Cement Logistics: How Supply Chain Intelligence Can Accelerate Material & Cash Flow in 2026

It is no exaggeration that cement production drives the economy. From roads to buildings and manufacturing, the entire economy can come to a standstill if cement is not available at the right time, in the right quantity, and at the right place.

Yet, despite this huge opportunity, a lot of manufacturers are struggling with inventory and cement logistics challenges failing to make the best of this golden opportunity at hand. Without a stable, responsive, and scalable supply chain, catering to the growing demands of customers is nearly impossible.

Cement logistics is a cost center that is holding back the efficiency, performance, and growth of this industry. Naturally, it makes sense to start your supply chain optimization efforts here.

But before that, let’s delve a little deeper into the challenges faced in cement logistics and how it is impacting your entire supply chain and the business.

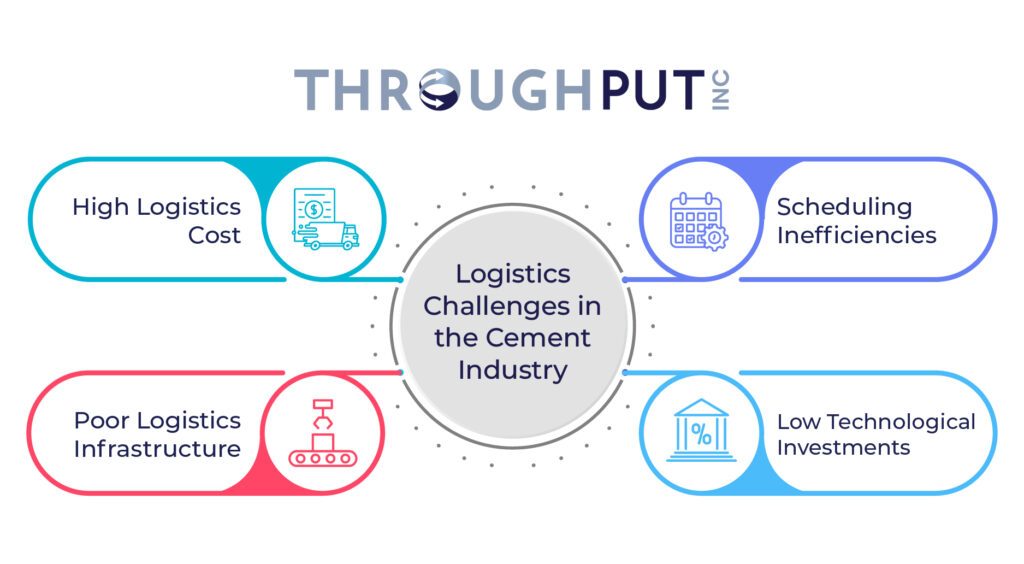

“Logistics” Challenges in the Cement Industry

As a cement manufacturer, you know how challenges in this space have been both intense and longstanding.

Firstly, the demand for cement often surpasses the production and delivery capacity. With the infrastructure industry and construction projects booming and demand fluctuating, it has become difficult for cement producers to keep up with the demand.

Some of the challenges in this regard are:

1. High Logistics Cost

Poor logistics management in the cement industry leads to revenue-related challenges. Transport, inventory, and time-related costs are the three most problematic areas of them all.

Cement transportation involves bulk movement and the total weight increases the freight costs. Additionally, cement is perishable, which is why there is a further need to optimize logistics for time sensitivity in the sector. This requirement for delivery within strict time frames ensures its freshness and usability, making logistics management in the cement industry even more complex and rather cost-sensitive.

Furthermore, consider transportation costs related to both inward and outward movements of raw materials and finished products. The movement of raw materials like gypsum, limestone, coal, etc., the movement of clinker to grinding units, and the outward movement of finished cement to the marketplace are critical time-bound components that can escalate costs.

2. Scheduling Inefficiencies

Scheduling inefficiencies is another challenge that plagues logistics in the cement industry. Inaccurate scheduling leads to wasted yards per hour during production, causing productivity losses and increased emissions.

Plus, inefficient scheduling also adds unnecessary costs to the entire supply chain.

Inevitably, these scheduling inefficiencies trickle down to missed deliveries. These missed deliveries not only lead to unrealized sales but also further contribute to increased emissions due to additional transportation efforts.

3. Poor Logistics Infrastructure

Another reason for the increase in the freight costs of cement is that commodities like cement need to be transported in bulk. In such cases, road transportation can be expensive and unreliable due to long transit times and high fuel costs. Vehicular movement restrictions add up to the woes of cement manufacturing companies.

In many countries where the road network is cluttered with unorganized players and due to the absence of the proper infrastructure, rail freight is the preferred mode. However, even rail transportation has its own challenges even though it is far more economical than roadways.

The lack of trackability makes it unreliable. Mini or small plant manufacturers face major problems in the procurement of railway rakes/wagons, especially during peak periods.

4. Low Technological Investments

Logistics in the cement industry globally also suffers from the slow adoption of advanced technologies and automated methods. Even though cement companies have tons of data at their disposal, they still fail to optimize this data due to low investments in technologies that deal in data science.

Similarly, the use of state-of-the-art tools to automate operations and the lack of know-how about using technology to track goods movement also add to the existing challenges of this industry.

Overall, the lack of integrated end-to-end supply chain planning and optimization creates major operational challenges for cement manufacturers. All these challenges together contribute to rapidly eroding margins for cement producers, putting further pressure on their profitability and sustainability, and also crippling their ability to grow and capture more market share!

Of course, addressing these persistent challenges can significantly impact the bottom line of your business. But to do so, you also need to approach the logistics problem more holistically.

Aiming to solve the challenges in cement logistics without considering its interdependence with other functions in the supply chain may only escalate the problem rather than resolve it.

How to Reduce Cement Logistics Costs With Supply Chain Intelligence?

The logistics problem in the cement industry is not an isolated one. That’s why a mere track and trace point solution for logistics alone may resolve your logistics problems, sure, but without a view of how your entire cement supply chain functions interdependently, this effort may not result in a significant bottom-line impact. It may even be counterproductive.

For instance, and to give the easiest example, cutting costs by reducing the number of trucks without considering its impact on other functions will lead to delays in delivery and upset customers!

A more ideal way to solve your issues related to logistics in the cement industry would be to take a holistic approach to logistics optimization.

Prioritize gaining end-to-end visibility of your supply chain and then identify areas of improvement within and outside the logistics function. This can have a direct and immediate impact on your logistics operational efficiency and also your bottom line.

Let us understand it better.

ThroughPut AI’s 360° Cement Logistics Intelligence leverages real-time data to enable you to benefit from:

- Accelerated material and cash flow

- Rapid, real-time understanding of complex logistics operations

- Agile, efficient logistics networks that adapt to volatile demand on the fly

- Prioritization of deliveries based on sales value as well as time sensitivity

You’ll be able to gain control over your cement logistics operations with a strategic and holistic view of your end-to-end supply chain, while gaining access to recommendations that will help you drive intelligent, data-informed decisions that can guarantee positive business outcomes – and value.

At a granular level, you will be able to:

- Access actionable insights into where operations are lagging, along with recommendations to achieve a smooth, seamless movement of material.

- Achieve real-time responsiveness to demand for faster delivery, while at the same time adapting to shifting customers, capacity constraints, and inflation.

- Improve order prioritization based on spend and underlying sales improvement potential.

- Affect a high rate of OTIFs (based on real-time data on carrier routes, port congestions, and runtime incidents layered over historical and planned delivery schedules and trends).

- Automatically reroute materials and associated purchase orders to optimize resources and market conditions at any point in time.

- Eliminate supply chain bottlenecks through proactive management of critical issues across the cement value stream.

ThroughPut AI helps cement logistics businesses to go beyond being able to merely track and trace material flow and allows them to instead focus on optimization of operations from procurement to distribution.

More importantly, you can leverage real-time data to predict demand with razor-sharp precision, allowing operational decisions to adapt to exceptions on the go. You no longer need to over-order or over-produce (make to stock), leading to inventory pile-up at both ends of your supply chain.

With ThroughPut AI, you can also predict demand variance, thus gaining the ability to proactively prepare for it by quickly optimizing your product offerings and reassigning material flow in real time.

The result?

The right output at the right place and the right time, and maximized profit margins – which can, in turn, be re-invested to grow manufacturing capacity.

Key Features of ThroughPut AI for Cement Logistics

- Full visibility of materials – across all legs and modes – in the value chain to quickly gain insights into areas where operations are lagging.

- Ability to review the impact of logistics performance on OTIF (fulfillment of orders from the stores), sales, and contribution to indirect logistics cost.

- Data and AI-driven intelligent recommendations that enable proactive decision-making to adapt operations on the fly.

- Ability to adopt a demand-driven approach to sales rather than a supply-driven one.

- Holistic and granular views for the flow of a particular SKU (or a cluster of selected SKUs) all the way from the supplier through the distribution network to stores, and ultimately to sales.

- Ability to easily identify tactical opportunities for improvement with assessment of bottom-line benefits associated with each opportunity.

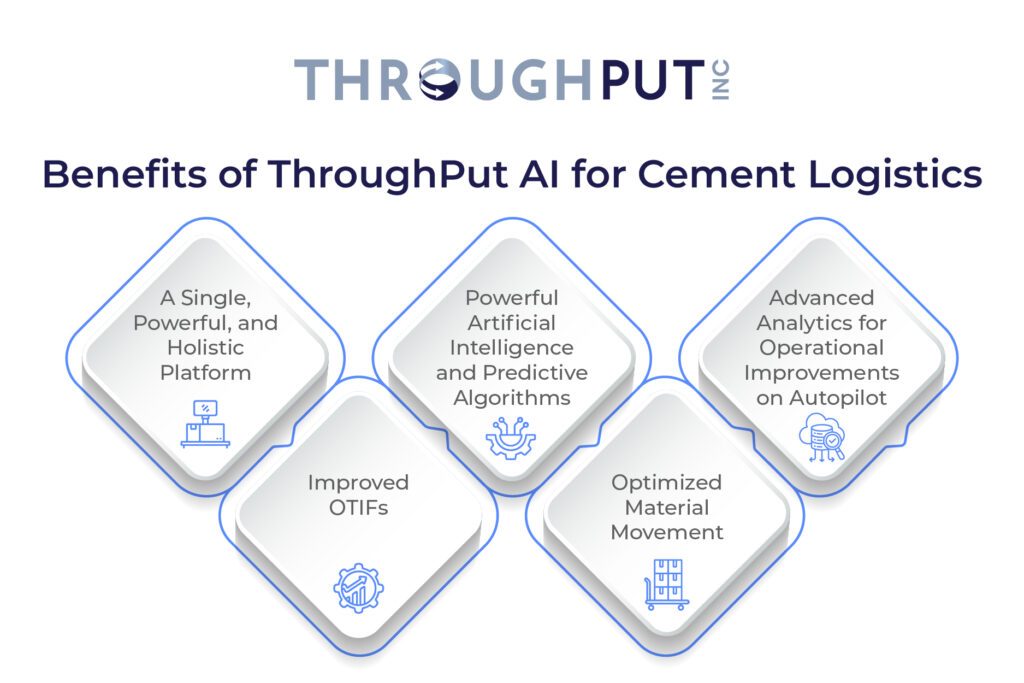

Benefits of ThroughPut AI for Cement Logistics

1. A Single, Powerful, and Holistic Platform

ThroughPut AI analyzes real-time data from across your cement logistics network and provides a centralized, holistic view of all shipments – stationary, in transit, or delayed.

With a leg-by-leg view across the entire journey via an interactive map that highlights current as well as potential bottlenecks, you can easily reroute materials to sidestep disruptions and ensure continuous operations.

2. Improved OTIFs

In the cement logistics industry, there is an overwhelming number of shipments and legs to track at any point in time. Manually tracking the details of every shipment – even if they stick to schedule – is impossible.

ThroughPut AI automates tracking of all shipments at scale with the help of AI in transportation and logistics. It also provides insights into when they deviate from the plan. Thus, critical supply chain issues across the cement value stream can be managed proactively and in real-time to avoid runtime bottlenecks, and businesses can automatically reroute materials in a manner that optimizes given conditions at any point in time.

Finally, with predictive tracking and ETAs, they can continuously track shipments and associated purchase orders, line items, or SKUs to keep improving and optimizing inventory management.

3. Powerful Artificial Intelligence and Predictive Algorithms

With the ability to predict unplanned disruptions, logistics teams acquire the ability to be data-driven and proactive rather than reactive.

ThroughPut AI’s powerful machine learning, artificial intelligence and predictive algorithms allow you to gain a whole new level of analytical capabilities – and intelligence – for logistics operations.

Using real-time data about cement carrier routes, port congestion, and runtime incidents layered over planned delivery schedules and historical trends, ThroughPut AI makes it possible to accurately predict ETAs and achieve a high rate of OTIFs.

4. Optimized Material Movement

ThroughPut AI has a proven track record of helping logistics businesses sustain agile operations that accelerate the shipping of the right goods at the right time while minimizing runtime costs and risks.

You can thus plan your shipments, book capacity, and track progress in real-time, at the same time adapting to capacity limits, rising costs, demand for faster delivery, and changing customer priorities.

Using a combination of business rule mapping and ML-based pattern extraction, you can dynamically prioritize items based on logistics costs, lost sales opportunities, and more.

5. Advanced Analytics for Operational Improvements on Autopilot

ThroughPut AI’s powerful artificial intelligence offers intelligent recommendations in real time to optimize overall shipment time, minimize demurrage, and maximize on-time, in-full (OTIF) delivery.

With ThroughPut AI, cement manufacturing and logistics operations and supply chain processes benefit from an infinite loop of intelligence. Our easily configurable dashboards and reports give shippers the ability to leverage the data for past shipments to plan increasingly intelligent future operations.

Simplify Cement Logistics With Supply Chain Intelligence

To summarize, optimizing cement logistics with supply chain intelligence can significantly impact cash flow and material.

With the help of advanced analytics and real-time data, logistics planning for building materials and the cement industry can be streamlined to enhance operational efficiency and reduce bottlenecks.

This shift to supply chain intelligence leads to cost savings and boosts customer satisfaction through reliable and timely deliveries.

ThroughPut AI harnesses AI-powered demand planning for building materials and the cement industry, providing actionable insights, and helping cement businesses make smarter and faster decisions, thus, boosting better outcomes for their supply chains.

Adopting new-age innovations is a prerequisite for cement companies to stay competitive in an ever-evolving cement industry.