How AI-powered Logistics Optimization Software Helped a Cement Manufacturer Optimize Yards Per Hour Utilization and Reduce CO₂ Emissions

Summary of the Impact

An industry-leading innovator in sustainable building solutions, this cement manufacturer used ThroughPut AI Logistics Optimization capabilities to achieve the following results:

- Improve operational efficiency with smarter asset utilization

- Reduce CO2 emission

- Achieve multi-dimensional customer segmentation

Explore the full case study below, or download it directly using the button provided.

About the Cement Manufacturer

Powered by its mission to drive progress for people as well as the planet, this company’s 60,000 employees are dedicated to decarbonizing buildings and improving living standards for everyone.

Around the world, with its extensive range of low-carbon, circular solutions, the company enables its customers to build better with less. Its innovative systems drive energy efficiency and green retrofitting in buildings, significantly boosting their sustainability. Led by its sustainability-centered strategy, the company is fast turning into a net-zero company and has 1.5°C targets validated by SBTi.

Logistics Challenges Faced by the Cement Manufacturer

Ready Mixed Concrete (RMC) is one of the most popular building materials in the modern construction industry, due to the several benefits that it offers over conventionally prepared concrete. Unfortunately, it has to be prepared on request. It cannot be stocked at batch plants as it solidifies quickly, and needs to be poured within 1–2 hours of being produced. This limits the service area of RMC batch plants, making production scheduling and truck dispatching a challenge.

Despite its laser focus on sustainability, the client’s trucks were not operating at maximum efficiency – in terms of travel time, time at site (including pouring time), and trips per vehicle. The company wanted to improve asset utilization of its trucks, while at the same time reducing carbon emissions. From this perspective, the company’s top challenges were:

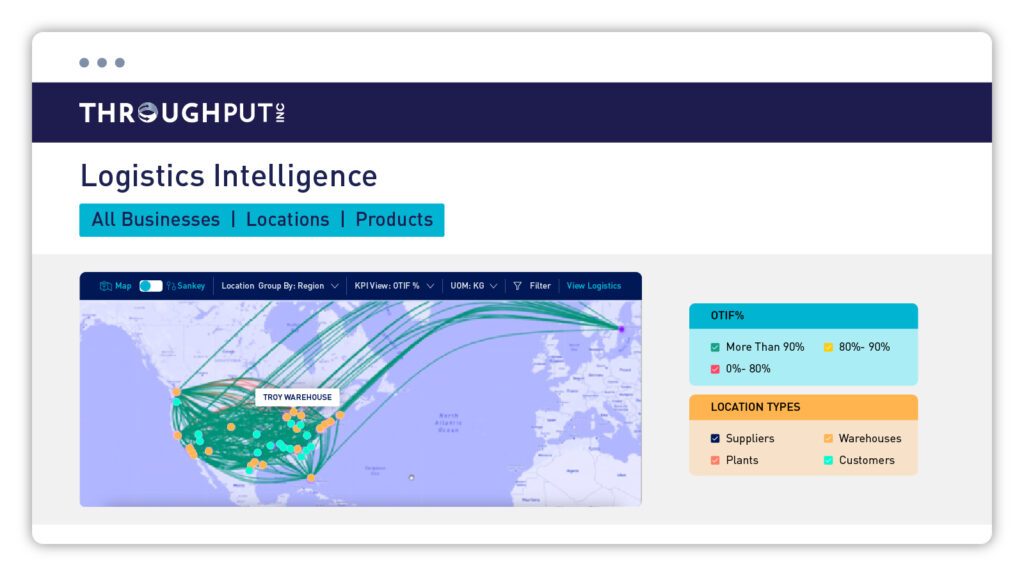

Network Optimization

With thousands of truck movements per day, it wanted granular visibility into the real-time pulse of its operations. In particular, the company wanted to:

- Identify truck route sources as most efficient versus least efficient/wasteful.

- Segment trips by the plant for a closer look at efficiencies. Identify plants with high travel times.

- Analyze why trucks did not always source material from the nearest plant.

- Shift customer clusters to optimize network routes better.

- Identify potential locations for new plants for further optimization.

- Evaluate missed delivery windows, unrealized sales, wasted round trips, and excess CO2 emissions and waste.

Effective Customer Segmentation for Optimized Truck Utilization

The company wanted to affect a 360°, multidimensional customer segmentation based on several KPIs, including:

- Volume (cubic yards delivered)

- Frequency (number of weeks with active orders)

- Recency (time since last customer interaction)

- Distribution (number of active sites)

- Specialty

- Efficiency (time at site, wait time, pouring time, On Time In Full – OTIF deliveries with demand ≥ 90% and time on site < 60 minutes, percentage recall)

The goal was to track customer relationships over time, strategically segment them into tiers, and prioritize prime delivery times for more effective delivery planning, demand fulfillment, and overall performance.

CO2 Emission

Finally, given the company’s commitment to sustainability, there was a need to find an immediate solution to minimize CO2 emissions and waste. This would in turn help achieve improved operational efficiencies and ROI. The company therefore wanted to find out where the maximum time and CO2 wastage was happening across its operations, whether it was happening while:

- Waiting at plants

- Loading

- Traveling to jobs

- Waiting at sites

- Pouring

- Washing

- Traveling to plants

The more time wasted, the higher the CO2 emission – meaning the higher the opportunity to cut emissions and waste as well as achieve better financial outcomes.

How the Cement Manufacturer Optimized Yards Per Hour Utilization With AI Logistics Optimization Software

The cement manufacturer used ThroughPut AI to deploy a multilevel framework to accelerate efficiencies for both, the sustainability and operational goals as follows:

- High level: This strategy aimed to establish the areas that the company should focus on. It implemented a strategic, multi-dimensional segmentation of the company’s customer base to arrive at an optimized customer mix for high throughput and delivery efficiency

- Mid-level: At this level, the focus was on identifying the key drivers to drive network design optimization. Strong emphasis was placed on holistic material flow visibility and improved OTIF and travel times.

- Granular level: This consisted of a tactical plan to monitor and analyze daily trips so that the company could highlight areas where asset utilization could be improved and CO2 emission reduced.

As an AI Logistics Optimization tool, ThroughPut AI automatically analyzed data from diverse sources and revealed insights to key questions such as:

- Where is the most time and CO2 being wasted?

- Which customers racked up the maximum time on-site?

- Which ones ended up with higher recall rates?

- What is the frequency of customer interaction?

- How effective is the asset utilization of trucks in terms of yards per hour, or time per cubic yard?

The Impact of Leveraging AI Logistics Optimization Software for the Concrete Manufacturer

Improved Asset Utilization

With ThroughPut AI, the company was able to highlight several opportunities to enhance enhance utilization by:

- Identifying why trucks were not sent to the closest plant.

- Analyzing the reasons for high return travel times (which could then be reduced).

- Reducing/re-prioritizing customers with high on-site times.

- Working with customers to reduce recall rates.

- Identifying where additional plants could be added to cater to high-volume customer sites

Besides the number of trips per vehicle, key time metrics considered were:

- Travel time

- Return travel time

- Time at site

- Pouring wait time

- Pouring time

Top volume routes were highlighted and color-coded – green, yellow, and red – based on travel times to customers. Plants with consistently high order fulfillment times were identified and focused on for flow improvement. The travel times were then reduced through better site-to-customer demand allocation. Thus, defined, actionable recommendations in the form of new plant allocations resulted in measurable positive outcomes by way of reduced number of trips per truck/day – which had an incremental effect on the entire network.

Multidimensional Customer Segmentation

ThroughPut then leveraged the time readings to segment the company’s customer base and re-prioritize deliveries. Actual time on-site was also compared with customer requests-for example, whether a request for 100 cycles/hour was fulfilled at 60 cycles/hour.

ThroughPut thus developed 360 customer scorecards, which also took into account several other KPIs such as:

- Number of jobs

- Total sales volume (cubic yards)

- Load size

- Average distance to plants

- Recall percentage

Customers were then segmented into platinum, gold, silver, bronze, new, and lost tiers and accordingly allocated prime/non-prime delivery times and motivated for better outcomes

CO2 Emission Reduction

The reallocation of plants and re-prioritization of deliveries resulted in a shift of customer clusters, leading to clearly demarcated operational zones with well-defined plant pairings.

Tactical daily truck trip views were then used to flag inefficiencies in –

- Total number of trips

- Volume delivered

- Total time

- Active time

- Idle time

- Average trips per truck

- Median trip time

This data was analyzed to recalculate potential improvement, new trips, and CO2 improvement ranges. With newly introduced efficiencies, there was a significant cumulative impact on CO2 emissions, which were reduced rapidly.

Leverage ThroughPut AI for Logistics Optimization

ThroughPut AI offers distinct and practical advantages that can significantly enhance your logistics operations, just as it did for the cement manufacturer in this case study. By leveraging the power of AI and machine learning, ThroughPut AI goes beyond traditional logistics planning by providing actionable insights that drive real-world improvements. This software’s ability to predict and optimize yard operations in real-time leads to a more streamlined process, reducing bottlenecks and maximizing throughput.

Working with Multiple & Vast Data Sources

One of the key advantages of ThroughPut AI is its capability to process vast amounts of data from various sources, including existing data sources, ranging from typical spreadsheets to ERP platforms, warehouse management systems, etc. to identify patterns that human analysis might overlook. This results in more accurate forecasting and better decision-making, ensuring that resources are allocated where they are needed most. Plus, no time or money is wasted in overhauling existing systems.

Ease of Implementation & Faster ROI

One of the key advantages of ThroughPut AI is its ease of implementation. The platform is designed for quick integration into existing systems, allowing you to start seeing results within just 90 days.

This rapid return on investment makes ThroughPut AI an attractive solution for businesses looking for immediate impact. Furthermore, ThroughPut AI offers the flexibility to scale operations at your own pace. Whether you want to start small and gradually expand or go all-in from the beginning, ThroughPut AI adapts to your unique needs, making it a versatile tool for any logistics environment.

Tailored Solutions for the Cement Industry

ThroughPut AI understands the unique needs and demands of the cement industry. It can be customized to address specific challenges related to yard management, one of the most common issues for logistics managers in the cement industry. ThroughPut AI works with a tailored approach, be it managing truck schedules, handling material flow, or optimizing storage space. Consequently, the business can maximize YPH (Yards Per Hour) utilization while complying with industry regulations and standards.

Advanced Optimization of Algorithms

ThroughPut AI uses the latest optimization algorithms to offer actionable insights that help improve yard efficiency. It accurately predicts traffic patterns, load times, and other critical variables. This way the tool enables the cement manufacturer to optimize yard operations with precision. This data-driven approach reduces idle times, enhances throughput, and ultimately boosts yards per hour utilization, giving the manufacturer a significant competitive edge in the market.

If you are in the cement industry with complex supply chain challenges, ThroughPut AI provides a robust solution that helps you achieve optimal yards her hour utilization and overall logistics excellence.