Minimizing Lost Sales and Lost Uptime: Essential Strategies for Effective Inventory Management in 2025

The Impact of Inventory Mismanagement in the Industrial World

In the Industrial World, inventory mismanagement typically leads to two significant preventable losses: Lost Uptime and Lost Sales. With an estimated $25 trillion of trade flowing from node-to-node, preventing these losses has a major macroeconomic impact on Global GDP. However, the sheer scale of material volume often prevents humanity from improving the situation. This is where advanced inventory management systems, particularly basic machine learning systems, can provide better visibility, focus, and impact through algorithmic prioritization. These systems can enable inventory buffer management at the scale of the world’s value chain.

Lost Uptime: A Persistent Challenge

Lost uptime is a well-known issue across various industries. Whether it’s trucks, planes, ships, factories, cars, robots, foundries, or MRI machines, almost all equipment faces downtime. Many companies have focused on predicting downtime but have overlooked the inventory-component of downtime. Better rebalancing of inventory allows for short-term solutions to keep machines running or fed. According to a report by Siemens, unplanned downtime now costs Fortune Global 500 companies 11% of their yearly turnover, amounting to almost $1.5 trillion. ThroughPut estimates that parts lead to about $100 BN in time losses.

Lost Sales: A Preventable Loss

Lost sales due to inventory mismanagement are also significant. Retailers lose an estimated $15 billion to $20 billion per year in the U.S. retail food industry alone due to stockouts. During events like Black Friday sales, the objective should never be to “run out” but to stock just enough. Studies from Harvard Business Review suggest that stockouts can lead to sales losses of 4% for a typical retailer, with nearly half of intended purchases abandoned when customers can’t find the desired item.

ThroughPut AI Inventory Management

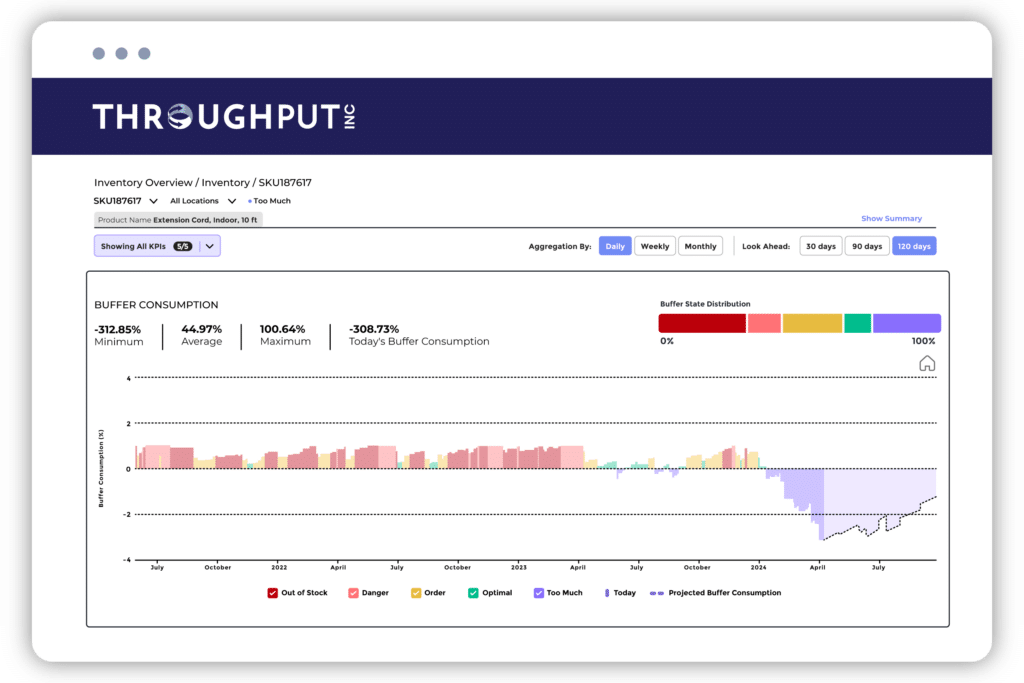

The ThroughPut AI Inventory Management allows executives to quickly identify and quantify working capital opportunities, while inventory and procurement teams pull the tactical levers, accelerating revenue and profitability within the business.

Click the link below to connect with one of our product experts in order to see YOUR tailored presentation based on YOUR unique inventory management and supply chain challenges and goals. ThroughPut AI can begin unlocking value from your existing systems – within days.

How Does ThroughPut AI Help Businesses with Inventory Rebalancing?

ThroughPut AI helps businesses transform inventory management by resolving key fundamental challenges such as lost uptime, sales, and inefficiencies in stock management. It employs a range of strategies to ensure inventory is effectively rebalanced across demand points, reducing overstock and understock situations that can cripple operations and financial performance.

ThroughPut focuses on the following key strategies to achieve this:

Rebalancing Available Inventory

ThroughPut uses fast logistics to move inventory from locations with surplus inventory to those with shortages, ensuring that starved demand points are adequately supplied.

Auditing Producers and Suppliers

ThroughPut monitors and audits suppliers and producers to identify those that consistently fail to meet quantity requirements, ensuring that only reliable partners are engaged.

Carrier Audits

Carriers that frequently delay deliveries are also audited out, helping businesses select more dependable logistics partners.

Reducing Overstock

ThroughPut actively cancels unnecessary orders, reallocating budgets to areas where inventory is lacking – thereby optimizing resource usage and preventing capital from being tied up in excess stock.

Key Benefits of ThroughPut AI Inventory Management

- Maximum output at optimized inventory levels

- Greater inventory planning reliability

- Rapid reduction of shortages and associated costs by auditing and eliminating unreliable, unprofitable, and suboptimal suppliers and carrier options

- Significantly reduced working capital spend

- Elimination of bottlenecks, downtime, and opportunity losses

- Intelligent dynamic recommendations for inventory rebalancing and replenishment at the SKU level

- Categorization and prioritization (critical vs standard) of inventory based on usage

- Improved inventory availability and reduced waste

- Optimization of profitability and working capital simultaneously for greater returns

ThroughPut AI Inventory Management Key Features

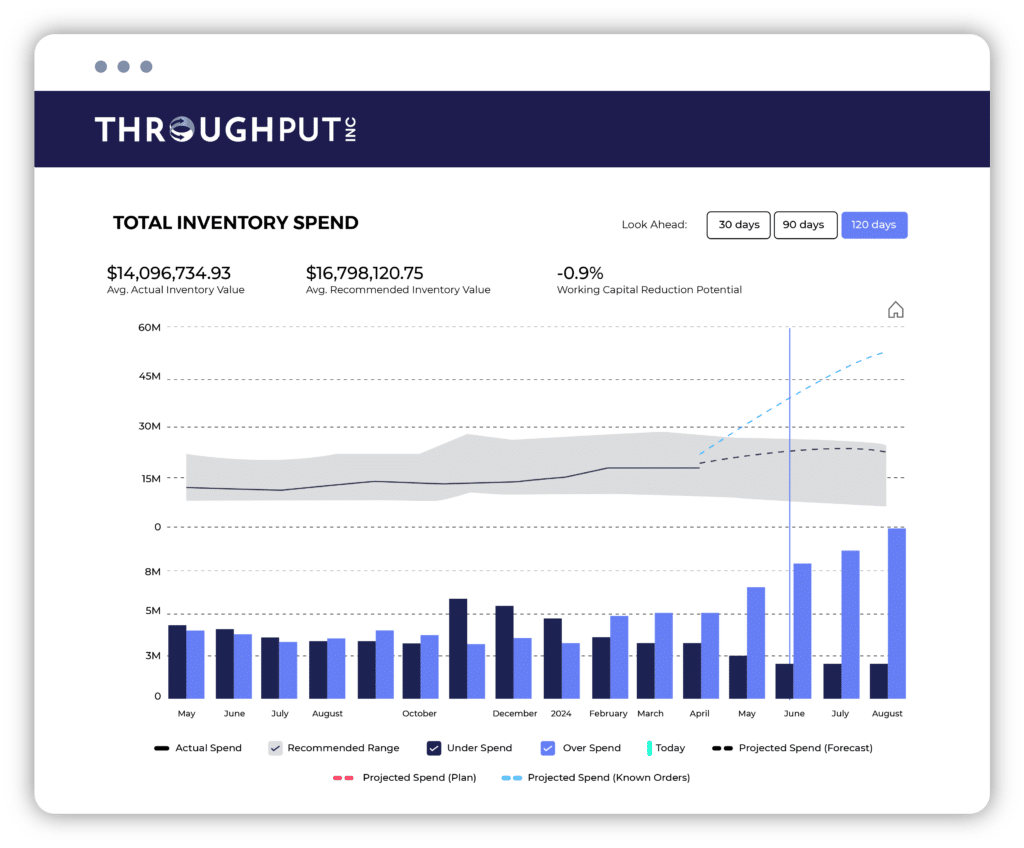

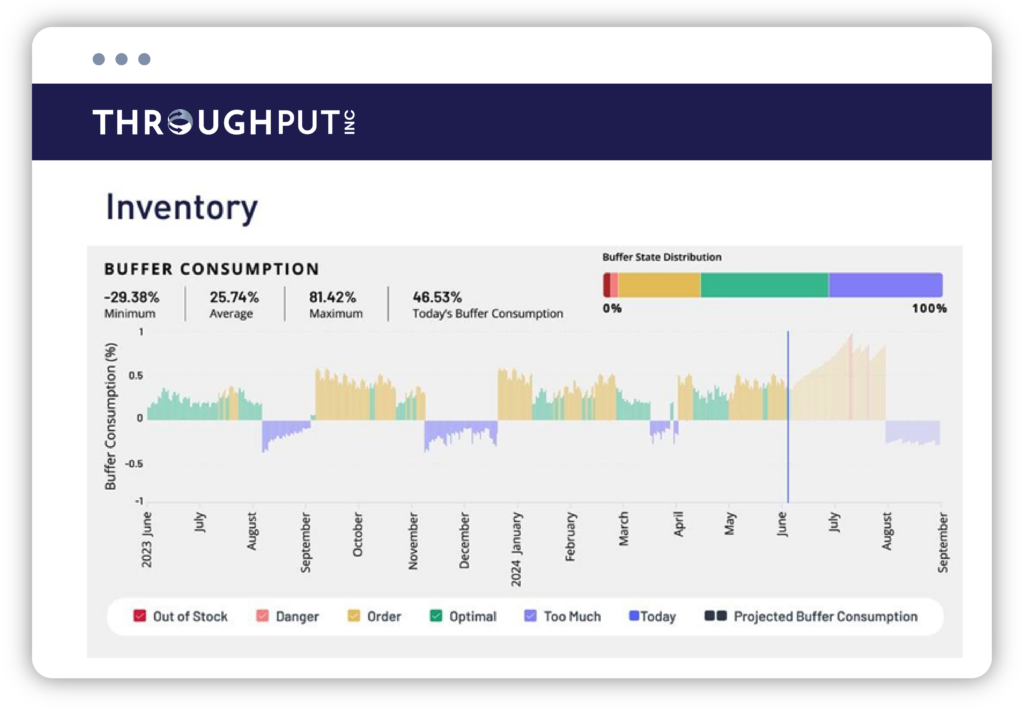

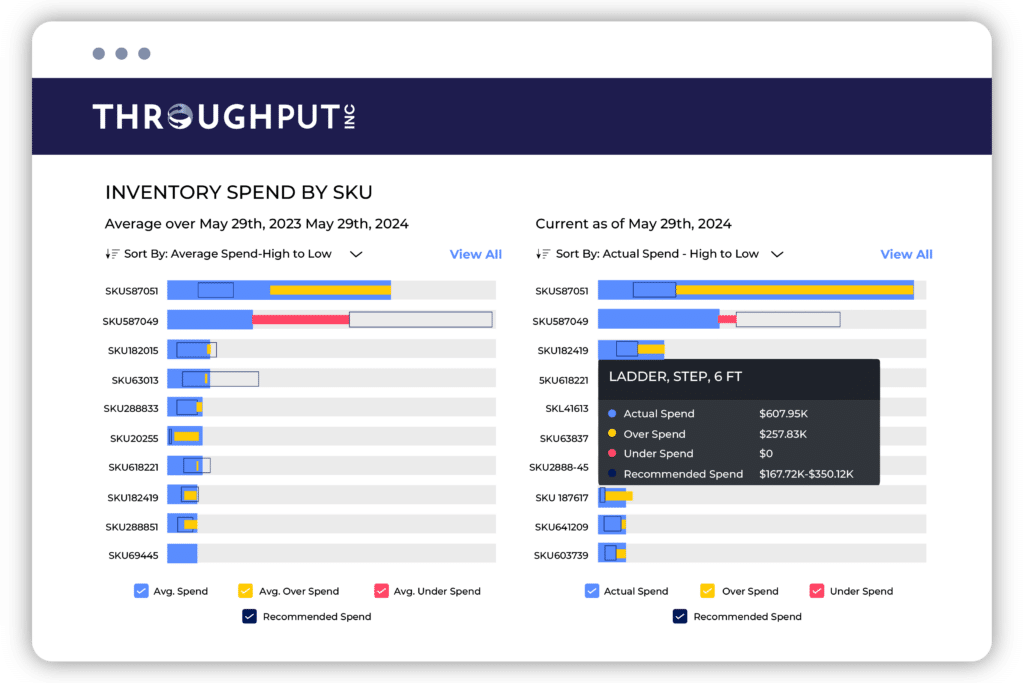

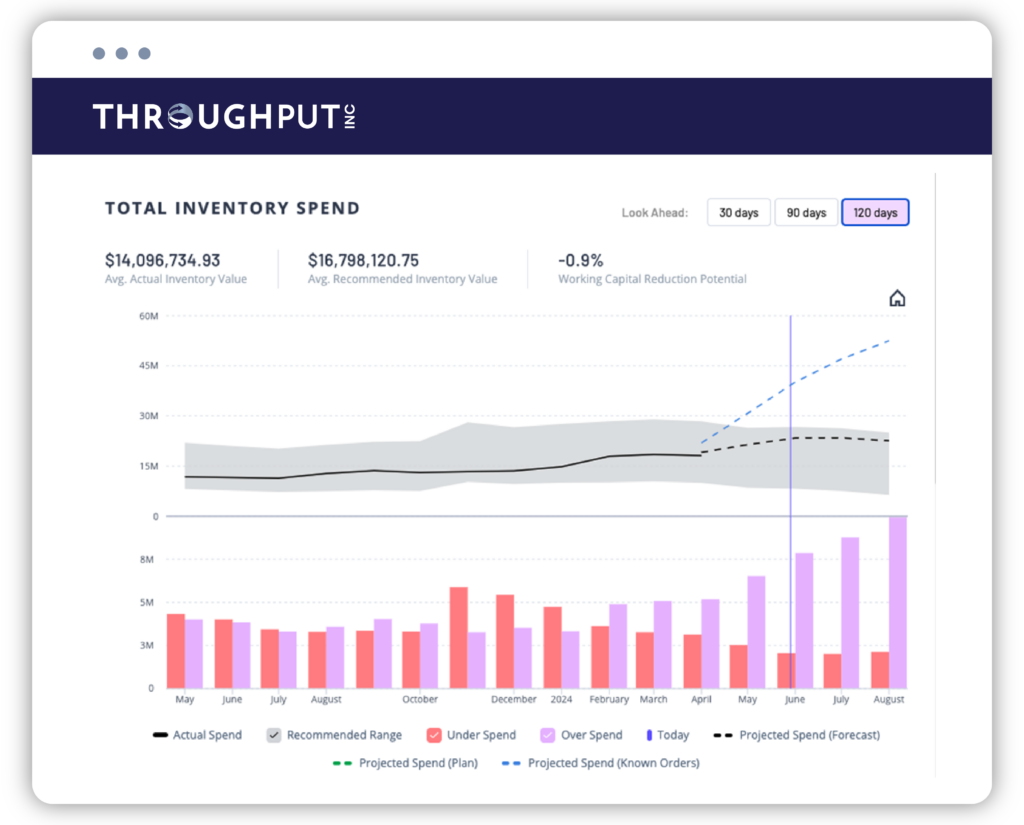

1. Projecting Working Capital Spend

Leveraging powerful algorithms to identify when and where capital is unnecessarily tied-up, or where it needs to be invested to optimize flow of goods, cash, and profits.

Benefit:

Accelerate pull through, revenue, and margins while knowing with greater confidence that the business is on the right track.

2. Keep Inventory Spend on Target and Understanding Future Opportunities

ThroughPut.ai sets the Target and understands the specific SKUs that needs to be reduced where the opportunities are, this provides business with a map to follow and the reasons the route should be followed.

Benefit:

Stock levels optimized while minimizing carrying costs, improving service levels, supporting scale while realizing operational potential.

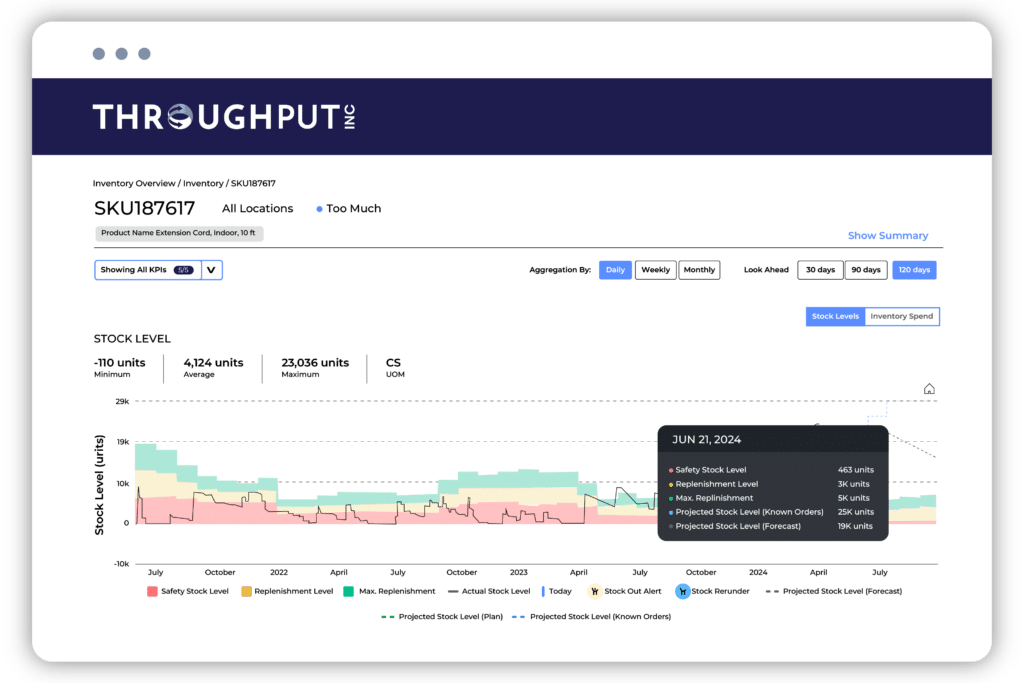

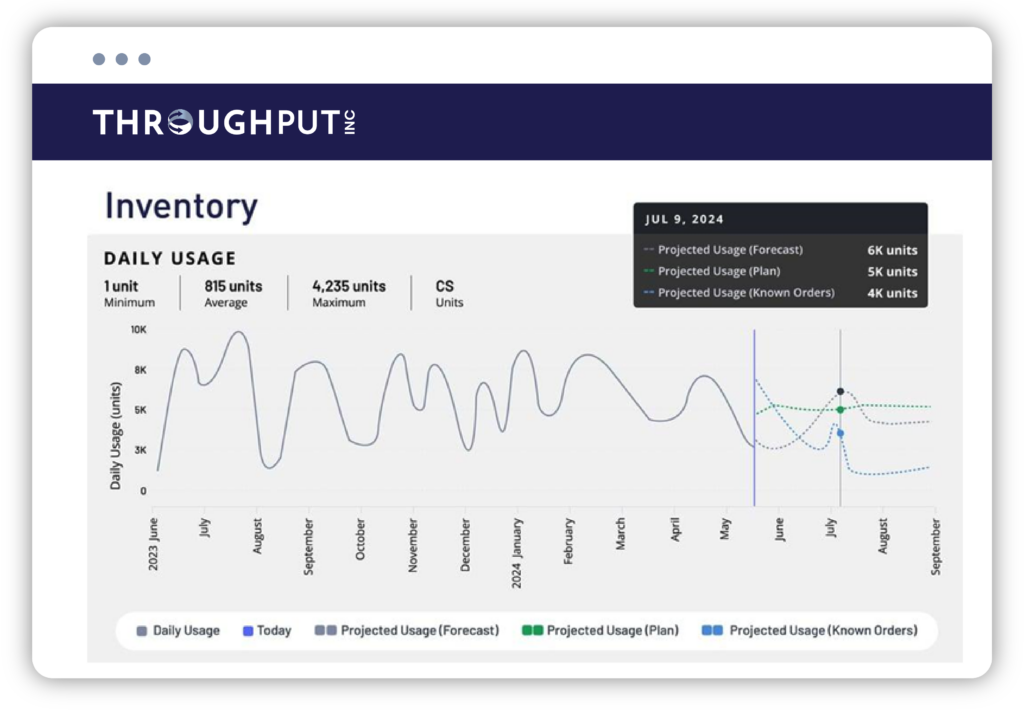

3. AI-powered Predictive Analytics

ThroughPut.ai perspective delivers actionable insights, predictions and recommendations – on everything from inventory turnover rates to potential stockouts – ensuring proactive informed decisions that optimize inventory performance.

Benefit:

Gain advanced visibility and actionability to manage inventory and material movements across all SKU’s, customers, locations, and supply chain end-points.

4. Advanced Demand Sensing:

Move beyond traditional demand forecasting with stale assumptions and old data, and enable more accurate dynamic demand sensing to rapidly respond to shifts in market trends and customer priorities. From seasonality to promotional activity, ThroughPut AI finds stability within the variability of consumption.

Benefit:

Prioritize resources strategically, driving stronger market competitiveness with an optimized inventory planning processes across YOUR end-to-end supply chain network.

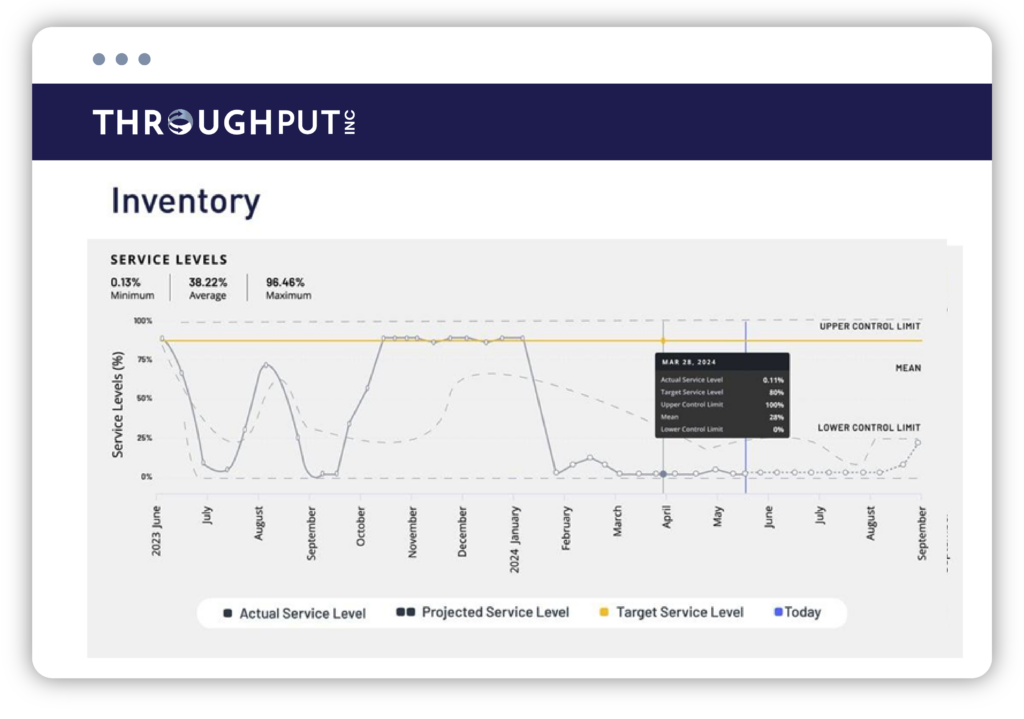

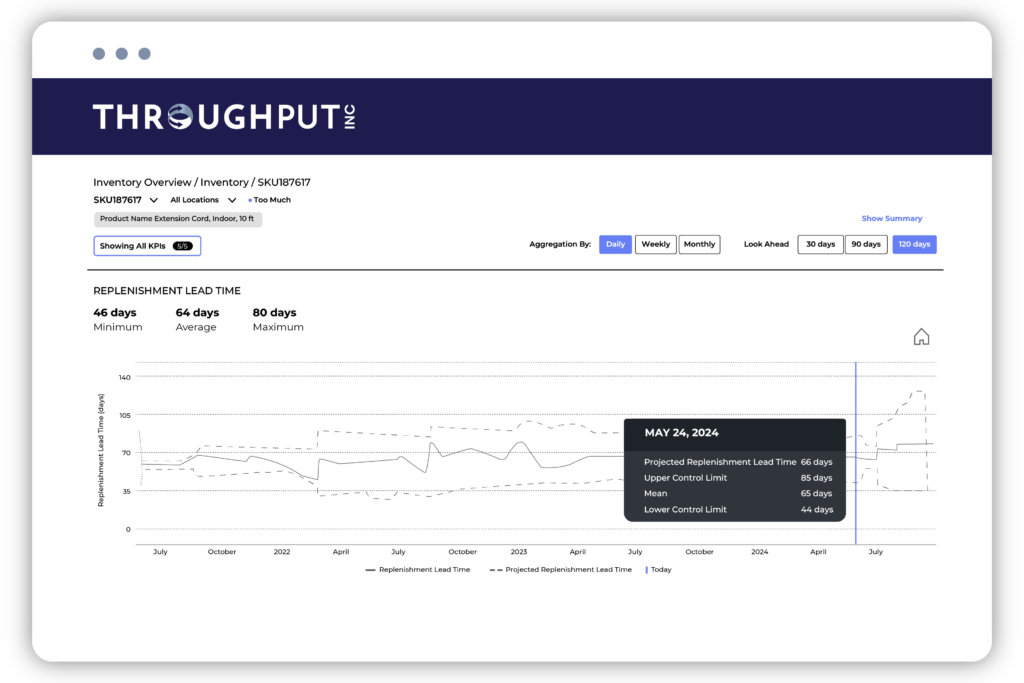

5. Preventing Supply Disruptions:

Prioritize action and take immediate steps to prevent supply disruptions. ThroughPut AI proactively predicts potential stockout situations and highlights growing critical inventory shortages.

Benefit:

YOUR customers will see the difference as you are able to meet their ever-changing demands. ThroughPut AI ensures key business drivers are protected by buffering inventory based on the reliability of the supply.

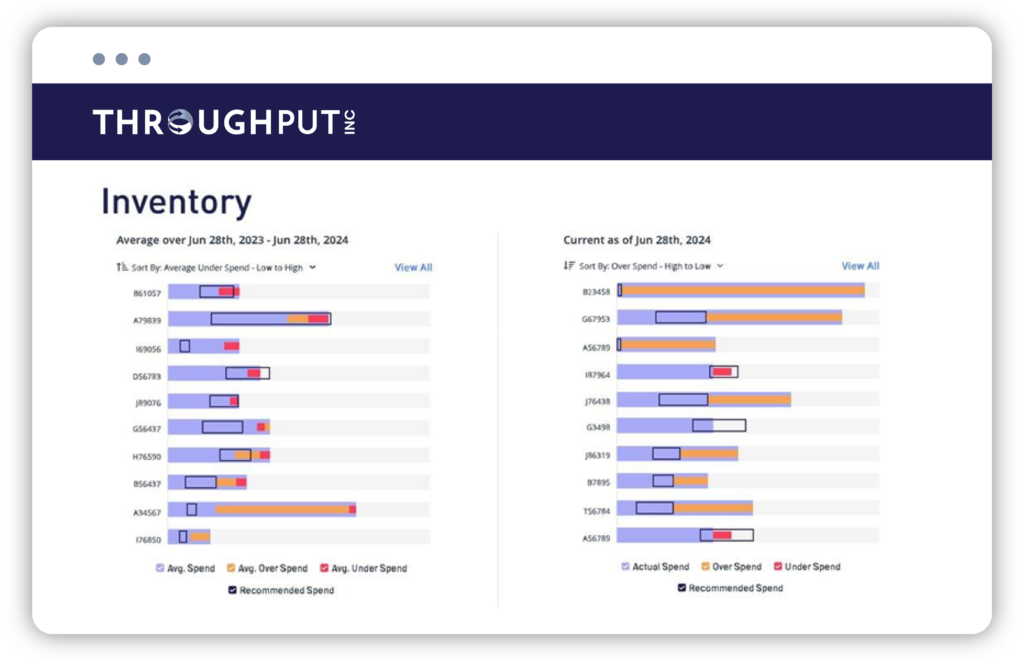

6. Stock Rebalancing:

Analyze inventory levels across locations and warehouses to identify stock rebalancing opportunities, strategically optimize inventory utilization, and minimize excess stock holding.

Benefit:

Stockpiled inventory is identified within ThroughPut AI and additional orders are flagged to ensure current inventory utilization is maximized.

7. Seasonal Demand Planning:

Dynamically adapt to seasonal variations in demand, as well as other external influences and unplanned circumstances, to better prepare for peak periods.

Benefit:

Prevent stockouts during high-demand seasons and times of otherwise unforeseen volatility.

8. Advanced Forecasting Algorithms:

Leverage state-of-the-art machine learning techniques to build more accurate demand forecasting plans.

Benefit:

Adapt to changing market conditions based on new data inputs and external events and gain real-time insights into inventory requirements.

9. Dynamic Replenishment Recommendations:

Get dynamic replenishment recommendations to proactively adjust inventory levels based on demand fluctuations, actual lead times, and supplier constraints.

Benefit:

Ensure optimal stock levels while minimizing carrying costs, manual reorder points and fixed order quantities.

10. Optimal Spend Recommendations:

Get recommendations for optimal working capital spend based on demand forecasts, lead times, and other relevant factors.

Benefit:

Gain visibility into areas where capital can be reallocated or reduced by comparing actual expenditure against recommendations.

11. Seasonal Demand Planning:

Rapidly identify the impact of seasonal variations on demand by identifying seasonal trends and adjusting forecasts accordingly.

Benefit:

Better prepare for peak periods and prevent stockouts during high-demand seasons.

12. Supplier Collaboration Tools:

Seamless collaboration with suppliers by providing visibility into inventory levels, demand forecasts, and order statuses.

Benefit:

Builds stronger supplier relationships and enables higher supply chain efficiency.

13. Holistic Predictive Analytics Summary:

Actionable insights about inventory turnover rates and potential stockouts prioritized based on financial impact.

Benefit:

Rapidly make informed decisions to optimize inventory performance.

The Role of AI in Inventory Management

Inventory mismanagement, whether leading to lost uptime or lost sales, is a significant financial drain on businesses everywhere. In both the context of lost uptime and lost sales, optimizing inventory management through advanced technology is essential to break free of today’s rigid and reactive inventory systems, which are far too focused on historical data and basic replenishment models that no longer work given the complexity and volatility of modern supply chains.

AI-based systems provide a dynamic approach by leveraging real-time data as well as historical patterns, and layering them with predictive algorithms to ensure that inventory is balanced across the supply chain, from production facilities to end customers. By providing better visibility, intelligent predictions, and real-time decision-making capabilities, these technologies enable businesses to optimize inventory levels, reduce downtime, and capture sales opportunities that would otherwise be lost – while helping them become responsive to both supply chain disruptions and changing market demands, leading to improved resiliency.

ThroughPut’s intelligent and highly accurate inventory rebalancing system enables businesses to leverage predictive analytics, strategic rebalancing, and proactive planning to optimize their supply chain, reduce costs, and increase efficiency – thus helping them address inventory availability issues, enhance service quality, and support scalable growth.