Unravel Hidden Insights To Address Top Automotive Challenges

Visibility across upstream & downstream plant quality

Get early insights into risks to measure the impact and plan accordingly.

Reduced downtime, scrap & rework

Boost output quality and save productive labour hours.

Balance demand and capacity management

Gain real-time demand trends and manage capacity for aligned and synchronized supply chains.

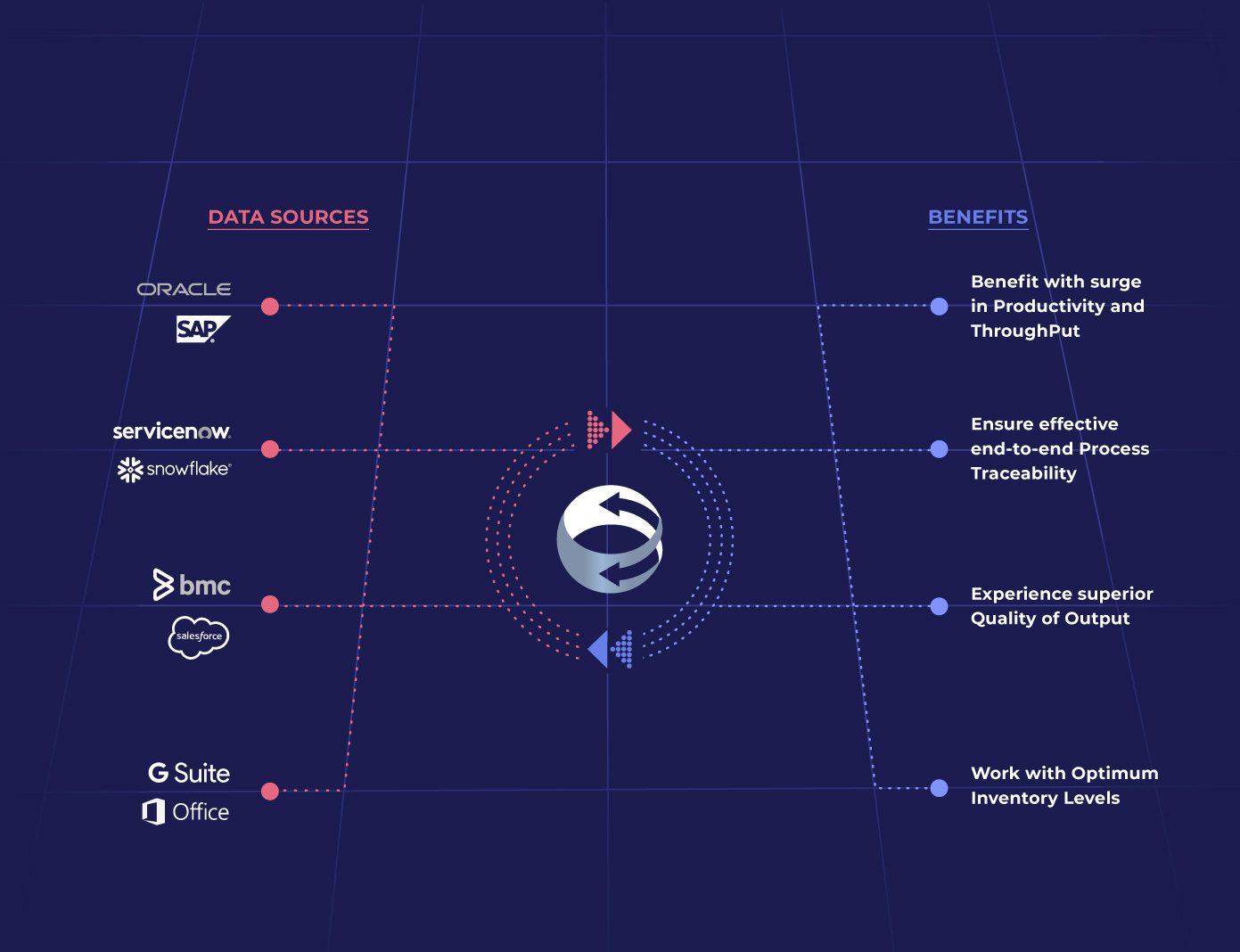

Fuel Efficiencies Across your Supply Chain Value Stream

ThroughPut’s AI-powered supply chain management and analytics platform radically enables manufacturers to meet customer demand on time and accelerate material flow, right from the upstream to the downstream.

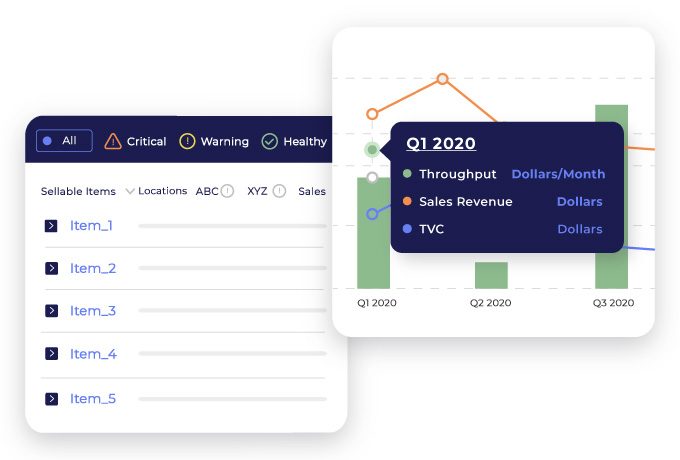

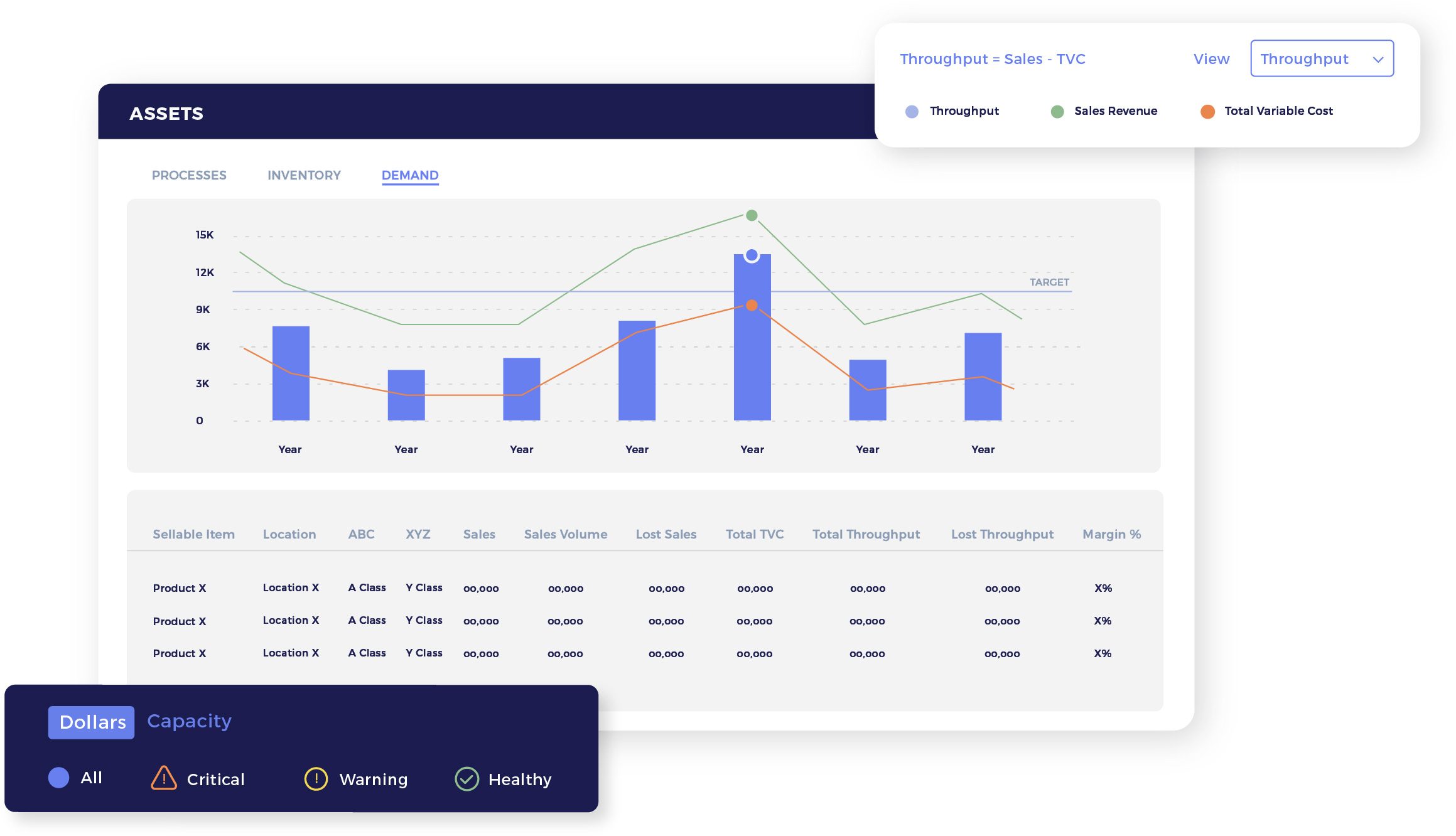

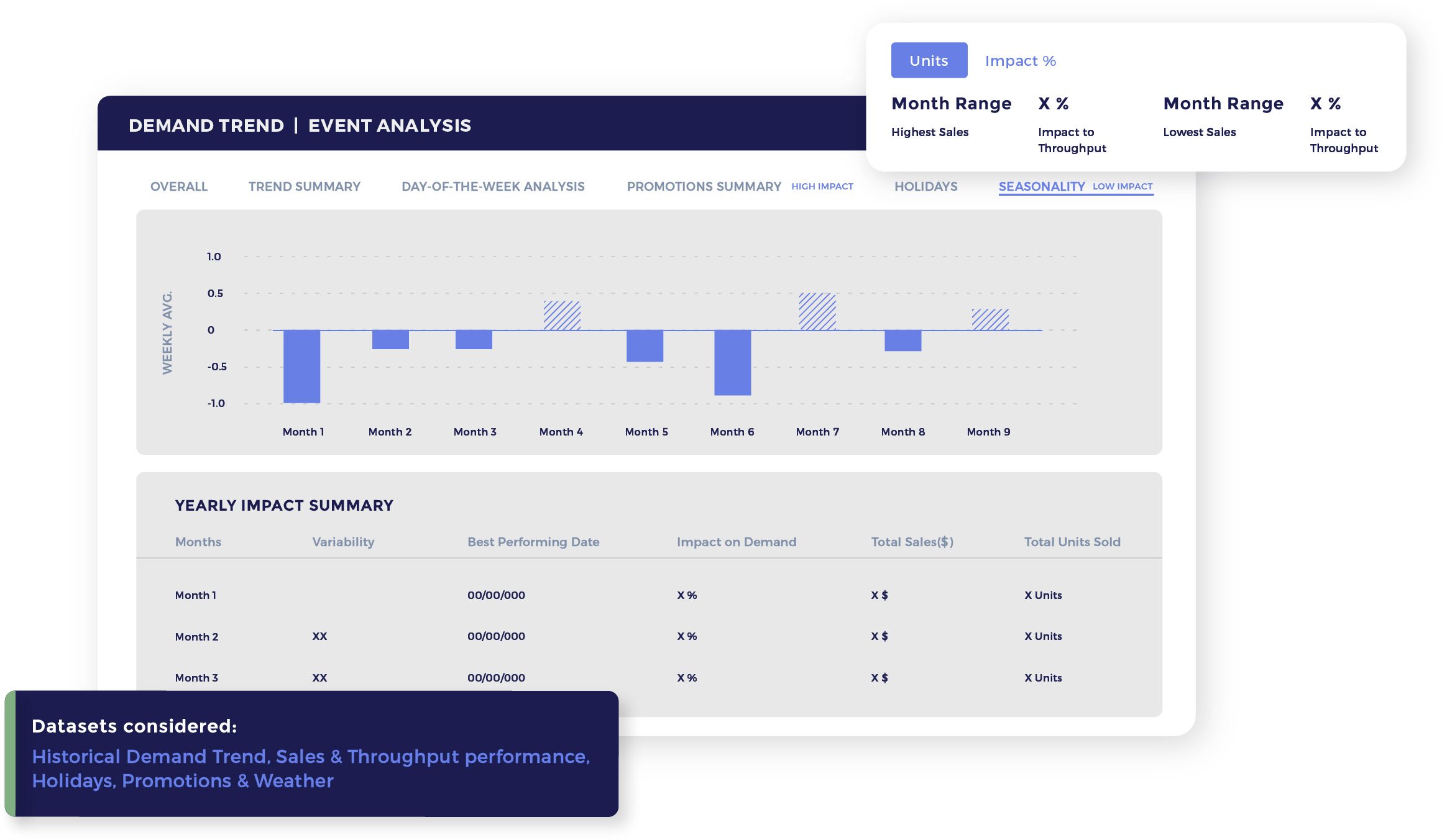

Demand Sensing

Use historical sales patterns to create a picture of true demand used for evaluating lost sales opportunities and uncovering new executable insights.

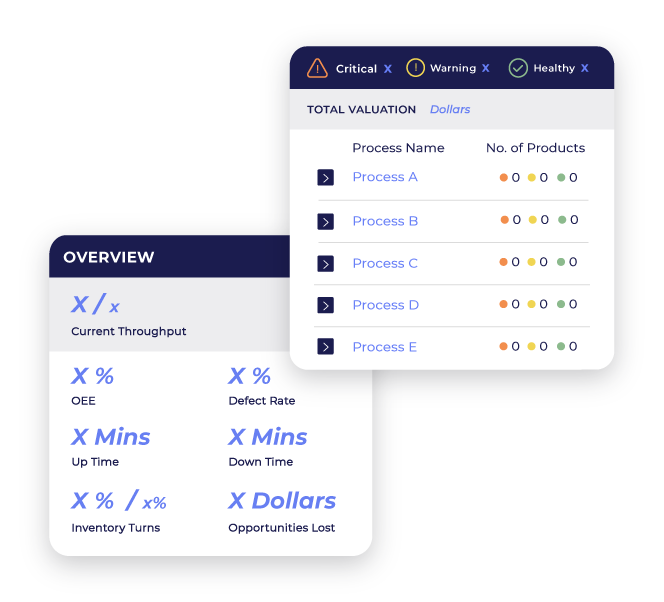

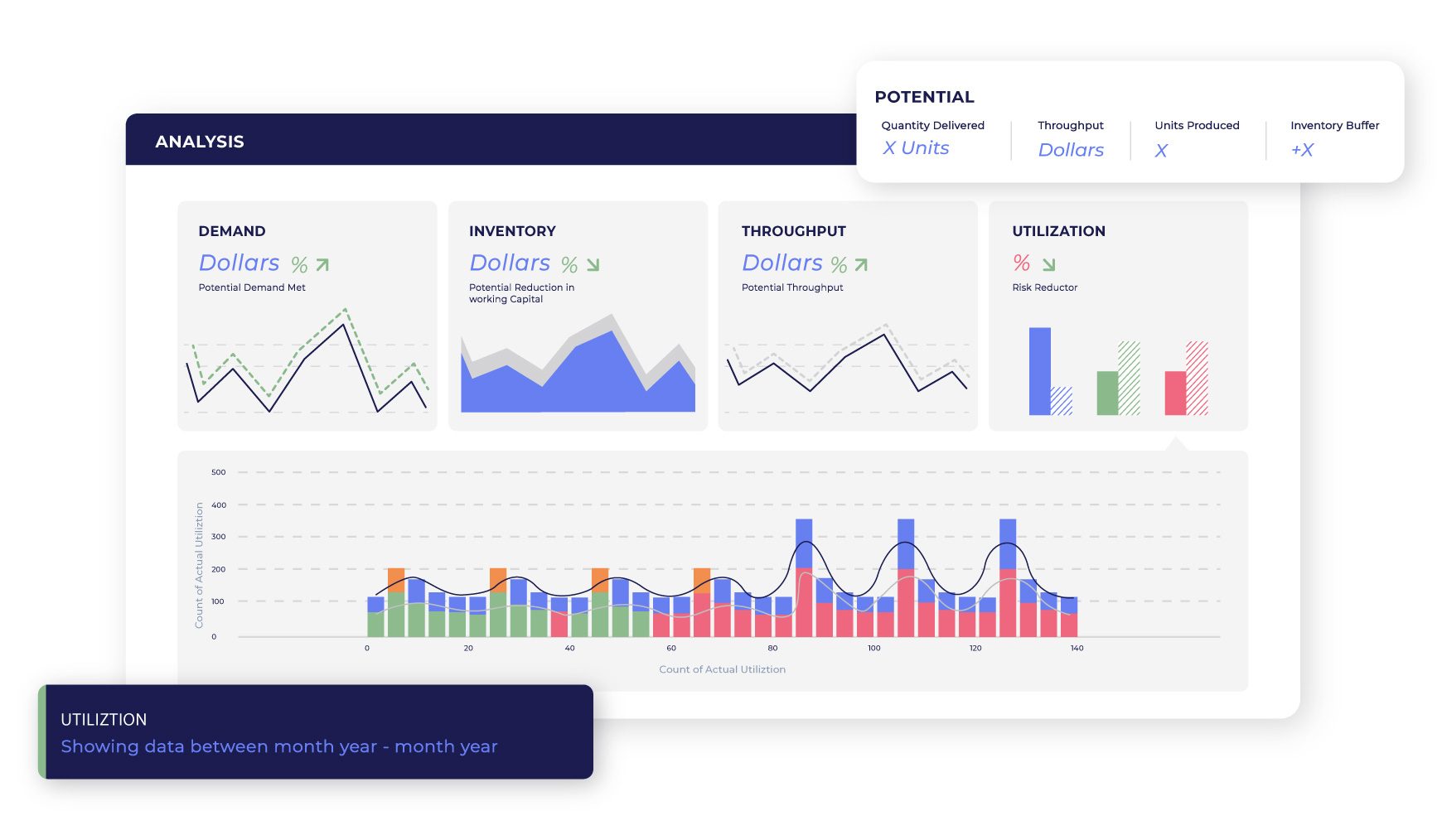

Capacity Management

Plan capacity based on demand patterns without overstocking or understocking of inventory.

Distribution & Logistics Management

Use a combination of business rules mapping and ML pattern extraction, to dynamically prioritize items based on logistics costs, lost sales opportunities, and more.

Finance Management

Use a high level assessment of the financial state and health of the business to focus the user’s attention on the specific metrics to improve for healthy continuous profitability as well as extract the most earning potential front their business.

Eric West

Director of Technology Partnerships, Ford

ThroughPut provides confidence in not just forecasting through greater transparency, but true demand sensing for improved real-time demand pull and democratization of communications across internal and external owners and partners alike.

ThroughPut provides confidence in not just forecasting through greater transparency, but true demand sensing for improved real-time demand pull and democratization of communications across internal and external owners and partners alike.

Demand and Capacity Balanced Operations For Integrated Supply Chains

ThroughPut’s AI-driven capabilities empowers Automotive Leaders to create game-changing business impact using demand-driven capacity planning to drive continuous supply chain improvement for demand-capacity balanced operations.

Case Study

Leading Automotive Interior Company Boosts Cart Utilization By Deploying Just-In-Time Across Shifts

$2M+

boost in cashflows with 1% reduction in downtime

30%

reduction in defects

$0.5M-$3M

additional annual output

Plan Optimal Capacity for your

Automotive Plant Floor

- 30% Boost in labour productivity

-

42+

- best in

- class

Operations Management Heuristics for driving the best operations decisions

- 15% Increase in Working Capital & Earnings-Per-Share in real-time