Eliminate Bottlenecks in Manufacturing with AI-Driven Supply Chain Analytics

Are you striving to maximize your production capacity? If so, you can’t overlook the critical question of how to eliminate bottlenecks in manufacturing.

In the world of manufacturing, bottlenecks are like those sneaky expenses that quietly chip away at your profits. You might not notice them at first, but over time, they can really add up, hitting you with longer lead times and higher operational costs. But here’s the thing: the real impact of these bottlenecks isn’t just about the dollars and cents.

And it’s not just the external effects. Inside your company, bottlenecks can create a sort of tension. Teams push hard to hit targets, but when things are clogged up, morale can dip. Think about it – it’s tough to stay motivated when your hard work gets stuck in the pipeline.

In this article, we go a step further to show you why it might be time to empower plant managers with supply chain analytics.

Why are bottleneck operations vital for supply chains?

Manufacturing and operations bottlenecks are more than just a financial headache. They touch every part of your business and supply chain, from customer satisfaction to team morale, and even your ability to grow and innovate.

Eliminating these bottlenecks in manufacturing is a key to balancing your supply chain, keeping your business healthy and ready for the future.

When production gets bogged down, it’s not just the numbers that suffer. Your customers start feeling the delays, which can shake their confidence in your brand. This isn’t just about a one-time sale; it’s about your reputation and the kind of relationships you’re building with your customers. Happy customers come back, but those who experience delays? Not so much.

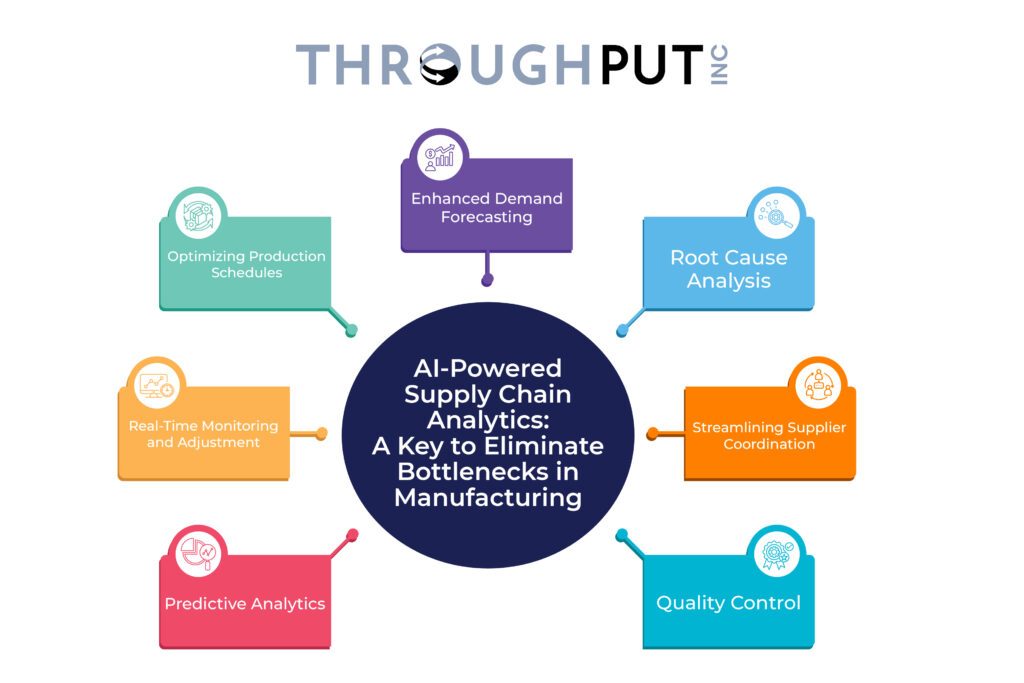

AI-Powered Supply Chain Analytics: A Key to Eliminate Bottlenecks in Manufacturing

A common query for many is whether technology has the capability to foresee and eliminate bottlenecks in the manufacturing process. The answer is affirmative – AI technology is indeed proficient in anticipating potential issues that may arise on the production floor.

Eliminating manufacturing bottlenecks with AI-driven supply chain analytics involves several strategic approaches:

- Predictive Analytics: Supply chain analytics powered by AI can predict bottlenecks before they occur. By analyzing historical data and current trends, predictive analytics, a subset of supply chain analytics, can forecast potential slowdowns in the supply chain, allowing you to take proactive measures. This could involve adjusting production schedules, reallocating resources, or changing supplier orders.

- Real-Time Monitoring and Adjustment: AI-powered analytics systems provide real-time insights into the manufacturing process. They can instantly detect when and where bottlenecks are occurring and suggest immediate adjustments. For example, if a machine is slowing down production, AI can recommend a shift in the workflow to other machines or suggest maintenance if needed.

- Optimizing Production Schedules: AI algorithms can also create highly efficient production schedules that account for various factors such as machine availability, worker shifts, and material supply. The optimization helps in evenly distributing the workload and preventing any stage in the production line from becoming a bottleneck.

- Enhanced Demand Forecasting: Accurately predicting future demand using AI means you can better align your production levels. Overproduction can lead to bottlenecks in storage and underutilization of resources, while underproduction can cause delays. AI helps in balancing this effectively.

- Root Cause Analysis: AI can also help in identifying the underlying causes of bottlenecks. Whether it’s machine inefficiency, process flaws, or human errors, AI-driven supply chain analytics can delve deep into data to find the root cause and suggest corrective actions.

- Streamlining Supplier Coordination: AI can analyze supplier performance and reliability, helping you to choose suppliers that are less likely to cause delays. It can also suggest alternate suppliers or contingency plans in case of unexpected supply chain disruptions.

- Quality Control: Finally, AI systems can monitor product quality in real-time, identifying defects that could cause slowdowns in the production line. By addressing these quality issues promptly, you can prevent the cascading effect they have on production speed.

Leveraging AI means manufacturers can eliminate bottlenecks in the manufacturing process to a great extent, resulting in a more efficient, responsive, and cost-effective supply chain.

Remember – bottlenecks are not easy to detect and eliminate manually. We spoke about the five ways in which plant managers can effectively manage bottlenecks in one of our earlier blogs.

Embracing the Future: How AI Can Eliminate Bottlenecks in Manufacturing & Redefine Efficiency

AI-driven data analytics has significantly transformed the global supply chain landscape. It’s brought a new level of visibility and control over operations, marking a substantial evolution in technology use.

In the arena of manufacturing, ThroughPut’s AI-powered supply chain analytics platform is helping businesses optimize production by eliminating bottlenecks in the manufacturing process, among other things. Simply put, it analyzes real-time data to identify patterns or anomalies. One of its key strengths is providing real-time visibility into the entire production process.

But what’s the real impact? Well, ThroughPut has been instrumental in achieving tangible results like reducing production downtime by 10%, increasing productivity by 15%, and cutting inventory costs by 20%.

To sum up, AI-driven supply chain analytics is more than just a technological advancement; it has become a vital tool to proactively identify and eliminate bottlenecks in manufacturing.

The integration of AI into manufacturing processes is rapidly evolving, reshaping supply chain management. This shift is not just about innovation; it’s also about achieving practical efficiency, cost reduction, and paving the way for a future of advanced manufacturing processes.

And if you’re keen to dive deeper into the topic of production bottlenecks, check out our whitepaper on the topic.