Key Features Every Supply Chain Management Software Should Include

Managing a supply chain and understanding the features of supply chain management software comes with its fair share of challenges (fair can sound like an understatement for a lot of you!)

From unpredictable demand to global disruptions, things can get messy fast. Without the right tools, it’s easy to lose track of shipments, inventory levels, and even supplier performance. That’s where a solid supply chain management (SCM) software comes in handy.

With so many moving parts — vendors, logistics providers, warehouses — keeping everything running smoothly requires real-time visibility and control. Add in things like fluctuating costs, tight delivery schedules, and ever-changing customer expectations, and you’ve got a lot to juggle. SCM software helps you handle it all by offering up-to-date cross-functional insights and recommendations, automating repetitive tasks, and keeping the entire process organized from end to end.

The right supply chain management solution helps you stay ahead of these challenges. Whether you’re managing supplier relationships or optimizing inventory, it gives you the clarity you need to make smart, quick decisions and reduce bottlenecks.

Here’s a look at the must-have features in supply chain management software to help you overcome these common challenges.

Key Features of Supply Chain Management Software

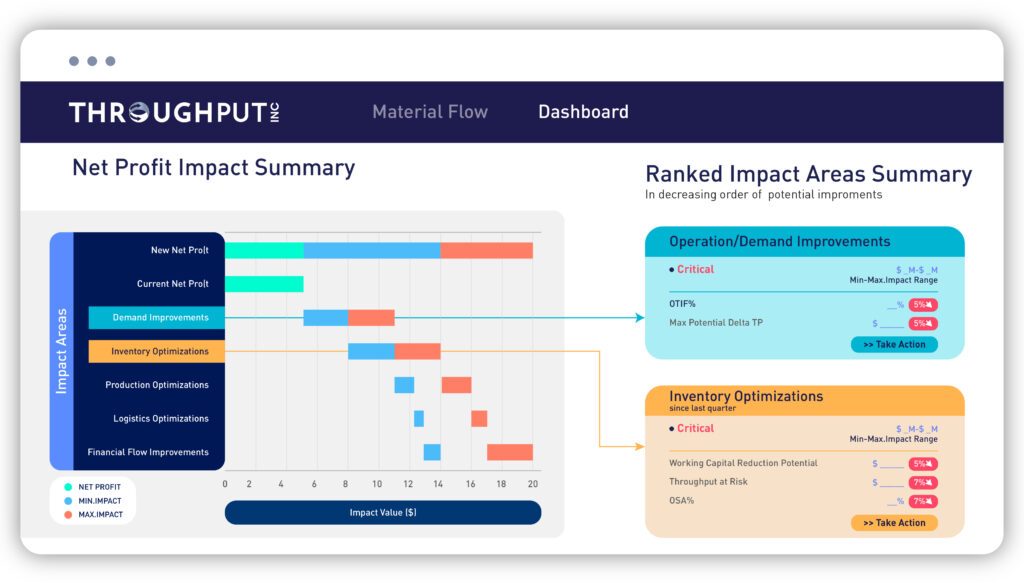

There are five non-negotiable, must-have functionalities of supply chain management software including demand sensing, inventory management, logistics planning, capacity planning and supply chain finance.

Let’s get to the details.

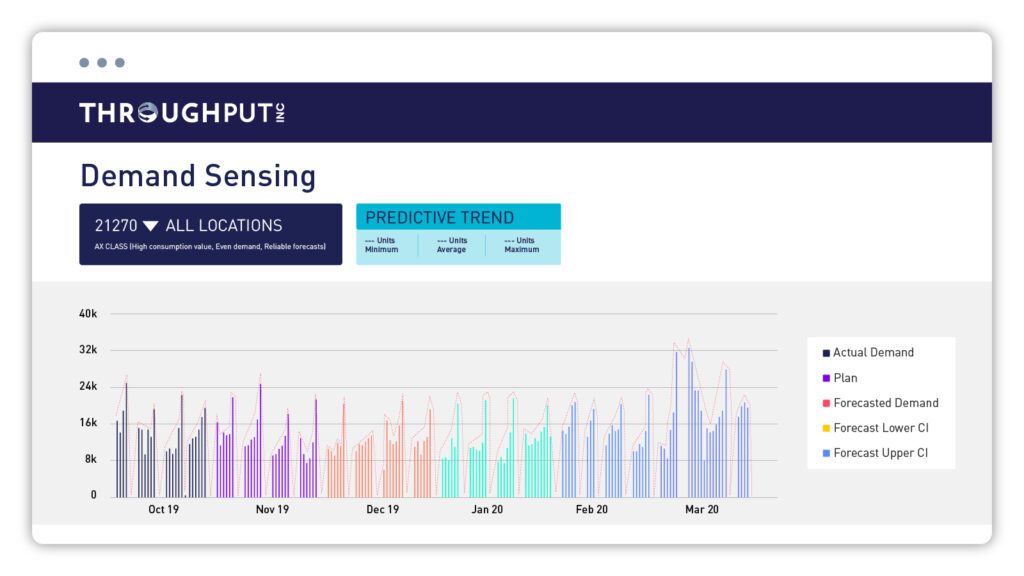

Demand Sensing

A strong supply chain management software should deliver accurate, detailed forecasts at the product, SKU, and location levels by analyzing both internal and external factors—such as holidays, weather, and market trends. By factoring in these data points, it can predict near-term and long-term demand, giving your supply chain the flexibility to adapt to changes and stay ahead.

This level of precision provides you with clear SKU-level demand insights, allowing you to prioritize products, optimize performance, and quickly respond to shifting market conditions. With demand sensing, the software offers real-time visibility and actionable recommendations, helping businesses make smarter production and inventory decisions.

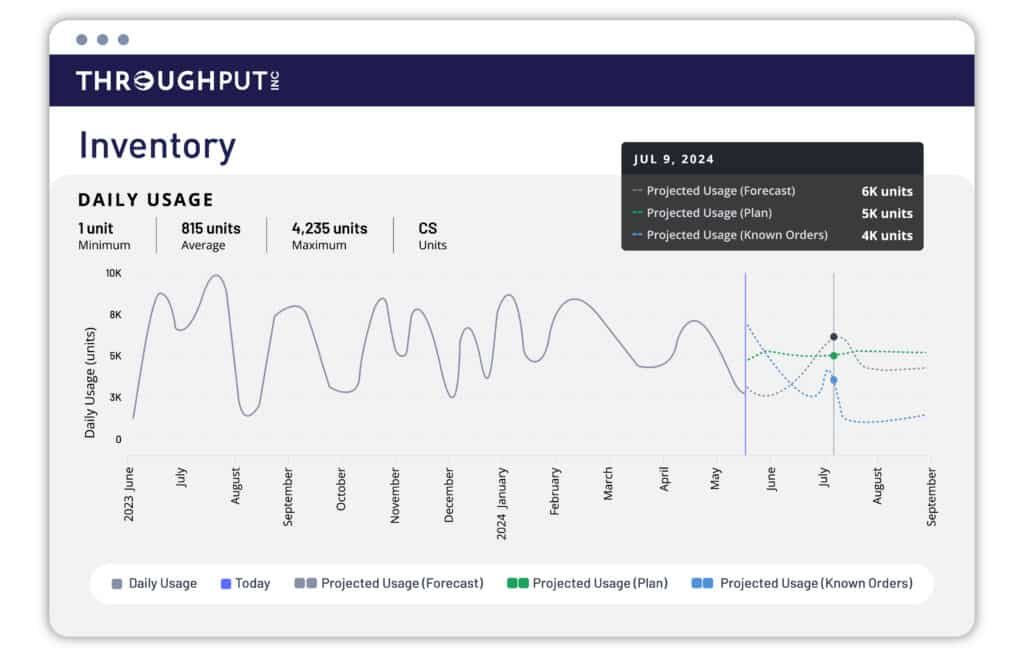

Inventory Management

The inventory management feature enables real-time tracking of inventory levels across warehouses, suppliers, and distribution centers, allowing you to make smarter decisions and avoid overstocking or stockouts, both of which can result in lost sales or increased holding costs.

Advanced capabilities like automated reordering helps minimize the risk of running out of critical items. Features such as dynamic buffer management, inventory control, and dynamic replenishment recommendations provide greater control over inventory, ensuring optimal stock levels are maintained at all times.

Read More: ThroughPut AI Launches Predictive Parts and Kit Management Capabilities

Accurate inventory management helps businesses optimize storage costs, meet delivery timelines, and improve overall operational efficiency. In today’s competitive landscape, having robust inventory management within supply chain software is essential for maintaining lean operations and responding quickly to market changes.

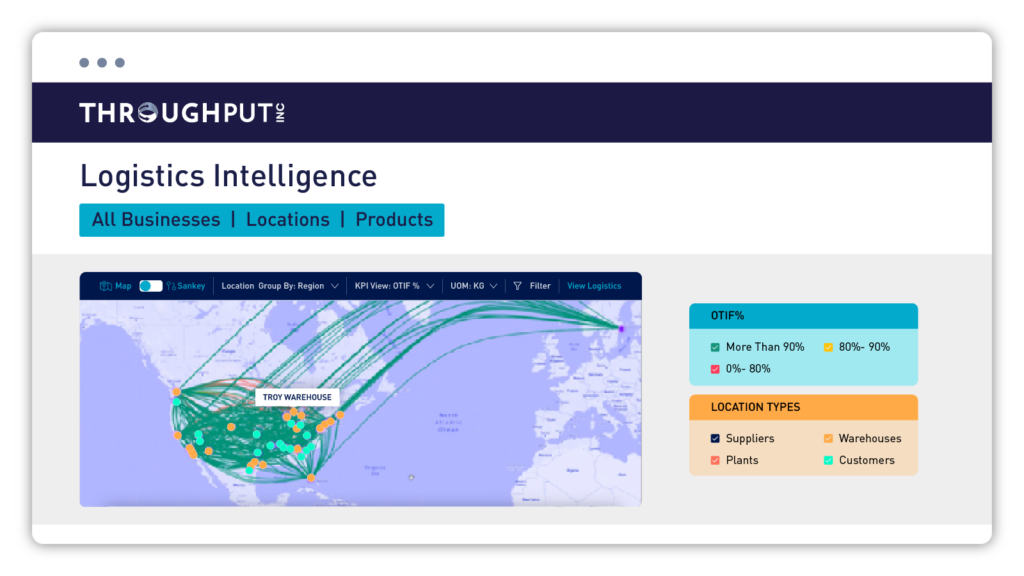

Logistics Management

The logistics management feature of the supply chain management software ensures that your business can take advantage of network optimization opportunities, reduce choke points, and identify the most cost-effective distribution routes.

With this feature, businesses have been able to streamline the movement of goods and ensure operational efficiency. The right software integrates key logistics functions like warehouse and order management, optimizing stock levels and warehouse operations to meet dynamic requirements cost-effectively. This ensures smooth order processing, allowing manufacturers to manage ad hoc requests with flexibility.

Supply Chain Finance

Supply chain finance is a critical feature of supply chain management software that gives you visibility into trapped capital and on how to improve cash flow. By streamlining supply chain operations with the organization’s financial goals, this feature allows you to manage your working capital more effectively. It directly impacts the bottom line by optimizing cash conversion cycles.

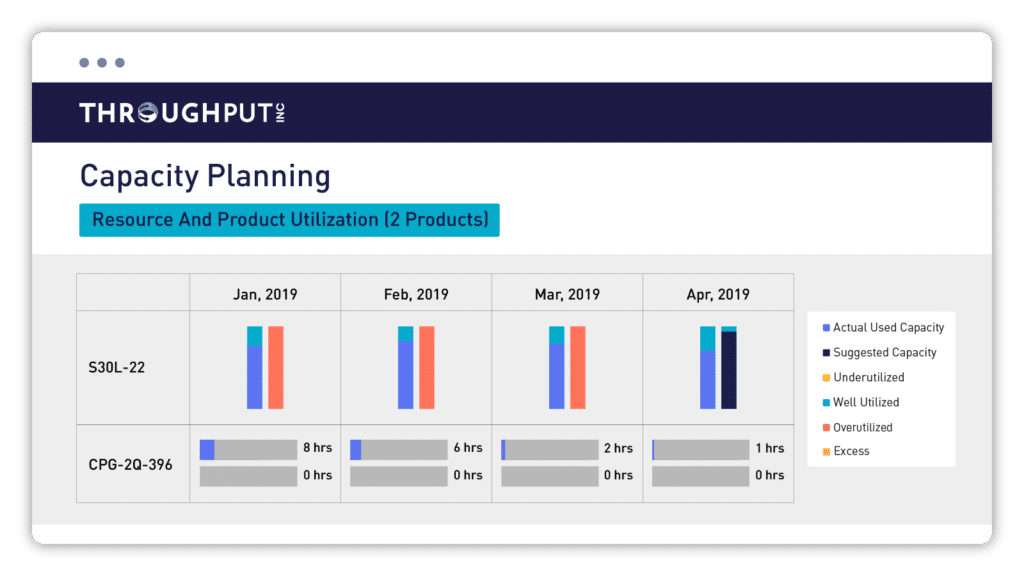

Capacity Planning

One of the overlooked features of supply chain management software is capacity planning. This feature helps optimize asset performance, reduce bottlenecks, and create a robust and responsive capacity plan. The right tool frees up your present manufacturing capacity so that the business can meet market demands promptly and adequately. In this way, businesses can meet all kinds of demand-supply scenarios with the available working capital.

For instance, the software helps select the right machines for product-wise production with detailed capacity insights. With demand insights, the tool helps balance demand and supply needs. Alongside, the tool offers crucial details about asset utilization showcasing overutilized, underutilized, overtime, or well-utilized assets.

What More to Look for in a Supply Chain Management Software?

There are certain other features of a supply chain management software that will help you effectively utilize the platform. These features include a common operating picture, real-time information, integration with existing data, analytics and decision intelligence.

Common Operating Picture for All Stakeholders

A supply chain management software must provide a unified picture for all stakeholders involved. This ensures that everyone—from planners to operation managers, procurement, and sales teams— uses the same set of data. This helps promote transparency, and seamless communication, preventing data silos, and enabling better decision-making. Various departments are better aligned reducing delays, miscommunication, and redundancies and promoting greater collaboration and coordination.

Real-Time Information

Access to real-time information is essential for effective supply chain management. By providing live updates on inventory levels, order statuses, and logistics movements, supply chain management software enables companies to respond quickly to changing circumstances. Whether it’s rerouting shipments due to weather disruptions or adjusting inventory based on sudden demand spikes, real-time data ensures businesses remain agile, with informed decision-making and improved operational efficiency, minimized bottlenecks, and enhanced customer satisfaction.

Integration with Existing Data

The supply chain management software should be able to integrate seamlessly with a company’s existing data systems to provide a holistic view of operations. Whether it’s ERP systems, inventory management, or production software, integration ensures that all data is centralized and easily accessible. This capability prevents information fragmentation, enabling comprehensive analysis and more accurate forecasting. Integration also reduces the need for manual data entry, minimizing the risk of errors or over-hauling the entire data system and the associated expenses.

Advanced Analytics and Decision Intelligence

Advanced analytics and decision intelligence are key capabilities that allow supply chain management software to go beyond basic reporting. These tools use data to generate insights into demand patterns, inventory optimization, logistics costs, and supplier performance. By analyzing historical data and real-time information, decision intelligence can recommend actionable strategies, simulate “what-if” scenarios, and predict future trends. This helps businesses mitigate risks, optimize resources, and make informed decisions at scale. Advanced analytics also enable companies to identify inefficiencies and uncover opportunities for improvement across the entire supply chain.

Industry-specific Customization

Supply chain management needs can vary significantly across industries, making industry-specific customization a must-have feature. For example, a retail business may require intricate demand forecasting and inventory management tools, while a manufacturing company may prioritize production scheduling and supplier management. Software with industry-specific customization ensures that the unique challenges and requirements of a business are addressed. It allows for tailored features, workflows, and analytics that cater to the specific needs of the industry, making the software more relevant, efficient, and effective in delivering optimal results.

The Future of Supply Chain Management Software

The future of supply chain management software is set to be shaped largely by analytics and decision intelligence. Businesses will increasingly rely on data from customer preferences, order changes, production processes, inventory levels, and logistics routes to automate decisions.

Decision Intelligence Will be the Cornerstone of Supply Chains

Real-time access to valuable recommendations and actionable insights allows businesses to make accurate and effective decisions faster than ever before. Decision intelligence-powered supply chain management software enables stakeholders to evaluate “what if” scenarios and trade-offs, helping them explore millions of potential decision-making alternatives. This capability leads to better business outcomes and boosts operational efficiency, even in the face of unpredictable market dynamics.

Additionally, decision intelligence integrates operational and regulatory constraints, empowering executives to make more refined and strategic decisions. Gartner’s recognition of platforms like ThroughPut as leaders in decision intelligence highlights the critical role this technology will play in shaping the future of supply chains.

Supply chain decision intelligence systems will offer decision support, augmentation, and automation across three distinct levels, providing businesses the flexibility to gradually increase automation. This allows them to build trust in the system while reaping the benefits of more efficient, data-driven decision-making processes.

AI: The Driving Force of Decision Intelligence

AI is the engine driving supply chain decision intelligence, enabling businesses to make faster, more accurate, and real-time decisions. By processing vast amounts of data, AI helps businesses automate decisions, reduce risks, and seize opportunities at scale—essential as they continuously work to improve operations.

A BCG report highlights that many planners struggle to interpret insights due to time constraints. Shifting from traditional visibility tools to AI-powered decision automation enables businesses to overcome these challenges and unlock significant growth opportunities.

AI-powered supply chain intelligence engines transform operations by prioritizing high-value customers and products, fostering collaboration with reliable suppliers, and optimizing real-time demand sensing. These enhancements lead to increased profitability and operational efficiency.

Seizing Decision-Making Opportunities in Real Time

Traditional methods of decision making can take hours or even days to analyze data, align on a plan, and execute. Frequently, this delay means missing the window of opportunity. AI-powered decision intelligence closes this gap by enabling faster, more accurate decision-making, driving continuous improvements to the bottom line.

As decision intelligence becomes a core component of supply chains, businesses will be better positioned to navigate future challenges and capitalize on emerging opportunities. With AI at its core, decision intelligence equips companies to proactively tackle obstacles and remain agile in an ever-evolving landscape.