Best Logistics Management Software Use Cases

As we step into 2025, the world of logistics isn’t what it used to be. It’s no longer just about getting goods from A to B; it’s become a vital piece of the supply chain puzzle.

Everything is connected – what happens in one part of the supply chain can shake things up in logistics and vice versa. We’ve all been witness to this!

That is why logistics management software (LMS) is so much more today than what it used to be. It’s not just about merely managing trucks and warehouses anymore; it’s about seeing the big picture (of your entire supply chain!) and making smart moves in real-time, as everything around keeps shifting.

In this blog, we’ll tell you what the evolution of a LMS has been and what you should look for while choosing the best Logistics Management Software.

What is Logistics Management Software And How Does It Work?

Logistics Management Software helps drive the logistics function of an organization by managing the actual flow of materials, goods, and services from the point of origin to the point of consumption. This includes the final customers or groups of businesses.

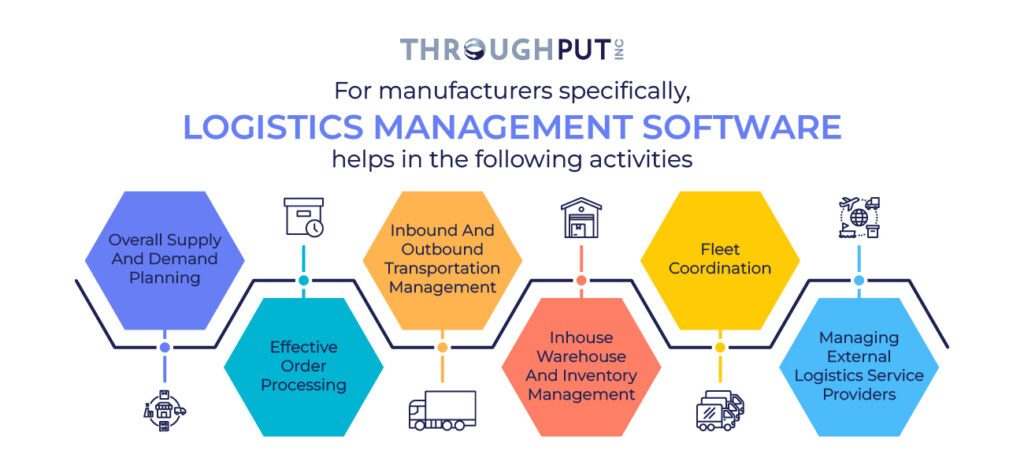

From a manufacturing perspective, the best logistics management software facilitates effective planning of the supply chain itself and implementation of the final delivery to the end consumers.

It helps coordinate the various supply chain activities, which include the complete range of procurement, development, implementation, commercialization, and delivery of the goods or services to the market.

The role of logistics management software here is to create a viable solution that can help you easily manage the flow of things for better accuracy and to ensure that the right product reaches the right person at the right place and time.

With the help of the best Logistics Management Software, you can effectively manage the multifaceted process involved right from the production cycle to the delivery of raw materials to shipping the finished products to the consumers.

Evolution of Logistics Management Software

As we mentioned earlier, today, Logistics Management Software has evolved to become broader in its scope and functionalities to help address a greater spectrum of complex operations and processes.

It now shares similarities with Supply Chain Management Software (SCMS), to help deal with manufacturing operations, processes, vendors and suppliers.

Logistics has, however, come a long way.

Before the 1950s, logistics was perceived in purely military terms. This involved procurement, maintenance, and transportation of military facilities, services, materials, and personnel.

After World War II, the focus of logistics moved from warfare to business and the physical distribution of products began with a focus on outbound activity. The objective now was to fulfill orders, smooth distribution of products, storage and warehousing.

Gradually, effective production planning and reliable customer service became important aspects of the logistics process. Companies started looking for software that can help move products and services from point A to B.

This saw multiple organizations adopting outsourcing for some or all of their supply chain management activities, which gave rise to the rapid development of third-party logistics companies for efficient delivery and tracking of goods.

As organizations started using full-fledged Logistics Management Software, the entire gamut of logistics activities rapidly evolved which included active supervision of operations across various levels.

One area that saw maximum growth and transformation was the instant digitization of its processes and resources. With this rapid digitization, physical devices and software solutions were combined to help streamline the complete logistics value chain cycle with the owner as the focal point.

As the demand for large-scale logistics peaked with the rising popularity of e-commerce, logistics management itself started adapting to the complex demands of various industries and their operations.

Today, as Software-as-a-service (SaaS) has become popular across industries, this model finds wide acceptance in logistics management and supply chain as well. This is also due to the benefits of security, convenience, and reliability that this model offers along with cloud computing benefits.

The best Logistics Management Software today uses Artificial Intelligence (AI) and its applications, as this holds the maximum potential to disrupt the way logistics is done in manufacturing.

With the automation of various tasks and several risk forecasting and predicting techniques being used across several areas, logistics management sees a massive shift in the coming few years.

Business Use Cases of the Best Logistics Management Software

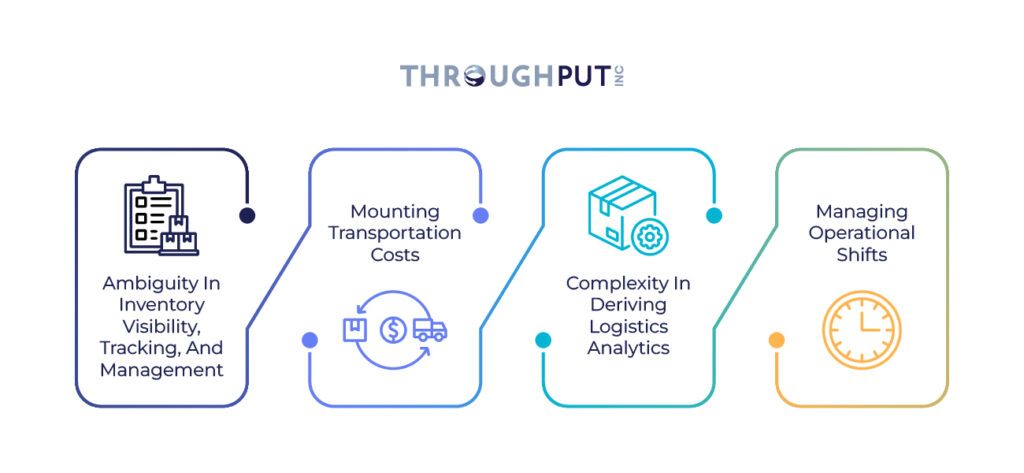

1. Ambiguity in Inventory Visibility, Tracking and Management

The Challenge

For a manufacturer, inventory acts as a foundation for a successful and efficient supply chain. However, in mid-sized to large scale businesses, it may be difficult to track inventory status and movement due to lack of detailed, real-time visibility.

This can significantly strain a business’ sales and operations activities. Also, as the supply chain often needs to track and manage inventory from various warehouses and locations, this can be a difficult task with decentralized operations.

The solution

To help address this, the best Logistics Management Software is the one that can provide valuable real-time data on inventory.

- To help give easy access to anyone in the organization regardless of the location across several systems, like warehouse management, transportation management, etc.

- To help in effective tracking and management of inventory across the organization saving time, money and resources.

2. Mounting Transportation Costs

The Challenge

Transportation costs form a major chunk of the several variable costs that manufacturers have to address. Rising fuel prices directly impact the shipping costs and they become an integral part of the logistics budget. A steep rise in this can further create a dent in the overall revenue stream and profitability for manufacturers.

The Solution

A Logistics Management Software can help address the above costs to a great extent.

- By implementing autonomous tracking and AI, the Logistics Management Software has access to the potential real-time data with prime routes as well as possible alternative routes to reduce the cumulative transportation costs.

- By deploying sensors, manufacturers can further intelligently improve fuel efficiency, evaluate various road conditions, and continuously monitor routes for tracking everyday logistics to optimize efficiency.

3. Complexity In Deriving Logistics Analytics

The Challenge

Most manufacturers find themselves struggling with driving valid outcomes using accurate logistics analytics solutions.

This is due to the growing competition within the transportation and logistics industry along with the rising fuel costs, complex market demands and the increased need for optimized delivery times.

The Solution

With the best Logistics Management Software, manufacturers can harness the true potential of their data to bring about significant improvements. This is across route optimization, traffic management, inventory movement, and predictive maintenance.

- Using accurate supply chain analytics and data, the software can analyze the shipping history and operations, to cut down logistical costs and slash down shipment delivery times.

- Also, by applying AI-based techniques, the software can develop advanced performance metrics and KPIs to create valid computer models to predict supply chain issues.

4. Managing Operational Shifts

The Challenge

Many times manufacturers face challenges in managing the batch units of operations scheduled based on certain assumptions.

Due to unforeseen factors like market volatility, weather conditions, worker absenteeism etc. which might affect these schedules, there could be a significant reduction of the units produced, impacting the transport capacity.

So, when a certain amount of space was budgeted to move X amount of units, this reduction could mean a longer lead time or inefficient use of existing capacity.

The Solution

With an efficient Logistics Management Software in place, manufacturers have the power and flexibility to adapt to these operational shifts by identifying the best routes, transport modes, and delivery windows.

- It can help reduce the possibilities of losses in resources and time to handle these changing variables.

- It can also help manufacturing companies to provide for simulations or what-if scenarios, which can create fool-proof strategies to avoid bottlenecks occurring from operational shifts.

Key Features Of a Logistics Management Software

Here are the top features to look for in a Logistics Management Software for optimum results.

Warehouse and Order Management

A good Logistics Management Software should help optimize an organization’s stock to increase overall warehouse efficiency directly. This will help meet dynamic warehouse requirements in a timely and cost-effective manner.

Further, since order and billing management is a top priority for operations managers, having a centralized system always helps. Manufacturers benefit with more flexibility in managing ad hoc requirements as well.

Inventory Tracking and Management

Most manufacturers channelize all their efforts in optimizing inventory levels. This ensures that the organization is well-equipped in storing optimum levels of stock of goods and raw materials and this is made available whenever required.

Using the best Logistics Management Software, manufacturers can apply real-time tracking tools to ensure inventory levels are always optimized, resulting in the proper flow of goods.

If the software has an inbuilt inventory tracking and control feature, it can also ensure ease in processing and that the customer gets the invoice on time.

Forecasting

A Logistics Management Software that is proficient in forecasting is the ideal choice for most organizations. With accurate forecasting, organizations can procure what is actually required and hence eliminate the possibilities of over or under stocking inventory.

Optimal forecasting efficiency improves customer satisfaction and eliminates bottlenecks in the operations cycle.

Accounts and Finance Integration

The best Logistics Management Software should be compatible with the supply chain finance and accounting aspects as well. All key features like the account payables/ receivables, general ledger features, expenditures, receipts details, etc. have to seamlessly integrate with it.

This helps guide accurate bookkeeping, general ledger functions, account payables and receivables of the organization.

Real-time Visibility and Analytics

One of the most critical factors in logistics is the real-time visibility and tracking of movement of cargo across various checkpoints.

A Logistics Management Software that can provide end-to-end visibility of the supply value chain is always preferred. Similarly, the software should be able to analyze existing data and real-time data to evaluate supply chain performance and business processes to optimize operations.

How to Solve Logistics Challenges with Logistics Management Software

Case studies are a great way to understand how a logistics management software can solve complex challenges.

1. Logistics of Time-sensitive Ready-mix Concrete Without Increasing Operational Costs

The Ready Mix Concrete (RMC) industry is inherently time-sensitive. RMC has to be delivered and used within a narrow window so that the quality and integrity are not compromised.

Additionally, RMC has to be transported in specialized mixer trucks running at the right speed and agitation and also needs to be maintained well to avoid breakdowns. The distance between the batching plant and the construction site cannot be too long, else there could be issues with the setting time.

Similarly, if there are sudden changes in construction schedules, last-minute orders, or congested traffic, there can be delays and losses.

Manually managing this complex permutation and combination of truck movements can lead to delays and errors – as you can imagine!

Instead, this particular RMC business engaged ThroughPut’s logistics planning capabilities to to categorize customers based on business value and frequency, thus, allowing customer prioritization synced with operational capabilities, profitability and sustainability goals.

The company also gained complete visibility of material flow and enhanced On-Time In-Full (OTIF) deliveries and travel times with efficient allocation of resources, better route planning, and a reduction in unnecessary travel, directly impacting both efficiency and environmental footprint.

2. Optimization of Shipments To Save As Much As €3.5 Million in Savings per Year in Logistics Costs

With the rise of e-commerce, DCs now house an extensive variety of products and support on-demand shipments to customers. For a European retailer, this meant undertaking expedited delivery of a diverse range of products leading to increased shipment costs.

The holding costs and shipping costs related to unplanned shipping were also quite high as they were incapable of adapting inventory levels without proper demand sensing, forecasting, or planning means.

Using ThroughPut’s logistics planning module, they were able to prioritize SKUs by identifying 150 top-selling SKUs, and dynamically adjust distribution per DC.

The company could reduce SKU volumes by 20%, transportation costs by almost 33% and achieve an OTIF rate of over 90%.

3. Improve On Time, In Full (OTIF) Performance and Save More Than $16 Million Per Year

What’s affecting your OTIF metrics? And what are the downstream effects of delayed or partial shipments?

Most businesses have the answer to this yet like this lime manufacturer, getting to the root cause especially when you are a large and fast-growing business can be challenging.

This lime manufacturer with production capacity of thousands of tons of hydrated lime per day and catering to large-scale construction segments globally wanted to strengthen their sustainability efforts and competitiveness to ensure they could continue producing and delivering as per capacity thresholds and demand levels.

Using ThroughPut, they streamlined their On-Time, In-Full (OTIF) Performance especially for critical routes and showed a significant potential for increased sales and gross margins.

It enabled the proper mapping of top-performing SKUs contributing to the majority of total throughput that helped reduce the total cost of ownership and further optimized tax & duty cost lines.

The overall impact was a whopping savings of $16 Million per year with a 13.5% increase in performance improvements in yield margin and working capital reduction opportunities of 6% with savings up to $50,000.

AI and Its Impact On Logistics Management Software

Today, AI has assumed a strategic role in delivering the much-needed efficiencies across the logistics industry. As the manufacturing world’s logistics become even more complex, big-data, machine learning and AI-driven applications have stepped in to streamline logistics on a global scale. A recent study shows AI-based logistics can generate from $1.3 trillion to $2 trillion per year.

The best Logistics Management Software is backed with robust AI-based analytics that can create value through predictive capabilities, automated processes, streamlined cargo management, accurate demand forecasting, etc. which help save time, cost and resources.

An AI-driven Logistics Management Software can also help eliminate potential bottlenecks across the logistics value stream, helping manufacturers save millions in operations costs and boost the bottom line as well.

ThroughPut is Not a Logistics Management Software!

We’re more than that!

We’re a decision intelligence supply chain solution that can also do what a typical logistics management software can do for you. (and more!)

ThroughPut’s AI-powered tool can optimize your logistics by having an integrated view of your entire supply chain and identifying improvement potential at both, a strategic and operational level.

Its advanced prescriptive and cognitive capabilities can enable data-driven decision making to reduce costs and improve bottom line, at the same time, on a granular level enable real-time optimization of routes, fleet, capacity and more.

Connect with us for a zero-obligation demo of ThroughPut’s capabilities.