Inventory is the backbone of the modern firm, and potentially its most important asset. It can affect production, sales, turnaround time, customer satisfaction and even profitability.

Thus, effective ai in inventory management is one of the crucial goals of modern-day businesses – and a critical element of supply chain management. It is the converging point of all the elements of the supply chain, which means that in the absence of proper control, the entire supply chain can unravel.

Yet, 43% of small businesses do not monitor their inventory, and a mere 6% of businesses report that they have full visibility of their supply chain – a prerequisite for effective inventory management.

But with the ever-growing complexity of global supply chain networks and the urgent need for disruption-immune operations, supply chain executives are increasingly realizing that the need of the hour is to focus on tighter inventory control if they wish to continue growing their margins and positive customer experiences.

What is Inventory Management?

Inventory management is the art of tracking goods from suppliers to manufacturers to warehouses and finally to points of sale, all while balancing stock levels to minimize costs and risks.

Every business relies on inventory management to maintain a steady flow of supplies, finished products, and other essential assets.

To accomplish this, businesses use various practices to control factors such as inventory levels, location, pricing and logistics. Until recently, this process was complex and time-consuming, particularly for large manufacturers and enterprises due to involvement from multiple stakeholders.

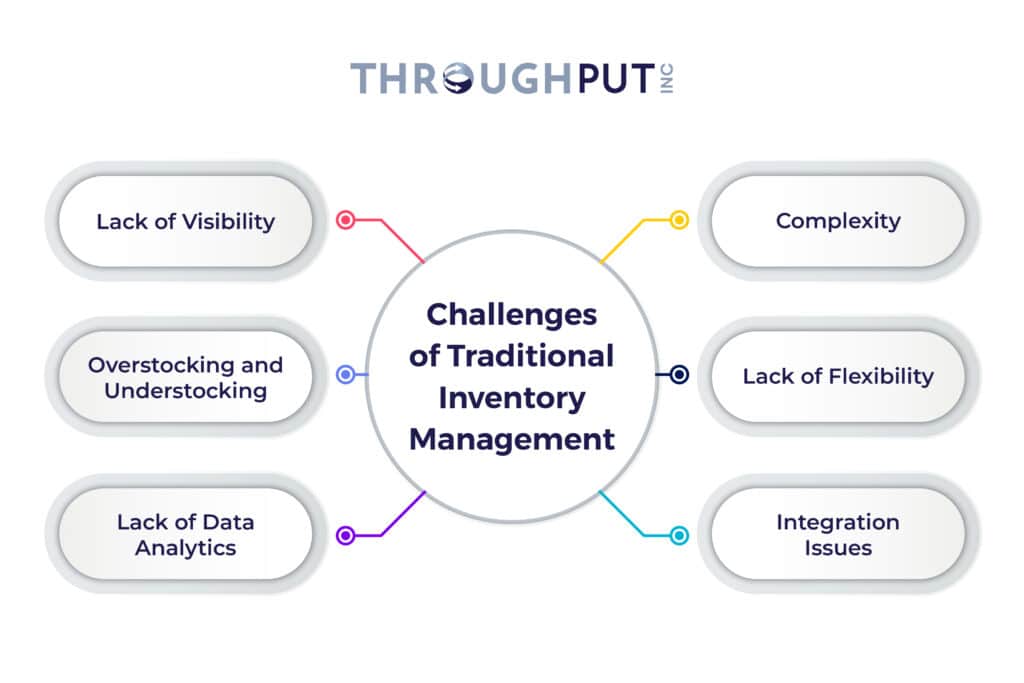

Challenges of Traditional Inventory Management

Traditional inventory management involves processes that do not talk to each other and often have varied goals.

As a result, there were quite a few challenges that emerge:

Lack of Visibility

Traditional inventory management systems find it challenging to effectively forecast customer demand due to the lack of visibility into real-time changes in inventory levels, as well as movement of stock. With no clear picture of current demand and its trend, executives have no way of determining the right inventory levels – of either supplies or finished goods.

Lack of visibility also means that it is difficult to track inventory or accurately account for its volume and/or location.

Overstocking and Understocking

Due to the lack of visibility, one of the major problems associated with traditional inventory management is the high risk of overstocking. This results in not only higher carrying costs – including the cost of holding, handling and moving inventory – but also potential spoilage and wastage.

Overstocking also causes cash flow constraints as working capital ends up remaining tied up in inventory that may remain unsold for a long time. Lack of visibility can also lead to understocking, which leads to lost sales and bad customer experiences, both of which have a significant impact on the bottom line.

Lack of Data Analytics

Traditional inventory management systems were mostly manual. As they did not leverage data analytics capabilities, it was difficult to discover trends and patterns in demand and supply as fast and as accurately as we can now. This made it challenging to make informed, accurate and timely decisions to manage inventory effectively.

Complexity

Traditional inventory management involved considerable time and effort-consuming tasks such as manual inventory checking and placement of purchase orders.

Modern methods of inventory management, on the other hand, leverage tools for automation and data analytics, ensuring accurate results at scale – while also avoiding human error and its ensuing costs.

Limited Flexibility

Traditional inventory management systems are incapable of adapting to real-time business dynamics such as fluctuating demand or delayed shipments.

Thus, sudden spikes in demand or changes in customer preferences can cause problems as inventory levels and material flow cannot be edited to address these changes.

Integration Issues

Integration issues were another common challenge with traditional inventory management systems, as they often could not communicate with other organizational systems such as enterprise resource planning (ERP) software or customer relationship management (CRM) applications.

This makes it harder to gain a complete picture of business processes, leading to operational discord and inefficiency.

AI in Inventory Management

The major limitation of traditional inventory management lies in the fact that it primarily focuses on optimizing only two key parameters – the ordering process and the buffer stock levels – in a bid to manage inventory effectively.

However, in today’s times, optimizing inventory involves controlling many more levers throughout the length of the supply chain as businesses look to meet and exceed customer expectations while navigating market disruptions that are becoming increasingly frequent.

This is why AI inventory management is emerging as a game-changer – with its advanced, intelligent capabilities, it is reshaping the way businesses manage their inventory.

With AI inventory management, businesses, whether large enterprises or small manufacturers, can revolutionize their operations end to end by streamlining processes, cutting costs and accelerating overall efficiency.

What Are the Benefits of AI in Inventory Management?

Leveraging AI in inventory management has numerous benefits.

Data Structuring and Analysis

One of the major challenges that businesses face today is managing the massive amounts of unstructured data generated by their inventories. AI is the only technology that can solve this problem at scale, by cleaning and structuring it so that businesses can focus on relevant data in a prioritized manner for analysis, forecasting, reporting and decision-making.

With rich insights, businesses can make far more informed, intelligent decisions to optimize their inventory and logistics and drive strategic business growth.

Demand Forecasting

AI can rapidly analyze historical and real-time data to accurately predict future demand, thus, enabling businesses to maintain optimal inventory levels and prevent overstocking or stockouts.

In addition, AI can factor in ongoing market trends, seasonal patterns, weather conditions, and other relevant factors for enhanced forecasting accuracy.

For instance, AI can identify why certain products witness increased demand during a major sporting event, and also predict these demand spikes based on event calendars and past sales data.

A sports goods company can then accordingly adjust inventory levels and marketing strategies to maximize the value of these potential opportunities.

Inventory Optimization

AI can find new correlations in data that are invisible to the human eye.

For example, AI can identify patterns in demand, value and other product traits and accordingly classify inventory into categories to enable prioritized management of stock.

Thus, certain SKUs can be organized in the warehouse for better efficiency based on how fast they move, or how quickly they need to be sold before they spoil – enabling businesses to streamline pick-and-pack processes and drive increased efficiency of logistics and distribution.

Increased Efficiency

AI can automate several aspects of inventory management such as demand forecasting, inventory tracking and reordering/inventory replenishment. This frees up valuable time for employees to focus on other critical areas of operations, thus, boosting overall productivity.

Eliminating manual tasks also helps reduce the risk of human error, further enhancing the accuracy and efficiency of the inventory management process.

Cost-effectiveness

By reducing storage costs, preventing wastage/lost sales caused by overstocking/understocking, and driving better sales via accurate demand forecasting, AI-based inventory management enables businesses to have vastly healthier bottom lines.

In addition, it enhances overall business efficiency, thus, helping businesses not only save substantial costs, but also maximize margins. In an increasingly competitive business landscape, such cost-effectiveness can give businesses a much-needed edge by allowing them to invest more in growth and innovation.

Supplier Management

AI inventory management can also empower businesses to analyze supplier performance based on a variety of factors such as price, lead times and quality.

Suppliers can thus be ranked based on their strengths and weaknesses, and chosen via an unbiased, optimal selection strategy.

Thus, AI inventory management can rank and recommend top suppliers, inform negotiations for favorable terms, and enhance relationship management.

AI Inventory Management: Implementation

While AI in inventory management offers many benefits, it is important to understand what it takes for its successful implementation.

The following are the key requirements for businesses adopting it to be able to ensure optimal results.

- Data Availability

AI systems rely heavily on data. Inadequate access to data can lead to inaccurate predictions and flawed decisions.

For best results, AI inventory management depends on full access to not only current but also historical data to ensure accurate forecasting and effective real-time decisions.

2. Integration With Existing Systems

Seamless integration of AI inventory management solutions with existing business systems is a critical requirement for their successful implementation. This is essential not only for adequate access to data, but also for visibility across operations so that all decisions are consistently tailored to achieve common business goals.

3. Security

Leveraging AI involves accessing all kinds of sensitive business data – including customer data. This presents privacy and security concerns, which means that systems must be robust enough to safeguard against security breaches and cyber threats.

How are Large Enterprises Leveraging AI for Optimized Inventory Management?

Globally, many businesses across various industries have been successfully leveraging AI for supply chains and logistics as well as inventory management.

The successful implementation and use of AI lead to increased efficiency and cost savings, as well as improved customer satisfaction. Here are a few major examples.

Amazon: Amazon leverages sophisticated AI algorithms for advanced inventory management and particularly for warehouse management.

Their system helps predict demand, optimize warehouse space utilization and streamlines the pick-and-pack process, allowing the company to efficiently manage its vast inventory and rapidly pivot in response to changing consumer demands.

Walmart: Walmart uses AI to optimize its inventory, and particularly focuses on predicting demand and automating replenishment.

By analyzing vast data including weather forecasts, past sales and trending market data, the company’s AI inventory management system accurately predicts future product demands to consistently ensure optimal stock levels in warehouses and stores.

Target: Target leverages AI to not only maintain the right inventory levels but also to enhance customer shopping experiences. Its AI systems focus on analyzing sales data to predict future demand trends and help its stores proactively stock products in anticipation of high demand in specific locations.

Nike: Nike has integrated AI into its supply chain to effectively manage inventory levels across its global locations.

The company leverages AI to enable demand forecasting, identify popular products across regions and ensure that these products are adequately in stock to cater to regional customer preferences.

This approach has proven particularly effective in managing the company’s inventory when catering to high demand for limited-edition releases.

While these are examples of large companies, AI inventory management can be scaled up or down to meet the requirements of businesses of all sizes. Small and medium-sized enterprises can also benefit from AI inventory management solutions that are tailored to their specific needs and budget requirements.

ThroughPut AI for Large-scale Inventory Management

ThroughPut simplifies the process of large scale inventory management for businesses in just three easy steps:

Step 1 – Analysis of SKU/Location Health

ThroughPut helps businesses analyze an exhaustive range of supply and demand signals to identify which SKUs/locations are running low on inventory levels while dynamically factoring in market shifts to eliminate flow disruptions and optimize inventory turnovers, service levels and days of supply.

Step 2 – Recommendation of Stock Levels

ThroughPut leverages AI-powered recommendations to allocate and distribute inventory to create a perfect “pull” effect driven by customer demand. Thus, businesses can avoid unnecessary material movement to POSes and instead focus on on time and in full (OTIF) deliveries so that they never miss a sale. They can also continuously improve service levels by optimizing their product mix priorities based on evolving demand patterns.

Step 3 – Buffer management

With ThroughPut, businesses can use the correct buffer sizing criteria to always minimize stock wastage and risk of exposure. They can also monitor buffer consumption against recommended stock level targets for the near, short or long term.

Shaping the Future for an Optimized, Smarter Inventory

Efficient, effective inventory management plays a key role in business success.

Traditional methods of inventory management are not only technologically inadequate in terms of dealing with today’s challenging business conditions, but also inefficient and expensive – both in terms of cost and missed opportunities.

It’s time to shift away from wasteful inventory management practices and toward a more intelligent and profitable way of managing inventory to unlock new ways to grow your business.

ThroughPut can help you start as small as necessary to ensure a comfortable transition as you modernize your inventory management. Reach out to us today to get started.