In today’s fast paced industrial world, inventory mismanagement poses substantial financial risks. With approximately $30 trillion of trade flowing from node to node, inventory rebalancing or mismanagement contributes to two major and often preventable issues: lost uptime, and lost sales.

The Hidden Cost of Lost Uptime

According to a Siemens report, in 2022 alone, unplanned downtime cost Fortune Global 500 companies $1.5 trillion. ThroughPut estimates $100 billion of this was due to parts-related downtime, showing the importance of inventory management.

Lost Sales: A Preventable Loss of Potential Revenue

Harvard Business Review reports that stockouts cost retailers $1 trillion yearly, with most purchases abandoned when items are unavailable.

Business Challenge

Replenishment: Lack of coordination of demand forecasting and inventory planning at a pan-organizational level.

Procurement: Parts procurement considers many factors, including demand, intelligence, risk, compliance, collaboration, delivery, and supplier availability.

Sourcing & Maintenance: Asset maintenance involves timely sourcing of the right parts that need to be available at the right time and in the right place to ensure optimal maintenance and operational continuity.

Business Continuity: Difficult to plan and optimize production schedules, operations, resources, capacity, yield, and predictive asset maintenance, leading to costly asset failure and downtime.

Business Impact

Replenishment: Difficult to automate inventory replenishment, waste reduction, and market-responsive production, while minimizing costs and maximizing margins.

Procurement: Complex to efficiently process many factors – at scale, in real time, and cost-effectively – leading to frequent operational disruptions.

Sourcing & Maintenance: Unable to minimize revenue risk through proactive optimization of working capital, production, and pricing.

Business Continuity: Businesses need to move beyond manual processes and spreadsheets to effectively address these challenges, ensure customer satisfaction, and maximize sales potential.

The Solution: ThroughPut.AI Inventory Management for Dynamic Lead times

ThroughPut.AI provides a Supply Chain Decision Intelligence platform that pulls together different parts of the inventory chain and meshes them together to standardize the logic for how businesses manage their inventory for critical issues such as lost sales and uptime, and inefficiencies in stock management. Thus organizations can proactively and dynamically rebalance inventory levels, allowing them to significantly unlock working capital while also avoiding overstocking or understocking their inventories and enhance their market responsiveness by tracking and categorizing real-time usage and expected supply lead times – ensuring the availability of the right inventory in the right quantities at the right time in the right place.

ThroughPut.AI Inventory Management highlights opportunities to cancel unnecessary planned orders, directly ship to inventory staging locations, and move existing spare stock faster internally, effectively rebalancing and optimizing supply chain processes end-to-end, from existing suppliers to individual staging and end-points. ThroughPut.AI’s innovative, patented AI and ML algorithms and processes for inventory flow management around bottlenecks help improve product availability while at the same time reducing material waste and unnecessary spend.ThroughPut.AI employs a range of strategies to ensure inventory is effectively rebalanced across demand points, reducing overstock and understock situations that can cripple operations and financial performance.

ThroughPut.AI focuses on the following key strategies to achieve optimal inventory management:

- Rebalancing Available Inventory: Fast logistics to move inventory from locations with surplus inventory to those with shortages, ensuring that starved demand points are adequately supplied.

- Auditing Producers and Suppliers: Monitor and audit suppliers and producers to identify those that consistently fail to meet quantity requirements, ensuring that only reliable partners are engaged.

- Carrier Audits: Audit carriers who frequently delay deliveries, helping businesses select more dependable logistics partners.

- Reducing Overstock: Actively cancel unnecessary orders, reallocating budgets to areas where inventory is lacking – thereby optimizing resource usage and preventing capital from being tied up in excess stock.

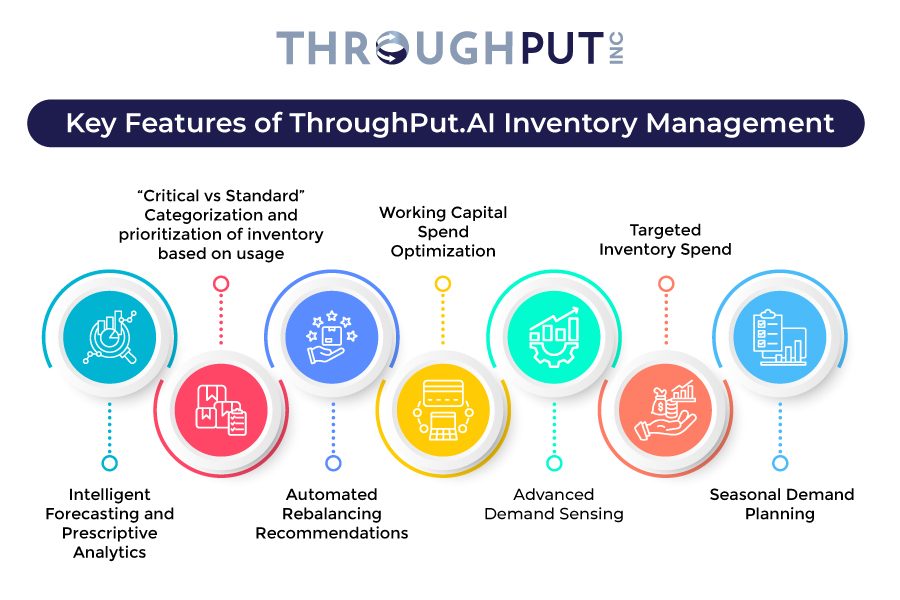

Key Features of ThroughPut.AI Inventory Management

1. Intelligent Forecasting and Prescriptive Analytics

Unlike traditional systems that provide retrospective data, ThroughPut.AI forecasts inventory needs up to 120 days in advance. In contrast to conventional and outdated solutions that operate on fixed orcontractual lead times, ThroughPut.AI considers dynamic lead times and inventory consumption rates to offer prescriptive analytics, guiding businesses on what to expect in terms of demand, and how to adjust daily, weekly, monthly, or quarterly budgets to avoid overspending or underspending on inventory.

2. “Critical vs Standard” Categorization and prioritization of inventory based on usage

ThroughPut.AI intelligently categorizes inventory to identify what to prioritize at SKU grouping and product line level, enabling businesses to focus on the stock that is most impactful for sales. This is particularly valuable for managing product lines to see if and where they are overspending or underspending, bucket those items appropriately.

3. Automated Rebalancing Recommendations

ThroughPut.AI addresses the critical challenge of inventory understocking and overstocking by identifying items that are overstocked, tying up capital unnecessarily, and those that are understocked, risking loss of sales and downtime. It then recommends redistributing inventory from overstocked locations to understocked ones, ensuring optimal stock levels across all sites, while taking into account lead times, in-transit inventory, buffer stock, and upcoming orders to provide precise, actionable insights.

4. Working Capital Spend Optimization

By identifying areas where capital is unnecessarily tied up, ThroughPut.AI helps businesses optimize the flow of goods, cash, and profits, accelerating revenue and margin growth.

5. Advanced Demand Sensing

ThroughPut.AI factors in market trends and customer priorities, improving the accuracy of inventory planning – thus helping businesses enhance their market competitiveness.

6. Targeted Inventory Spend

ThroughPut.AI sets precise targets for inventory levels and identifies opportunities to reduce stock where needed, helping businesses minimize carrying costs while improving service levels.

7. Seasonal Demand Planning

The system dynamically adapts to seasonal demand variations, ensuring that businesses are prepared for peak periods without overstocking.

Benefits: Why AI-Driven Inventory Rebalancing Matters

- Maximum output at optimized inventory levels

- Greater inventory planning reliability

- Rapid reduction of shortages and associated costs by auditing and eliminating unreliable, unprofitable, and suboptimal suppliers and carrier options

- Significantly reduced working capital spend

- Elimination of bottlenecks, downtime, and opportunity losses

- Intelligent dynamic recommendations for inventory rebalancing and replenishment at the SKU level

- Categorization and prioritization (critical vs standard) of inventory based on usage

- Improved inventory availability and reduced waste

- Optimization of profitability and working capital simultaneously for greater returns

How ThroughPut.AI Inventory Management Works:

Step 1: Right-Size Inventory by Real-Time Lead Times

Step 2: Dynamically Recommend Orders and Flag Urgent Stock Outs

Step 3: Predict Order Cancellation Opportunities

Why ThroughPut.AI Inventory Management Software

ThroughPut.AI Inventory Rebalancing solution provides a dynamic approach by leveraging real lead times and real-time data as well as historical patterns, and layering them with predictive algorithms to ensure that inventory is balanced across the supply chain, from production facilities to end customers. By providing better visibility, intelligent predictions, and real-time decision-making capabilities, ThroughPut.AI enables businesses to optimize inventory levels, reduce downtime, and capture sales opportunities.