How Can Large Retail Companies Leverage ThroughPut To Optimize Their Product Mix

Your company’s product mix can literally make or break your business. If you offer a strict product line or the wrong product mix, you could leave your customers dissatisfied and not capture enough market share.

On the other hand, if you end up adding too many or an over-extended product mix, you can overwhelm your customers and even more, your supply chain.

Choosing the “just right” product mix that maximizes your revenue would be ideal but unfortunately, it is not as easy as it sounds, especially with the wildly fluctuating customer demand and concurrent market disruptions.

The Challenges of Handling Large Retail Product Lines

Managing a large product portfolio of hundreds and thousands of SKUs is hard in itself given all the complexity. With different demand patterns, lead times and sourcing requirements for each product, effectively managing the end-to-end supply chain without running into stockouts and pile-ups is a unique challenge in itself.

In the midst of all that day-to-day operational and planning demands, getting a more strategic perspective on figuring out the “right product mix” often takes a backseat and for multiple reasons:

- Failure To Get A Data-Driven Demand Perspective of the Large Portfolio

Gaining a comprehensive understanding of retail demand for each product is crucial for enhancing operational efficiency, reducing costs, and enhancing the customer experience.

However, in the absence of a data-driven approach to comprehend demand for so many different products, planners struggle to prioritize and efficiently allocate resources to products that yield worthwhile returns on investment.

For example, utilizing demand data enables businesses to address essential questions, such as identifying which SKUs generate positive margins and how profit margins fluctuate in response to product value and demand variations.

- Presence Of Low-Value SKUs

Without an accurate demand forecasting approach, companies have poor visibility into SKUs with low value and low demand, stripping them off the ability to eliminate or reduce these products.

Ideally, this strategic move would create more opportunities to produce higher-value, higher-demand products that could significantly impact the bottom line and sales margins. Packaging, space allocation, and stock replenishment could be carefully planned to ensure consistent availability of “never-out-of-stock” products while freeing up the capacity to experiment with new products.

This exercise would also additionally aid in minimizing transportation costs, ultimately leading to a substantial impact on the bottom line.

- Increase In Operational And Material Expenses

When product mix is not optimized by eliminating or deprioritizing underperforming SKUs, companies, in turn, see escalating material and operational investments and choke up capacity which could ideally have been utilized in producing larger value orders. This further impacts inventory buffers and free cash flow.

- Rise In Logistics Expenses

By narrowing the focus to the most relevant SKUs, businesses can, ideally, allocate more resources towards meeting customers’ quality expectations and, importantly, ensuring on-time and complete deliveries (OTIF). However, inability to prioritize SKUs leads to poor planning and numerous unplanned deliveries that often incur costly expedited shipping expenses.

How Can You Optimize Your Product Mix Using ThroughPut?

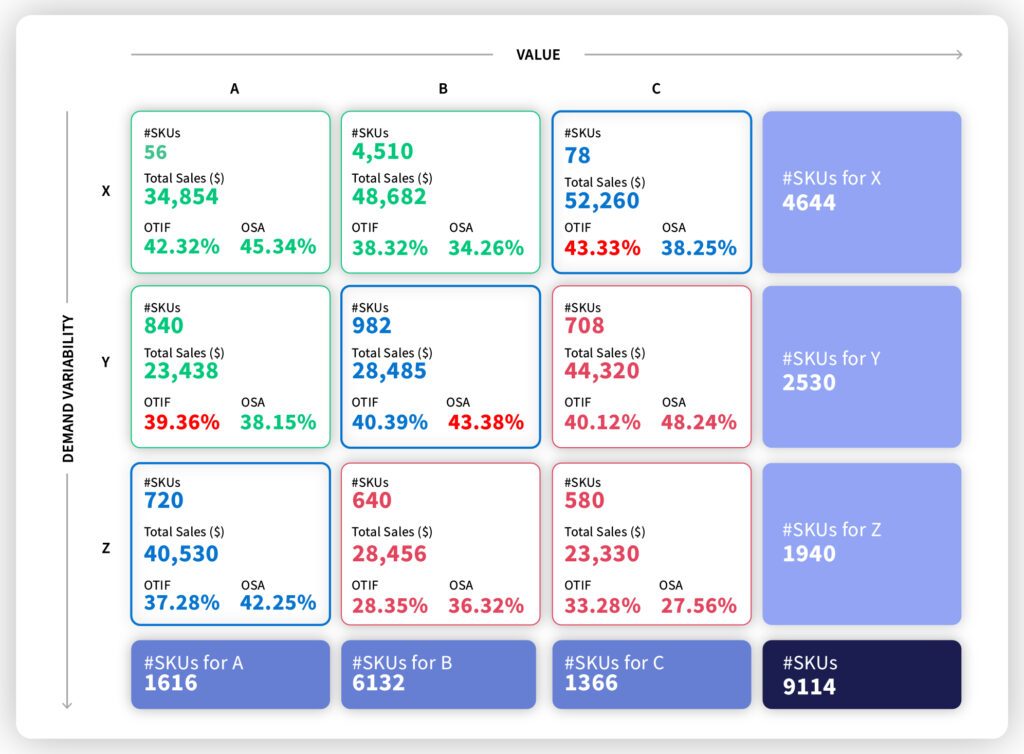

With ThroughPut’s AI-powered product mix rationalization solution, you can automatically segregate thousands of SKUs based on the demand-value matrix, letting you identify both, your “high-value, high-demand” SKUs and your “low-value, low-demand” SKUs.

With this level of visibility and understanding, you can then prioritize the right products (“high-value, high-demand”) and eliminate or de-prioritize the others to free up capacity and capital for the production of your hot-selling products and even add new products if required.

Considering demand fluctuates at the blink of an eye in the post-COVID world, ThroughPut’s solution predicts short-term and near-term demand to dynamically adjust the demand-value matrix and show you the right product mix on the go and in real-time.

The platform does this by leveraging a company’s time-stamped sales datapoint along with external data like seasonality, weather, etc. to support real-time product mix rationalization. For a lot of retail businesses, product mix optimization on auto-pilot comes as a ready relief after using siloed data systems and manual Excel calculations for years.

They can now precisely predict demand in real-time and work towards streamlining the product mix for the highest sales, profits, and inventory turnover while reducing transportation expenses. Low-value SKUs with low demand can be promptly eliminated, freeing up resources for more efficient utilization.

Product mix optimization can have a positive snowball effect on every other function in the supply chain. For instance, after optimizing the SKUs based on demand and value, logistics planning can become more efficient, resulting in the minimal need for unplanned expedited deliveries and the associated charges.

The allocation, packaging, and distribution of SKUs also become significantly streamlined, leading to smoother operations throughout the value chain.

By aligning the SKUs with customer demand, businesses could enhance logistics processes, reduce costs, and ensure a seamless flow of products from production to delivery.

Case Study: Impact Of Product Mix Optimization With ThroughPut

A European Retail MegaCorp optimized its 15000+ SKU product mix using ThroughPut’s SKU rationalization solution. As a result:

- The company recognized the opportunity to lead a bottom-line impact of €10 million for every facility

- It further reduced its operational cost by €2 million with the efficient use of 150 SKUs

- It recognized 200 products with irregular demands and bad OTIF fulfillment rates

With ThroughPut, large retail companies can analyze and optimize their product mix to achieve better financial standing.

As a platform, ThroughPut marries a financial outlook into every part of the optimization so you not only improve operations but can also have an informed perspective on the impact of the optimization on the company’s bottom line.

Check out more case studies on how ThroughPut AI has been enabling large retail companies across the globe.