Optimize Logistics Processes and Distribution With AI-powered Supply Chain Intelligence Software

Theoretically, optimize logistics processes and distribution are straightforward: move an item from Point A to Point B to satisfy customer expectations at an agreed service level, all while generating a profit for your company. Practically, however, it’s often chaotic.

In the real world, logistics isn’t about managing one product, one route, and one customer—it’s about juggling hundreds of products, thousands of routes, and a diverse array of customer needs. The permutations and combinations are vast, and the daily operational challenges are numerous—from late deliveries and vehicle breakdowns to delayed production and expedited shipments. These issues make the task incredibly taxing.

Moreover, trying to extract valuable and timely insights from sprawling spreadsheets and complex software often adds to the frustration rather than alleviating it.

If you find yourself stuck between optimizing routes, cutting costs, responding with agility to fluctuating demands, and managing your fleet and labor efficiently, this blog is tailored for you.

We dive deep into the challenges that you will likely resonate with, explore how AI solutions like ThroughPut can offer effective strategies, and share best practices that you can implement immediately.

So dive right in. Feel free to use the menu sidebar to navigate directly to specific topics of interest.

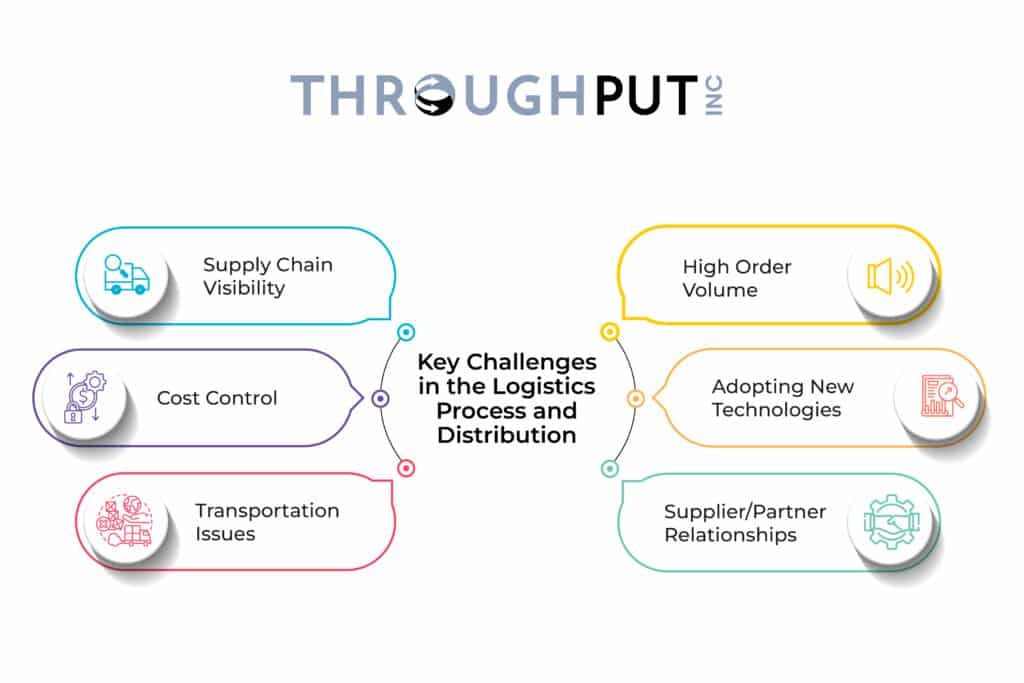

What Are the Key Challenges in the Logistics Process and Distribution?

Before we dive first into the solution to your problems, let’s glimpse through your most pressing challenges right now:

- Supply Chain Visibility: Achieving real-time transparency throughout the supply chain—from receiving inventory to fulfilling orders and shipping—is crucial for timely deliveries but often difficult to attain.

- Cost Control: Managing transportation costs is continually challenging, especially with fluctuating fuel prices and rising fleet maintenance expenses.

- Transportation Issues: High fuel costs, poor road infrastructure, traffic congestion, and inefficient rail networks significantly increase logistics expenses.

- High Order Volume: During peak seasons, companies often struggle to manage a surge in orders, resulting in delivery delays and failures.

- Adopting New Technologies: Integrating advanced technologies like AI is essential yet challenging due to the plethora of options and the need for customization to fit specific business needs.

- Supplier/Partner Relationships: Establishing and maintaining efficient relationships with suppliers and partners, ensuring compliance with agreed standards, is crucial yet challenging.

Of course, new and advanced technologies are now offering answers to most of these challenges, if not all.

Here’s a detailed look at how one such tool, ThroughPut AI, optimizes logistics processes and distribution for multiple industries.

Use ThroughPut AI to Optimize Logistics Processes and Distribution

A supply chain intelligence tool like ThroughPut AI adds a powerful layer of analytics and artificial intelligence to your existing logistics environment.

Along with end-to-end visibility, which is a promise of many tools in the market these days, supply chain intelligence software for logistics will also offer actionable insights to decision-makers, enabling you to take those actions with the most improvement potential in the shortest time possible.

ThroughPut AI is built for strategic, tactical and operational decision-making; which means, it provides a common operating picture that’ll let you analyze and optimize routes, prioritize items based on logistics costs, identify potential lost sales opportunities and enhance deep-rooted efficiencies across your value chain.

Let’s take a deeper look at its capabilities.

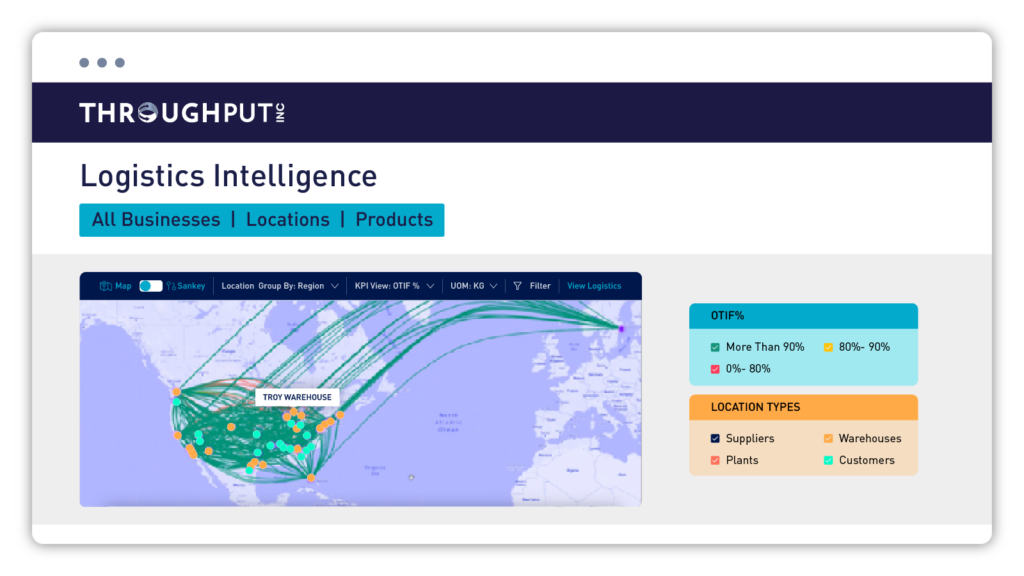

ThroughPut’s Unique Logistics and Distribution Features

- Instant comparison of multiple review period volumes

You can instantly compare volumes across multiple review periods, gaining a comprehensive view of all shipments from suppliers to distribution centers, between distribution centers, to stores, and ultimately to your customers, including final sales.

This feature uses smart graphical representations to analyze data by route and shipment type—whether received, delivered, or sold—helping you quickly visualize and assess performance trends and inefficiencies.

Moreover, you can dynamically prioritize items based on factors like logistics costs and potential lost sales opportunities. This capability empowers you to make informed decisions swiftly, optimize operations, and maximize profitability by responding to real-time market demands and logistical challenges.

- Actionable Insights on Operational gaps

ThroughPut AI delivers actionable insights on operational gaps, enabling you to pinpoint and address areas where your operations are significantly lagging.

This feature not only highlights specific inefficiencies but also exposes tactical opportunities for process improvement. By providing an in-depth assessment of the bottom-line benefits associated with each opportunity, it aids in better prioritization and decision-making.

This strategic insight allows you to refine operations, enhance efficiency, and ultimately improve profitability by focusing on the most impactful areas for improvement within your supply chain.

- SKU-Driven Holistic Logistics Flow

ThroughPut AI offers an SKU-driven holistic logistics flow feature that enables you to quickly view and assess the flow of specific SKUs or groups of SKUs throughout the entire distribution network—from suppliers to stores.

This tool allows you to connect and analyze sales flow volumes from multiple metrics, providing a comprehensive understanding of how each SKU performs.

By mapping the flow end-to-end, you can thoroughly analyze the performance of your logistics value chain.

This granular insight helps you identify bottlenecks, optimize inventory levels, and ensure efficient movement of goods, enhancing the overall effectiveness of your supply chain operations.

Benefits of ThroughPut AI for Optimizing Logistics and Distribution

By optimizing logistics processes using ThroughPut AI, here are benefits you can expect to see:

- Both allocation and distribution recommendations powered by ThroughPut AI are focused on creating a perfect pull and removing unnecessary moves to get the product to where it is needed, on time and in full (OTIF) so the user never misses a sale. Target Service levels are continuously updated based on the product mix priorities for each period.

- Monitoring buffer consumption helps translate the performance against recommended stock level targets over time and exposes risk/waste in the system. Using correct buffer-sizing criteria, ThroughPut AI ensures the user can always supply the next node in the supply chain to the desired level of service regardless of the variability or reliability of the vendors or the customer’s demand.

- The health of Supply (Replenishment Lead times) and Demand (Average Daily Usage) signals are dynamically factored into the recommended inventory buffers to avoid flow disruptions while optimizing Inventory Turns, Service Levels, and Days of Supply.

What Are the Best Practices in Logistics and Distribution Optimization?

Lastly, let’s take a look at some of the best practices in logistics and distribution optimization.

Best practices in logistics optimization are crucial for enhancing efficiency and responsiveness within supply chains. Here’s how leading companies are setting standards:

- Leverage Predictive Analytics: Utilizing predictive analytics to analyze historical data is a foundational step. This approach helps in recognizing established patterns, enabling AI to forecast demands with higher accuracy. Optimizing inventory levels based on these predictions minimizes the risks of stockouts or excess inventory. For example, fashion giant Zara employs predictive analytics to fine-tune its inventory management, leading to quicker turnaround times and minimal waste.

- Real-time Tracking and Visibility: Implementing real-time tracking enhances logistics processes significantly. By integrating AI software with IoT devices, companies can continuously monitor goods, especially during transit. This capability allows for proactive decision-making and timely alerts on potential disruptions, reducing delays and enhancing reliability. DHL, for instance, uses smart sensors and AI tools to track shipments continuously, ensuring transparency and dependability in its operations.

- Automate Routine Tasks: Automating repetitive tasks such as route planning or order processing can significantly boost operational efficiency. Amazon exemplifies this practice by employing AI-driven robots in its fulfillment centers, which enhances both accuracy and efficiency in its logistics operations.

- Dynamic Route Planning and Optimization: AI can dynamically optimize routes, taking into account traffic patterns and environmental conditions such as weather, thereby minimizing delivery times and reducing fuel costs. Tools like ThroughPut AI play a critical role here, suggesting the most efficient routes for delivery vehicles.

- Utilize AI-powered Supply Chain Intelligence: AI-powered tools can sift through vast amounts of data to provide actionable insights, identifying inefficiencies and areas for improvement within the logistics process. The adoption of such intelligent systems enables businesses to quickly adapt and evolve, staying ahead in a competitive market.

For logistics and distribution companies looking to optimize their operations, the integration of AI and the continuous update of AI models are essential. Choosing the right software and regularly updating AI models are critical steps toward maintaining an efficient and responsive logistics system.