AI software for cement material flow optimization is crucial for minimizing supply and demand variance in the cement industry. By leveraging AI software, cement manufacturers can significantly improve their operational efficiency and reduce financial losses associated with inaccurate demand forecasting. Traditional methods, such as spreadsheets and siloed software, are no longer sufficient in today’s dynamic market environment, where supply chain disruptions are common.

The Problem: Uncertainty in Cement Demand Planning

Accurately forecasting demand remains a critical challenge for cement manufacturers, especially in a post-pandemic world where supply chain disruptions have intensified. With supply and demand shocks occurring unpredictably, traditional forecasting methods are inadequate.

Key Challenges

- Demand Fluctuations: Demand planners struggle to keep up with rapid market fluctuations.

- Inventory Inefficiencies: Poor demand planning results in stockouts, excess inventory, and financial loss.

- Lack of Real-Time Insights: Inefficiencies in inventory management and distribution arise due to the absence of real-time data.

A leading global lime manufacturer achieved AI-powered $16 million savings in inventory optimization and distribution using ThroughPut’s solutions, highlighting the potential of AI in addressing these challenges.

The Solution: ThroughPut AI-Driven Demand Forecasting for Cement Manufacturers

ThroughPut Demand Sensing software solution provides a single source of truth for demand planners, enabling real-time insights and AI-powered predictions. By integrating AI into demand forecasting, cement manufacturers can better align production capabilities with market needs, reducing supply chain inefficiencies.

Key benefits include:

- Accurate Demand Forecasting: Predict near-future demand with AI-driven insights.

- Optimized Inventory Management: Reduce stockouts and excess inventory.

- Improved Supply Chain Agility: Adapt to fluctuations in demand quickly.

- Better Capital Utilization: Optimize working capital and minimize waste.

Features of ThroughPut AI-Driven Demand Forecasting

- Rapid Demand Analysis: AI-powered insights help planners make data-driven decisions.

- Predictive Analytics: Identify emerging demand trends before they impact operations.

- Real-Time Adjustments: Adapt to fluctuating margins and inventory needs dynamically.

- Enhanced Product Mix: Improve product availability while maximizing revenue margins.

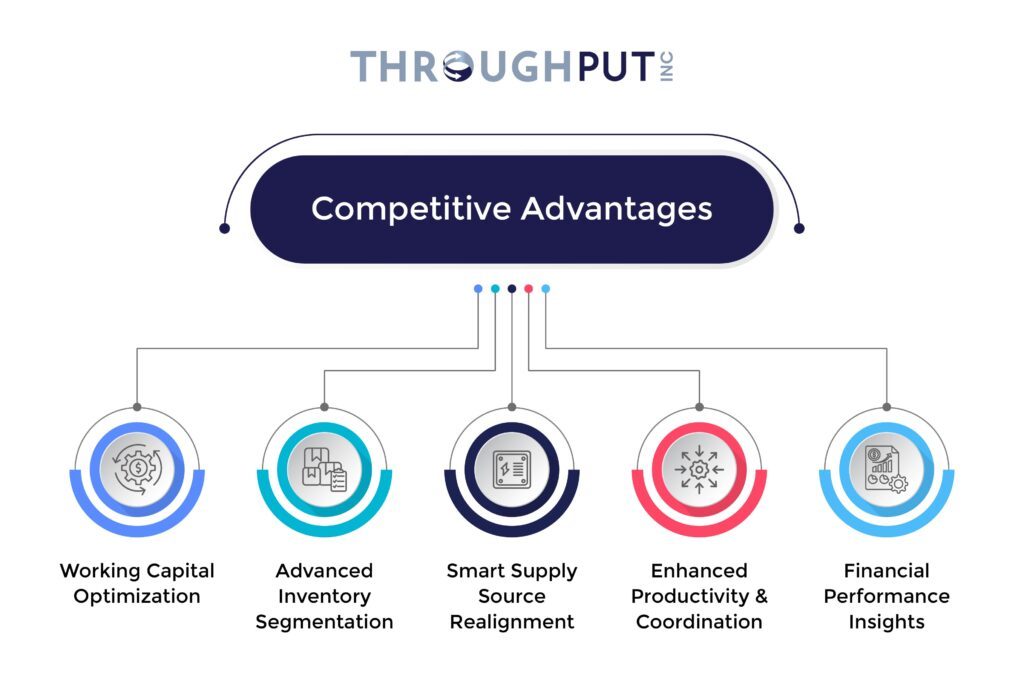

Competitive Advantages of ThroughPut.AI

- Working Capital Optimization: Gain a 360-degree view of demand plans to make informed product-mix decisions across the cement value chain.

- Advanced Inventory Segmentation: Utilize ABC/XYZ segmentation to optimize stock levels and reduce planning efforts.

- Smart Supply Source Realignment: Eliminate unnecessary waste by considering external factors such as economic, political, and climatic influences.

- Enhanced Productivity & Coordination: Improve collaboration between S&OP and operations teams for seamless supply-demand alignment.

- Financial Performance Insights: Analyze SKUs by country, material costs, sales price changes, shipping costs, and duties to make strategic decisions.

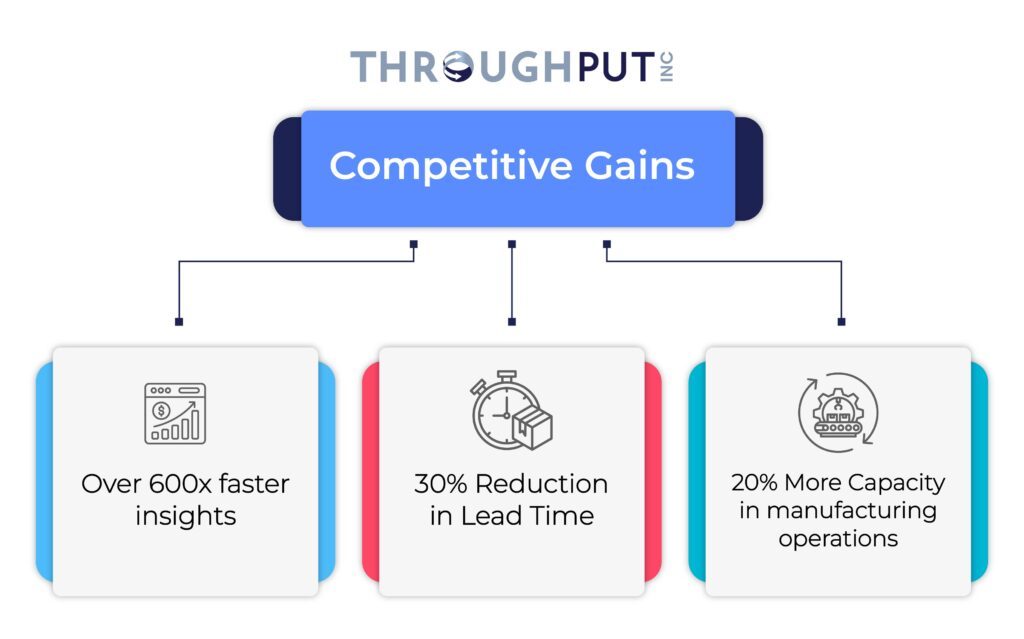

Business Gains from ThroughPut AI-Powered Demand Sensing Software

ThroughPut.AI transforms cement supply chains by leveraging AI-driven predictive analytics to optimize demand planning, reduce waste, and improve material flow. The platform helps businesses achieve operational excellence with real-time demand sensing, inventory rebalancing, and predictive decision-making.

- 600x Faster Insights for improved lead times, defect rates, and cycle times.

- 30% Reduction in Lead Time to enhance supply chain responsiveness.

- 20% More Capacity in manufacturing operations to meet fluctuating demand.

How ThroughPut AI Software Enhances Cement Manufacturing Efficiency

Beyond demand forecasting, ThroughPut AI software can significantly enhance cement manufacturing efficiency by optimizing production processes and reducing environmental impact. For instance, AI can be used to optimize fuel usage in kilns, predict quality issues in real-time, and improve raw material utilization.

- AI in Cement Production: AI algorithms can streamline production processes, reduce energy consumption, and enhance quality control by detecting defects early.

- Sustainability Efforts: AI-driven solutions help cement manufacturers achieve sustainability goals by optimizing kiln operations and reducing CO2 emissions.

Implementing ThroughPut AI Software for Cement Material Flow Optimization

Implementing AI software like ThroughPut.AI involves several steps:

- Integration with Existing Systems: Integrate AI solutions with current inventory management and demand forecasting systems to ensure seamless data flow.

- Training and Support: Provide comprehensive training to demand planners and operations teams to ensure they can effectively utilize AI-driven insights.

- Continuous Monitoring and Improvement: Regularly review and refine AI models based on new data and market trends to maintain optimal performance.

Case Study: ThroughPut AI Logistics Optimization for Cement Manufacturer

A recent case study highlights how a cement manufacturer leveraged AI logistics optimization to improve operational efficiency and reduce costs. ThroughPut AI helped the company achieve smarter asset utilization, reduce CO2 emissions, and enhance customer segmentation.

Conclusion

Leveraging AI software for cement material flow optimization is essential for minimizing supply and demand variance. By adopting AI-driven demand forecasting solutions like ThroughPut.AI, cement manufacturers can significantly enhance their operational efficiency, reduce financial losses, and improve their competitive edge in the market.

Frequently Asked Questions

What is the role of AI software in cement material flow optimization?

AI plays a crucial role in optimizing cement material flow by providing real-time insights and predictive analytics to improve demand forecasting, inventory management, and supply chain agility.

How does AI enhance cement manufacturing efficiency?

AI enhances cement manufacturing efficiency by optimizing production processes, reducing energy consumption, and improving quality control through real-time monitoring and predictive analytics.

What are the benefits of using ThroughPut.AI software in the cement industry?

ThroughPut.AI offers benefits such as working capital optimization, advanced inventory segmentation and prioritization, and enhanced productivity, leading to faster insights, reduced lead times, and increased manufacturing capacity.