The client is a leading cement and lime manufacturer and has over a century of experience in the production of lime with an established production capacity of thousand tons of hydrated lime per day. In recent times, the cement and lime production industry has seen unpredictable spikes and dips in demand for its products, leading to over and under capacity. In this context, the client wanted to strengthen their sustainability efforts and competitiveness to ensure they can continue producing as per capacity thresholds and demand levels.

3 Major Challenges faced by the Lime Manufacturer

Identify Accurate Savings and ROI Driven Opportunities

Streamline Product Material Flow and Profitability Streams

Identify Core Financial Impact of Operations Budget

The Solution

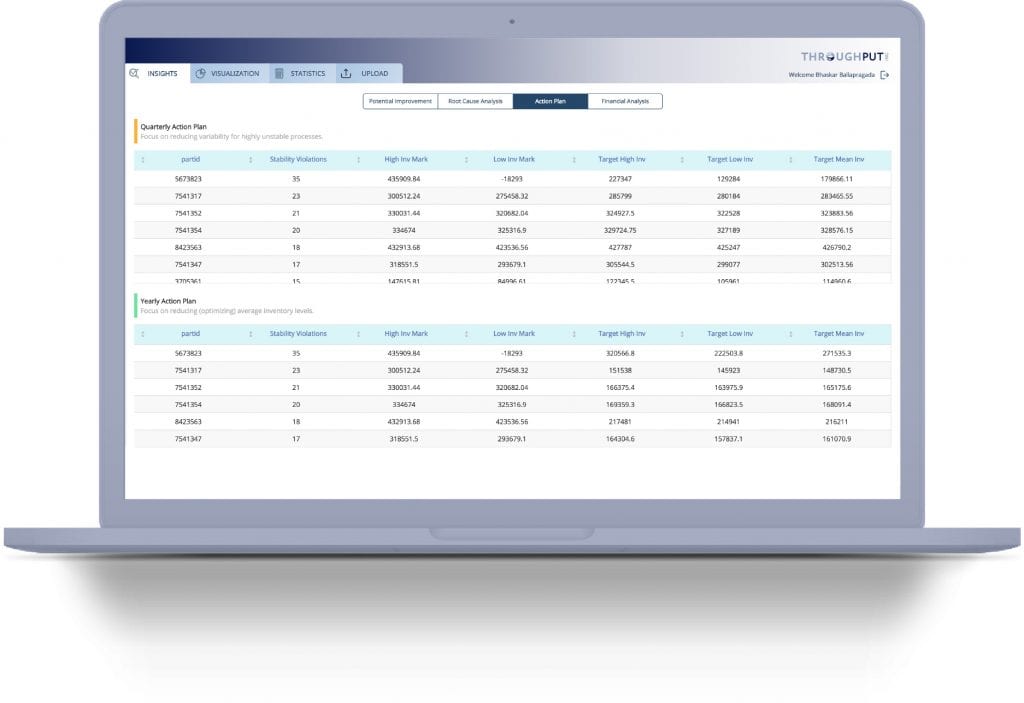

Efficient OTIF Deliveries and Optimal SKUs

Ability to create effective Product Mix Segmentation to focus on priority items based on

demand-supply dynamics. This helped to unlock more sales and thus identify key Working Capital Reduction Opportunities across the value chain on optimal Stock-Levels per SKU / Location, along with OTIF route suggestions.

Deeper Analysis of Demand and Financial Performance

Better understanding of Export Demand and Financial Performance that automatically broke down 1000’s SKUs by country and surfaced hidden operational insights. A better grasp of Material Costs, Sales Price Changes, Shipping Cost and Taxes and Duties to map out top- performing SKUs that contribute to the majority of total throughput.

Greater Supply Chain Visibility

Work with a futuristic view with step-through time-ranges to visualize the changes across the Supply Chain and track the performance over time to assess significant OTIF Improvements over two years.

Leading through Uncertain Times with

Conviction & Commitment

With ThroughPut, you are better equipped to respond to crisis. Our expertise and technology both keep you prepared for emergency- response, while tackling supply chain complexities.

Together, let’s get things under control, back on track, flowing smoothly once again.

![]() It’s not only business as usual, but system Throughput like you’ve

It’s not only business as usual, but system Throughput like you’ve

never seen it before.![]()

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Related Resources

White Paper

Boost Your Supply Chain Resilience with Demand-driven Logistics

Download Now

Blog

A Complete Guide to Real-Time Supply Chain Planning

Know More

Get a Headstart for your Building Materials & Cement Business with our AI-powered Supply Chain Solution

Find an Executive Sponsor

Find an Executive Sponsor

Board Member or C-Suite Executive (Operations & Finance Background Preferred.)

Pick a Distribution Center or Production Line

Pick a Distribution Center or Production Line

Provide Material Flow-Related Data, No Initial IT Support Required.

Pick a Business Model

Pick a Business Model

Flat Fee for 3 Months or Lower Fee +10% Success & Impact Fee.

White Paper

5 Warning Signs That Your Demand Planning is Off Track

Download Now

Blog

How To Balance Supply & Demand with AI-powered Demand Planning for Building Materials and Cement Industry

Know More