Ineffective Demand Planning: 5 Warning Signs to Look Out For

Thanks to the increasing competition in today’s global markets, growing customer expectations, and the rising demand for products with shorter life cycles, most businesses have been forced to sharply focus their attention on accurate demand sensing – and planning for it – to stay profitable and sustainable.

Add to that the growing demands of sustainability all around!

Achieving any kind of business and operational efficiency is possible only when you lead plans by demand.

However, demand planning is a complex function and ineffective demand planning can spell doom in the modern commercial world.

When done right, it has the potential to add value to a variety of strategic functions, ranging from procurement and supply chain optimization to effective production and distribution. Businesses can consistently meet and exceed customer expectations, while at the same time improving profitability – both goals that are unattainable via alternative strategies.

Finally, it helps you predict and eliminate operational bottlenecks before they can affect subsequent operations, meaning that you can save thousands or millions of dollars in terms of costs. With cutting costs being the order of the day in most industries, that alone means a lot.

So, what is demand planning?

It is the process of estimating the future demand for your products so that you can plan to supply them accordingly – because producing anything more is a waste, and falling short is disastrous.

With ineffective demand planning, there are too many repercussions, not to mention far-reaching ones – it affects everything across the chain down to the customer.

Inefficient demand planning can lead to missed opportunities and costly disruptions. From stockouts to increased costs, excess inventory, and reduced customer satisfaction, there are endless issues.

The best way to save yourself is to watch out for warning signs that indicate ineffective demand planning.

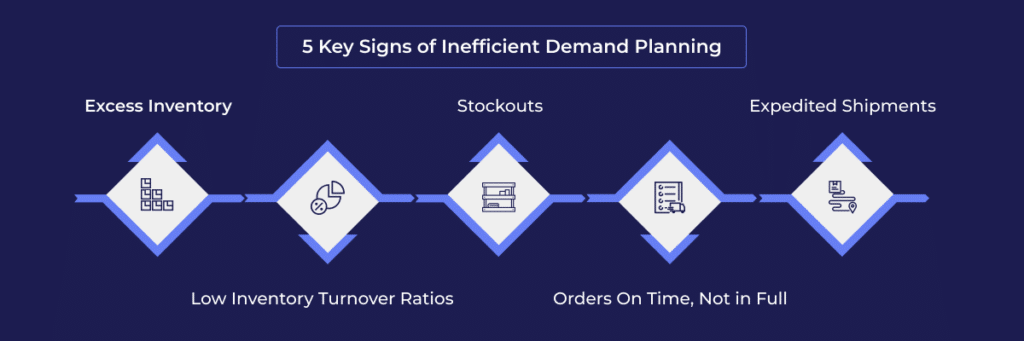

5 Key Signs of Inefficient Demand Planning

Demand planning is interconnected with nearly every function across your value chain. Any of the warning signs listed below could just as easily be indicative of issues not only with demand planning but also with supply planning, capacity planning, production, S&OP, and other functions.

To remain competitive in today’s market, you need to remain operationally agile, allowing you to rapidly adapt to unexpected changes in demand and keep your inventory and demand balanced at all times.

Five indicators of ineffective demand planning are:

1. Excess Inventory

Excess or obsolete inventory is usually a result of maintaining high safety stock levels. It is the first indicator of a disconnect between demand and supply.

To be able to plan demand accurately, you need to have complete granular visibility into your supply chain at each item, category, process, customer, and distribution channel level. This helps you optimize inventory on both sides of the supply chain – for procurement as well as distribution.

2. Low Inventory Turnover Ratios

The frequency at which your inventory turns over – in full – is a great indicator of how healthy your supply chain is. If your inventory turnover is lower than the industry standard, it is a sign of inaccurate demand sensing and planning.

Proactive, data-based demand planning can help you identify what and how much to produce – in turn helping you ascertain what and how much raw material to order.

3. Stockouts

Running out of particular materials faster than expected is just as dangerous – if not more so – than having excess inventory, because it has the potential to halt operations.

This, too, is easily rectified with accurate demand forecasting. Stockouts – which cause considerable heartache by way of missed deliveries and disappointing customer service – usually, happen when your estimates are too spreadsheet-based and rigid or are just simply negatively biased.

Both causes can be addressed by opting for an automated, AI-based solution that by its nature is bias-free and responsive to dynamic market changes even in the near term.

What’s more, an automated demand planning solution is infinitely scalable, leaving you free to pursue growth plans without the slightest worry.

4. Orders on Time, But Not in Full

The biggest challenge about accurate demand planning is that it is a continuous exercise. It is not something that can be done only for the long term and executed over 6–18 months.

Customer demand is a dynamic metric, which means that you need to keep estimating it based on evolving market forces such as customer preferences, weather changes, and changing industry trends.

The inability to effectively adapt to fluctuations in demand can lead to too many orders being sent out only partially filled.

This usually happens when you do not have a clear view of demand, and are forced to adopt a reactive mode to surges and dips in demand for certain products – instead of proactively predicting these shifts and responsively adapting your product mix on the fly.

When demand planning is as agile as demand, you can significantly improve on-time, in-full deliveries, thus maximizing customer satisfaction.

5. Expedited Shipments

Expedited shipments happens when orders are not ready by the time they can be shipped cost-effectively.

It is a trademark of ineffective demand planning. To stick to committed delivery dates, you end up having to expedite shipments – at premium charges.

When this happens consistently, you may end up delivering orders on time, but your shipping costs keep eating into your profit margins.

When you plan demand effectively, you can plan enough time for production so that you don’t incur last-minute express shipping costs, thus allowing not just sustained but improved profit margins.

What’s the Impact of Ineffective Demand Planning

Stockouts or Excess Inventory

Either way, inaccuracies in demand planning can toss your inventory management upside down. Stockouts or excess inventory – both are undesirable conditions. Stockouts happen when customer demand exceeds available stock levels, leading to lost sales opportunities and customer dissatisfaction.

Overstocking, on the other hand, happens when inventory levels are way more than demand. As a result, your capital gets stuck, spaces in your warehouse get blocked, carrying costs increase, and the risks of damage to inventory get considerably higher.

In both cases, the company stands to lose its reputation and earning opportunities to drive better profitability.

Reduced Customer Satisfaction

Businesses that take a chance with demand planning risk customer relationships. Customers today are not just well-informed, smart, and dynamic, they are tech-savvy, are demanding, love personalized attention, and want instant gratification.

They have a seamless omnichannel at their disposal and have no time to wait.

Ineffective demand planning can lead to delays in meeting customer orders. At times, the wrong products get delivered. There’s too much to risk here! Before long, the dissatisfaction levels in your customers hit rock bottom and you find them queuing up to your closest competitors.

Increased Costs

With inaccurate demand planning, businesses incur huge losses financially. That’s because costs across the chain increase phenomenally.

Whether it is a stockout situation or excess stock, inventory holding and handling costs, expenses required to meet rush orders and expedited shipping, disruption in production schedules, or missed opportunities, there’s a cascading effect.

Each of these direct and indirect costs eats into the profitability and erodes the earning capacity of the business.

Production Inefficiencies

Without proper demand planning, a business is like a lost ship in deep waters. Inaccuracies in demand forecasts can disrupt production schedules resulting in the under or over-utilization of resources.

In both cases, the production capacity is not optimized leading to increased production costs, reduced productivity, idle or over-active machinery, and labor.

Financial Impact

With loopholes in demand forecast and planning, the business starts to suffer from the cumulative effect within no time. Ultimately, it hits where it hurts the most – your finances, and the company’s bottom line. On one hand, there is a spiraling increase in costs, and on the other, lost opportunities to earn revenues.

All in all, ineffective demand planning is just not the ideal way of progression in the marketplace today. Needless to say, there are many benefits of demand planning.

When done effectively, it helps your business stay competitive, and agile to respond to dynamic market conditions.

How to Improve Demand Planning Accuracy: Two Real-Life Examples

Businesses cannot take chances with demand planning. It has to be proper, accurate, and timely.

What is the one thing that can guarantee demand planning accuracy?

Accurate demand forecasting.

That’s because the better your customer demands are forecasted, the higher the chances of your business making informed decisions about inventory and resource allocation, and scheduling production.

A game-changer in this context is AI demand forecasting, where artificial intelligence-based algorithms dig deep into complex data sets to provide you with real-time insights about changing trends and customer demands. At ThroughPut, we use AI-powered demand sensing capabilities to enable our clients optimize their product-mix, replenishment plan, logistics and capacity, among other things.

Once demand forecasting happens accurately, it causes a ripple effect helping production and supply align with actual demand and preventing stockout or excess stock situations.

Here are some tips to relook at your demand planning methods:

1. Opt for Demand Sensing Over Traditional Demand Planning

Demand sensing is a technique for short-term or near-term demand forecasting. It works with real-time data and advanced analytics to understand demand fluctuations in the near future. The difference between demand sensing and traditional demand planning is that the latter depends on historical data for long-term forecasts.

Throughput offers near-term insights with the help of demand sensing. The tool analyzes point-of-sale data, weather patterns, social media trends, and economic indicators for predicting short-term demand.

Consequently, the forecasts are far more accurate vis-a-vis traditional demand planning helping companies adjust their production schedules, and manage their inventory levels quickly in response to changing market dynamics.

2. Look at Real-time Data So You Can Respond Faster

Real-time data empowers businesses in the new age to respond faster to changing demands. This up-to-the-minute data fetched from different sources like inventory, sales, marketing, consumer behavior, etc. facilitates accurate demand planning. One of the pros of assessing real-time data is to make relevant decisions in dynamic market conditions, be it your production, inventory, logistics, or distribution.

Throughput leverages machine learning algorithms and advanced analytics to read real-time data from different sources.

Clients using Throughput can anticipate demand shifts proactively and accurately. Consequently, they can make rapid adjustments to their supply chain operations to optimize resource allocation and capacity planning in response to market events and disruptions.

If you want your business to be agile today, you need tools that can offer real-time data analytics for accurate demand planning.

3. Ensure You’re Looking at Internal and External Data Because Multiple Variables Affect Demand

To ensure that your demand planning is accurate, you need to consider internal and external data sources that influence demand.

Remember multiple variables influence demand. Sales data, inventory levels, and production capacities are internal data that offer past performance insights.

External data that need to be considered while demand planning are current market trends, demand patterns, competitor activities, and economic indicators.

Both these datasets need to be considered comprehensively to gain a holistic understanding of all the drivers that affect demand for accurate planning.

For instance, ThroughPut’s demand sensing tool is designed to consider internal and external data that affect your business.

We understand that these factors can be different for different businesses. Enabling this customization capability is one of those things that improves the precision of ThroughPut’s demand forecasts

4. Adopt a Tool That Can Make This All Possible at Speed Like ThroughPut

Demand planning accuracy is attainable with the right tool. Going in for an AI-powered tool like Throughput that uses advanced analytics and machine learning will let you process real-time data and gain valuable and actionable insights.

The tool works as a single super-connector software that sits on top of existing data architecture countering all demand forecasting challenges. The software predicts demand accurately, reorients production capacity, reassigns warehouse space, and reorders materials just in time, so businesses minimize overpromising & under-delivering performances.

ThroughPut improves material flow and free cash flow, across the entire end-to-end value chain 5 times faster than alternative solutions.

Real-life Example 1: European Retailer Saves 3.5 Million Euros Per Year in Logistics Costs with Improved Demand Sensing

Retailers are the worst hit today with frequent disruptions in distribution on one hand, and the need to be ever-prepared for accelerated customer service expectations, on the other. To top it off, the industry also sees low margins.

This 65-year-old European retail chain with 25,000+ products across several categories faced operational challenges related to DC shipment management, higher distribution and logistics costs especially related to last-minute expedited shipping costs and rapidly changing demand seasonality. What added to the chaos was the rise of the e-commerce industry with rapid order fulfilment models.

What the retail chain needed was an intelligent cognitive approach to boost precision in demand sensing, demand planning, and demand forecasting.

With ThroughPut, the impact was immediate as the client could eliminate unnecessary DC-to-DC shipments, affecting a 20% reduction in SKU volume and a 33% reduction in transportation costs, besides achieving an OTIF rate of over 90%.

It could identify its top 150 SKUs and revise the allocations, realizing logistics savings of up to €2 million per year.

With Dynamic Adjustment of Distribution per DC, there was granular visibility of all SKUs with a demand-value matrix.

The retailer could dynamically adjust indirect and transfer shipments to shifts in demand that eventually helped save €3-6.5 million per year.

Real-life Example 2: Apparel Giant Optimizes Product-Mix and Streamlines Material Flow to Avoid Stockouts

The global apparel industry, valued at $1.15 trillion needs to constantly face issues related to changing demand profiles, continuous disruptions, increased awareness about textile wastes, and sustainability challenges. One of the main reasons for the humongous waste is demand unpredictability, over-utilized resources, and extended lead times.

Our client, a leading global fashion and lifestyle retail conglomerate, was unable to bridge the gap between capacity and demand forecasts.

Their dependence on human judgment planning and manual efforts was failing them because of scalability issues. There was no way to identify low-value, low-demand products, and OTIF underperformers so that these could be removed from the product mix.

Consequently, higher-value, higher-demand products and larger-value OTIFs could not be optimized to better sales margins and free up capacity. Overall, with most of the strategies depending on guesswork, the company was falling short of expectations and missing profitable opportunities.

With the entry of Throughput, almost 840,000 rows of delivery data including over 280,000 unique SKUs were analyzed and automatically segmented the SKUs by demand and value for product mix optimization and OTIF maximization.

With precise demand predictions and demand sensing, patterns at the SKU level were visible. Throughput’s recommendations of ideal inventory levels boosted the smooth and continuous movements of goods. This helped reorient production capacity, reassign warehouse spaces and streamline stocks to fulfill demand on time.

All instances of over-ordering or over-producing and logistics costs were minimized. As a result, profitability, sales, and inventory turnover were maximized during one of the busiest times of the year.

Eventually, the company realized 3X savings, freed up 15% of shelf space, created 10–20% free capacity to test new product lines, and achieved a 275% increase in overall performance based on products with relatively consistent sales.

Turn Ineffective Demand Planning on its Head

Ineffective demand planning has to exit!

Businesses need to replace traditional tools with AI-powered systems like Throughput to leverage advanced analytics.

Throughput runs through vast data sets in real-time, processes them rapidly, identifies patterns, offers actionable insights, and anticipates demand fluctuations so that businesses can optimize their demand forecasting and planning processes based on what’s happening in real-time. That’s how your business can stay on top of market trends and achieve accurate demand planning.

If you need to turn ineffective demand planning on its head, book a demo with us today.