production and distribution. Optimizing logistics is thus critical to successful demand fulfillment.

AI enables businesses to optimize the movement of material to ensure OTIF order fulfillment at the least possible cost – leading to enhanced customer satisfaction and a much-needed competitive edge in the market.

Strategic Asset Utilization

In 2021, it cost more than $20,000 to ship a regular 40-foot container from China to the US east coast – compared to less than $3,000 only two years ago.

In the face of such disruptions, it is essential for businesses to maximize the outcomes of their logistics processes and enhance the value derived from all of their logistics assets.

AI helps this by offering fully transparent visibility into fleet performance, allowing logistics executives to strategically utilize their assets as well as safeguard them against unanticipated risk.

AI also enables businesses to match capacity to demand – thus decreasing shipment of empty containers, and reducing the number of vehicles on the go.

These vehicles can then be directed to locations where there is demand (or is predicted to go up), ensuring efficient asset utilization while significantly reducing operational costs.

In summary, AI in transportation and logistics holds the potential to accelerate efficiency, cost, and sustainability across the entire logistics network.

What Are the Most Promising Use Cases of AI in Logistics

While AI adoption in the logistics and transportation space has been slightly slower than in other segments, it has rapidly gained momentum over the past few years.

It is now revolutionizing the way businesses manage production, warehouse and distribution centers, and customer demand while improving efficiency, reducing costs, and increasing profits.

Here are the top four high-impact AI use cases in logistics today.

Route Optimization and Freight Management

AI helps businesses analyze existing routes, evaluate the cost-benefit ratios for alternative routes, and optimize them for the best outcomes under varied business conditions.

Route optimization leverages shortest path algorithms to help identify the most efficient routes for rail, road, or sea freight – at scale, and in real time.

Thus, businesses can significantly speed up the shipping process while at the same time minimizing shipping costs.

Importantly, route optimization is also an effective tool to minimize carbon emissions and accelerate sustainable transportation.

Recommend Optimum Stock Levels

The challenges in maintaining the right stock levels are many.

There is a lack of visibility of product movement across several supply chain layers. Overstocking/understocking of inventory is common due to this, creating a dent in critical working capital. Inadequate product mix levels are another limitation of manual or siloed logistics management software systems that need to be streamlined based on demand vs supply changes.

With ThroughPut’s AI-based supply chain software, for instance, both allocation and distribution recommendations are focused on creating a perfect pull and removing unnecessary moves to get the product to where it is needed, on time and in full (OTIF).

It means that you never miss a sale opportunity. The tool also continuously updates the Target Service levels based on the product mix priorities for each period.

Buffer Management/Emergency Stock Creation and Management

Matching customer demand to the actual supply of products/ services is a constant war footing zone today. That’s because of the imbalance between recommended stock versus actual inventory levels at any point in time.

For example, with ThroughPut AI, monitoring buffer consumption is a seamless process, helping translate quality performance against recommended stock level targets with the passage of time.

The tool helps expose risk and waste in the system.

Using correct buffer-sizing criteria, ThroughPut ensures that the user can supply the next node in the supply chain to the desired level of service regardless of the reliability of the vendors or the variability of customer demand.

SKU/Location Health

The lack of a streamlined approach to ensure optimum SKU health at all times is a constant challenge for businesses. Another area of concern is the process of constantly replenishing lead times to avoid low stock levels while catering to a minimum average daily usage.

The health of supply (Replenishment Lead times) and demand (Average Daily Usage) signals are dynamically factored into the recommended inventory buffers in order to avoid flow disruptions.

This helps optimize inventory turns, service levels, and days of supply.

What Are Some Examples of AI in Transportation and Logistics

DHL

DHL has adopted AI to optimize its delivery routes and also to reduce fuel costs. The company leverages AI to analyze data such as delivery addresses, traffic patterns, and weather conditions to identify the most efficient delivery routes, resulting in lower fuel consumption and enhanced delivery times.

UPS

UPS leverages AI-powered predictive analytics to analyze data on customer demand, package volume, and delivery routes to predict and prevent delivery delays – and optimize its delivery network. This has resulted in vastly better delivery times at much lower costs for the company.

Maersk

The world’s largest shipping company, Maersk leverages AI to optimize its shipping routes and fuel consumption. With an AI-powered routing system that factors in weather patterns, ocean currents, and other influencing factors, the company determines the most optimized route for each of its shipments.

Amazon

AI shows up in nearly all of Amazon’s processes, from months before delivery begins right up to when a driver is assigned to the delivery of a package to a customer’s doorstep.

The company famously deployed AI-powered robots in its warehouses to maximize efficiency and cut back labor costs. The robots move packages around the warehouse, pick and pack orders, and transport packages to the shipping area.

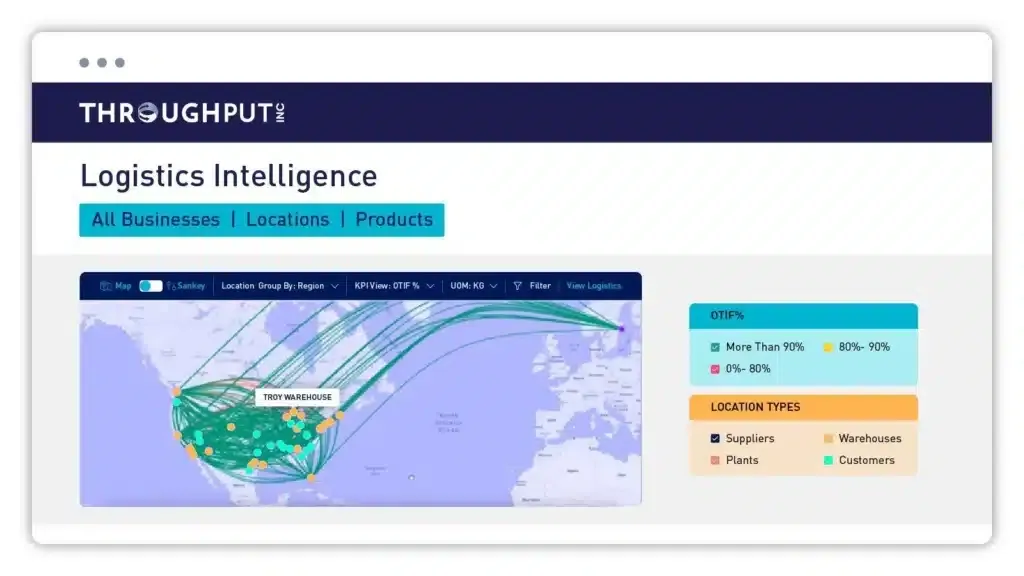

How Can ThroughPut AI Improve Your Logistics?

ThroughPut’s AI-powered supply chain intelligence software helps you get instant AI-based insights to identify where logistics operations are lagging, while easily exposing strategic and tactical opportunities for improvement.

Using a combination of business rules mapping and machine learning pattern extraction, it assesses bottom-line benefits associated with each opportunity for better prioritization, related to logistics spending and underlying sales improvement potential.

ThroughPut’s AI-powered suite also drives real-time distribution and logistics planning to bridge the gap between demand and supply so that operational decision-making is quicker and smarter. The tool helps companies with continuous optimization of warehouse strategies, streamline labor processes and efficient fleet management to achieve all-around efficiencies across the supply chain.

With ThroughPut, it is possible to:

1. Instantly compare multiple review period volumes

- Comprehensive view to assimilating all the shipments from supplier to DC, DC to DC, DC to Store, and Store to Customer including final sales.

- Analyze using smart graphical representation by the route and shipment type of received, delivered and sold aggregate volumes

- Dynamically prioritize items based on logistics costs, lost sales opportunities, and more.

2. Obtain actionable insights on operational gaps

- Fix the spots where operations are lagging significantly

- Expose tactical opportunities for improvement of processes

- In-depth assessment of the bottom-line benefits associated with each opportunity for better prioritization

3. Achieve SKU-driven holistic logistics flow

- Quickly view and assess the flow of a particular SKU or a cluster of selected SKUs all the way from supplier through the distribution network to stores

- Connect the sales flow volumes from the perspective of various metrics

- Map the flow end-to-end to analyze the performance of the logistics value chain

Are You Ready to Fully Utilize AI in Logistics? A Recommendation…

Even with tangible benefits, there are innumerable challenges in the logistics sector for fully leveraging the potential of AI.

Firstly, the upfront implementation costs are usually quite high.

Secondly, AI tools work with data; hence, there is an immediate requirement for the business to produce voluminous and quality data.

Thirdly, data privacy concerns and compliance issues are challenges that need focused work.

Most of all, integrating the AI tool with the existing processes and infrastructure can be a complex domain, requiring technical expertise.

The best way to overcome these challenges is to ‘Start Small.’

Begin with a pilot project.

For example, you can consider optimizing a single route or a facility. And see how it goes.

Once the pilot project yields successful results over a targeted period, you can build up a compelling case and take it up with your stakeholders for scaling up with additional resources and budget.

For a secured buy-in to include more facilities and routes, you can highlight how the pilot project helped save costs while improving efficiency.

This step-up or incremental process of implementing AI in transportation and logistics can help prepare and inculcate organizational readiness while minimizing risks, and making your operations smarter.

Expert FAQs: How AI Solves High-Impact Transportation & Logistics Challenges

Question 1. How can AI in transportation and logistics help reduce unplanned downtime for industrial operations?

Answer: AI uses real-time machine health insights, anomaly detection, and predictive alerts to identify early signs of failure in vehicles, material-handling equipment, and fleet assets. VP/Heads of Maintenance can reduce unplanned downtime by 20–40% by scheduling service before breakdowns occur, optimizing maintenance windows, and improving asset availability across the logistics network.

Question 2. What ROI can supply chain leaders expect after implementing AI-driven logistics optimization?

Answer: AI typically delivers 8–15% logistics cost savings through optimized routing, fewer expedites, improved carrier selection, and better load utilization. It also reduces inventory carrying costs and shortens cycle time. Most enterprises see measurable ROI within 8–12 weeks when AI connects directly to operational data (ERP, WMS, TMS).

Question 3. How does AI improve decision-making for cross-functional teams like maintenance, sourcing, and supply chain?

Answer: AI creates a single version of operational truth by pulling data across ERP, MES, WMS, and fleet systems. It surfaces actionable recommendations—such as alternative sourcing options, predicted bottlenecks, optimal transport modes, or critical spare requirements—so leaders can act proactively rather than reactively.

Question 4. Can AI help industrial companies handle transportation disruptions or supplier failures in real time?

Answer: Yes. AI continuously monitors demand signals, supplier commitments, carrier reliability, and route constraints. When disruptions occur, it automatically recommends alternative suppliers, re-routes shipments, reprioritizes production orders, and predicts potential service-level failures before they impact customers.

Question 5. How quickly can AI be deployed across an industrial transportation and logistics network?

Answer: Modern no-code AI platforms can ingest ERP, TMS, and sensor/fleet data within hours and start generating insights in less than two weeks. Full operational optimization can go live in 4–6 weeks without requiring IT-heavy implementation.

Question 6. How does AI support sourcing leaders in balancing cost, risk, and supplier performance?

Answer: AI evaluates multi-variable supplier performance—OTIF, lead times, freight reliability, cost volatility, and risk exposure—and uses predictive modeling to recommend optimal supplier mix. It can also simulate cost scenarios and forecast upcoming supply shortages.

Question 7. What data does an AI system need from TMS/ERP/WMS to optimize transportation and logistics?

Answer: AI requires: shipment history, carrier performance, route-level transit times, material master data, demand patterns, lead-time variability, capacity plans, and cost structures. The more real-time the inputs (IoT, telematics, WMS logs), the better the predictive accuracy and optimization.

Question 8. Will AI disrupt existing workflows for operations, maintenance, or sourcing teams?

Answer: No. AI overlays insights onto existing systems and simplifies workflows. Instead of replacing processes, it enhances them by automating repetitive tasks, improving forecast reliability, and giving teams prescriptive guidance to make faster and more accurate decisions.

Question 9. How does AI identify root causes of delays, bottlenecks, or high transportation costs?

Answer: AI correlates millions of data points—carrier history, lane performance, order priority, loading delays, supplier behavior, and asset health—to pinpoint root causes. It then quantifies impact (e.g., “This lane causes a 12% cost overrun”, “This SKU drives 40% of delays”) and prescribes corrective actions.

Question 10. Can AI predict fleet and equipment failures affecting logistics efficiency?

Answer: Yes. With telematics, sensor data, and historical maintenance logs, AI predicts asset degradation, remaining useful life, and part failure risks. It alerts maintenance teams ahead of time, helping avoid service delays, missed deliveries, and costly breakdowns.

Question 11. How does AI improve sourcing agility during supply chain volatility?

Answer: AI uses probabilistic forecasting and scenario modeling to identify supply risk early, recommend alternative suppliers, simulate transportation lead times, and optimize order allocation. This helps sourcing leaders negotiate better and secure materials before constraints escalate.

Question 12. What KPIs improve the most when using AI for transportation and logistics optimization?

Answer: Typical improvements include:

- 20–30% faster cycle times

- 10–15% logistics cost reduction

- 25–40% fewer stockouts

- 15–20% improved OTIF

- 20–40% reduction in maintenance-related delays

- 2–3x faster decision-making

These KPIs directly support executive-level operational goals.

Question 13. How does AI help industrial companies shift from reactive firefighting to proactive logistics management?

Answer: AI gives early warnings for disruptions, identifies hidden cost drivers, predicts demand variability, and prescribes optimal action plans. Instead of reacting to delays or shortages, leaders get proactive recommendations they can execute immediately.

Question 14. Is AI secure enough for industrial-grade logistics and maintenance operations?

Answer: Enterprise-grade platforms follow strict data governance, encrypted pipelines, role-based access, and SOC2/ISO27001 standards. Data stays within your cloud environment, and models adapt to internal rules, making AI safe for proprietary supply chain and maintenance datasets.