In the ever-evolving landscape of global commerce, businesses face a significant challenge: the pain of inaccurate forecasts and the relentless pace of market conditions, highlighting the need for Supply Chain Forecasting with AI.

These inaccuracies can lead to overstocking or understocking, missed opportunities, and a failure to meet customer demand. The agitation stems from the financial loss and operational inefficiencies accompanying these inaccurate forecasts.

In a world where margins are thin, and competition is fierce, such losses can be debilitating.

Fortunately, a solution is emerging that not only relieves these pains but also transforms them into competitive advantages: AI forecasting, a paradigm shift in supply chain management.

AI in supply chain forecasting is a game-changer. It has the power to analyze vast datasets, predict future trends with remarkable accuracy, and adapt to changes in real time, offering businesses a competitive edge.

This article is a thorough introduction to AI’s role in solving supply chain forecasting problems and sets the stage for a deeper exploration of its capabilities and benefits.

What is Supply Chain Forecasting?

Supply chain forecasting predicts future demand for products and services, inventory needs, and production planning based on historical data, market analysis, and current trends.

Its significance must be balanced, as accurate forecasting is crucial for efficient supply chain operations. It enables businesses to meet customer demand without the excess cost of overstocking or the risk of stockouts.

Demand planning, inventory management, production scheduling, and distribution planning are the components of supply chain forecasting.

Each plays a vital role in ensuring that the right products are available at the right time and place, optimizing the supply chain’s efficiency and responsiveness.

Problems with Traditional Supply Chain Forecasting Methods

Traditional supply chain forecasting methods must often catch up in today’s dynamic market environment.

One of their primary limitations is the lack of real-time data analysis, which means they cannot adapt quickly to sudden market changes or unexpected demand patterns. This rigidity can lead to significant discrepancies between forecasts and actual demand.

Several case studies highlight these shortcomings. For instance, a major retailer might stock up on winter clothing based on historical sales data only to experience a hot winter, resulting in excess inventory and heavy discounts to clear stock.

Such instances underscore the impact of traditional forecasting methods’ limitations on business operations and profitability, leading to wasted resources and missed opportunities.

One of traditional forecasting methods’ drawbacks is their inability to adapt to market changes.

They often rely on simplistic models that fail to capture the complexity of modern supply chains, ignoring factors like geopolitical events, economic shifts, and social trends that can drastically affect demand.

These methods’ limitations are not just theoretical; they have real-world consequences.

Businesses that rely on outdated forecasting techniques may be outpaced by more agile competitors embracing advanced technologies.

The financial implications can be severe, with companies experiencing lost revenue, increased operational costs, and damaged customer relationships.

Can AI Be Used for Forecasting?

Absolutely, AI can and is being used for forecasting across various industries. Its ability to handle large volumes of data and complex variables suits this task well.

AI’s predictive capabilities are not limited to supply chain management; they extend to fields such as finance, healthcare, and energy, where forecasting plays a crucial role in operational planning.

AI is also used in supply chain management to enhance various aspects beyond demand forecasting. It improves logistics optimization by determining the most efficient routes and modes of transportation.

AI also plays a role in risk management by identifying potential disruptions in the supply chain and suggesting mitigation strategies.

Additionally, AI can automate routine tasks, such as order processing and invoice management, freeing up human resources for more strategic activities.

Why Should Companies Use Supply Chain Forecasting with AI?

Companies should use AI for supply chain demand forecasting because of its accuracy and data processing capabilities. AI’s advantages over traditional methods are numerous and significant.

Adopting AI for supply chain demand forecasting is not just a trend; it’s a strategic imperative for companies looking to stay ahead in the game.

AI-driven forecasting models offer vastly improved accuracy by learning from historical data patterns and continuously refining their predictions.

This heightened accuracy translates into more efficient operations, as companies can better align their supply with actual demand.

AI’s ability to process and analyze large datasets is unparalleled. It can sift through vast amounts of information from various sources, including market trends, weather patterns, social media sentiment, and more, to make informed predictions.

This comprehensive analysis allows AI to adapt to changes dynamically, providing businesses with forecasts that reflect the latest market conditions.

AI-based demand forecasting can result in substantial cost savings due to optimizing inventory levels. Companies reduce holding costs and minimize the risk of obsolescence.

Moreover, AI enhances customer service by ensuring product availability, which can lead to increased sales and customer loyalty.

The competitive advantage gained from AI forecasting is crystal clear: companies can make more informed decisions, respond faster to market changes, and allocate resources more effectively.

Moreover, AI can significantly enhance logistics optimization and risk management, providing a solid foundation for business operations.

How can AI Improve Supply Chain Forecasting?

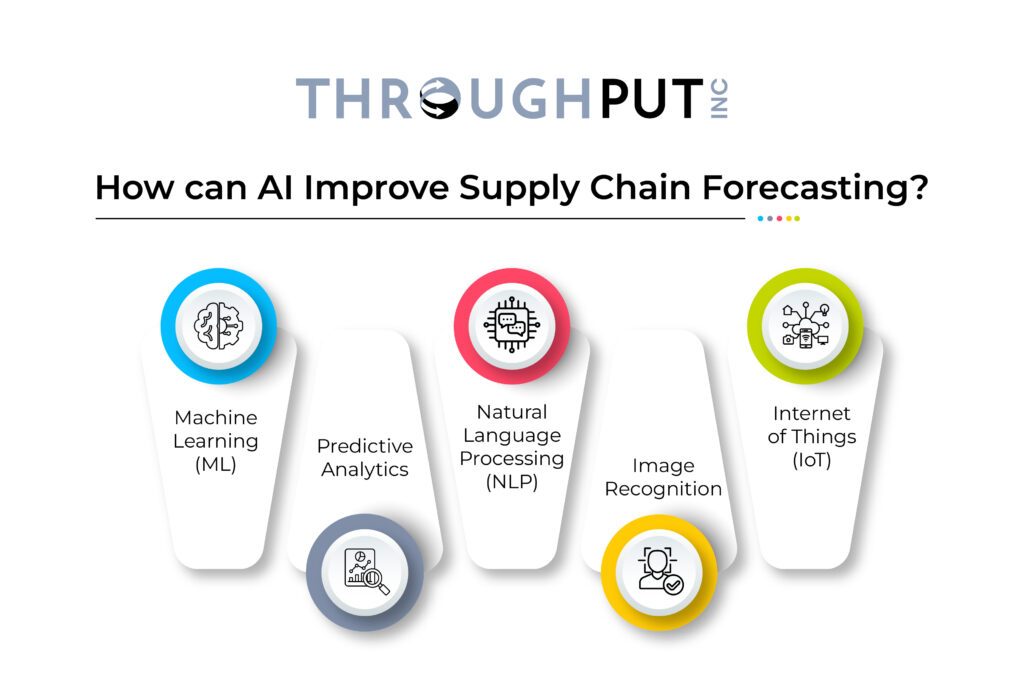

AI improves supply chain forecasting by leveraging technologies such as machine learning, predictive analytics, natural language processing (NLP), and image recognition to identify complex patterns in historical data, increase forecasting accuracy, and enhance the overall management of the supply chain.

Let’s see how each AI technology can be applied to improve supply chain forecasting:

Machine Learning (ML)

Machine Learning algorithms are at the heart of AI’s forecasting prowess. These algorithms can identify complex patterns in historical data and use these insights to predict future demand with high accuracy.

For instance, ML can detect seasonal trends and incorporate them into forecasts, ensuring that companies are prepared for predictable fluctuations in demand.

Predictive Analytics

Predictive analytics goes beyond simple trend analysis. It uses data, statistical algorithms, and machine learning techniques to identify the likelihood of future outcomes.

This method can forecast demand spikes resulting from promotions or events, allowing companies to proactively adjust their supply chain strategies.

Natural Language Processing (NLP)

NLP enables AI to understand and interpret human language, allowing it to analyze customer feedback, product reviews, and social media chatter.

This analysis can provide early indicators of changing consumer preferences and emerging trends, which can be factored into demand forecasts.

Image Recognition

AI-powered image recognition can monitor inventory levels by analyzing images from warehouse cameras.

This technology can detect when stocks are low and trigger reordering processes, ensuring continuous product availability without manual intervention.

Internet of Things (IoT)

IoT devices can collect real-time data from various points in the supply chain, such as sensors on production equipment, RFID tags on inventory, or GPS data from delivery vehicles.

This data can be fed into AI models to provide up-to-the-minute forecasts, allowing for unprecedented responsiveness in supply chain management.

How does AI Supply Chain Forecasting Work?

AI supply chain forecasting works by integrating various AI technologies to create a comprehensive forecasting system.

It starts with data collection, where AI gathers information from internal and external sources. The data is then cleaned and prepared for analysis, a crucial step to ensure accuracy.

Next, AI algorithms analyze the data to identify patterns and correlations that might not be apparent to human analysts. The forecasting models then use these insights to make predictions about future demand.

These models are continuously updated with new data, allowing them to learn and improve. The final step is disseminating the forecasts to decision-makers, who can use the information to optimize supply chain operations.

How Can AI Forecast Demand in Supply Chain?

AI forecasts demand in the supply chain by leveraging predictive models that can anticipate future needs based on current and historical data.

These models consider various factors, including sales data, market trends, economic indicators, and weather patterns.

AI analyzes this data and provides accurate predictions of customer demand, which companies can use to make informed decisions about production, inventory management, and distribution.

Supply chain forecasting with Throughput

With ThroughPut’s AI-powered supply chain software, you can predict demand, reorient production capacity, reassign warehouse space, and optimize materials, minimizing overpromising and under-delivering while maximizing your desired outcomes.

This solution’s powerful Demand Sensing Module employs cutting-edge algorithms and machine learning to tailor forecasting plans, recommend optimal inventory levels, and adapt operational strategies to changing market conditions.

This module enables you to efficiently receive actionable demand trends, reduce waste by adjusting supply sources, and optimize the flow of materials and processes.

The software implements sustainable predictability to enhance your supply chain’s overall cash flow while incorporating external factors such as geological considerations, climate conditions, and economic risks alongside historical data, empowering you to make better decisions.

Book your demo today to find out more..