A 5-point Checklist to Identify Manufacturing Bottlenecks Before It’s Too Late

Manufacturing bottlenecks can slash productivity by up to 40%! That’s a huge chunk of potential output just vanishing into thin air. Interestingly, not being able to identify manufacturing bottlenecks before it is too late is a real issue in most supply chain businesses.

So, what’s causing these bottlenecks? It could be a mix of things – maybe your processes aren’t as sharp as they could be, or your equipment’s seen better days. Sometimes, it’s about not having enough skilled hands on deck or not planning your capacity right. And let’s not forget those unexpected machine downtimes that catch everyone off guard.

According to the Manufacturing Institute (MI), an agile and resilient supply chain is the answer.

Here’s the deal: identifying manufacturing bottlenecks and tackling them isn’t just a good idea; it’s essential for ramping up your productivity, cutting costs, and keeping your customers happy. In this blog, we share with you five anomalies that you can watch out for to identify manufacturing bottlenecks.

What is a Bottleneck in Operations and Why Does it Matter for Supply Chains?

In operations management, a bottleneck refers to a point in a production system that slows or stops progress and eventually severely impacts the efficiency of the manufacturing system. The bottlenecks can occur in various stages of a production line, a computer network, or any other system where the bottleneck limits the entire system’s capacity to produce at its optimum level.

As a result, the impact of bottlenecks are delays, higher production costs, and reduced performance.

Short-term bottlenecks are temporary and often caused by factors such as employees unavailability, or a sudden increase in demand. Long-term bottlenecks, on the other hand, are more incorporated into the system itself and are often the result of inefficient processes or procedures.

Manufacturers need to have a proper bottleneck management in place and identify bottlenecks before they occur and find efficient solutions to eliminate them. Eliminating bottlenecks will then result with:

- better responsiveness to the market

- improved efficiency

- improved productivity and profits

- reduced overheads

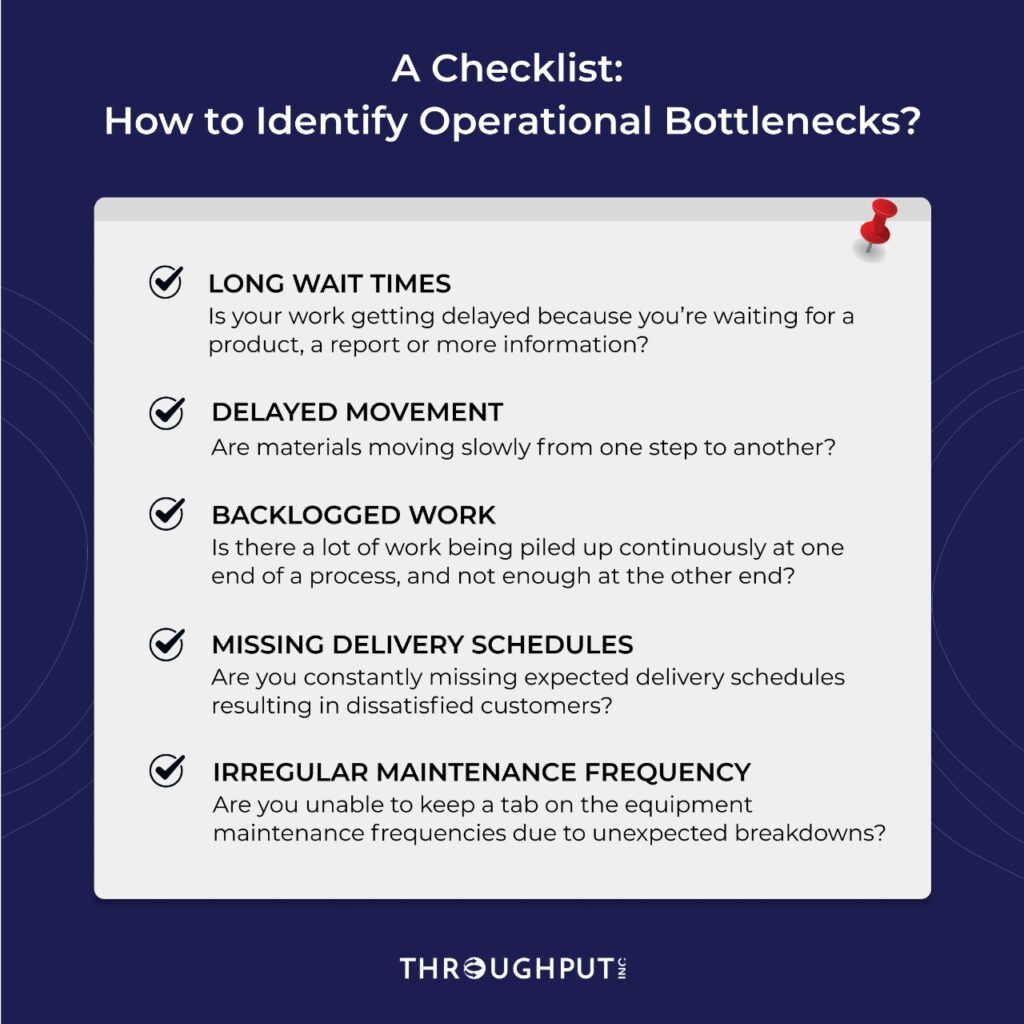

The 5-Point Checklist to Identify Manufacturing Bottlenecks

#1 Long Wait Times

Manufacturing wait time serves as a crucial litmus test for gauging the efficiency of your production line. When you start noticing that things are taking longer than they should, it’s a strong indicator that you’ve run into a bottleneck. These bottlenecks can seriously hamper productivity, slowing down the entire manufacturing process.

It’s like a traffic jam in your workflow; everything backs up, leading to delays and frustration. Identifying and addressing these long wait times is essential for keeping your operations running smoothly. If you stay vigilant and responsive to these wait time indicators, you can maintain a more efficient, productive manufacturing environment.

#2 Delayed Movement

Delayed movement in a production line is a telltale sign of a bottleneck. When you notice that materials or products are taking longer than usual to move from one stage to another, it’s a clear indicator that something is holding up the process. This kind of slowdown can significantly impact the overall efficiency of your manufacturing operations.

It’s akin to a blockage in a pipeline, where the flow is interrupted, causing a build-up and delay. Addressing these delayed movements promptly is crucial for maintaining a smooth, efficient workflow. Keeping a keen eye on these delays helps you identify and resolve bottlenecks quickly, ensuring your production stays on track.

#3 Backlogged Work

A pile-up of work in your manufacturing process? That’s a classic sign of a bottleneck. This usually means there’s a slowdown somewhere further along in your production line.

When tasks start to pile up at one point in the process, it quietly leads to inefficiency. Your workforce might end up feeling overwhelmed too, which can slow things down even more, resulting in longer lead times and less throughput.

#4 Missing Delivery Schedules

Missing delivery schedules is a significant red flag indicating a production bottleneck. When you consistently fail to meet your delivery timelines, it often points to inefficiencies or delays somewhere in your production line. This not only impacts your ability to fulfill customer orders on time but also can harm your business’s reputation for reliability.

#5 Irregular Maintenance Frequency

Irregular maintenance frequency can be a subtle yet telling indicator of a production bottleneck. When maintenance schedules are inconsistent, it often suggests that equipment is being overused or neglected, leading to inefficiencies and slowdowns in the production process. This irregularity can result in unexpected breakdowns or reduced performance of machinery, directly impacting the flow of operations.

Regular, scheduled maintenance is key to preventing these bottlenecks, ensuring that equipment runs optimally and production stays on track. Addressing maintenance irregularities helps in maintaining a consistent, efficient production line.

Identify Manufacturing Bottlenecks and Turning Them Into Breakthroughs

If you’re a plant manager, you know how critical it is to keep an eye on manufacturing bottlenecks. They can disrupt your production flow, increase costs, and affect customer satisfaction.

The trick is in identifying these bottlenecks early and managing them effectively. Our five-point checklist is a great tool for doing just that. It helps you identify potential manufacturing bottlenecks before they escalate, keeping your supply chain running smoothly.

Remember, it’s not enough to just address manufacturing bottlenecks – you need to eliminate them. Utilizing advanced tools and techniques like those offered by ThroughPut can transform the way you handle production challenges.

Embracing a data-driven and analytics-led approach positions you ahead in the competitive world of manufacturing. Adopt these smarter strategies and see the difference in your operational efficiency and success.

And if you’re keen to dive deeper into the topic of production bottlenecks, check out our whitepaper on the topic.