Managing spare parts inventory has always been a delicate balancing act—excess inventory ties up capital, while shortages risk costly downtime and production delays. In asset-intensive industries, this challenge has only intensified with the growing complexity across supply chains. In addition, poor visibility, unpredictable demand, and disjointed systems worsen the situation further and lead to inefficient procurement, misplaced stock, and emergency orders.

In fact, spare parts mismanagement is one of the leading contributors to operational disruptions—particularly in the manufacturing, automotive, aerospace, and heavy equipment industries. When a critical part is not available at the right time and/or in the right place, it can halt production lines, delay maintenance, and incur millions in unplanned costs.

That’s why a growing number of organizations are turning to AI software for spare parts inventory management. AI helps businesses proactively align supply with real-time demand, optimize inventory levels, identify cost-saving opportunities, and predict maintenance needs—transforming spare parts management from a cost center into a competitive advantage.

Let’s break it down.

What is Spare Parts Inventory Management?

Spare parts inventory management is the process of ensuring the right quantity of components and parts are available at the right time to support maintenance and repair activities—without tying up unnecessary capital or space. It plays a pivotal role in maintaining business continuity, particularly in industries where equipment performance and uptime directly impact production output and revenue.

To do this effectively, organizations must juggle numerous variables such as lead times, part criticality, supplier reliability, usage trends, and compliance requirements. A single oversight can lead to ripple effects across maintenance schedules, production runs, and customer deliveries.

Businesses commonly face the following challenges due to ineffective spare parts inventory management:

- Overstocked components, which tie up working capital and warehouse/storage space

- Obsolete or underused parts, which continue to pile up due to lack of/inaccurate demand forecasting

- Limited visibility into which parts are needed, where, and when

- Emergency orders, which in turn lead to premium shipping costs

With supply chains becoming increasingly global and interdependent, the number of SKUs, suppliers, and storage locations organizations must manage is growing. Without a scalable system in place, these complexities quickly result in inefficiencies and uncontrollable operational costs. Why Traditional Methods Just Can’t Cut It Anymore.

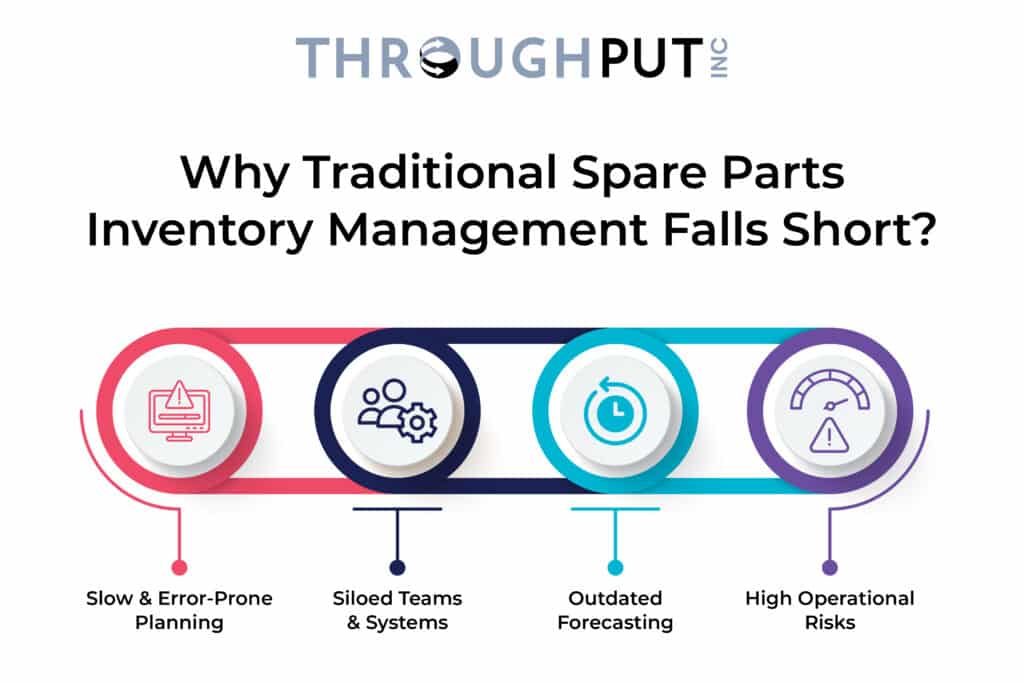

Despite being mission-critical, spare parts inventory management in many organizations still relies heavily on spreadsheets, siloed databases, and outdated ERP tools. These legacy methods lack the agility, accuracy, and cross-functional coordination needed in today’s fast-paced supply network.

The following are the top limitations of conventional spare parts management methods:

- Delayed Response Times and Inventory Planning Inaccuracies: Inventory planning and procurement decisions often require hours of manual work gathering and reconciling data from various systems. This slows down response times, and also increases the chances of inaccuracies due to human error/bias.

- Siloed Data: With maintenance, procurement, and inventory teams operating in separate silos, collaboration is minimal, leading to misaligned priorities, inconsistent stock levels, and reactive replenishment processes.

- Inaccurate Demand Forecasting: Traditional spare parts management methods frequently rely on static reorder points and historical averages, which do not account for real-time variables like machine usage, production schedules, or supplier disruptions. The result is either excess inventory or critical shortages.

- Operational Risks: The above inefficiencies expose businesses to significant operational risks such as unplanned downtime, unplanned and/or higher maintenance costs, and increased overall operational costs.

The inability to coordinate demand forecasting and inventory planning at an enterprise-wide level makes it difficult to minimize revenue risk – particularly due to avoidable inventory failures. Without automation or data-driven intelligence, companies struggle to maintain asset quality and ensure operational continuity.

Why AI is the Answer—How Does it Improve Spare Parts Inventory Management?

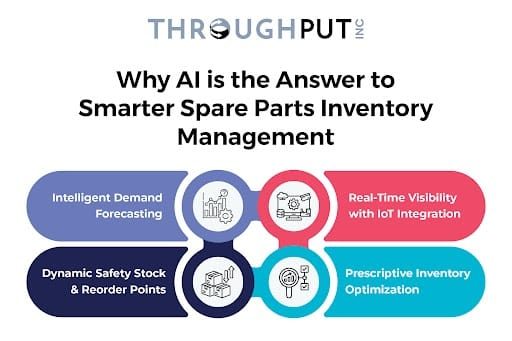

AI software for spare parts inventory management is a gamechanger because it transforms the spare parts management process by enabling automation, intelligent and data-backed decision-making, and flexibility at every stage of the inventory lifecycle. Importantly, AI-powered spare parts inventory solutions like ThroughPut bring together disparate data sources from inventory systems and maintenance logs to procurement records and supplier performance metrics—and applies advanced algorithms to uncover operational patterns, forecast demand, and recommend the best actions based on real-time opportunities and constraints.

Here’s how AI software for spare parts inventory management works:

- Demand Forecasting: AI analyzes current and historical data on several parameters such as spare parts usage patterns, supplier quality and lead times, and production schedules to accurately predict which parts will be needed, when, where, and in what quantity. ThroughPut.AI even ranks suppliers based on their reliability, delivery performance, and cost-effectiveness. In other words, businesses can eliminate the guesswork in demand forecasting and proactively plan for it with the help of data-backed decision-making.

- Dynamic Safety Stock & Reorder Calculations: Unlike traditional static models, AI continuously adjusts safety stock thresholds and reorder points based on real-time demand, part criticality, and location-based usage. This ensures inventory is balanced across locations, at all times—while significantly reducing waste and preventing shortages.

- Real-Time Tracking with AI & IoT Integration: Leveraging data from the entire supplier ecosystem and all its variables, AI provides real-time visibility into equipment health, part consumption, and supplier performance. For example, ThroughPut’s MRO inventory management software creates a single source of truth across the network, enabling better decision-making around supplier selection, maintenance frequency, and productions schedules.

- Prescriptive Analytics for Inventory Optimization: Finally, AI-based forecasting not only identifies incidents or problems—it also recommends actions. For example, ThroughPut.AI’s patented algorithms identify when it is more cost-effective to cancel planned orders, redistribute spare parts internally, or directly ship to production locations. This streamlines inventory movement and eliminates bottlenecks, ensuring optimal flow of materials across the supply chain.

In other words, with AI software for spare parts inventory management, businesses can now reduce downtime with MRO inventory optimization, improve spare parts availability with AI, and increase service levels with real-time inventory tracking—all while freeing up working capital that would otherwise be tied up for no good reason.

Business Challenges Addressed by ThroughPut.AI

ThroughPut.AI was built specifically to address the real-world pain points that affect supply chain, maintenance, and procurement teams, such as:

- Difficulty aligning procurement with real-time demand due to disconnected planning tools

- Inability to automate replenishment based on part usage and equipment condition

- Delayed identification of critical part shortages that affect operational continuity

- Overdependence on suboptimal suppliers due to lack of real-time ranking mechanisms

- Inability to rebalance excess stock or repurpose unused parts within the network

These challenges are especially pronounced in large organizations, where inventory is spread across multiple facilities and governed by diverse procurement cycles. ThroughPut’s AI solutions for MRO inventory provide the intelligence and automation needed to bring all stakeholders onto the same page.

Features That Power ThroughPut AI’s Spare Parts Optimization Software

ThroughPut AI spare parts inventory management software includes several powerful features designed to improve speed, efficiency, and accuracy across all phases of MRO planning:

- AI-driven prediction of parts demand, usage, and location needs

- Granular decision-making capabilities using real-time maintenance and supplier data

- Supplier ranking based on ability to meet requirements by time, cost, and location

- Opportunities to reduce working capital while increasing parts readiness

- Automated predictive replenishment for critical kits and components

With its deep industry expertise and granular understanding of how the complex ecosystem of procurement works with all its variables and moving targets, ThroughPut stands out as the best AI software for spare parts management – and a leading spare parts optimization software for manufacturing.

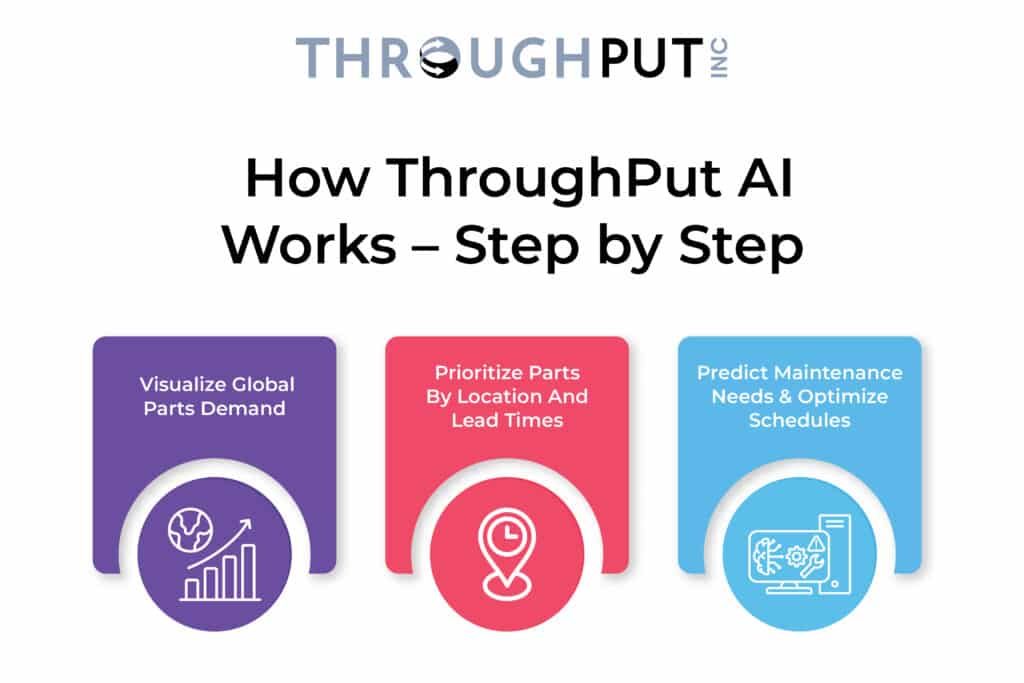

How ThroughPut.AI Works – Step by Step

Step 1: Visualize Global Parts Demand

ThroughPut gathers data from disparate sources (inventory systems, purchase orders, requisition logs, and transactions) to create a unified picture of parts demand across facilities. This visibility is crucial for global inventory coordination.

Step 2: Prioritize Parts by Location and Lead Times

The system then evaluates actual maintenance usage at each site, compares it to current stock levels, and overlays it with actual lead time data to prioritize parts for replenishment or redistribution.

Step 3: Predict Maintenance Needs and Optimize Schedules

Based on current usage trends and equipment requirement forecasts, ThroughPut finally recommends schedules to minimize downtime, preserve asset health, and reduce short and long-term working capital expenditure.

Tangible Benefits of Using ThroughPut’s AI Spare Parts Planning Software

Organizations deploying ThroughPut.AI have reported the following benefits:

- Up to 60% reduction in working capital spend

- Faster issue resolution through elimination of unreliable suppliers and late deliveries

- Maximum production output at minimal inventory levels

- Increased service levels due to better parts readiness and reduced delays

- Fewer maintenance bottlenecks, improving uptime and equipment life

- Greater visibility across the supply chain through integrated, consolidated views that enable real-time data-driven decisions

- Smarter, prescriptive recommendations for safety stock and replenishment

ThroughPut in Action: Top Customer Success Stories

ThroughPut.AI is already transforming spare parts planning and execution for leading industrial organizations across the globe. By applying advanced AI to complex inventory challenges, it helps businesses unlock working capital, reduce inefficiencies, and build more resilient operations.

Listed below are a few real-world outcomes that ThroughPut has achieved across various industries:

Heavy Equipment Manufacturing

A global equipment manufacturer struggled with surplus inventory and high carrying costs. With ThroughPut, they:

- Reduced excess inventory by over 30% across global depots

- Identified $568,000 in avoidable ordering costs

- Enabled dynamic reallocation of parts across 140+ locations for faster fulfillment

- Reallocated stock based on actual consumption, leading to higher capital efficiency and reduced material waste

Find out more in the full case study.

Automotive Manufacturing

A global automotive OEM struggled with part shortages that caused frequent line stoppages. By implementing ThroughPut’s AI-powered forecasting, they were able to:

- Achieve a 40% reduction in emergency orders

- Significantly increase part availability at critical sites

- Improve supplier responsiveness using real-time, performance-based scorecards

- Reduce downtime and accelerate maintenance turnaround across plants

Download the full case study for more details.

Aerospace

An aerospace MRO provider needed better alignment between parts availability and scheduled maintenance. ThroughPut integrated their inventory and IoT systems to:

- Forecast part needs aligned with aircraft usage

- Improve asset availability and reduce grounded time

- Extend asset life through optimized maintenance planning

Find out how in the full case study.

The Business Impact of AI in Spare Parts Management

In high-pressure environments where every dollar saved and every second of uptime counts, AI solutions for MRO inventory give businesses the critical competitive edge they need as they navigate relentless economic and political uncertainty. Here’s a deeper look at the benefits:

Reduced Carrying Costs

AI analyzes millions of data points to help businesses stock only what’s necessary. By eliminating excess inventory, companies unlock working capital and reduce warehousing overhead – without sacrificing availability.

Increased Part Availability

ThroughPut ensures that parts are prioritized based on actual equipment usage, lead times, and criticality. This increases inventory readiness and ensures that the right part is available at the right place and time – while reducing reliance on emergency procurement and last-minute shipping.

Minimized Downtime and Emergency Orders

By integrating predictive maintenance data, ThroughPut forecasts equipment failures before they happen – so that parts can be replenished and staged proactively. This minimizes production disruptions, prevents expensive unplanned downtime, and smooths MRO workflows, while simultaneously minimizing the need for last-minute orders and expedited shipping costs.

Better Resource Allocation and Planning

AI empowers teams with real-time insights and prescriptive recommendations so that instead of maintenance and procurement being carried out reactively, they can be planned strategically – with prioritized spending, vendor selection, and labor planning.

ThroughPut even helps categorize parts by criticality, enabling organizations to streamline their procurement strategies and avoid investing in low-impact components.

What’s Next for AI in Spare Parts Management?

The future of spare parts management is fully autonomous, data-driven, and predictive. Here’s a look at what’s on the horizon:

Generative AI for Supply Planning

Next-generation AI can simulate demand scenarios and automatically generate optimized replenishment plans, adapting to shifts in market demand, supplier/part availability, and production schedules, and logistics constraints.

End-to-End Autonomous Inventory Management

AI can not only automate every step of the inventory management process – from forecasting and procurement to internal stock transfers and staging – without requiring human intervention (and by extension, its inherent errors), but also make it highly intelligent and responsive. With a data-driven, seamless, self-adjusting inventory ecosystem in place, businesses can afford to focus on core operational and financial decisions.

Predictive Maintenance Integrations

With deeper integration between IoT sensors, inventory platforms, and maintenance processes, spare parts replenishment can be automatically triggered by machine health indicators – eliminating delays and improving asset performance.

ThroughPut.AI is already leading the way in these innovations, combining patented AI models with real-time operational data to deliver smarter, faster, and more resilient inventory systems.

The Time to Act is Now

In today’s environment, where asset reliability, cost control, and business continuity are non-negotiable, adopting AI solutions for MRO inventory isn’t just a smart move – it’s a competitive necessity.

That’s why AI is no longer a concept for the future. It’s a present-day need for businesses serious about minimizing resource leaks and driving operational excellence. From reducing excess inventory and improving part availability to minimizing expensive emergency orders and accelerating asset uptime, AI software for spare parts inventory management is already helping organizations solve real-world spare parts management challenges effectively, while saving valuable time and money.

ThroughPut.AI is built to deliver these results – fast. Our platform empowers supply chain and operations leaders to make confident, data-driven decisions, reduce costs, and stay ahead of disruptions. To discover how ThroughPut.AI can transform your spare parts operations end to end – eliminating your inefficiencies, improving your service levels, and modernizing your MRO strategy – book a personalized demo.

FAQ for AI Spare Parts Inventory Management Software

Q1: How can AI-driven spare parts inventory management help maintenance leaders minimize unplanned downtime?

A. AI-powered inventory systems predict part failures and optimize stock levels based on equipment usage and historical breakdowns. This ensures critical parts are always available before failures occur—reducing unplanned downtime and improving asset reliability.

Q2: What measurable ROI can supply leaders expect from implementing AI in spare parts management?

A. Supply leaders typically see up to a 20–30% reduction in working capital tied up in spare parts inventory and a 10–15% improvement in service level agreements (SLAs) due to better demand visibility and faster replenishment decisions.

Q3: How does AI improve sourcing efficiency for high-value or long-lead spare parts?

A. AI algorithms analyze supplier lead times, cost variability, and reliability to recommend the best sourcing options. This helps sourcing heads negotiate better contracts, avoid stockouts, and ensure continuity of supply even during disruptions.

Q4: Can AI tools integrate with existing ERP and CMMS systems used by maintenance and supply teams?

A. Yes. Most advanced AI spare parts management platforms seamlessly integrate with ERP (like SAP, Oracle) and CMMS tools (like IBM Maximo or Infor EAM) to unify data, enabling end-to-end visibility across maintenance, sourcing, and supply operations.

Q5: How quickly can industrial companies realize value from AI-based spare parts optimization?

A. Most organizations begin seeing measurable results within 60–90 days—such as improved part availability, reduced excess inventory, and enhanced decision-making through automated insights and anomaly detection.

Q6: What makes AI-based spare parts inventory management better than traditional planning methods?

A. Traditional systems rely on static reorder points and manual forecasts, which miss dynamic demand patterns. AI uses predictive analytics, real-time data, and machine learning to adapt continuously—offering far higher accuracy in planning and fulfillment.

Q7: How can maintenance and supply teams collaborate better through AI insights?

A. AI platforms create shared visibility between maintenance, supply, and sourcing departments by using a unified data model. This eliminates silos, aligns decision-making, and helps teams proactively plan maintenance schedules around part availability.