Replenishment planning

that

adapts to Demand Uncertainty

Optimize inventory

management

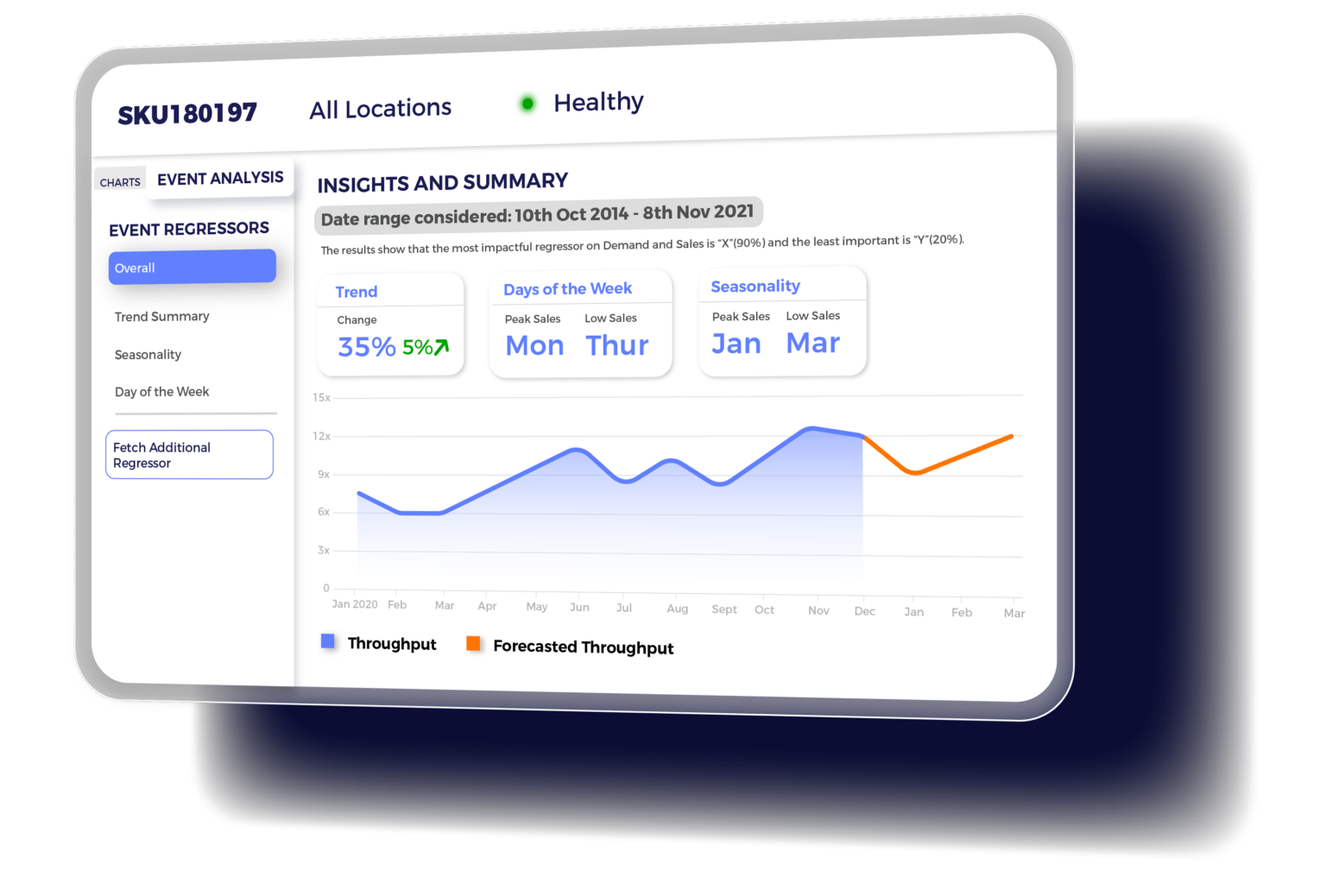

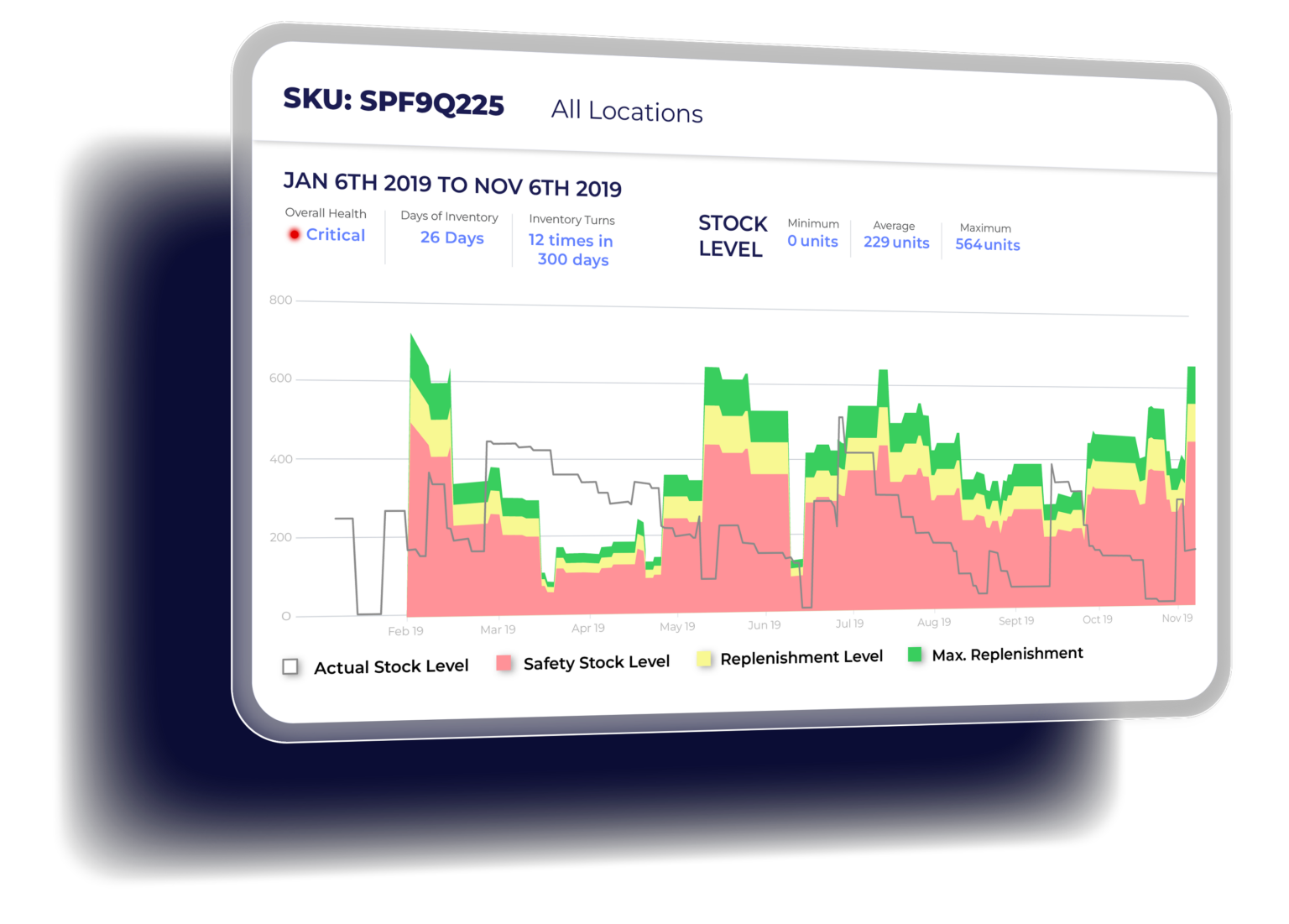

Take the guesswork out of demand planning with automated material replenishment software that recommends precise quantities down to the SKU level. Factor in real-time demand and supply dynamics for razor-sharp forecasts, so that you never overstock or understock again.

Maximize

high-value sales

Leverage point of sale data to sense demand and generate automatic early warning signals for replenishment. Identify “hot” products to intelligently prioritize auto-replenishment and maximize revenue.

Continuously exceed sales

target and service levels

Rapidly analyze product demand by SKU and location to identify shifts in real time. Factor in changes in demand signals and supply chain constraints and affect incremental, end-to-end changes across the supply chain to continuously meet and exceed expectations.

Optimize

replenishments costs

Leverage demand-driven replenishment planning to optimize network flow, reduce lead times, and streamline replenishment costs. Gain supply chain agility and a critical competitive edge by eliminating stockouts and accelerating availaibility.

How ThroughPut’s

Replenishment

Planning Works

Automate inventory

management process

Optimize inventory and automate replenishment based on demand, factoring in distribution center (DC) and store capacities and other operational constraints.

Accelerate inventory productivity

and minimize lost sales

Forecast demand at local, regional, or global levels based on a variety of internal and external drivers including trends, promotions, seasons, special dates, holidays, and weather changes.

Accelerate supply chain agility

for new product launches

Fast-track time to market and adapt to market shifts to enable continuous business growth and support new product launches, store locations, and geographical expansions.

Top 3 Reasons to Choose ThroughPut

Increased on-shelf

availability

Real-time visibility into supply

chain, inventory, inventory in

transit, sales, and more enables

automatic, intelligent,

demand-driven replenishment

recommendations for optimal

inventory levels.

Optimized inventory

management

Leverage fully automated

allocation and replenishment,

monitor key business metrics,

and set up preventive alerts to

identify critical inventory

levels. Set realistic production –

and optimal distribution –

targets to meet market needs.

Maximized supply

chain efficiency

Accurately fulfill orders every

day by setting replenishment

and distribution targets that

create a perfect “pull.” Focus

on driving improvements that

deliver the maximum value to

the financial bottom line.