Dynamic Buffer Inventory Planning for Supply Chain Resilience

As an inventory planner, you’re constantly navigating a catch-22.

You need buffer inventory to protect against emergencies and unexpected demand spikes, but excess buffer stock ties up valuable working capital and risks becoming obsolete.

Striking this balance can be quite a challenge.

In this article, we’ll explore how modern inventory planners optimize buffer stock levels to enhance supply chain resilience and efficiency.

What Is Buffer Inventory? [& Why Does It Matter for Inventory Planners]

Buffer inventory, often referred to as safety stock, is the additional inventory maintained to mitigate uncertainties in supply and demand. This reserve stock acts as a safeguard against unforeseen spikes in demand, delays in supply, or other disruptions that might otherwise cause stockouts.

Here’s a list of good reasons why buffer inventory matters for inventory planners:

Prevents Stockouts

Buffer inventory ensures you always have enough stock to meet customer demand, even during unexpected spikes or supply chain disruptions.

This excess stock helps keep your customers happy and loyal while preventing stockouts, which can lead to lost sales and customers turning to competitors.

Mitigates Supply Chain Disruptions

Buffer inventory is a safety net against various supply chain disruptions, such as natural disasters, port congestion, or supplier issues. It provides you with buffer time to continue meeting customer demand despite these challenges.

Keeps Seasonal and Demand Variability in Check

Buffer inventory helps you manage seasonal fluctuations and demand variability. Buffer levels should be adjusted based on historical data and market trends so that there is enough stock during peak periods and avoid overstocking during off-peak times.

Next, let’s explore how buffer inventory plays a leading role in enhancing supply chain resilience.

What’s the Connection Between Buffer Inventory and Supply Chain Resilience?

The pandemic really showed how fragile our supply chains can be, with empty shelves and delayed deliveries becoming all too common.

It drove home the need for supply chains to be resilient, to keep things moving smoothly even when unexpected things happen. At the same time, businesses still needed to keep operations lean and costs down, which can feel like trying to mix oil and water.

Buffer inventory is key here. It acts like a safety net, letting companies handle sudden changes in demand or supply issues, building resilience. But finding the right balance between having enough stock to be safe and not so much that it eats into profits is tricky.

Getting it right is crucial for keeping customers happy and staying ahead in today’s unpredictable market. And here’s how best you can go about it.

How Can Inventory Planners Improve Buffer Inventory Planning?

Static buffer inventory can be counterproductive for resilience. A better, smarter and reliable method is dynamic buffer management. This process dynamically adjusts the size of inventory buffers based on real-time data about demand and supply variability.

Here’s what you need to know:

What is Dynamic Buffer Management?

Dynamic Buffer Management uses intuitive signals from your internal and external data to indicate when adjustments are needed in inventory. This approach helps inventory planners respond quickly to changes, ensuring optimal stock levels.

How is Dynamic Buffer Management Different [& Better]?

Unlike static buffer management, dynamic buffer management uses algorithms, historical data, and machine learning models to predict changes in real-time and recalibrate buffer stocks accordingly, aiming to optimize inventory levels to minimize costs while still preventing stockouts.

| Static Buffer Management | Dynamic Buffer Management |

| Fixed Quantities The buffer inventory levels are set and remain constant over time. | Adjustable Levels Buffer inventory levels are continuously adjusted based on real-time data and analysis of demand and supply variability. |

| Simple Management Because the quantities do not change, it is easier to manage and predict. | Complex Management Requires more sophisticated systems and processes to monitor changes and make adjustments. |

| Best for Stable Environments This approach works well in scenarios where demand and supply are relatively predictable and consistent. | Best for Volatile Environments Ideal for industries or markets where demand can shift dramatically or supply can be uncertain due to various factors like economic shifts, natural disasters, or changes in consumer preferences. |

How Can Supply Chain Decision Intelligence Help with Dynamic Buffer Inventory Planning?

Supply chain decision intelligence is a data-driven approach that empowers businesses to make more effective, efficient, and profitable decisions in real time and at scale. It revolutionizes dynamic buffer inventory planning through advanced analytics, AI, and machine learning.

Supply chain decision intelligence continuously adjusts safety stock levels based on real-time data, including current demand patterns, lead times, and supply risks.

Unlike traditional static buffer management, which relies on static calculations based on historical data, decision intelligence tools like ThroughPut AI ensures that buffer levels are always aligned with current market conditions and business objectives.

Scenario planning is another powerful feature of supply chain decision intelligence. It allows you to simulate various supply and demand conditions to see how different scenarios might impact your operations. This capability helps in crafting more effective inventory strategies that are robust against a range of potential future states.

Decision intelligence also aids in risk management by identifying potential risks and vulnerabilities within your supply chain, from supplier issues to sudden market changes. Armed with this knowledge, you can strategically adjust your buffer stocks to mitigate risks.

Additionally, the automation provided by decision intelligence systems streamlines the process of adjusting inventory levels. This not only reduces the need for manual intervention, thus minimizing human error but also ensures that inventory adjustments are made efficiently and promptly.

What Are the Best Practices for Inventory Planners Regarding Buffer Inventory and Optimal Stock Levels?

When it comes to effective management of buffer inventory, you need access to near-term demand forecasts and adopt tools that enable dynamic buffer management.

Here’s how each practice addresses specific challenges and how to implement it across different supply chains:

Gain Access to Near-term Demand Forecasts

Inaccurate demand forecasts can lead to costly overstocking or understocking. To solve this costly problem, you need advanced forecasting tools that analyze historical data and current market trends.

These tools can predict near-term demand accurately, which is particularly beneficial for supply chains with high variability, such as retail or seasonal products.

For example, ThroughPut AI’s advanced algorithms analyze historical existing data and external data to sense demand patterns accurately and in real-time. This helps businesses anticipate inventory needs before they escalate into problems.

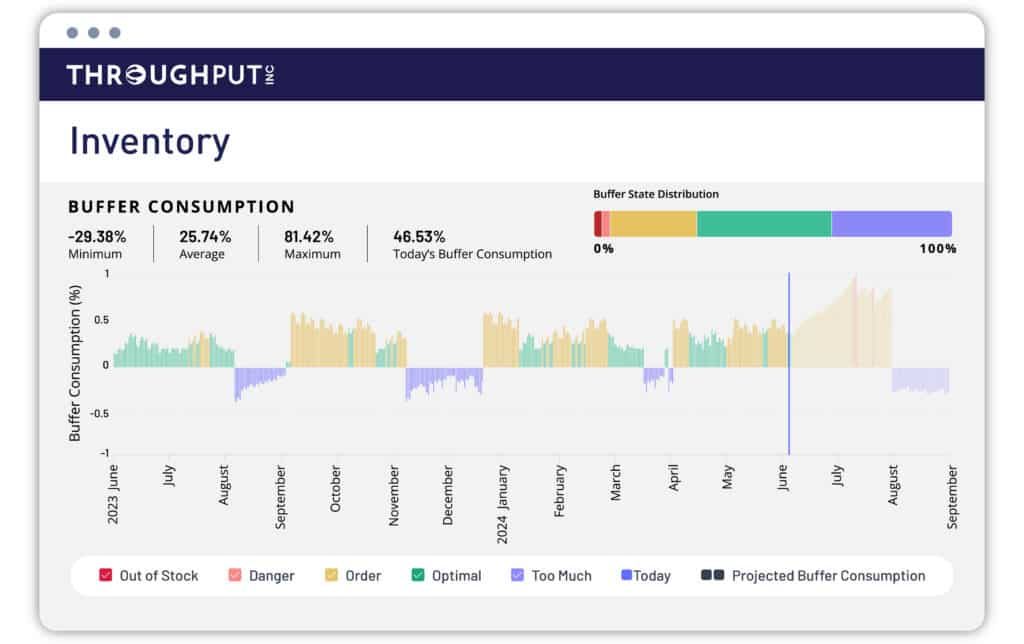

Adopt a Tool That Can Enable Dynamic Buffer Management

Static buffer levels can’t adapt to real-time changes in demand and supply, leading to inefficiencies. To address this, use software that offers dynamic buffer management.

This software adjusts buffer sizes based on real-time data, making it ideal for supply chains with fluctuating demand and supply conditions, such as manufacturing or fast-moving consumer goods (FMCG).

ThroughPut AI uses correct buffer sizing criteria to ensure that you can always supply the next node in your supply chain to the desired level of service, regardless of variability in demand or supplier performance.

Next, let’s explore how effective data usage can transform inventory management.

Use Data Effectively

Poor data integration and analysis can lead to suboptimal inventory decisions. To overcome this, you need to integrate data from various sources like ERP systems, POS data, and material movement data. Use advanced analytics to transform this data into actionable insights.

This practice is essential for complex supply chains with multiple data points, such as global logistics or multi-channel retail.

ThroughPut AI seamlessly connects with existing data sources, and provides real-time analytics and actionable insights to optimize inventory costs and improve working capital allocation.

Finally, consider the importance of tools that offer a faster return on investment.

Look for Tools with Faster ROI

Long implementation times and delayed ROI can hinder the adoption of new inventory management tools.

When looking at different solutions, choose tools that offer rapid deployment and quick ROI.

The right tools are a crucial investment for businesses looking to improve their inventory management processes without significant downtime or upfront costs.

ThroughPut AI is recognized for its fast deployment and ability to deliver quick ROI, making it an ideal choice for businesses aiming to promptly enhance their inventory management efficiency.

Dynamic Buffer Management With ThroughPut AI

When managed in real-time, buffer inventory can shield your business against disruptions, giving you the much needed resilience.

ThroughPut AI-like supply chain intelligence tools simplify this task with its advanced features, offering dynamic buffer management that continuously adjusts safety stock levels based on real-time data.

Real-world results speak volumes.

A coffee retail chain used ThroughPut AI to reduce excess inventory by 15% while maintaining high service levels. Another company – a retail megacorp optimized its product mix and improved margins by up to €30 million.

Try out ThroughPut AI and book a free demo here.

FAQ – Dynamic Buffer Inventory Planning for Supply Chain Resilience

Question: How can COOs reduce excess buffer stock without increasing stockouts?

Answer: By using dynamic buffer management powered by AI, you can recalibrate safety stock based on real-time variability.

Question: What is the ROI of AI-driven buffer inventory planning?

Answer: Most enterprises achieve measurable ROI in 4–12 weeks, primarily through reduced working capital and fewer supply disruptions.

Question: What data is needed for accurate buffer inventory optimization?

Answer: ERP data, lead times, supplier performance, demand velocity, POS data, and material movement data.

Question: Can AI reduce working capital by adjusting buffer inventory?

Answer: Yes — AI identifies where capital is over-allocated and automatically corrects buffer levels.

Question: How does dynamic buffer management help CFOs?

Answer: It reduces cash trapped in inventory while protecting service levels.

Question: Does buffer optimization work for volatile markets?

Answer: Yes — dynamic buffer management is designed specifically for unpredictable, high-variability environments.

Question: How fast is implementation?

Answer: ThroughPut.ai can connect to existing systems and deliver results in weeks, not months.

Question: Can this help multi-plant or multi-country manufacturing?

Answer: Yes — AI unifies all nodes, demand streams, and supplier inputs for synchronized buffer planning.