Just-In-Time Management – How to Manage Inventory in 2025

The Just-In-Time inventory management approach revolutionized manufacturing forever.

Though this topic has been thoroughly researched, its basics and practical advice on successfully implementing it have often been overlooked in the endless blog posts on Google search results pages.

To help out fellow supply chain experts and professionals, we’ve crafted this guide to deepen your comprehension of Just-In-Time, illuminating its fundamental principles, myriad benefits, strategic implementation, and the challenges that may arise.

With this insight, you’ll be poised to judiciously evaluate and adeptly integrate Just-In-Time into your organizational fabric, thereby sharpening operational acuity and bolstering decision-making prowess.

The knowledge from this guide will boost your organization’s operational effectiveness, cutting costs and driving overall financial performance.

What is Just-In-Time (JIT) Inventory Management?

Just-In-Time (JIT) Inventory Management, also known as lean manufacturing or the Toyota Production System (TPS), is a strategy that aligns raw-material orders from suppliers directly with production schedules.

Its central mission is to curt inventory expenses and amplify operational efficiency by timing the receipt of goods to coincide with their actual need in the manufacturing cycle.

This approach hinges on the manufacturer’s ability to forecast demand precisely, ensuring materials are delivered at the precise moment they are required on the production floor.

At its core, Just-In-Time represents a meticulously calibrated mechanism designed to synchronize material supply with production demand. It’s akin to a precision dance that demands exact forecasting, seamless supplier communication, and an intimate knowledge of the manufacturing process.

When executed effectively, JIT can yield substantial savings and operational enhancements, positioning it as an invaluable tool for supply chain specialists.

The JIT approach relies on five key operational levers:

- Precise Demand Forecasting

- Real-Time Inventory Visibility

- Supplier Coordination

- Pull-Based Replenishment (e.g., Kanban)

- Lean Production Scheduling

How Does Just-In-Time (JIT) Work?

The JIT inventory system works by minimizing inventory and increasing efficiency. It hinges on a harmonious supply chain, precise demand forecasting, and supply chain inventory optimization.

The system must operate in lockstep, a complex task given the numerous components involved. JIT ensures materials are transported to the exact location at the precise time they are needed, enhancing efficiency by reducing the need to store materials before use.

Successful implementation of Just-In-Time also reduces waste and loss by aligning the receipt of goods with the production requirements.

In practical terms, JIT resembles a well-orchestrated ballet, with each participant acutely aware of their movements. It demands an in-depth understanding of every stage of the supply chain, from the initial procurement of raw materials to the delivery of the final product.

When applied successfully, JIT significantly enhances efficiency, reduces costs, and elevates customer satisfaction.

What Does Just-In-Time (JIT) Management Involve?

JIT management involves strategic supply chain management, oversight of the supply chain, modifications to production systems and inventory strategies, and process optimization through ongoing analysis and improvement.

The ultimate aim of JIT inventory is to cultivate a streamlined yet robust supply chain populated by vendors who consistently meet crucial Key Performance Indicators (KPIs) for your company’s production needs.

In essence, Just-In-Time management transcends mere inventory reduction; it’s about forging a more streamlined and effective supply chain.

This involves nurturing solid partnerships with dependable suppliers, adapting production systems to accommodate JIT principles, and perpetually refining processes to achieve peak performance.

Just-In-Time is a all-encompassing strategy that demands a profound comprehension of the supply chain and a dedication to perpetual enhancement.

Core Activities – JIT:

- Supply chain analysis

- Production process optimization

- Strategic vendor collaboration

- Implementation of digital tools

Key Objectives – JIT:

- Reduce non-value-added activities

- Build supplier reliability

- Align production with real-time customer demand

What Kind of Companies Use Just-In-Time (JIT) Inventory Management?

Companies of all sizes across various industries use JIT Inventory Management. Retail giants such as Target Corporation and Walmart Inc. implement JIT strategies to pare down inventory costs while ensuring timely availability of substantial merchandise volumes for their customers.

Similarly, fast-food behemoths like Burger King, Taco Bell, and McDonald’s utilize JIT to guarantee the production of fresh, hot food precisely when ordered.

Moreover, numerous other businesses across a spectrum of sectors also leverage JIT. This includes manufacturers in the automotive, electronics, and aerospace fields and service providers within the healthcare and hospitality realms.

The unifying factor for all these entities is a dedication to operational efficiency and cost reduction, which are the defining features of JIT.

What are the Benefits of Just-In-Time (JIT) Inventory Management?

The benefits of JIT Inventory Management are confers a ongoing quality enhancement, waste reduction, production cost reduction, productivity gains, and stronger supplier partnerships.

It optimizes storage utilization, diminishes storage-related expenses, and shortens manufacturing durations. With JIT, inventory costs are minimized due to the absence of surplus stock and the associated storage fees.

Beyond these measurable gains, JIT also cultivates an organizational culture steeped in continuous improvement and operational efficiency. It prompts employees to critically assess their workflows and seek avenues to minimize waste and bolster efficiency.

This mindset leads to a more engaged and productive workforce, further amplifying JIT’s advantages.

How does Just-In-Time (JIT) Inventory Management Reduce Costs?

JIT Inventory Management reduces costs by eliminating the need for excess inventory and storage costs. It also yields savings by eliminating the necessity to hold inventory intended for unfulfilled or invalid orders.

Moreover, it enhances cash flow by freeing up capital expenditures and channeling working capital into other ventures and product innovation.

Beyond these immediate cost reductions, JIT can also indirectly lower expenses through heightened efficiency and productivity.

Curtailing the time and resources devoted to managing and storing excess inventory, enables employees to concentrate on activities that add more value, such as refining production processes or creating new products.

What are the Principles of Just-In-Time (JIT) Inventory Management?

The principles of JIT Inventory Management are maintaining predictable production, flawless production workflows and machinery, providing exceptional quality in workmanship and products, and a supply chain populated by dependable, vetted vendors.

These principles are not mere suggestions; they form the bedrock of a successful JIT framework. They necessitate a commitment to excellence, a focus on ongoing improvement, and a readiness to invest in the requisite resources and technology.

Businesses can fully harness the benefits of JIT and revolutionize their supply chain operations only when they fully embrace these principles.

How to Implement Just-In-Time (JIT) Inventory Management?

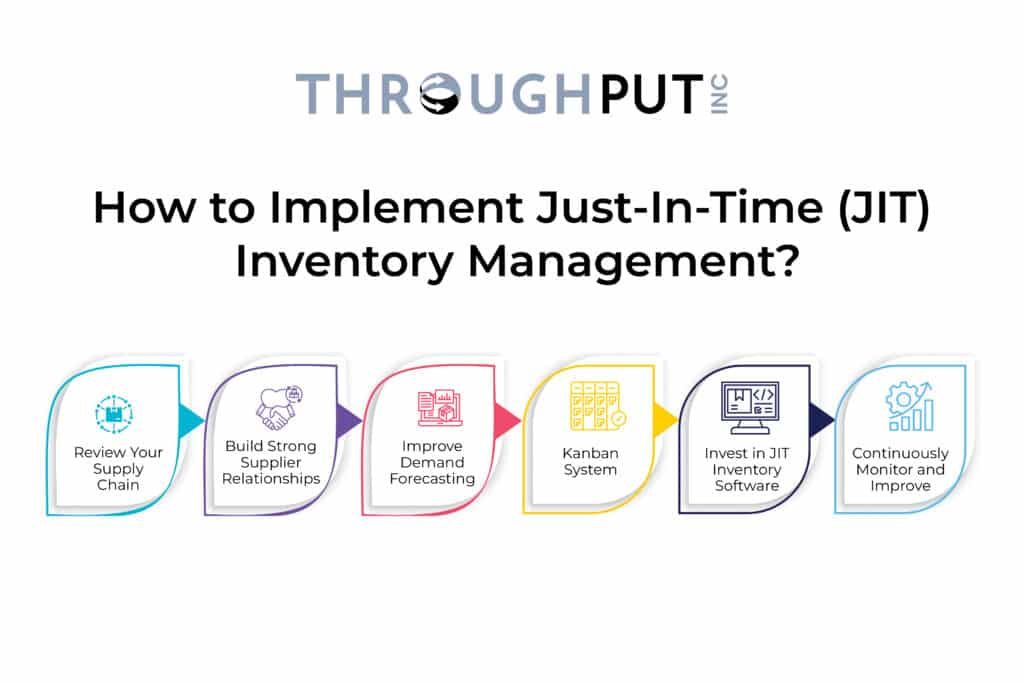

To implement Just-In-Time (JIT) inventory management, thoroughly review your supply chain, build strong supplier relationships, improve demand forecasting, implement a Kanban system, invest in JIT inventory software, and continuously monitor and improve the process to align production closely with actual demand while minimizing excess inventory.

It involves constructing a dependable supply chain, establishing high-quality production and goods standards, and employing state-of-the-art software tools. It’s imperative to grasp both the workings of JIT and the necessary process alterations and resources to support it.

To successfully implement Just-In-Time (JIT) Inventory Management in your supply chain, follow these actionable steps:

- Review Your Supply Chain

Begin by thoroughly examining your supply chain. Identify potential bottlenecks, inefficiencies, and areas for improvement. This step is crucial for understanding the current state of your operations and identifying where JIT principles can be applied. - Build Strong Supplier Relationships

JIT relies heavily on timely and reliable deliveries from suppliers. Therefore, it’s essential to establish strong, long-term relationships with your suppliers. Ensure they understand your requirements and are capable of meeting them consistently. - Improve Demand Forecasting

Accurate demand forecasting is a cornerstone of JIT. Invest in advanced forecasting tools and techniques to predict demand more accurately. This will allow you to align your production schedules more closely with actual demand, reducing the need for excess inventory. - Implement a Kanban System

A Kanban system can be a valuable tool for managing the flow of materials in a JIT system. It provides a visual representation of the production process, helping to identify potential bottlenecks and prevent overproduction. - Invest in JIT Inventory Software

Utilize JIT Inventory Software to automate and streamline the JIT process. This software provides real-time visibility into inventory levels, automates the ordering process, and offers analytics to help optimize supply chain operations. - Continuously Monitor and Improve

JIT is not a one-time event but a continuous process of improvement. Regularly review your supply chain operations, identify areas for improvement, and make necessary adjustments. This will ensure your JIT system remains effective and continues to deliver benefits.

Remember, implementing JIT is an ongoing journey of enhancement and fine-tuning. It requires an intimate understanding of the supply chain, a dedication to quality and efficiency, and the agility to adapt to demand and supply dynamics fluctuations.

With the correct strategy and resources, JIT can serve as a potent instrument for elevating supply chain efficacy and profitability.

What are the Risks of Just-In-Time (JIT) Inventory Management?

The risks of JIT inventory management are a lack of reliable suppliers, supply chain disruptions, unpredictable demand, quality issues, operational hazards, missed opportunities, excessive reliance on forecasts, and the costs associated with local sourcing.

To counter these risks, businesses can implement strategies such as forging robust relationships with trustworthy suppliers, maintaining a safety stock, investing in demand forecasting technology, and instituting quality control protocols.

While these risks are tangible, they can be effectively managed with appropriate strategies and resources. Acknowledgement of the possible challenges of JIT and proactively addressing them enables companies to enjoy the advantages of JIT while minimizing the associated risks.

This approach requires a dedication to continuous improvement, an emphasis on quality and dependability, and a willingness to invest in the necessary resources and technology.

| Risk | Mitigation Strategy |

|---|---|

| Supplier Delays | Build multi-supplier networks, add backup vendors |

| Demand Fluctuations | Invest in AI-based forecasting |

| Quality Control Issues | Set strict quality SLAs and inspections |

| Supply Chain Disruptions | Maintain strategic safety stocks or nearshoring options |

| Over-Reliance on Forecasting | Use dynamic, AI-powered predictive analytics |

Proactive risk mitigation is key to maintaining a resilient JIT system.

Why is Kanban Significant for the JIT Inventory System?

The Kanban system is significant for JIT because it highlights problem areas by measuring lead and cycle times across the production process, which helps identify upper limits for work-in-process inventory to avoid overcapacity.

In simpler terms, Kanban serves as a pivotal tool for managing material flow within a JIT framework. It offers a graphical depiction of the production process, enabling managers to identify potential bottlenecks or delays.

This visibility helps avert overproduction and ensures materials are supplied just in time, further boosting the efficiency and efficacy of the JIT system.

What is a Real-life Example of the Just-In-Time (JIT) Inventory Management?

A great real-life example of Just-In-Time (JIT) Inventory Management can be found in Dell Technologies.

Dell’s implementation of JIT is a textbook case of how a company can effectively synchronize its supply chain to meet customer demand without the need for extensive inventories.

How Dell Implemented JIT:

- Direct-to-Customer Model

Dell pioneered the direct-to-customer business model, which allowed customers to customize their computer orders. This approach meant that Dell started assembling a computer when an order was placed, significantly reducing the need for finished goods inventory. - Supplier Integration

Dell developed a highly integrated supply chain with its suppliers, often locating them near its assembly plants. This allowed for rapid delivery of components, often several times a day, ensuring that Dell could maintain a low inventory level. - Real-Time Orders and Assembly

Orders received in real-time were quickly translated into production instructions. The assembly line was then able to respond swiftly, building the customized computers as the orders were placed, thus adhering to the JIT philosophy. - Continuous Improvement

Dell continuously refined its processes to reduce cycle times and improve quality. This commitment to continuous improvement is a crucial tenet of JIT and has been instrumental in Dell’s success.

Results Achieved by Dell:

- Reduced Inventory Costs

Dell was no longer holding excess inventory, the company could significantly reduce storage and handling costs, which contributed to their competitive pricing strategy. - Improved Cash Flow

The reduced inventory levels also meant Dell could enjoy improved cash flow, as less capital was tied up in stock. This financial flexibility allowed Dell to invest in other strategic areas of the business. - Customization and Responsiveness

The JIT system enabled Dell to offer a high degree of customization to its customers, which was a strong selling point and contributed to customer satisfaction. - Supply Chain Efficiency

Dell’s supply chain became a benchmark in the industry for its efficiency and responsiveness, demonstrating the potential of JIT when combined with innovative business models and strong supplier relationships.

In the context of JIT implementation, Dell’s approach was revolutionary at the time and has since influenced many other companies in various industries.

Dell’s ability to integrate technology, process innovation, and a unique business model showcases the transformative power of JIT Inventory Management when executed with precision and strategic foresight.

Artificial Intelligence and its Impact on Just-In-Time (JIT) Inventory Management

The expanding influence of digital transformation, including artificial intelligence, has positioned JIT as a cornerstone of contemporary supply chain management strategies.

AI-driven analytics can facilitate strategic sourcing, the creation of adaptive, context-aware internal workflows and process controls, and integrating inventory management with existing software ecosystems.

Simply put, AI acts as a formidable ally in enhancing the effectiveness of JIT. It delivers real-time insights into demand trends, aids in refining supply chain operations, and automates routine tasks, freeing personnel to concentrate on more strategic endeavors.

Harnessing AI enables companies to elevate their JIT practices to new heights, achieving superior efficiency and cost savings.

What is Just-In-Time (JIT) Inventory Software?

JIT Inventory Software is a tool that can streamline and automate the JIT process. It offers immediate insights into inventory levels, simplifies the ordering process, and provides analytics to optimize supply chain operations.

JIT Inventory Software represents a holistic, cloud-based procurement platform that supports the implementation of JIT inventory.

It incorporates process automation tailored for continuous improvement, centralized data management for heightened transparency and precision, and robust analytics driven by artificial intelligence.

These technological capabilities enable the formulation of an intelligent inventory management strategy that is both responsive and flexible, ensuring an uninterrupted supply of raw materials, the avoidance of unnecessary expenses, and the conservation of your organization’s valuable capital, labor, and time.

Companies can significantly amplify the benefits of JIT and transform their supply chain practices when leveraging this technology,

ThroughPut’s Inventory Management Solution

ThroughPut is an AI-Powered Decision Intelligence and Bottleneck Operation Elimination Engine that analyzes your existing industrial data in real-time.

With ThroughPut you have an industry-scale, automated, enterprise-ready Artificial Intelligence (AI) software that gives you complete control of your inventory.

ThroughPut helps you implement JIT Manufacturing principles with ease while not compromising on product quality improvement in manufacturing and smart supply chain standards.

If you wish to get started with our Supply chain management software ThroughPut for your inventory management needs, you should contact us for a demo today.