The retail industry has been witnessing unending turmoil over the last couple of years by way of a series of challenges – ranging from shifts in purchasing habits and consumer demands to the vagaries of a relentless global pandemic that continues to trigger seismic upheavals. To navigate these disruptions effectively, businesses are increasingly relying on Retail Supply Chain Planning Software to enhance agility and optimize operations.

In 2025, the strongest players started rethinking their planning strategies.

While acknowledging the need to reassess planning approaches is indeed a positive sign, however, the unfortunate truth is that existing planning capabilities will not cut it if retail businesses want to remain relevant over the next decade.

As challenges continue to emerge, managers of global supply chains will only find it more difficult to ensure continued demand fulfillment at an optimized cost. But only enhanced supply chain performance via optimization can help retail businesses maximize – and stabilize – revenue.

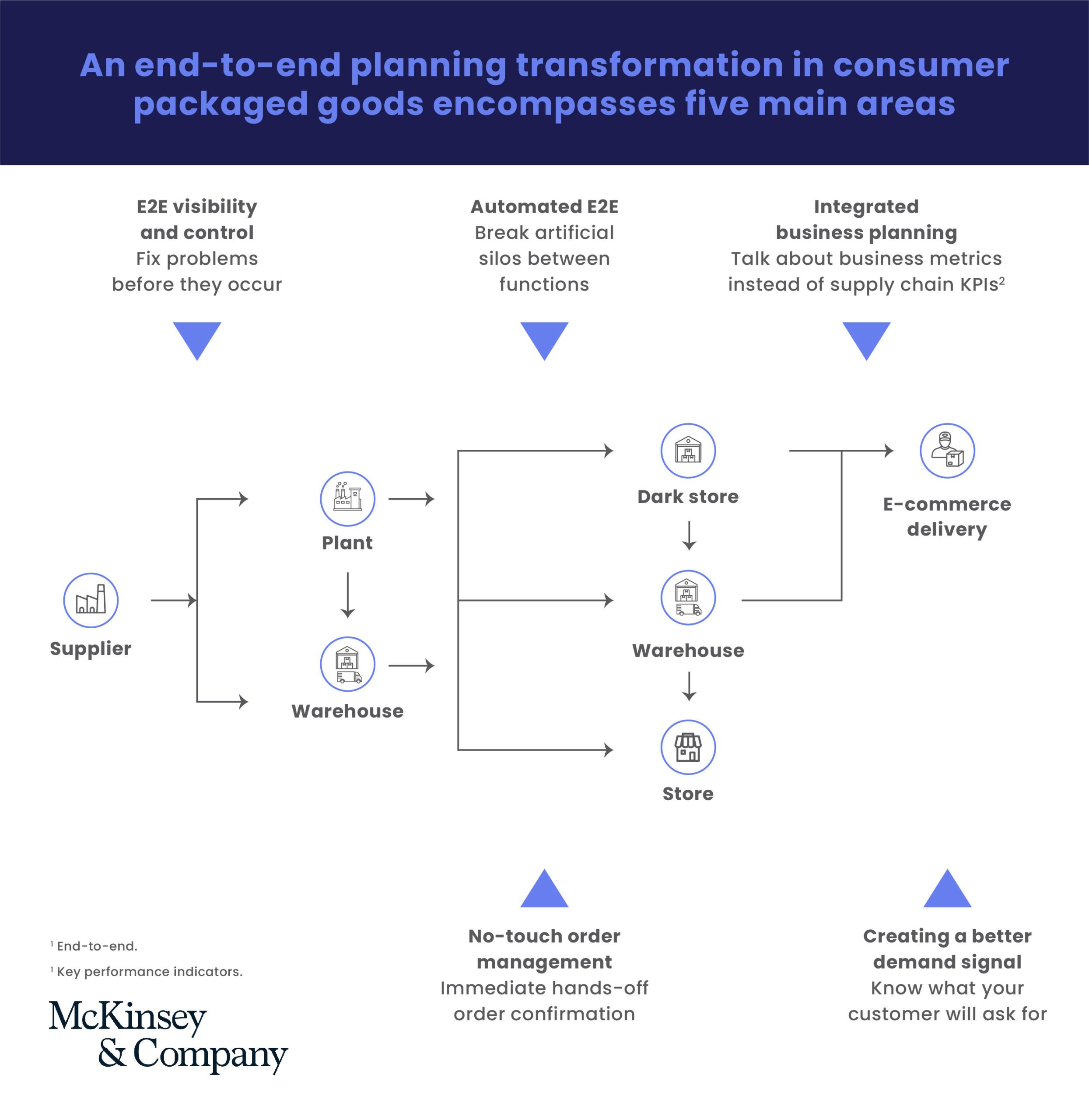

Thus, there is an urgent need for an end-to-end transformation of retail supply chain planning software, or a need to completely reimagine planning capabilities, processes, operations, and company performance.

As retailers look to make this change without compromising on core functions, machine learning and artificial intelligence will play a focal role. To be able to generate the maximum value from such a shift, they should prioritize the following when choosing their supply chain software.

Focus on the Top and Bottom-line Growth

Over the past few years, the retail industry has exploded, thanks in part to the boom in e-commerce triggered by an unending pandemic and changing customer preferences.

This in turn has led to the emergence of omnichannel sales, which means that there are many more channels to maintain and leverage as retailers look to improve customer experience.

At the same time, however, they also need to do this at the lowest possible cost so that they can conserve and grow their margins across all channels.

As retailers face a growing number of challenges by way of increasing product mix complexity, excess inventory, and stockouts and missed sales opportunities, there is a growing need for more transparent, resilient supply chains.

Ensure cross-functional integration and end-to-end planning

Traditionally, businesses have always approached digitalization as a process that needs to be done one step – or function – at a time.

They ended up investing in planning tools and technologies in a few areas, meaning that these selected areas witnessed improvements, leaving the rest of the areas underdeveloped – and underperforming.

Thankfully, retailers are now beginning to realize the need to manage planning efforts for different functions (for example, demand, procurement, manufacturing, and distribution) in a coordinated manner so that they can address their entire network of complex issues while at the same time driving the most optimized decisions for the whole value chain.

To achieve this, they need to affect a high degree of automation and transparency in their supply chain activities.

Chart a Clear Path to Value

To derive the maximum value from planned end to end operations, many retailers will have to affect a comprehensive operational transformation.

They will need to focus on business metrics rather than standard key performance indicators for their supply chains – in other words, they need to prioritize integrated business planning, which leverages real-time financial scenarios to improve the quality of operational planning decisions, while retaining the agility to adapt the planning process to runtime market changes.

Key enablers of this approach are real-time scenario identification and evaluation, artificial intelligence enabled demand forecasting, financial planning, and supply chain planning.

While this approach is important for all player in the consumer market, it is particularly critical for omnichannel retailers that require cross-channel decision making (such as prioritization decisions in the event of bottlenecks).

Thus, by enabling a coordinated supply chain strategy, retailers can benefit from optimized trade-offs involving pricing, promotions, and product availability – a task that is highly challenging to achieve with conventional planning systems.

Retail Supply Chain Planning Software that Creates Better Demand Signals

AI-powered demand forecasting algorithms make use of both internal and external data sources to “learn” from historic demand patterns, and thus keep improving forecast accuracy – thus eliminating the need for manual planning and minimizing human bias and error.

Thus, supply chain leaders in retail are increasingly leveraging the capabilities of such advanced forecasting tools to close the gap between demand forecasts and business targets.

However, planning transformations are very complex to implement successfully.

Retailers that want to explore advanced planning should therefore start by identifying a core list of strategic business priorities and aligning them with their business goals across their operations, in the process setting clear improvement objectives for each functional area.

Finally, they should devise a clear deployment plan that takes into account key performance indicators across organizational skills, processes, functions, and business structures to ensure that all potential challenges are identified, anticipated, and addressed from the start.

Only then can their supply chain transformation be considered to be complete.