What is Advanced Total Quality Management (TQM) in the Modern Supply Chain?

Advanced Total Quality Management (TQM) in the modern supply chain represents a holistic approach to quality improvement that integrates customer focus, process orientation, and continuous improvement across every link in the supply chain. Unlike traditional quality methods, advanced TQM incorporates digital tools, data analytics platforms, and collaboration technologies to optimize supply chain operations in real time. This modern TQM supply chain management paradigm ensures that every process — from procurement and manufacturing to distribution and customer service — meets stringent quality standards consistently.

The advanced TQM definition expands beyond defect reduction to include responsiveness, agility, and sustainability metrics. It leverages innovative TQM digital tools for supply chains to streamline workflows and enhance visibility across global networks. Digital transformation with TQM analytics platforms such as ThroughPut.ai empowers firms to accurately monitor quality metrics, enabling proactive decision-making to prevent disruptions and enhance performance.

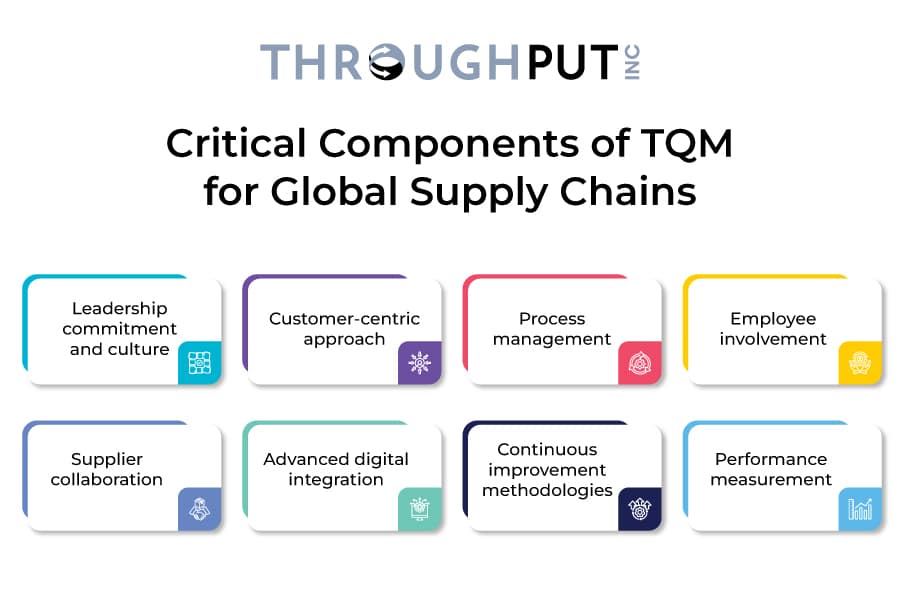

What are the Critical Components of TQM for Global Supply Chains?

The key TQM components for global supply chain excellence include:

- Leadership commitment and culture: Ensuring strong leadership support focused on quality at all organizational levels.

- Customer-centric approach: Aligning all supply chain activities with customer requirements and satisfaction metrics.

- Process management: Defining and optimizing core supply chain processes for consistency and efficiency.

- Employee involvement: Encouraging active employee involvement in quality initiatives fosters ownership and innovation.

- Supplier collaboration: Building partnerships with suppliers to co-create quality standards and drive continuous improvement.

- Advanced digital integration: Using TQM digital tools for real-time monitoring, data analytics, and automated quality controls.

- Continuous improvement methodologies: Applying Kaizen and lean principles to ensure process regular enhancements.

- Performance measurement: Establishing clear TQM performance metrics and KPIs to track progress toward quality goals.

These elements are vital to tailor TQM implementation uniquely for global supply chains, where complexity and scale create additional challenges.

Why is TQM Crucial for Long-Term Supply Chain Competitiveness?

TQM benefits long-term competitiveness by embedding quality into the DNA of supply chain operations. Companies with mature TQM processes experience:

- Reduced defects and waste, improving overall supply chain quality improvement solutions.

- Enhanced supplier collaboration TQM, enabling reliability and trust throughout extended networks.

- Higher customer satisfaction through consistent delivery of superior products and services.

- Increased agility to respond to market changes and regulations faster.

- Sustainable operations that minimize environmental and social risks.

- Data-driven insights via TQM analytics platforms for continuous process refinement.

The importance of TQM in supply chain management lies in creating a robust and scalable system that can adapt to evolving demands while maintaining excellence, which is critical in today’s global competitive landscape.

How to Build and Scale a TQM-Driven Supply Chain Strategy?

Building a TQM supply chain strategy involves:

- Assessment: Conduct a comprehensive quality audit across the entire supply chain to identify gaps and improvement areas.

- Design: Develop a roadmap that defines key TQM elements for supply chain success, including leadership roles, training programs, and process standards.

- Implementation: Initiate pilot projects utilizing supply chain quality improvement solutions and integrate digital TQM tools for automation and analytics.

- Scaling: Expand successful pilots organization-wide with standardized processes and shared best practices to scale TQM implementation supply chain-wide.

- Continuous Improvement: Embed a culture of continuous improvement in TQM with regular Kaizen events, performance reviews, and employee/supplier engagement initiatives.

Regular training and collaboration with partners help sustain momentum and embed quality as a strategic priority.

How Does TQM Integrate with Advanced Digital Tools and Analytics?

Modern TQM leverages advanced digital tools and analytics platforms to drive visibility, accuracy, and predictive insights. Integration involves:

- Connecting IoT-enabled devices and sensors to monitor real-time process performance.

- Using TQM analytics platforms like ThroughPut.ai to visualize data trends and identify root causes of quality issues.

- Applying AI and machine learning for predictive maintenance and demand forecasting.

- Automating quality inspections and corrective actions.

- Facilitating collaboration through cloud-based communication platforms for supplier and employee engagement for TQM success.

Digital TQM tools for supply chains enable firms to evolve from reactive problem-solving to proactive quality management, which is increasingly critical in complex global networks.

What Are Some Real-Life Examples of Advanced TQM in Supply Chain?

Many leading companies provide real life TQM supply chain examples demonstrating significant improvements through advanced TQM practices:

- A global automotive manufacturer integrated TQM digital tools to reduce defect rates by 30%, streamlining inspections and strengthening supplier collaboration.

- A pharmaceutical firm’s TQM case studies supply chain highlight how continuous improvement in TQM cut lead times by 25% while ensuring regulatory compliance.

- Electronics companies leveraging TQM success stories reduce operational costs by applying lean and Six Sigma techniques alongside TQM for higher throughput and quality.

These case studies exemplify how organizations achieve better cost efficiencies, product quality, and customer satisfaction by embracing advanced TQM across their supply chains.

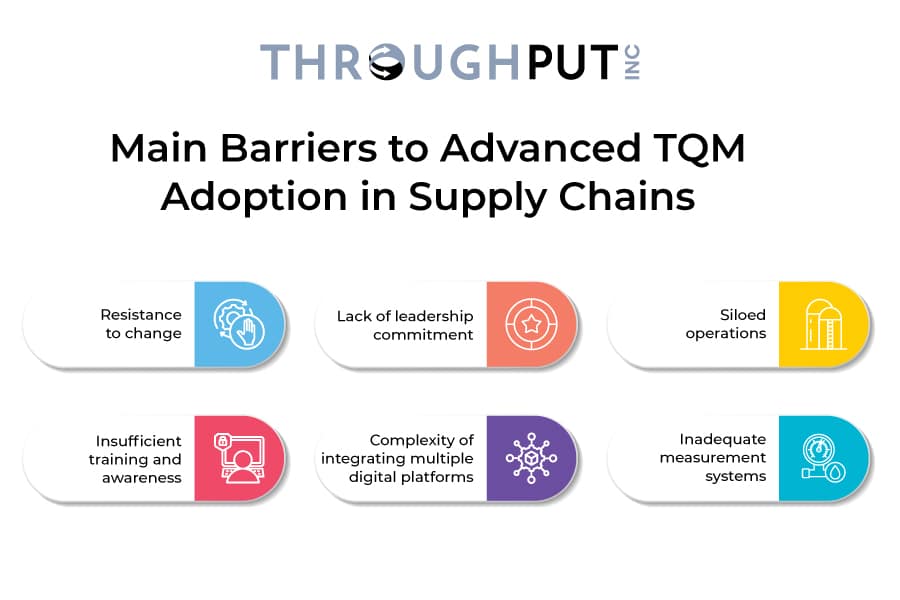

What Are the Main Barriers to Advanced TQM Adoption in Supply Chains?

Despite its benefits, many organizations face significant barriers to TQM adoption in supply chains, including:

- Resistance to change: Cultural inertia and fear of new processes.

- Lack of leadership commitment to drive TQM initiatives consistently.

- Siloed operations that hinder collaboration across functions and partners.

- Insufficient training and awareness around TQM principles and digital tools.

- Complexity of integrating multiple digital platforms, causing slow adoption.

- Inadequate measurement systems to calculate TQM cost benefits and ROI accurately.

Addressing these barriers requires robust change management, employee involvement in TQM initiatives, and strategic investments in scalable technology solutions.

Why is Continuous Improvement a Core Guiding Principle for Supply Chain TQM?

Continuous improvement — often guided by Kaizen in supply chain contexts — is fundamental to TQM because it fosters an ongoing commitment to enhance processes, reduce waste, and elevate quality. Unlike one-time fixes, continuous improvement ensures:

- Processes evolve in response to emerging challenges and customer expectations.

- Employee ideas and feedback contribute to incremental innovations.

- Supply chain agility is maintained through regular refinement cycles.

- TQM process improvement benefits accumulate over time, resulting in sustainable competitive advantage.

This principle transforms static supply chains into dynamic ecosystems where quality constantly advances.

How Does Employee and Supplier Engagement Transform TQM Results?

Employee involvement in TQM and active supplier collaboration TQM are critical success factors. Engaged employees are more motivated to identify problems, suggest improvements, and implement quality standards. Similarly, supplier engagement ensures alignment on quality expectations and facilitates transparent communication to resolve issues promptly.

Engagement for TQM success creates a culture of shared accountability and continuous learning, which strengthens the overall supply chain ecosystem—enhancing trust and cooperation that lead to consistent quality delivery.

How to Measure ROI and Performance Impact of TQM Investments?

Measuring TQM ROI and performance involves establishing clear metrics that quantify cost savings, quality improvements, and business outcomes. Key performance indicators include:

Defect rates before and after TQM adoption.

- Reduction in supply chain disruptions.

- Cost savings from waste reduction and process efficiencies.

- Customer satisfaction scores and retention.

- Productivity improvements using TQM performance metrics.

- Financial metrics such as return on quality (ROQ) and overall TQM ROI.

Leveraging analytics platforms to calculate TQM cost benefits helps justify investments and identify high-impact improvement areas.

What Are Best Practices for TQM Integration with Other Quality Frameworks (ISO, Six Sigma, Lean)?

TQM often synergizes effectively with frameworks like ISO standards, Six Sigma, and lean manufacturing methodologies. Best practices for integration include:

- Using ISO certification processes to establish baseline quality management systems aligned with TQM principles.

- Combining Six Sigma statistical tools with TQM’s cultural and leadership focus to drive data-driven process improvement.

- Applying lean principles—waste reduction and flow optimization—as critical components within a broader TQM strategy.

- Developing cross-functional teams trained in all methodologies to create a unified quality culture.

Such integrative approaches future-proof TQM strategies and maximize overall supply chain value.

How Are Leading Firms Future-Proofing Supply Chain Quality with TQM?

Leading firms future-proof supply chain quality by adopting:

- Digital TQM tools for supply chains with predictive analytics to anticipate quality issues before they occur.

- Innovative TQM applications such as blockchain for transparency and traceability.

- Scaling TQM implementation supply chain-wide to ensure resilience and agility against disruptions.

- Deep employee and supplier engagement programs encouraging flexible and creative problem-solving.

- Continuous investment in training and technology upgrades to evolve with market demands.

These future-proof TQM strategies enable firms to maintain quality leadership amid rapid technological and geopolitical changes, securing long-term supply chain excellence.

How ThroughPut.ai can help in Total Quality Management (TQM) for supply chain optimization

Certainly! Here’s how ThroughPut.ai can help in Total Quality Management (TQM) for supply chain optimization, explained in bullet points for clarity:

- Real-time Quality Monitoring: ThroughPut.ai continuously tracks quality metrics across all stages of the supply chain, enabling early detection of defects or deviations from standards.

- Predictive Analytics: By leveraging machine learning, ThroughPut.ai forecasts potential quality issues before they arise, allowing the supply chain team to take proactive corrective actions.

- Comprehensive Data Visualization: It provides easy-to-understand dashboards and reports that highlight trends, performance gaps, and root causes, helping decision-makers act effectively.

- Seamless Integration: ThroughPut.ai integrates smoothly with existing TQM digital tools and IoT devices, aggregating data from suppliers, manufacturing, and distribution networks for holistic quality insight.

- Enhanced Collaboration: The platform fosters better communication between employees and suppliers on quality issues, supporting a culture of engagement and shared responsibility for continuous improvement.

- Supports Continuous Improvement Initiatives: Through actionable insights and performance tracking, ThroughPut.ai facilitates Kaizen and other process improvement methodologies to systematically reduce waste and enhance efficiency.

- Improves ROI and Reduces Costs: By minimizing defects and disruptions, it helps optimize resource use and reduces operational costs, thus increasing the overall ROI of TQM investments.

- Builds Supply Chain Resilience: With early warnings and data-driven decision-making, ThroughPut.ai helps firms maintain high quality standards even amid complex, dynamic supply chain environments.

In summary, ThroughPut.ai accelerates the modernization of TQM in supply chains by providing advanced analytics, real-time visibility, and collaborative tools that drive quality excellence and operational agility.