Spare parts and MRO inventory planning is undergoing a major transformation. With supply chains facing unpredictable demand patterns, longer lead times, and aging assets, organizations can no longer rely on manual spreadsheets or gut-feel planning. In 2026, AI, predictive analytics, and digital twins are fundamentally reshaping how manufacturing plants, energy facilities, utilities, oil & gas, logistics, and industrial operations maintain parts availability and control working capital.

If you want to reduce stockouts, avoid emergency purchases, eliminate excess inventory, and raise equipment uptime, this guide provides everything you need — based on modern AI-optimized MRO practices.

What is Spare Parts & MRO Inventory Optimization?

Spare parts and MRO inventory optimization is an AI-supported process that ensures the right parts are available at the right time with minimal cost. Using predictive analytics, failure modeling, and real-time data, companies reduce stockouts, emergency purchases, and excess inventory. This improves uptime, reliability, and working capital performance across plants, assets, and maintenance operations.

Spare parts inventory exists to keep assets running. But poor planning leads to:

- high carrying costs

- unplanned downtime

- emergency orders

- unreliable maintenance

- budget waste

- customer service issues

Modern optimization requires transitioning from reactive stocking to predictive, data-driven replenishment based on demand sensing, probabilistic forecasting, and maintenance insights.

Why Traditional MRO Planning Fails Today

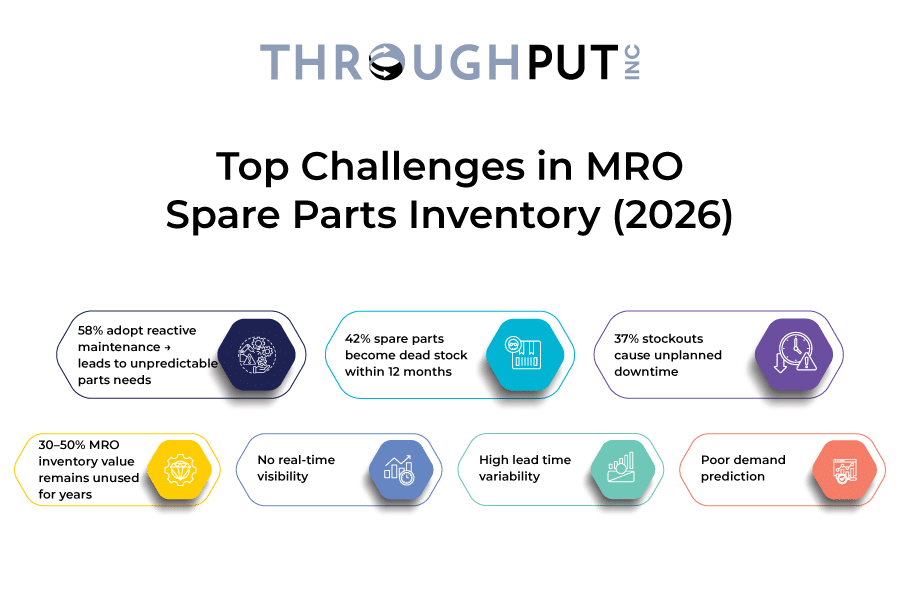

Traditional planning methods struggle because:

- Consumption is unpredictable

- Lead times vary dramatically

- Failure patterns are complex

- SKUs contain duplicates and inconsistent naming

- Lubricants, consumables, tools, motors, and spares follow different patterns

- ERP/CMMS systems lack intelligence for forecasting

- Maintenance teams overstock to avoid risk

This leads to imbalanced inventory — shortages of critical components while thousands of dollars sit unused on shelves.

Why Spare Parts Optimization Is Critical in 2026

In 2026, spare parts optimization is crucial because asset complexity is rising, supply chains face longer global lead times, and equipment downtime is more expensive than ever. AI-driven optimization reduces working capital by 15–30%, improves service levels, and stabilizes maintenance planning across multi-plant operations.

Impact of Stockouts on Operations

A single missing part can lead to:

- 2–12 hours of lost production

- Shutdown of entire lines

- Rush orders that cost 3–6x more

- Delayed customer shipments

- Maintenance backlogs

Downtime is far more expensive than inventory.

Cost of Excess & Obsolete Parts

Holding thousands of unnecessary parts creates:

- high carrying and storage costs

- spoiled, expired, or rusted parts

- tied-up working capital

- demand uncertainty

Most organizations discover that 30–50% of MRO parts have not moved in 24 months.

How Spare Parts Optimization Prevents Downtime

AI-powered spare parts optimization continuously monitors inventory levels, failure risks, and consumption patterns in real time. By detecting early warning signals and automatically adjusting reorder points, organizations prevent last-minute shortages, reduce emergency purchases, and keep critical assets running without disruption.

Why Traditional Forecasting Doesn’t Work for MRO

MRO parts have:

- irregular demand

- low-volume consumption

- long lead times

- unpredictable failure

AI-based forecasting is required to understand these patterns.

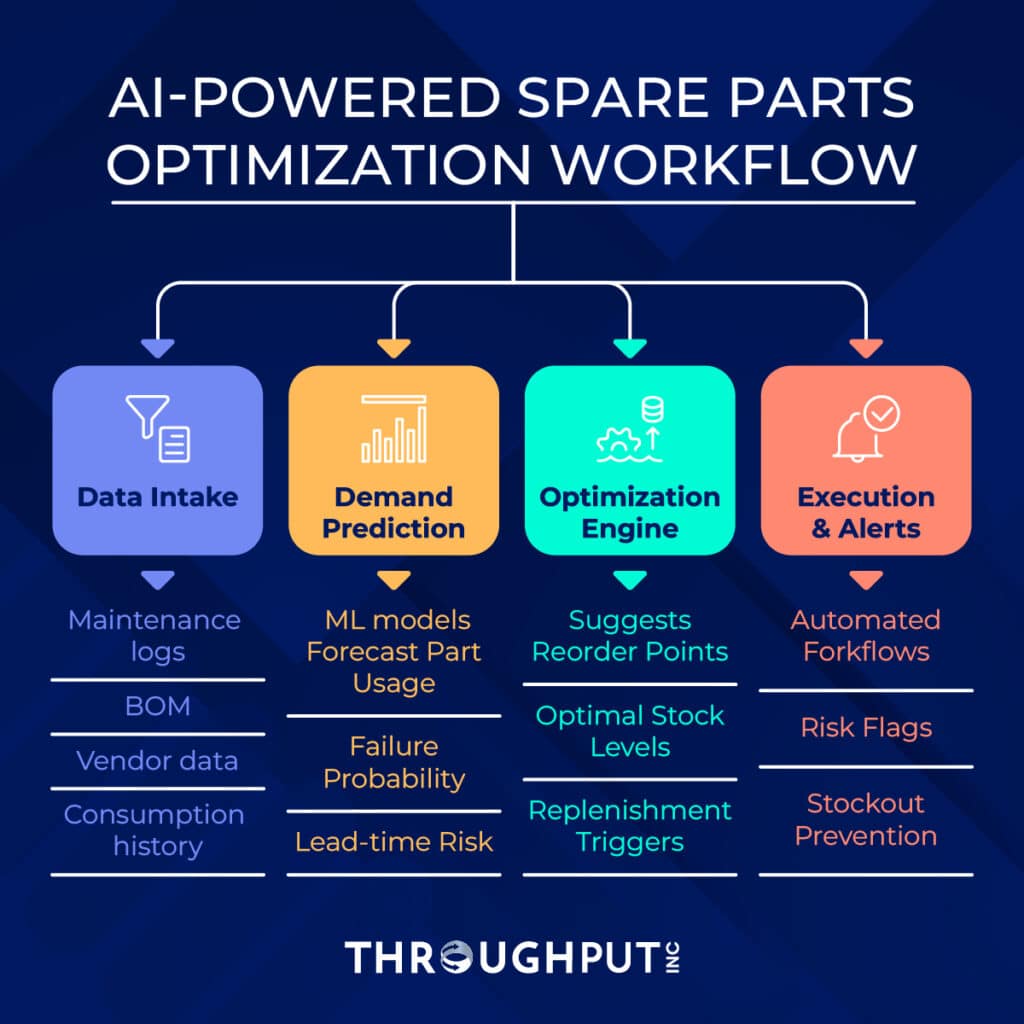

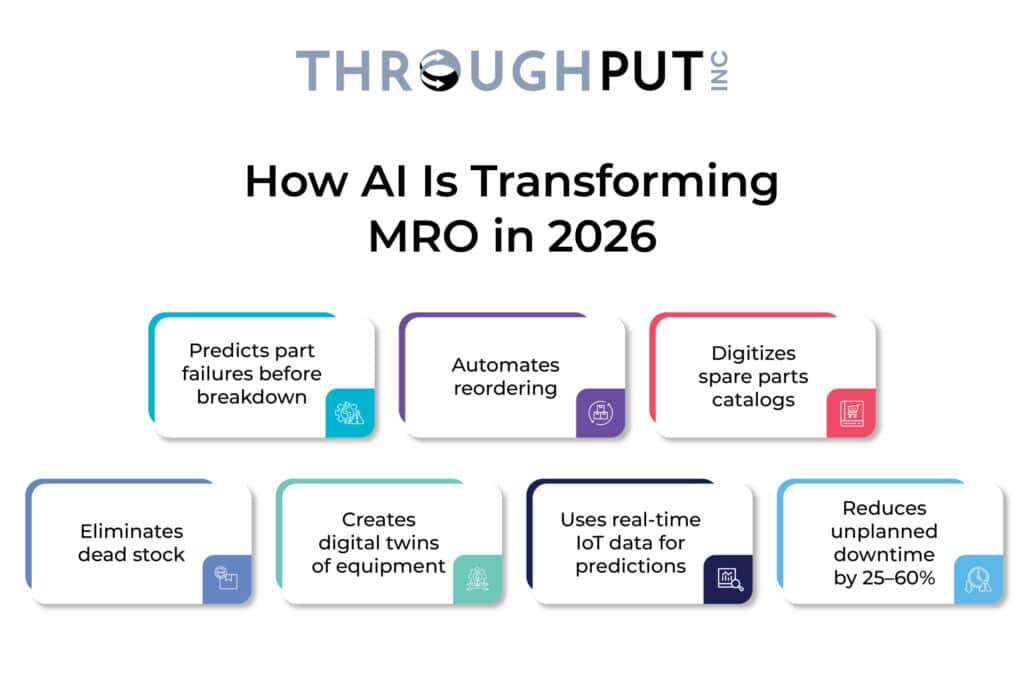

How AI & Predictive Analytics Are Transforming MRO in 2026

AI transforms MRO inventory by predicting part failures, modeling demand probabilistically, and generating optimal reorder points. Plants using real-time demand sensing report 20–40% fewer emergencies and 15–25% lower inventory costs. AI also integrates with ERP/CMMS to automate enterprise-wide optimization.

Predictive Modeling & Probabilistic Forecasting

AI uses:

- failure curves

- MTBF, MTTR

- consumption behavior

- environmental impact

- seasonal patterns

- machine health data

to estimate future part needs more accurately than traditional models.

Real-Time Demand Sensing for MRO

Data from machines, maintenance tickets, and sensors feeds algorithms that detect early warnings of shortages.

Scenario Planning & What-If Simulation

- AI models simulate:

- supplier delays

- production spikes

- asset overuse

- maintenance backlogs

and recommend inventory adjustments proactively.

Digital Twins for Maintenance & Spare Parts

Digital twins virtually mirror asset behavior to forecast:

- failure probability

- wear patterns

- upcoming maintenance events

- required spares in advance

Autonomous Replenishment With AI

AI engines automatically:

- trigger reorder suggestions

- adjust safety stock in real time

- balance critical and non-critical parts

- provide procurement guidance

- This reduces manual work and human error.

Traditional MRO vs AI-Powered MRO Optimization

At this stage, it’s important to clearly understand how AI-powered MRO optimization differs from traditional, manual planning approaches.

AI-powered MRO replaces reactive, spreadsheet-driven decisions with continuous forecasting, real-time visibility, and automated replenishment—dramatically reducing stockouts and excess inventory.

Common Causes of MRO Inventory Inefficiency

Most MRO inefficiencies come from inaccurate data, unmanaged criticality, inconsistent consumption patterns, unreliable supplier lead times, and reactive inventory planning. These issues increase stockouts, emergency purchases, and excess inventory.

Inaccurate Data & Duplicate SKUs

Duplicate parts inflate:

- inventory value

- confusion

- ordering errors

- planning time

Critical vs Non-Critical Parts Confusion

Plants often overstock non-critical items while understocking essential components.

Supplier Lead-Time Blind Spots

Suppliers often miss committed schedules.

AI models correct lead times by using historical performance data.

Reactive Instead of Predictive Planning

Most organizations order parts only after running low — a high-risk strategy.

How to Optimize Spare Parts & MRO Inventory (Step-by-Step Guide)

Optimizing MRO inventory requires segmenting parts by criticality, cleaning data, forecasting demand using AI, determining optimal safety stock, and implementing predictive replenishment rules. Plants that follow a structured model reduce inventory cost by 20% while preventing stockouts.

Step 1 — Conduct Criticality Segmentation

Classify parts based on:

- safety

- downtime impact

- supplier risk

- failure probability

- interdependence with other assets

Step 2 — Clean & Harmonize Master Data

Standardize:

- part names

- manufacturer details

- dimensions

- units of measure

- alternative part mappings

Step 3 — Build AI-Based Demand Forecasting Model

AI handles:

- intermittent demand

- erratic consumption

- seasonality

- failure probabilities

- This ensures more accurate reorder points.

Step 4 — Calculate Optimal Safety Stock

Use mathematical and AI-driven models to determine:

- service levels

- demand variability

- lead time variation

Step 5 — Implement Predictive Reorder Rules

Rules should consider:

- criticality

- failure rate

- predicted usage

- supplier performance

- cost of downtime

Step 6 — Automate Inventory Optimization With ThroughPut.ai

ThroughPut.ai automatically:

- recommends reorder points

- calculates safety stock

- removes duplicates

- predicts consumption patterns

- prevents shortages

KPIs to Track for Spare Parts Optimization

Key MRO KPIs include service level, inventory turns, stockout frequency, carrying cost, emergency order percentage, lead-time accuracy, and maintenance uptime. Tracking these metrics drives better predictive planning.

KPIs

1. Fill Rate

Target: 95–98%

2. Inventory Turns

Target: 1.5–3 turns for MRO

3. Emergency Purchase Frequency

Target: <5%

4. Stockout Incidents

Target: Zero for critical parts

5. Inventory Carrying Cost

Target: 18–25%

6. Lead Time Accuracy

Target: 90% supplier reliability

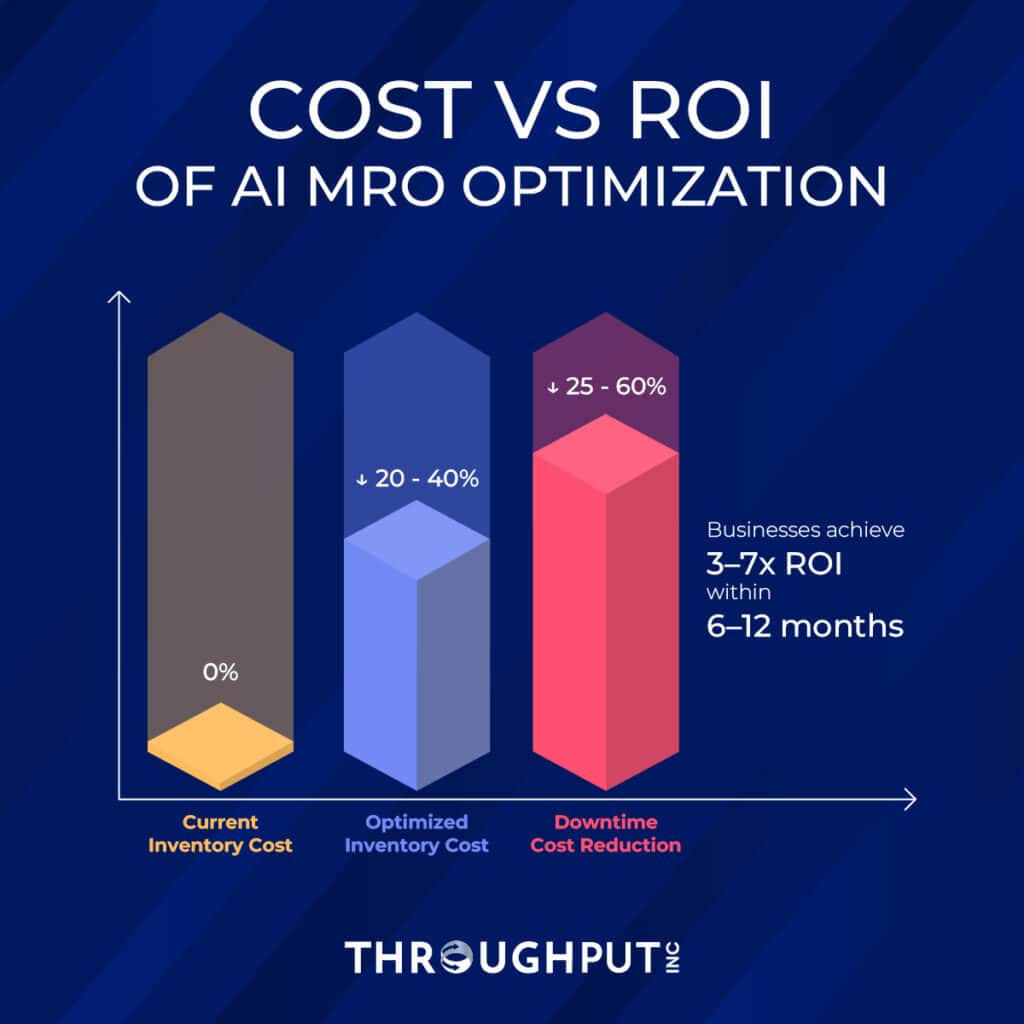

Cost vs ROI of AI MRO Optimization

AI-powered MRO optimization delivers measurable financial impact by reducing inventory carrying costs while significantly lowering downtime-related losses. Most enterprises achieve a 3–7x return on investment within 6–12 months of implementation.

Real-World Examples: How Companies Are Optimizing MRO

Organizations using AI for MRO have reported 20–40% fewer emergencies, 15–30% lower inventory cost, and significantly improved reliability KPIs.

Case Study 1 — Large Manufacturing Plant

- Reduced stockouts by 35%

- Lowered working capital by $3.2M

- Improved maintenance response time 22%

Case Study 2 — Energy & Oil/Gas Facility

- Improved uptime by 18%

- Cut urgent orders by 42%

- Achieved accurate lead-time prediction for 1,200+ SKUs

Case Study 3 — Automotive Production Facility

- Eliminated 27% obsolete parts

- Reduced spare parts spend by 22%

ThroughPut.ai — AI-Powered Spare Parts & MRO Inventory Optimization

ThroughPut.ai uses advanced demand sensing, predictive modeling, and optimization engines to ensure plants never face stockouts or excess. It improves uptime, reduces working capital, and provides complete visibility across all assets and plants.

- ThroughPut.ai offers:

- AI-based forecasting

- Safety stock automation

- Duplicate SKU resolution

- Lead-time intelligence

- Vendor performance analytics

- Autonomous recommendations

- Multi-plant visibility

Manual Management vs Traditional ERP vs ThroughPut.AI Comparison Matrix

Implementation Roadmap for Enterprises

Most companies achieve significant MRO improvements within 6–12 weeks by following a structured roadmap.

Week 1–2: Data Discovery & Mapping

Master data + consumption + lead times + failures.

Week 3–5: AI Modeling

Failure prediction, demand modeling, variability analysis.

Week 6–8: Optimization Deployment

Safety stock, reorder policies, supplier intelligence.

Week 9–12: Full Automation

Predictive recommendations with AI-driven approvals.

Checklist to Select the Right MRO Optimization Tool

The right MRO platform should include AI forecasting, real-time analytics, digital twin support, automated safety stock, and ERP/CMMS integrations.

Checklist:

- Predictive demand forecasting

- Digital twin modeling

- Safety stock automation

- Multi-plant visibility

- ERP/CMMS integration

- What-if simulation

- Optimization engine

- Scenario planning

FAQ Section

1. What is MRO inventory optimization?

MRO inventory optimization ensures you maintain the right spare parts at optimal cost using forecasting, analytics, and AI.

2. Why do companies face spare parts shortages?

Due to inaccurate data, poor criticality segmentation, and reactive planning.

3. How does AI forecasting work for spare parts?

AI analyzes consumption patterns, failure rates, and lead times to predict future needs.

4. How do you calculate safety stock for MRO?

Using demand variability, lead-time fluctuations, and criticality.

5. What KPIs matter most in MRO planning?

Fill rate, emergency orders, uptime, inventory turns, and lead-time accuracy.

6. Can AI reduce emergency purchases?

Yes — predictive analytics can reduce emergencies by 20–40%.

7. How does ThroughPut.ai help?

It automates forecasting, generates reorder points, eliminates duplicates, and predicts shortages.