6 Ways AI Drives Inventory Delivery for Retail Supply Chains in 2026

Retailers often need help with inefficiencies, stockouts, and overstocking due to a lack of real-time data and insights into their inventory processes.

This lack of visibility can lead to increased costs, dissatisfied customers, and lost sales opportunities.

Many retailers need to know how to leverage AI to address these challenges.

Keep reading this article to understand how AI can transform your retail supply chain, improve efficiency, and boost customer satisfaction.

What are the Challenges of Inventory Delivery Management in Retail Supply Chain?

The challenges of inventory delivering management are lack of inventory visibility, supply chain disruptions, loss prevention, difficulties with integration and last mile delivery.

Below is a detailed view of each of the mentioned challenges:

Last-Mile Delivery

The last mile of delivery involves transporting goods from a distribution centre to the final customer and is often the most challenging and costly part of the delivery process.

Issues such as traffic congestion, delivery time windows, and the need for multiple delivery attempts can complicate last-mile logistics and increase costs.

Lack of Inventory Visibility and Accuracy

Maintaining real-time visibility and accuracy of inventory across multiple locations, including physical stores and online channels, is crucial but challenging.

Accurate inventory tracking ensures that stock levels are up-to-date, reducing the risk of stockouts and overstocking. However, achieving this requires robust inventory management systems and technologies.

Supply Chain Disruptions

Disruptions in the supply chain, such as supplier delays or transportation issues, can lead to inventory shortages and affect the ability to meet customer demand.

Retailers must develop contingency plans and build resilient supply chains to mitigate the impact of such disruptions.

Shrinkage and Loss Prevention

Retailers must manage inventory shrinkage due to theft, damage, or administrative errors, which can significantly impact profitability.

Implementing effective loss prevention strategies and technologies, such as surveillance systems and inventory audits, is essential to minimize shrinkage.

Integration with Other Systems

Ensuring seamless integration of inventory management systems with other business systems, such as ERP, POS, and e-commerce platforms, is essential for efficient operations.

Integration allows for the smooth flow of information across different departments, reducing data silos and improving overall operational efficiency.

How is AI used for Inventory Delivery Management?

AI is used for inventory delivery management to optimize routes, predict delivery times, and automate logistics processes to enhance efficiency and accuracy.

AI systems analyze data such as traffic patterns and weather conditions to determine the most efficient routes, reducing costs and ensuring timely deliveries.

They also enhance predictive analytics, allowing businesses to anticipate delays and adjust schedules, providing real-time updates to manage customer expectations. AI automates tasks like order processing and shipment tracking, minimizing errors and speeding up deliveries.

Additionally, AI detects anomalies in delivery patterns and facilitates better collaboration within the supply chain by integrating data from various sources, ensuring all stakeholders have access to real-time information.

What are the Benefits of AI in Retail Inventory Management?

The benefits of AI in retail inventory management management are enhanced demand forecasting, early anticipation of bottlenecks, intelligent warehousing and capacity buffering.

Let’s take a deeper look at each of the mentioned benefits:

Machine Learning for Anticipating Bottlenecks and Finding Alternative Routes

Machine learning is excellent for detecting patterns in data and generating insights. This capability is precious in planning delivery and logistics. ML systems forecast potential bottlenecks and suggest alternative delivery routes based on the analyzed data.

This is beneficial at every stage of the supply chain, whether it’s the delivery of inventory to storage facilities, products to customers, or goods to retail stores. Anticipating and mitigating bottlenecks ensures smoother operations and timely deliveries.

Enhanced Demand Forecasting

AI’s trend-spotting abilities make it a powerful tool for anticipating demand. Accurate demand forecasting is crucial for retail supply chains, ensuring that inventory levels align with customer needs.

AI predicts trends ahead of time, helping businesses maintain optimal stock levels and reducing the risk of overstocking or stockouts.

Additionally, demand forecasting allows supply chain managers to pre-plan trucking and shipping routes, ensuring on-time delivery of retail inventory and improving overall customer satisfaction.

Data Analysis to Inform Logistics

AI can process and analyze vast amounts of unstructured data, identifying trends, clustering similar data, and highlighting anomalies. This data-driven approach is constructive for selecting delivery routes, assigning goods, and choosing the most efficient transport channels.

With AI-powered analytics, logistics decision-making becomes more accurate and efficient, leading to cost savings and improved operational performance.

Intelligent Warehousing with AI Analytics

AI analytics can optimize warehouse management by taking stock of available storage and informing inventory decisions accordingly.

Intelligent warehousing can reduce personnel and maintenance costs, whether dealing with intermediary storage solutions or retail brick-and-mortar warehouses.

AI-driven warehouse management includes storage and retrieval systems and robotic material handling automation. Advanced analytics derived from Big Data can enhance these processes, ensuring full, on-time delivery and improving overall warehouse efficiency.

Capacity Buffers to Ensure On-time Delivery

Capacity buffering involves increasing capacity to meet elevated demand, including hiring extra workers, outsourcing logistics, or deploying backup teams.

Accurate demand forecasting allows businesses to proactively implement capacity buffers, ensuring delivery commitments are met even during peak periods. This approach helps maintain high levels of customer satisfaction by providing timely deliveries.

Real-time Updates

AI enables real-time updates through sensors and individual tagging, providing visibility into the status of goods at every stage of the supply chain. Real-time updates inform raw material sources, manufacturing plants, storage facilities, and customers about estimated delivery times.

This enhanced visibility reduces the need for capacity buffers and ensures that inventory is delivered on time. Real-time data also helps vendors and customers make informed decisions, further streamlining the supply chain.

What is an example of AI in retail inventory delivery management?

The retail giant Amazon is the best example of AI in inventory delivery management.

Walmart faced challenges managing its vast inventory across numerous stores and distribution centers. The company needed to ensure timely deliveries while minimizing costs and maintaining high customer satisfaction.

Walmart’s AI Implementation

Walmart implemented AI-powered systems to optimize its delivery routes and efficiently manage inventory.

The AI algorithms analyzed vast amounts of data, including traffic patterns, weather conditions, and historical delivery times, to determine the most efficient routes for delivery vehicles.

Additionally, AI was used to predict demand and optimize inventory levels, ensuring that products were available when and where they were needed.

Results

The implementation of AI-led to significant improvements in Walmart’s delivery management. The optimized routes reduced fuel consumption and transportation costs, while the predictive analytics ensured timely deliveries and minimized stockouts.

As a result, Walmart enhanced its operational efficiency, reduced costs, and improved customer satisfaction.

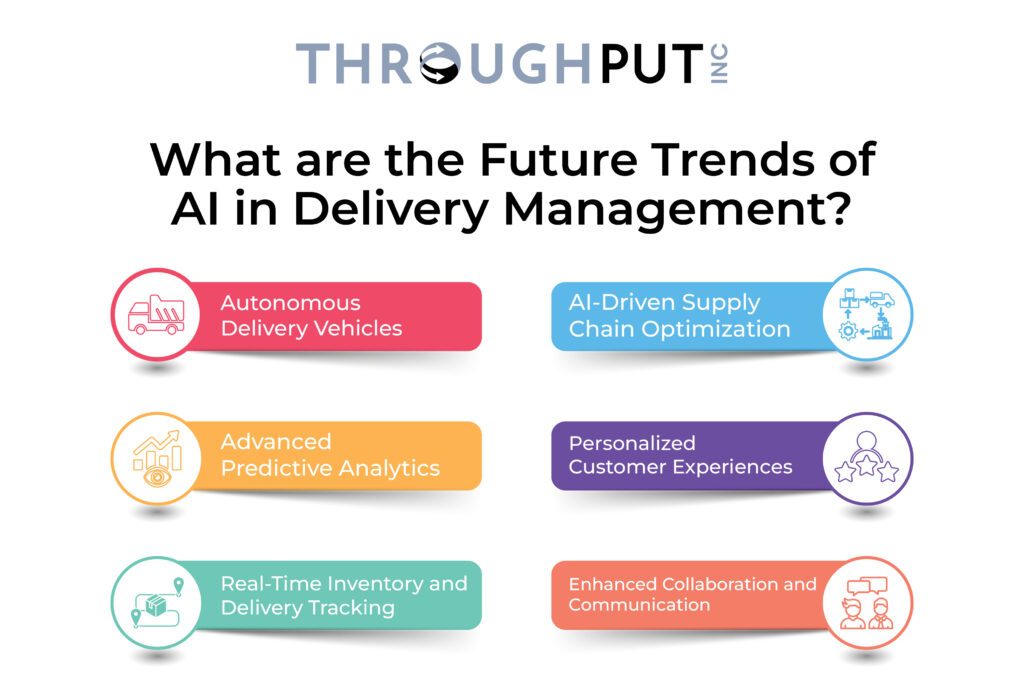

What are the Future Trends of AI in Delivery Management?

The future trends of AI in delivery management are AI-driven supply chain inventory optimization, leveraging advanced predictive analytics, real-time inventory tracking and enabling personalized customer experiences.

These future trends will bring transformative changes and enhance efficiency, accuracy, and customer satisfaction.

Autonomous Delivery Vehicles

One of the most anticipated trends is autonomous delivery vehicles, including drones and self-driving trucks. Companies like Amazon and UPS are already experimenting with drone deliveries to reduce delivery times and costs, especially for last-mile logistics.

Autonomous trucks, equipped with AI and machine learning, can optimize routes in real-time, reduce fuel consumption, and operate continuously without breaking, significantly improving delivery efficiency.

Advanced Predictive Analytics

AI’s predictive analytics capabilities will continue to evolve, providing even more accurate demand forecasting and delivery time predictions.

Analyzing vast amounts of data, including weather patterns, traffic conditions, and historical delivery times, enables AI to anticipate potential delays and suggest alternative routes.

This will help businesses maintain high levels of on-time delivery performance and improve overall customer satisfaction.

Real-Time Inventory and Delivery Tracking

Integrating AI with Internet of Things (IoT) devices will enable real-time tracking of inventory and deliveries. Sensors and RFID tags can provide continuous updates on the location and condition of goods, allowing businesses to monitor shipments in real time.

This enhanced visibility will help quickly address any issues during transit, such as delays or damage, ensuring that customers receive their orders on time and in good condition.

AI-Driven Supply Chain Optimization

AI will be crucial in optimizing the entire supply chain, from inventory management to delivery logistics.

AI analyzes data from various sources to identify inefficiencies and suggest improvements in processes such as inventory placement, order fulfilment, and transportation.

This holistic approach will help businesses reduce costs, improve delivery times, and enhance overall supply chain performance.

Personalized Customer Experiences

AI will enable more personalized customer experiences by analyzing customer data and preferences.

For example, AI can predict the best delivery times for individual customers based on their past behaviour and preferences, ensuring that deliveries are made at the most convenient times.

Additionally, AI can provide personalized recommendations for products and services, enhancing the overall customer experience and driving sales.

Enhanced Collaboration and Communication

AI will integrate data from various stakeholders, including suppliers, manufacturers, and logistics providers, to facilitate better collaboration and communication within the supply chain.

This integration will ensure all parties access the same real-time information, improving coordination and decision-making. Enhanced collaboration will lead to more efficient and reliable delivery management, reducing the risk of delays and disruptions.

Managing Inventory delivery with Throughput

Throughput software is a powerful tool for managing inventory delivery in retail supply chains. It offers real-time tracking, accurate data capture, and advanced analytics to streamline operations.

Throughput software helps retailers maintain optimal stock levels, prevent overstocking and stockouts, and ensure timely and efficient order fulfilment.

The software provides real-time visibility into inventory status, allowing businesses to make informed decisions about purchasing, production, and sales.

This enhanced visibility reduces errors and speeds up stocktaking, receiving, and order fulfilment processes, ultimately improving overall operational efficiency.

Throughput’s reporting and analytics features offer valuable insights into inventory performance, helping businesses identify trends, uncover inefficiencies, and make data-driven decisions to optimize inventory levels and reduce costs.