AI-Powered Spare Parts Optimization Software that reduces shortages,

eliminates unreliable suppliers, and improves operational uptime.

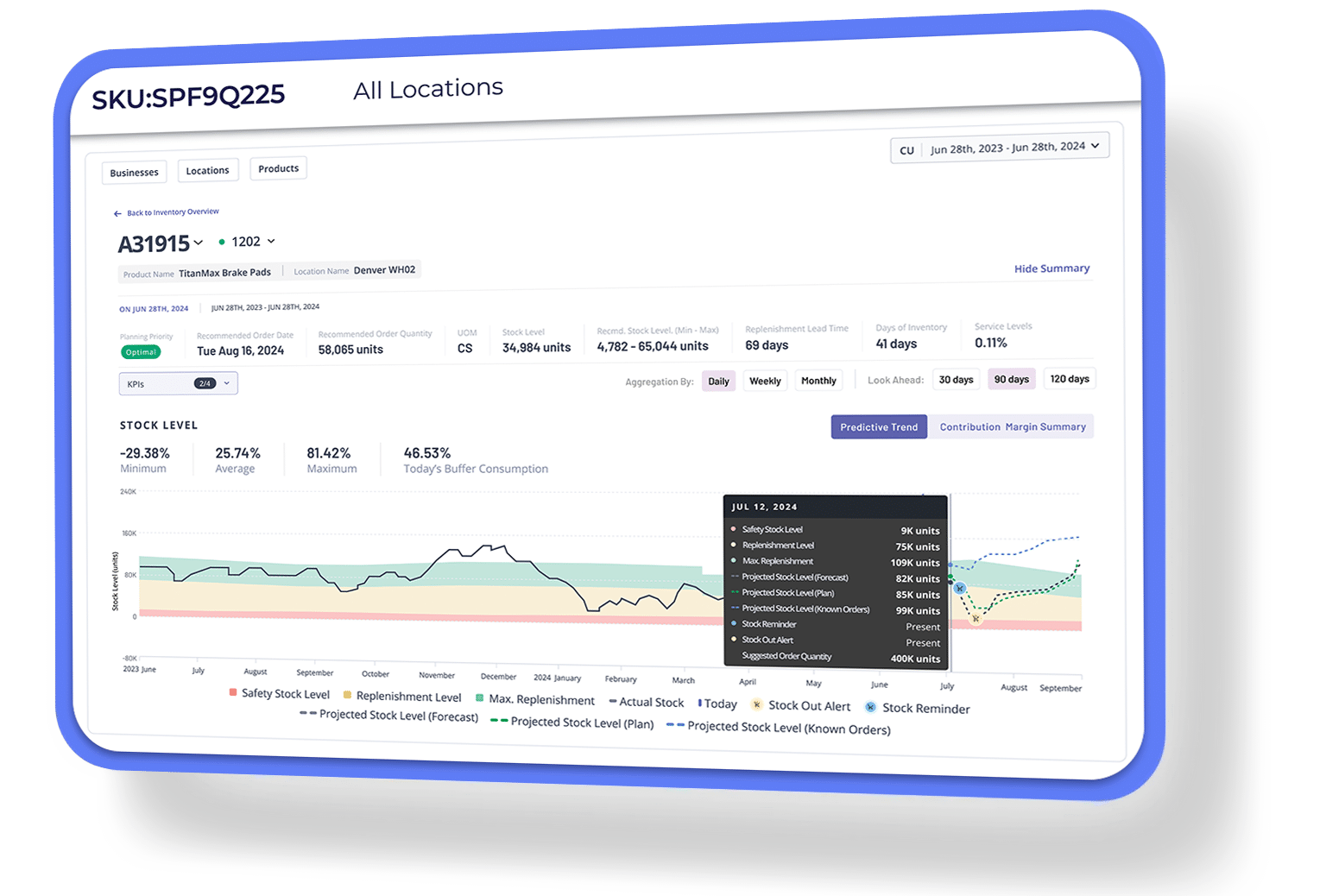

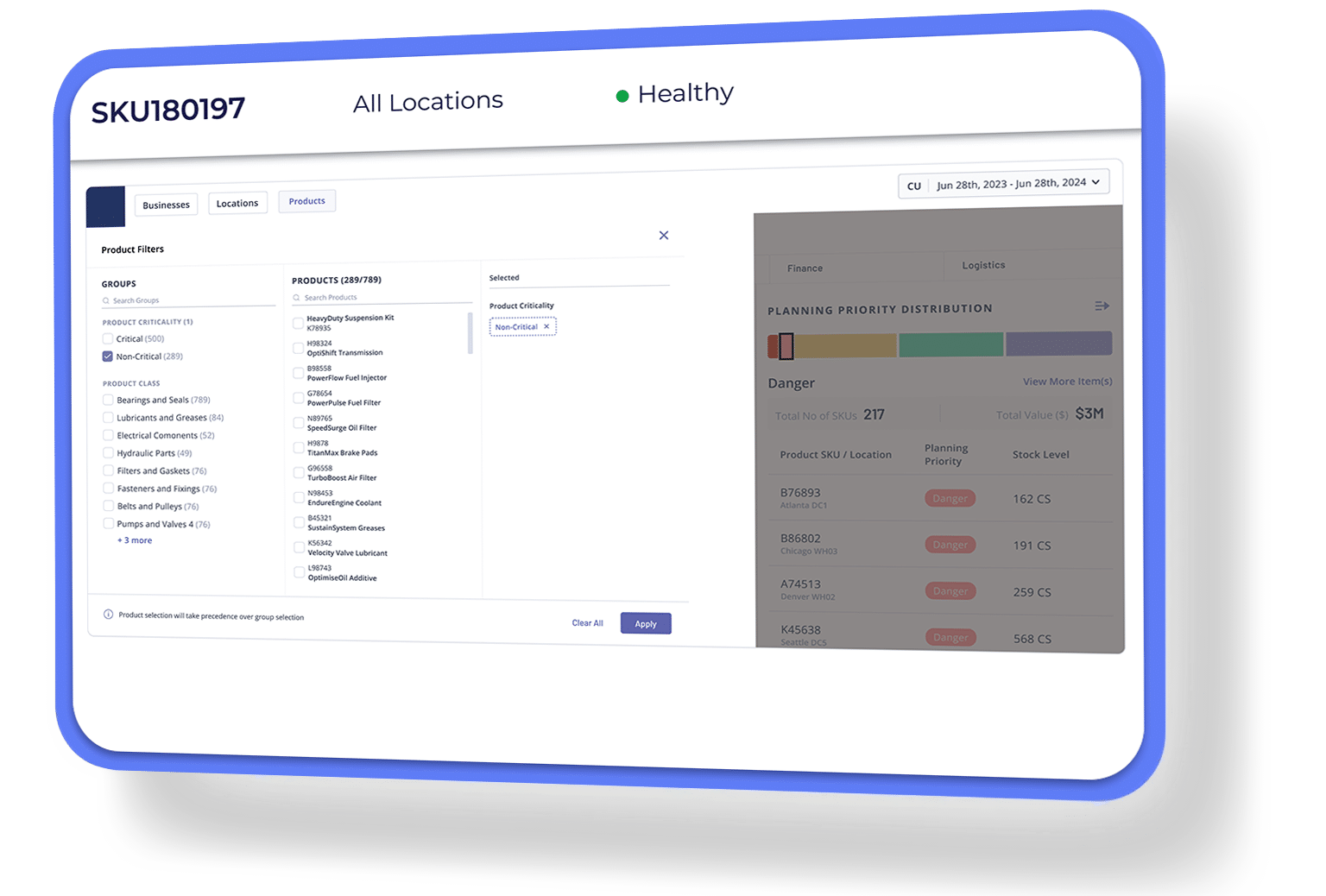

Dynamically Manage Spare Parts Using AI-powered Decision Intelligence Based on Administrative Lead Times & Real Usage

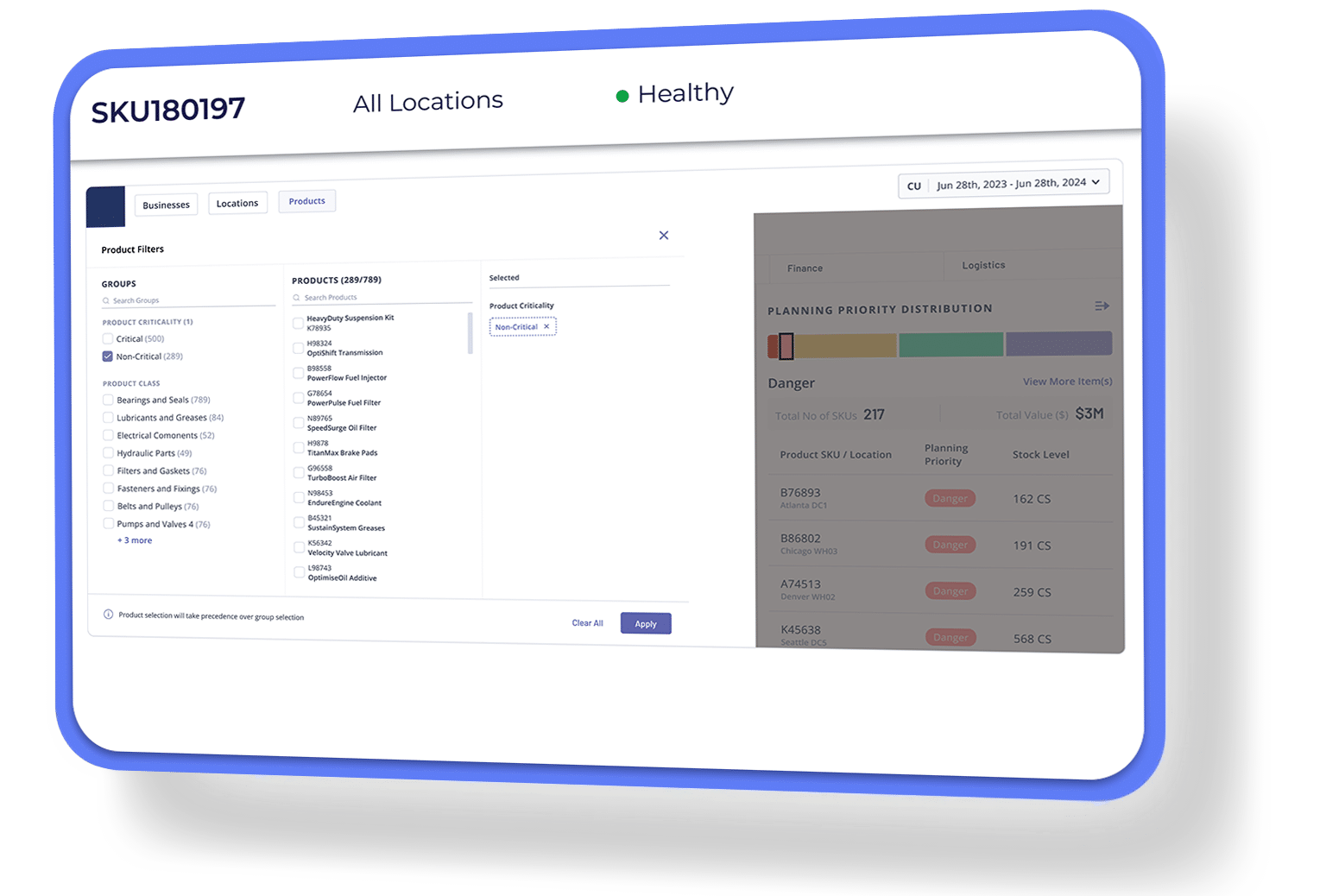

Categorize and prioritize spare parts based on real-time usage, upcoming maintenance plans, downtime risk and lead times. ThroughPut.AI’s Spare Parts Optimization software empowers you to make the most use of your constrained budget, coordinate planned & unplanned maintenance by aligning job schedules to real-world spare part lead times:

– Predict future parts demand with AI-powered forecasting.

– Align planned and unplanned maintenance with actual supplier lead times.

– Prevent excess and obsolete inventory while ensuring critical parts availability.

– Rebalance inventory levels across plants and warehouses to maximize working capital efficiency.

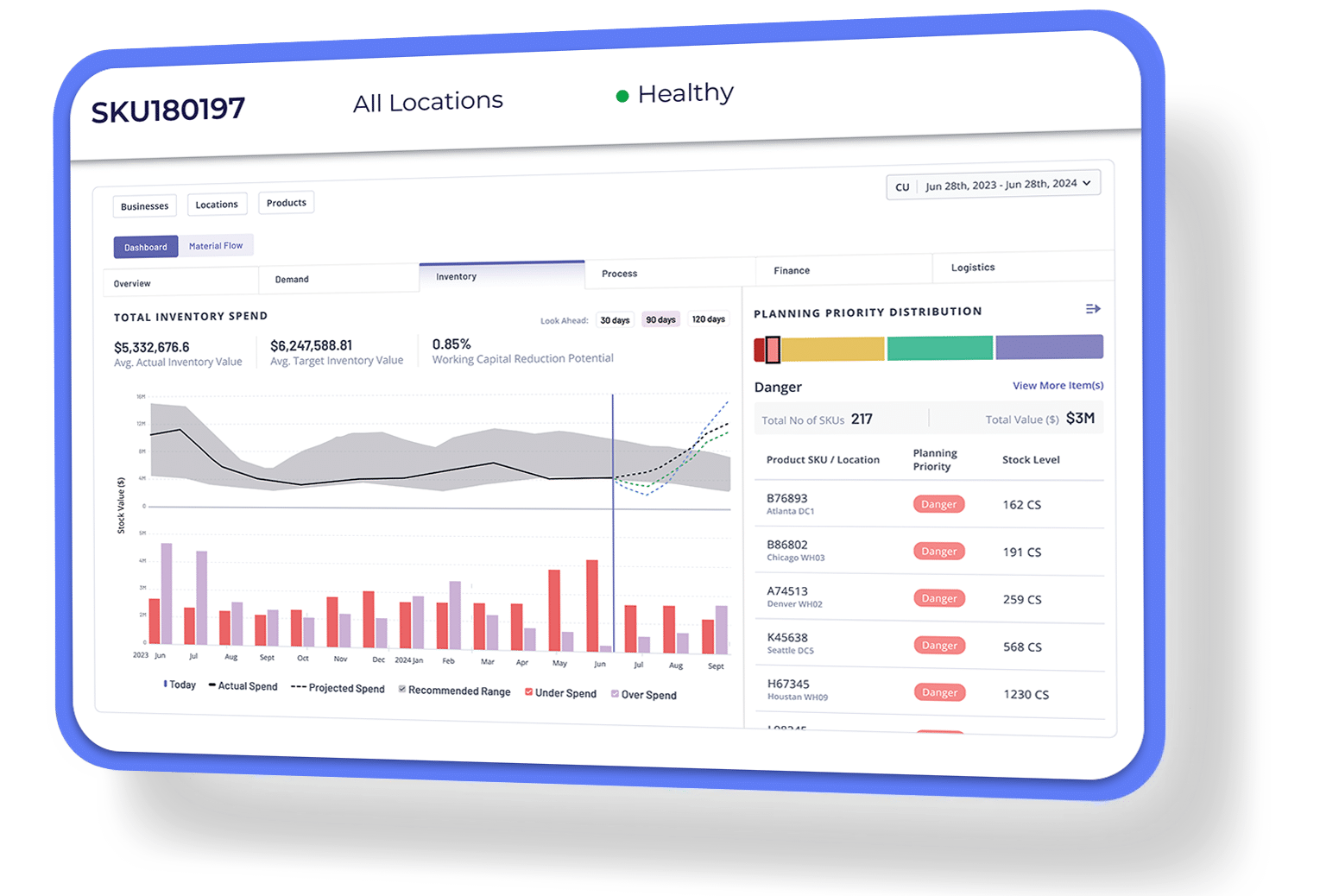

Reduce Unplanned Downtime Due to Parts Shortages

Avoid asset failure by matching parts availability with maintenance demand in real time. ThroughPut.AI Spare Parts Optimization software ensures every critical spare part is available before downtime occurs by:

– Predict parts replenishment needs using historical and live usage patterns.

– Visualize expected supplier lead times and material readiness.

– Automatically recommend replenishment schedules and safety stock levels.

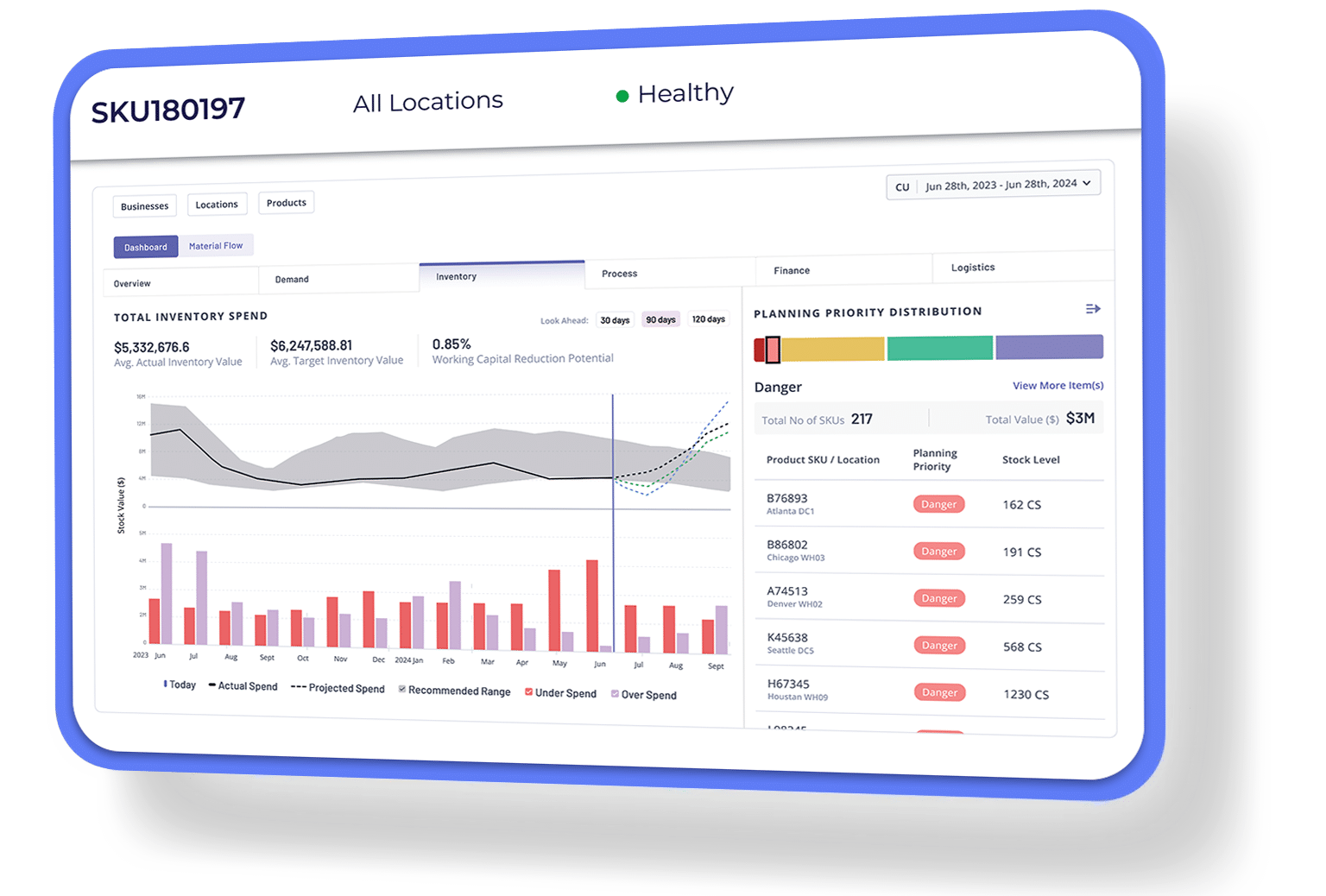

Find, Replace, and Rank Existing and New Suppliers Intelligently

Identify the best suppliers and reduce procurement risks. ThroughPut.AI’s Spare Parts Optimization software helps you:

– Rank suppliers based on delivery reliability, lead time, and cost performance.

– Replace weak or non-performing vendors with high-performing alternatives.

– Detect supply gaps and recommend new supplier certification opportunities.

– Achieve proactive sourcing decisions to ensure continuous parts flow and reduce working capital dependency.

– Find gaps in material availability to stand up and certify new suppliers.

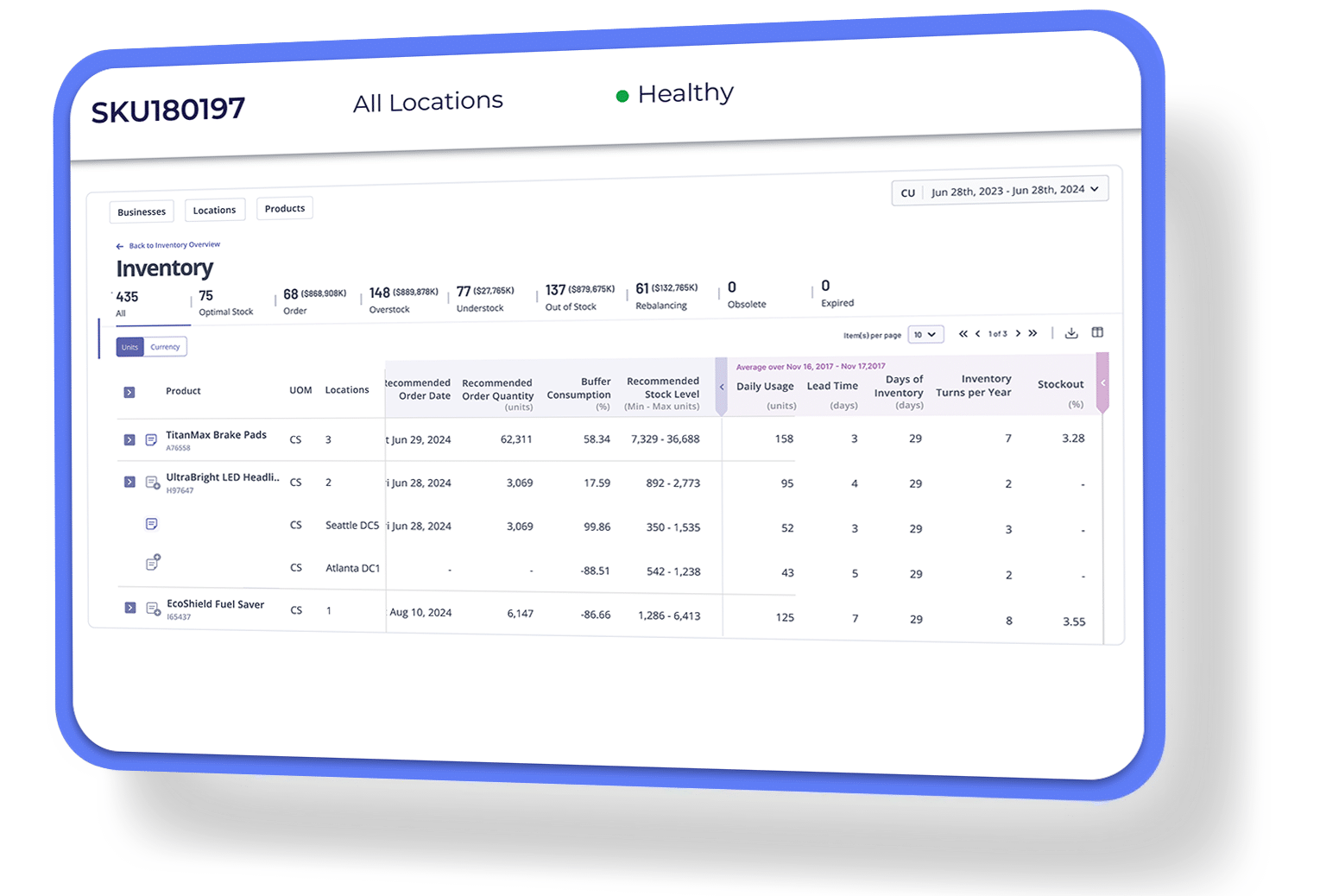

Stock the Right Parts, Without Taking Up More Warehouse Space planning

Accurately maintain dynamic safety stock, kit-level replenishment and availability. Free up capital while keeping critical spares always available. Reduce Storage Costs.

How ThroughPut.AI

Spare Parts

Management Software Works

Integrate

Connect spare parts and maintenance data.

Diagonise

Analyze critical KPIs like Request-to-delivery time, Material flows across sites and suppliers and Demand processing timelines on standard stock.

Get Recommendations

Categorization of critical vs. standard parts. When, how, and who to order from for best lead-times and availability. Maintenance scheduling aligned with supply availability.Dynamic safety stock and kit-level replenishment levels.