What is Total Quality Management (TQM)?

Total Quality Management (TQM) is a comprehensive management approach focused on continuously improving the quality of products, services, and processes within an organization. The core philosophy of TQM is customer-centric, emphasizing that every department, employee, and process contributes to delivering consistent value.

Originating in the mid-20th century, TQM integrates quality discipline at every stage of business operations, aiming to reduce errors, enhance efficiency, and boost customer satisfaction. Unlike quality control which inspects final products, TQM is proactive and systemic—it seeks to prevent defects by embedding quality in organizational culture.

TQM involves all employees from top management to frontline workers and emphasizes collaboration, communication, and continual learning to drive quality improvements. It’s widely applied across manufacturing, healthcare, supply chains, and service industries.

What is the TQM approach in modern supply chains?

The TQM approach in modern supply chains revolves around optimizing each step of the supply chain to ensure quality consistency and customer satisfaction. This is crucial as supply chains have grown increasingly complex and globalized, demanding rigorous quality standards and real-time monitoring.

Key characteristics of TQM in supply chains include:

- Supplier Quality Management: Evaluating and collaborating with suppliers to ensure raw materials and components meet stringent quality criteria.

- Process Standardization: Establishing uniform workflows to minimize errors and variability across logistics, warehousing, and production stages.

- Continuous Improvement Culture: Encouraging feedback loops, root cause analysis, and corrective actions to resolve inefficiencies or defects swiftly.

- Advanced Analytics and Traceability: Leveraging data to track quality metrics, detect bottlenecks, and predict issues to prevent disruptions.

- Employee Engagement: Involving workers at every node in quality control activities, fostering ownership and accountability.

Incorporating TQM principles in supply chain management leads to enhanced product reliability, reduced costs, timely deliveries, and better risk mitigation—all critical for competitive advantage.

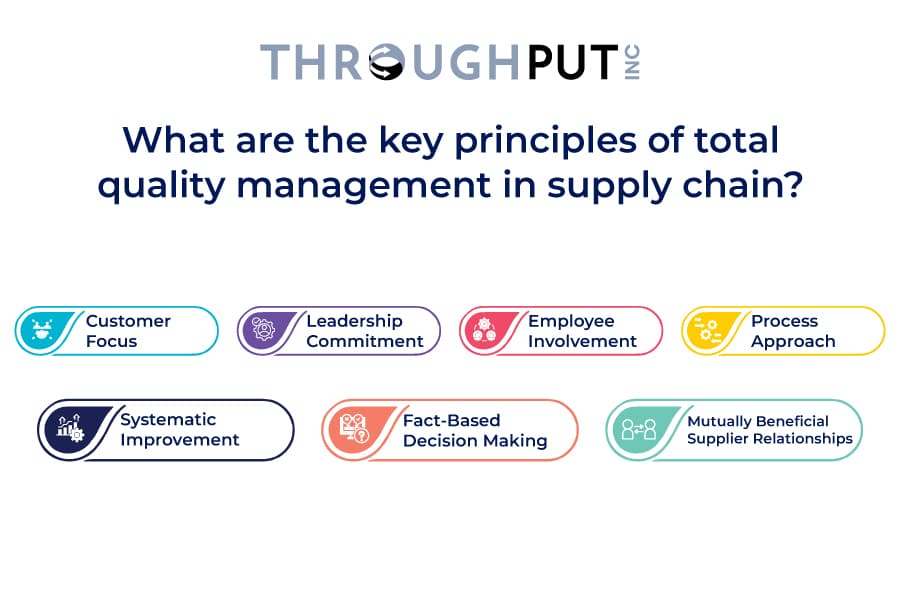

What are the key principles of total quality management in supply chain?

The effectiveness of TQM in supply chains rests on several foundational principles. These principles guide businesses toward embedding quality holistically and involve:

- Customer Focus: Every supply chain activity is designed to meet or exceed customer expectations, building loyalty and trust.

- Leadership Commitment: Senior leaders champion quality initiatives, allocate resources, and foster a quality-centric organizational culture.

- Employee Involvement: TQM thrives on the active participation of all employees through training, empowerment, and communication.

- Process Approach: Viewing activities as processes helps in identifying inefficiencies and streamlining workflows for consistency.

- Systematic Improvement: Continuous improvement using tools like PDCA (Plan, Do, Check, Act) ensures ongoing enhancements.

- Fact-Based Decision Making: Data and performance metrics guide decisions, replacing guesswork.

- Mutually Beneficial Supplier Relationships: Partnerships based on open communication and collaboration enhance overall value.

Adhering to these principles provides a structured path for quality excellence throughout the supply chain.

What are TQM tools and techniques for manufacturing?

Manufacturing firms benefit immensely from specific TQM tools and techniques designed to identify defects, optimize processes, and maintain standards. Common tools include:

- Cause-and-Effect Diagrams (Fishbone/Ishikawa): Help diagnose root causes of quality problems.

- Control Charts: Monitor process variations and identify deviations early.

- Pareto Analysis: Identifies the most significant factors affecting quality based on the 80/20 rule.

- Six Sigma Integration: Uses statistical methods to reduce defects and variation.

- 5S Methodology: Workplace organization technique improving efficiency and safety.

- Kaizen (Continuous Improvement): Encourages small incremental improvements daily.

- Quality Function Deployment (QFD): Translates customer requirements into technical specifications.

- Failure Mode and Effects Analysis (FMEA): Anticipates potential failure points and implements preventive measures.

Manufacturers using these tools can enhance product reliability, reduce waste, and meet stringent quality standards critical for competitiveness.

What are the benefits of implementing TQM in an organization?

Implementing TQM delivers comprehensive benefits, transcending quality improvements alone. Key advantages include:

- Enhanced Customer Satisfaction: Consistent quality leads to higher trust and repeat business.

- Reduced Costs: Lower rework, scrap, and warranty claims improve the bottom line.

- Improved Efficiency: Streamlined processes reduce cycle times and resource waste.

- Better Employee Morale: Engagement and empowerment increase productivity and job satisfaction.

- Competitive Advantage: Superior product and service quality differentiates brands in the marketplace.

- Risk Management: Early detection and prevention of defects reduce operational risks.

- Stronger Supplier Relations: Cooperative quality goals improve reliability and reduce delays.

In supply chains specifically, TQM benefits include improved delivery performance, inventory management, and agility to market changes.

What are the main steps in TQM implementation process?

Successful TQM implementation follows a structured, phased approach:

Certainly! Here is the main steps in the TQM implementation process presented in a clear table format:

| Step Number | Step Name | Description |

| 1 | Leadership Commitment | Secure executive sponsorship and define a quality vision aligned with business goals. |

| 2 | Training and Awareness | Educate employees on TQM principles, tools, and their roles in quality improvement. |

| 3 | Establish Quality Teams | Form cross-functional teams to lead TQM initiatives and problem-solving efforts. |

| 4 | Process Mapping and Documentation | Analyze current workflows, identify gaps, and standardize processes. |

| 5 | Set Measurable Objectives | Define key performance indicators (KPIs) based on customer requirements and internal benchmarks. |

| 6 | Deploy Quality Tools | Apply methodologies like Six Sigma, root cause analysis, 5S, and other quality improvement tools. |

| 7 | Monitor and Analyze Results | Use data to review progress regularly and adjust strategies as needed. |

| 8 | Continuous Improvement | Institutionalize feedback loops, audits, and ongoing refinements to sustain quality gains. |

| 9 | Recognition and Rewards | Motivate employees by acknowledging and rewarding quality achievements. |

| 10 | Expand and Sustain | Scale best practices across the organization and maintain a culture of continuous quality improvement. |

How ThroughPut.ai Can Help With Total Quality Management?

ThroughPut.ai is an advanced AI-driven platform that transforms TQM execution across industries, particularly manufacturing and supply chain operations. The platform offers:

- Real-Time Quality Monitoring: Integrates IoT sensors and data streams to provide live defect detection and process alerts.

- Predictive Analytics: Uses machine learning to forecast quality risks, optimize maintenance, and prevent downtime.

- Automated Reporting and Dashboards: Gives leadership instant insights into TQM KPIs and improvement opportunities.

- Collaboration Tools: Facilitates seamless communication between quality teams, suppliers, and stakeholders.

- Customizable TQM Solutions: Adapts workflows and tools tailored for specific industries and organizational scales.

By utilizing ThroughPut.ai, companies can accelerate their TQM implementation roadmap, increase process reliability, and drive continuous improvements with data-driven precision.