LOGISTICS PLANNING SOLUTION OVERVIEW

Predictive Insights for

Sustainable Cost Efficiencies

With uncertainties gripping the demand-supply dynamics in the logistics industry, companies have to transform their game plan. Continuous optimization of warehouse strategies, labour processes and fleet management is the only way to achieve sustainable, all-round efficiencies across the supply chain.

ThroughPut helps logistics planners & managers with AI-driven actionable insights to analyze routes, carriers and load efficiencies.

Enhanced Real-time visibility across transportation, warehouses & inventory

Enhanced Real-time visibility across transportation, warehouses & inventory

Demand-driven logistics planning to reduce logistics costs & carbon emissions

Demand-driven logistics planning to reduce logistics costs & carbon emissions

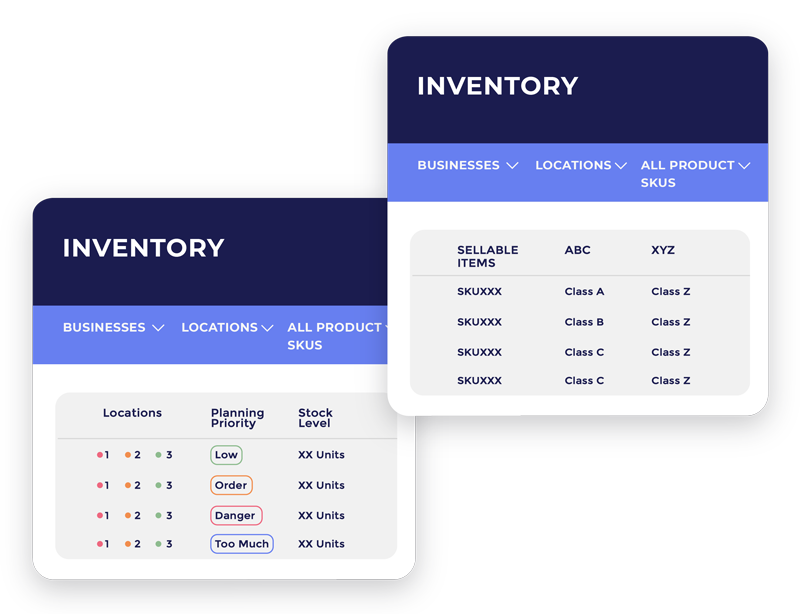

Connected warehouse management to optimize distribution & inventory levels

Connected warehouse management to optimize distribution & inventory levels

Clients Who Trust Us

Thomas Deakins

SVP, Global Partnerships & Alliances | project44

With ThroughPut, we empower our customers to not just optimize their logistics, but their supply chain operations as a whole. ThroughPut’s demand-first, AI-powered, predictive approach to supply chain management is the key to solving the product and customer prioritization puzzle that all businesses seek to solve on an everyday basis these days as they look to expedite lead times and better serve their customers.

With ThroughPut, we empower our customers to not just optimize their logistics, but their supply chain operations as a whole. ThroughPut’s demand-first, AI-powered, predictive approach to supply chain management is the key to solving the product and customer prioritization puzzle that all businesses seek to solve on an everyday basis these days as they look to expedite lead times and better serve their customers.

Why Do Businesses Need Logistics Planning Solution?

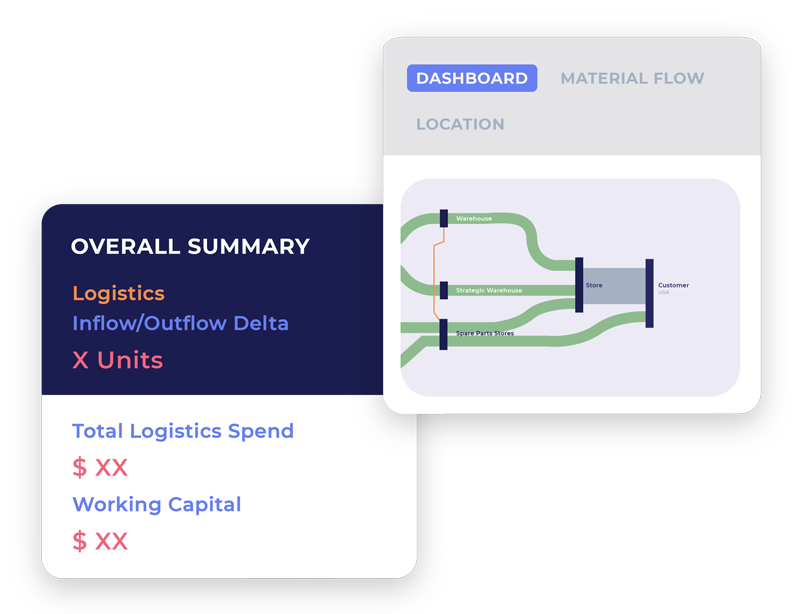

Single View of All Shipments

Compare Multiple Shipments And Period Volumes Easily

| Challenge | Manage overlapping shipment cycles over a staggered period of time. |

| Solution | Compare received, delivered and sold aggregate volumes by route and shipment type to understand impact of fulfillment orders. |

600x

Faster insights for improved Lead Times.

~2x

Improvement through Inventory Turns

SKU Optimization

Review Impact Of Logistics Performance On OTIF

| Challenge | End-to-end SKU analysis across multiple channels. |

| Solution | Holistic SKU flow all the way from supplier through distribution networks to stores to analyze the impact of sales and contribution to indirect logistics cost. |

13.5%

Increase in Performance Improvement Yield Margin

6%

Working Capital Reduction Opportunities

Improved OTIFs with Reduced Carbon Emissions

Visually Depict The Flow Of A Particular SKU Or A Cluster Of Selected SKUs

| Challenge | Siloed material flow views across the distribution network. |

| Solution | Accelerate shipping of the right goods at the right time, while minimizing runtime costs and risks. Using a combination of business rule mapping and ML-based pattern extraction, predict ETAs and achieve a high rate of OTIFs. |

~16M

Throughput Saving per year

~20%

More capacity in Production Operations

CASE STUDY

Leading Cement Manufacturer Reduces Logistics Costs by 20% with Demand-driven Logistics Planning & SKU Optimization

1M+

SKUs Optimized

17.8%

Reduction in Trucking Costs

278,000

Tonnes of excess annual inventory relieved

Logistics Planning Software

Features

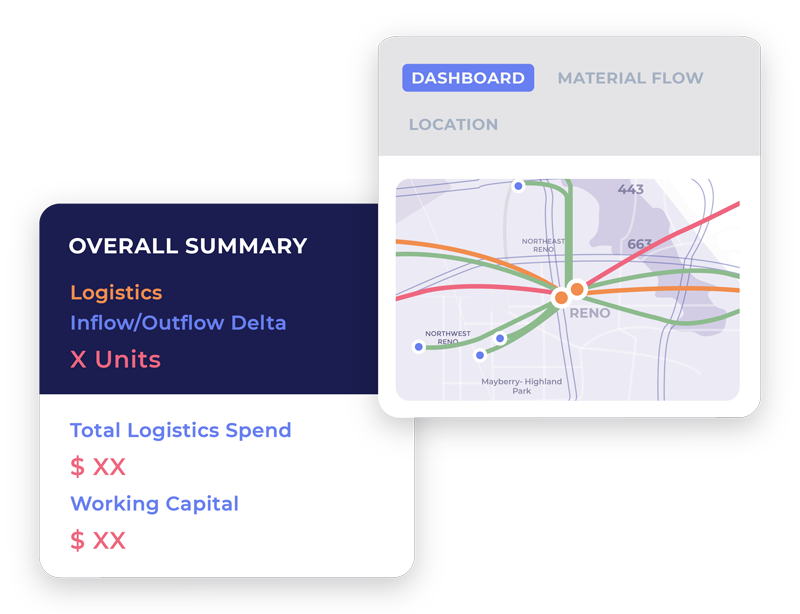

Supply Chain Network Optimization with Dynamic Lead Times

- Examine material flows overlaid on geo maps and identify choke points across their supply chain networks

- Accurately generate customized forecasts for demand, near-term OTIF potential, and product mix optimization to maximize profit margins and other factors

- AI-powered analysis, predictions and recommendations by route and shipment type of received, delivered and sold aggregate volumes.

Actionable Insights to Prioritize OTIF Deliveries

- Review the impact of logistics performance on OTIF fulfillment of orders and associated logistics spend

- Visualize performance against a business’s unique priority KPI’s such as lead-time-to-customer vs. product expiry thresholds, product criticality

- Prioritize orders and customers by demand and order-value for improved profitability

Adopt a Data-Driven Approach to Analyze Logistics Flow

- Quickly view and assess the flow of a particular SKU or a cluster of selected SKUs all the way from supplier through the distribution network to stores.

- Easily expose tactical opportunities for improvement with assessment of the bottom-line benefits associated with each opportunity

- Optimize material movement to dynamically prioritize Items based on logistics costs and lost sales opportunities.