How AI-powered Retail Logistics Optimization Software Saved € 3.5 Million Per Year for a European Enterprise

Summary of the Impact

An innovative European retail behemoth with 65 years of presence leveraged the power of ThroughPut’s AI-powered retail logistics optimization software demo to drive cost reduction and logistics efficiency and shipment optimization module to:

- Reduce logistics costs by 33% (~€2 million) per year

- Reduce SKU volume by 20% and transportation costs by 33%

- Achieve an OTIF rate of 90%+

- Drive bottom-line impact of up to €10 million per facility via real-time optimization

- Realize €3.5 million savings per year in logistics costs

Download the complete retail logistics optimization case study below.

About the European Retailer

One of the first retailers in the European region to pioneer the transition to organic products and online shopping, this innovative company employs more than 20,000 people across hundreds of stores and warehouses, offering a variety spanning more than 25,000 products across several categories and has been catering to online orders for over 18 years.

Challenges of Retail Logistics Optimization

Retail logistics distribution, despite having undergone considerable improvement over time, faces more disruptions than ever before today. While the advent of e-commerce has disrupted distribution and accelerated service expectations on one hand, it has triggered unprecedented demand on the other. In an industry plagued by low margins (typically 1-3%), this can quickly escalate into a huge problem, because incurring higher distribution costs is not a feasible option in the long term.

The client thus faced the following major challenges related to DC shipment management.

Frequent Disruptions

Thanks to Amazon’s moving benchmark of constantly better delivery times – no matter what the cost – distribution is now complicated beyond imagination, leading to frequent bottlenecks and disruptions. With escalating demand, continuously rising service requirements, and increased operational complexity, there is no room for error – which means that the right shipment needs to be moved at the right time, so that shipment volume as well as logistics costs can be minimized.

Skyrocketing Logistics Costs

Fuel costs are at an all-time high, and when coupled with the rising scarcity of DC labor, are frequently causing logistics costs to overshoot estimates by far. It also does not help when unanticipated demand leads to last-minute, expedited shipping expenses – on top of already flimsy margins. Retailers, therefore, need to accurately sense and plan for demand, and trickle down that data to enable effective shipment optimization – with fewer outlier events and spiraling fallouts by way of cost.

Rise of E-commerce and Rapid Order Fulfillment

The rise of e-commerce, which has triggered the need for DCs that can house an extensive variety of products as well as support on-demand shipment to customers, has placed significant pressure on DCs everywhere. The constantly growing emphasis on expedited delivery of a diverse range of products further strains DCs, forcing retailers to exercise extreme care and walk a narrow line to guarantee quick order fulfillment without incurring uncontrollable shipping costs.

Ability to Adapt Inventory Levels in Response to Demand Variance

A lot of the time, demand is seasonal. Thus, something that is witnessing high demand today may not be as popular tomorrow, or maybe next month. This means that inventory needs to be positioned just right to support ready access to products with varying demands, still without racking up additional costs in the form of unnecessary movement of goods, holding cost for too much inventory, or unplanned shipping to make up for insufficient stock.

The client wanted to adopt an intelligent, cognitive approach to its DC shipment operations based on highly precise demand sensing, prediction, and planning – allowing for maximum optimization.

How to Optimize Retail Logistics to Reduce Costs?

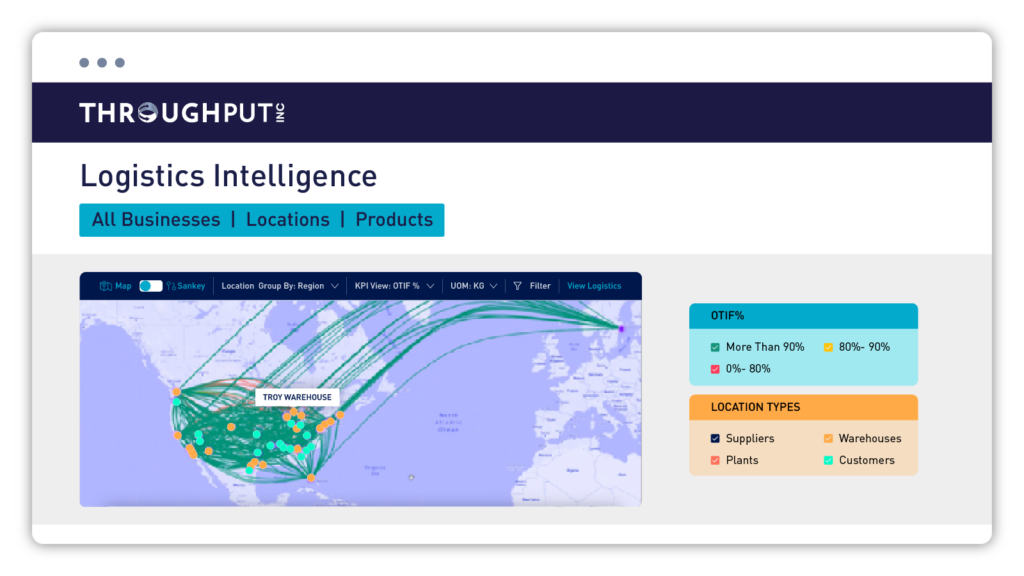

With ThroughPut’s AI-driven logistics management solution, the retailer was able to immediately eliminate unnecessary DC-to-DC shipments, impacting shipment volumes and reducing transportation costs with an OTIF rate of over 90%.

After years of using siloed data systems and manual Excel sheet calculations, the retail logistics group was finally able to clearly view an SKU-level demand-value matrix, based on which shipments could be prioritized and optimized to reduce logistics costs and enhance free cash flow.

The solutions offered by the tool make it an ideal retail logistics case study. Here’s how and why.

Revised Allocation Practices for Prioritized SKUs

With custom AI the client identified its top 150 SKUs and revised the allocations for them, immediately realizing logistics savings of up to €2 million per year. ThroughPut AI enabled the client to ship the right stock to the right DC, starting all the way from supplier deliveries. This eliminated all unnecessary logistics and also cleared the path for more effective utilization of existing resources.

Dynamic Adjustment of Distribution per DC

All SKUs were subject to a granular as well as flow analysis, which provided immediate insights into how to reduce shipment volume. Indirect as well as transfer shipments were dynamically adjusted in response to shifts in demand, making it possible to realize savings of €3-6.5 million per year.

Impact of Retail Logistics Optimization on Cost Reduction

ThroughPut’s AI enabled the client to minimize logistics costs consistently, while at the same time ensuring healthy inventory levels and turnover.

- Reduced logistics costs by 33% (~€2 million) per year by reprioritizing shipments and eliminating unnecessary ones

- Identified 10 more items that reduced shipment volume by 20% overall

- Flagged 200 items with sporadic demand and bad OTIFs for internal transfer to the right DC

- Drove bottom-line impact of up to €10 million per facility via real-time optimization

Explore the ThroughPut AI logistics optimization case study

Benefits of Retail Logistics Optimization

ROI in 90 Days

ThroughPut AI for retail logistics optimization offers a rapid return on investment, with many businesses seeing measurable results almost within 90 days of implementation. By leveraging AI-driven insights, organizations are able to quickly identify inefficiencies, reduce costs, and optimize their supply chain processes.

It is like your ROI is on the fast-track mode with ThrouhgPut AI. No lengthy implementation periods. And immediate observable impacts! The tool helps streamline operations and improve decision-making. This in turn, accelerates profitability, making it a valuable tool for companies looking to enhance their operational efficiency swiftly.

Work with Existing Data

ThroughPut AI starts to work immediately – as soon as it is integrated with your existing infrastructure. That’s because it can work with the existing data – no need to overhaul the present systems or implement new data sources.

The tool uses historical data that your organization already has and converts it into actionable insights. Thus, you do not have to deal with the initial complexities or costs associated with shifting to new data management systems. Businesses can unlock hidden potential and maximize the capabilities of their existing data with ThroughPut AI.

Customizable to Your Industry

A big advantage of ThroughtPut AI is its flexibility to adapt across different industrial domains. The tool works across industries, be it manufacturing, retail logistics, or cement to address the unique challenges of your sector. This flexibility ensures that the insights generated are relevant to your specific operational needs, providing actionable recommendations tailored to your environment. ThroughPut AI’s industry-specific customization allows businesses to optimize workflows, reduce bottlenecks, and enhance overall performance. It is a solution that comprehends your market’s nuances flawlessly.

Patented Algorithms for Analytics

The core of ThroughPut AI is its advanced, patented algorithm technology, powered by AI and designed to analyze vast amounts of data quickly and accurately. These are proprietary algorithms that go beyond standard analytics. With AI and ML, the tool offers deeper insights into operational efficiency, demand forecasting, and resource optimization. By leveraging this new-age technology, businesses can make data-driven decisions with better accuracy. The use of patented algorithms ensures that ThroughPut AI offers a unique and innovative approach to supply chain management, enabling you to stay ahead of your competitors in delivering insightful, actionable analytics.

Ready to see it in action? Schedule a demo for AI retail logistics software and discover how ThroughPut.ai can accelerate your cost-reduction goals.