The Complete Guide to Supply Chain Planning in 2024

Effective supply chain planning is more vital than ever in today’s fast-paced business world. It plays a crucial role in streamlining the production and delivery of products, all while ensuring supply and demand are in equilibrium.

With this comprehensive article, we’ll dive deep into the complexities of supply chain planning. We’ll also cover indispensable factors that supply chain experts must weigh carefully when helping companies prepare to compete globally.

Finally, we’ll show how you can understand supply chain planning holistically with a tool that helps global companies save money daily.

What is Supply Chain Planning?

Supply chain planning is a forward-looking process aiming to optimize the delivery of goods, services, and information from suppliers to customers while balancing supply and demand.

The planning involves anticipating customer demand and planning materials, components, production, marketing, distribution, and sales accordingly.

The overall goal of supply chain planning is to ensure that sales revenue opportunities are fully utilized on time and at the lowest possible cost.

The process is essential for businesses to optimize operations, enhance efficiency, reduce costs, and create happy customers.

What is the First Step in Planning Supply Chain Operations?

The first step in planning supply chain operations is demand planning and forecasting.

Demand planning is a supply chain management process organizations use to accurately project future demand and customize their output based on the plans.

When matching demand planning with supply planning, organizations have more control over the output, meaning customer needs are better met.

Demand planning typically involves forecasting demand based on historical data, market trends, and other factors that help make informed decisions about production levels, inventory management, and resource allocation.

What are the Benefits of Supply Chain Planning?

The benefits of supply chain planning are reduced costs, increased customer satisfaction, optimized supply chain operations, simplified inventory management, and increased revenue.

To be honest, there are numerous benefits of supply chain planning. Here’s the full list:

- Increased customer satisfaction ensures that products are delivered at the right time and place. Having satisfied customers builds brand loyalty and gives businesses a competitive edge.

- Simplified inventory management by aligning supply with demand to prevent stockouts or excess inventory.

- Improved quality control that ensures high-quality products and services by implementing quality control measures, monitoring supplier performance, and improving processes to meet customer expectations.

- Streamlined operations, enhanced efficiency, and reduced delays, all of which translate into lower operating costs.

- Optimized supply chain operations mean businesses can reduce costs, improve efficiency, and increase profits.

- Helping organizations identify and mitigate risks, developing contingency plans, and monitoring potential threats to business.

- Adaptability and responsiveness are another result of supply chain planning – it enables organizations to adapt to changing market conditions and customer demands and respond to disruptions.

- Fostering collaboration and integration among supply chain partners – suppliers, manufacturers, distributors, and customers. The results are more streamlined operations, improved communication, and enhanced overall supply chain performance.

What are the Key Elements of Effective Supply Chain Planning?

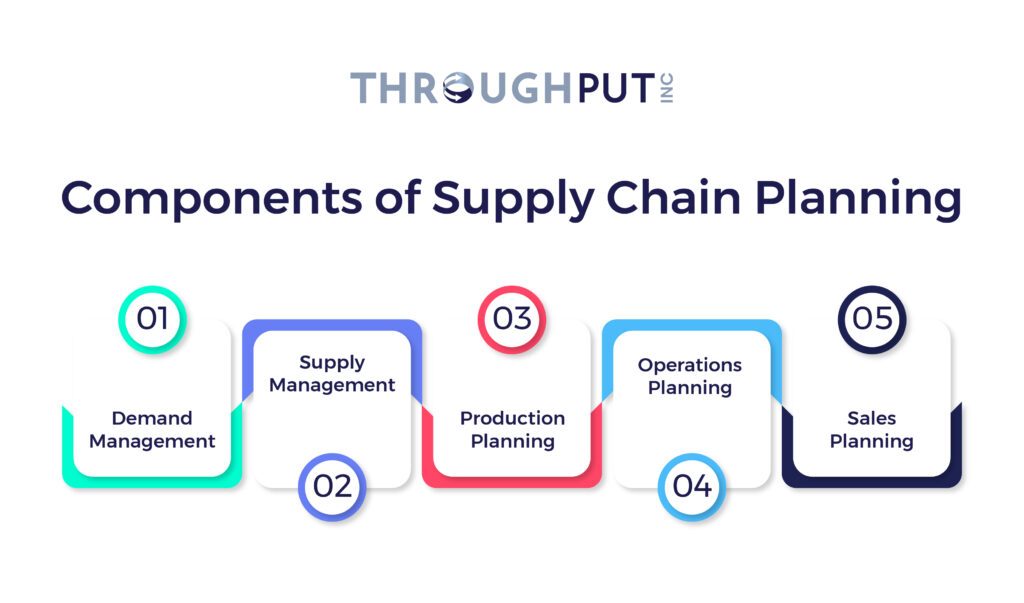

The key elements of demand planning are production planning, demand and supply planning, inventory management, logistics management, supplier management, risk management, and sales and operations planning.

The planning process needs to optimize the delivery of goods, services, and information from suppliers to customers. It involves coordinating the mentioned elements of the supply chain.

Production Planning

Production planning aligns production capacities with customer demand to ensure optimal efficiency and customer satisfaction.

There are several important points when it comes to production planning:

Aligning production capacities with customer demand

To ensure that the production capacities are in sync with the forecasted customer demand, companies must analyze historical data, observe market trends, and include customer feedback to predict future demand and accurately adjust production.

When this alignment of production and customer data is in place, companies avoid issues such as stockouts or excess inventory that often lead to financial losses and dissatisfaction in the market value chain.

Strategies for efficient production planning and scheduling

To optimize production planning, companies employ various strategies, such as implementing lean manufacturing principles, utilizing advanced scheduling tools, and adopting just-in-time (JIT) production techniques.

The correct strategies result in minimizing waste, reducing lead times, and improving operational efficiency.

Resource management and optimization in production planning

Resource management and optimization involve effectively allocating resources such as labour, machines, and materials to ensure smooth production processes.

With the correct resource utilization, operational efficiency meets customer demand within the desired time frame. As a result, companies minimize idle time, reduce production bottlenecks, and increase productivity.

Demand and Supply Planning

Demand and supply planning are two essential processes in supply chain management. Including them in planning improves decision-making and enhances overall supply chain performance.

Demand planning

Demand planning is a supply chain management process organizations use to project future demand and customize their output accurately.

Demand planning involves supply chain forecasting based on historical data, market trends, and other factors that help make informed decisions about production levels, inventory management, and resource allocation.

Supply planning

Supply planning works with demand planning – organizations must manufacture and supply enough products to meet the forecasted demand.

Supply planning involves coordinating various aspects of the supply chain – procurement, production, distribution, and resource management and considering factors like the availability of raw materials and employee responsibilities.

Coordination of demand and supply planning

Coordinating demand and supply planning involves integrating demand forecasts with supply planning processes to ensure that all parts of the organization work together.

Once a well-executed sales and operations planning (S&OP) process comes into play, organizations balance supply and demand, improve decision-making, and enhance overall supply chain performance.

Inventory Management

Supply chain professionals always aim to maintain optimal inventory levels to meet demand while minimizing costs and risks associated with over or understocking.

Effective inventory management means meeting demand while reducing expenses and improving cash flow. Demand planning determines how much inventory is needed and when to order it.

How does inventory management impact supply chain planning?

Your supply chain is optimized when the right products are available at the right time, in the right quantities, and at the suitable locations.

Proper inventory management means the companies can:

- Reduce stockouts and ensure high customer satisfaction.

- Minimize holding costs and optimize working capital.

- Enhance operational efficiency and reduce lead times.

- Improve forecasting accuracy and demand planning.

Inventory optimization strategies and techniques

Inventory optimization needs to balance inventory levels and customer service levels. Analyzing demand patterns, lead times, and other factors to determine the optimal inventory levels.

Some common inventory optimization strategies and techniques include:

- ABC analysis to classify items based on their value and prioritize inventory management efforts

- Just-in-Time (JIT) inventory management to minimize holding costs and reduce inventory levels

- Economic Order Quantity (EOQ) model to calculate the optimal order quantity to minimize ordering and carrying costs

- Vendor-managed inventory (VMI) to allow suppliers to monitor and replenish inventory levels directly

Inventory control methods and best practices

Inventory control methods help maintain optimal inventory levels through proper monitoring, tracking, and replenishment. Some of the best practices include:

- Regular inventory audits to identify discrepancies and prevent stockouts or excess inventory

- Implementing safety stock to buffer against demand fluctuations or supplier delays

- Using serialization and barcoding to track and trace inventory accurately

- Applying advanced inventory management software to automate processes and enable real-time visibility

Logistics Management

Logistics management is a crucial link that ensures the smooth flow of products from suppliers to customers.

Coordinating the movement of goods, materials, and information in the supply chain

One of the primary responsibilities of logistics management is to ensure the timely and cost-effective movement of goods, materials, and information throughout the supply chain. It involves coordinating various activities, such as transportation, warehousing, inventory management, and order processing.

Transportation:

- Choosing the most suitable mode of transportation

- Optimizing routes for efficient delivery

- Tracking and monitoring shipments

Warehousing:

- Strategically locating warehouses for optimal inventory positioning

- Implementing efficient storage and retrieval systems

- Ensuring proper handling and security of goods

Inventory Management:

- Optimizing inventory levels to meet demand while minimizing holding costs

- Implementing effective replenishment strategies

- Utilizing technologies like RFID and barcode scanning for accurate tracking

Order Processing:

- Efficiently managing the order fulfillment process.

- Ensuring accuracy and timeliness in the process

- Streamlining communication between suppliers, manufacturers, and customers

Key concepts and principles of logistics management

- Supply Chain Integration: Collaboration and coordination among all supply chain partners to facilitate seamless information flow and decision-making.

- Lean Logistics: Eliminating waste and non-value-added activities to optimize efficiency and reduce costs.

- Reverse Logistics: Managing the return, disposal, and recycling of products to minimize environmental impact and maximize value recovery.

- Third-Party Logistics (3PL): Outsourcing logistics operations to specialized service providers to leverage their expertise and resources.

Optimizing transportation, warehousing, and distribution activities

Logistics management aims to optimize various activities involved in the movement of goods, including transportation, warehousing, and distribution:

- Transportation optimization with efficient route planning, load consolidation, and carrier selection strategies to minimize transportation costs and improve delivery speed.

- Optimizing warehouse layout, storage systems, and picking processes to increase throughput, reduce handling time, and improve inventory accuracy.

- Distribution Optimization by designing an effective distribution network that ensures the right products are delivered to the suitable locations at the right time while minimizing costs.

Supplier Management

Without proper supplier management, businesses can face various challenges that may hinder their success in meeting customer demands. Establish strong relationships with suppliers and develop strategies for collaboration.

What’s the importance of supplier management in supply chain planning?

Proper supplier management helps businesses to strategically align their supply chain operations with their overall business goals. Supplier management directly impacts the availability and quality of materials and services required for production and distribution.

When suppliers are reliable and capable of meeting the organization’s demands, businesses can minimize disruptions and maintain a seamless flow of goods and services.

What’s the supplier selection criteria in supply chains?

Organizations must consider factors like reliability, quality, capacity, cost, and responsiveness when selecting suppliers.

Best practices in supplier selection involve conducting thorough research and due diligence. Suppliers’ financial stability, reputation, and previous performance must be included in the study.

Collaborative strategies for building strong supplier relationships

Collaboration and cooperation between businesses and suppliers can improve efficiency, flexibility, and innovation. To build strong supplier relationships, organizations can implement collaborative strategies such as:

- Maintaining open and transparent communication channels with suppliers to share information, address issues, and align goals.

- Involving suppliers in decision-making and jointly developing plans to optimize supply chain performance.

- Investing in supplier development programs enhances suppliers’ capabilities and ensures continuous improvement.

- Establishing clear performance metrics to evaluate supplier performance and provide feedback for improvement.

- Collaborating with suppliers to assess and mitigate potential risks in the supply chain to minimize disruptions.

Risk Management

Businesses must identify and mitigate potential risks to ensure a smooth supply chain. Companies can minimize disruptions and enhance their supply chain resilience by implementing effective risk management strategies.

Identifying and mitigating risks in supply chain planning

In supply chain planning, it is essential to identify the various risks that may impact the flow of goods and services. These risks include natural disasters, political instability, supplier bankruptcies, and transportation delays.

Once these risks are identified, businesses can develop strategies to mitigate them.

- Diversify the supplier base to mitigate the risk of supplier bankruptcies or disruptions. Thus, avoid the complete halt of the supply chain by having multiple suppliers in case one supplier cannot deliver.

- Companies can also purchase insurance policies that cover supply chain disruptions. Additionally, developing contingency plans for potential risks can help companies react swiftly and minimize the impact of disorders.

- Data analytics helps enterprises identify potential risks and make informed decisions. Companies can proactively mitigate risks and optimize their supply chain planning by analyzing historical data and market trends.

Strategies for enhancing supply chain resilience

An effective risk management plan also involves strategies to enhance supply chain resilience. These strategies include:

- Building solid relationships with suppliers and key partners improves supply chain resilience while enabling businesses to address risks promptly.

- Maintaining buffer stocks, implementing agile production processes, and having alternate transportation routes ensure supply chain flexibility.

- Monitoring the supply chain performance and identifying potential risks is crucial for enhancing resilience. Monitor the performance by leveraging real-time tracking systems, performing regular audits, and communicating with all stakeholders.

Tools and frameworks for effective risk management

These tools and frameworks facilitate effective risk management in supply chain planning:

- Performing risk assessments to understand and prioritize potential risks. Analyze the impact and likelihood of risks and develop mitigation plans accordingly.

- Conducting scenario planning exercises to simulate risk scenarios and evaluate their preparedness. Companies can identify gaps and improve before an actual risk event occurs by testing various scenarios.

- Implementing supply chain visibility technologies enables tracking goods’ movement and identifying bottlenecks or disruptions. This real-time visibility helps in proactive risk management.

Sales and Operations Planning (S&OP)

Sales and Operations Planning (S&OP) allows businesses to effectively manage their demand and supply to ensure smooth operations and customer satisfaction.

Integrating of sales and operations data enables companies to make informed decisions and align their resources to meet customer demands. This integrated approach helps optimize production, inventory levels, and distribution, resulting in improved customer service, reduced costs, and increased profitability.

The key elements and steps involved in the S&OP process are:

- Collaborative forecasting between sales and marketing teams collaborate with other functional areas to develop a demand forecast. This forecast serves as a basis for the supply planning process.

- Supply review assesses the company’s capacity and capability to meet the forecasted demand. It considers factors like production capacity, inventory levels, and supplier capabilities.

- Consensus planning of the production and inventory plans by the sales and operations teams to reconcile discrepancies between the demand forecast and supply capabilities.

- The executive review by senior management to review and approve the production and inventory plans to ensure alignment with the company’s strategic objectives.

- Performance Measurement of the results against the planned objectives to identify deviations and take corrective actions.

What is an Example of Supply Chain Planning?

Prime examples of supply chain planning are Amazon and Orkla Food. Here’s additional context behind their demand planning success:

Orkla Food

Orkla Food is a leading branded consumer products company in the Nordics and one of Norway’s largest companies. The organization has more than 25,000 direct suppliers globally and many sub-suppliers, such as farmers.

Orkla Food faced challenges in coordinating its planning activities due to the large number of SKUs in its portfolio and the complexities of its supply chain.

Orkla Food implemented supply chain planning to optimize its operations and enhance efficiency.

The effective management of demand planning, supply planning, and inventory management, along with other aspects of the supply chain enabled Orkla Food to streamline operations, enhance efficiency, avoid delays, and reduce operating costs.

This approach also help the company adapt to changing market conditions, manage disruptions, and improve customer satisfaction.

Amazon

Amazon’s supply chain strategy is a prime example of how a company can optimize its operations and enhance efficiency.

Some key components of Amazon’s supply chain planning include:

- Warehousing: Amazon has a vast network of fulfillment centers and warehouses strategically located near metropolitan areas to ensure efficient storage and management of inventory.

- Inventory Management: The company uses advanced technologies and algorithms to manage and replenish inventory, aligning supply with demand and preventing stock outs or excess inventory.

- Delivery: Amazon has developed a robust delivery network, including partnerships with USPS and UPS, its fleet of trucks, vans, bikes, and even robots in some cases, to optimize delivery times and costs.

- Technology: Amazon embraces technology in its supply chain management, utilizing automation, robotics, and data-driven solutions to streamline operations and improve efficiency.

By effectively managing these aspects of its supply chain, Amazon can streamline operations, enhance efficiency, avoid delays, and reduce operating costs.

What are Supply Chain Technologies?

Supply chain technologies are software, tools and systems that streamline supply chain processes, increase efficiency, and reduce costs. Some of the most popular supply chain technologies include:

- Supply Chain Planning Software for managing and replenishing inventory through sales and demand forecasting. It enables companies to balance supply and demand, improve decision-making, and enhance overall supply chain performance.

- Warehouse Management Software (WMS) for managing warehouse operations, including inventory tracking, order processing, and shipping. These systems improve warehouse efficiency, reduce errors, and lower operational costs.

- Transportation Management Systems (TMS) for transportation and logistics operations, including carrier selection, route optimization, and shipment tracking. These systems reduce transportation costs, improve delivery times, and enhance customer service.

- Artificial Intelligence (AI) and Machine Learning are revolutionizing supply chain management by automating tasks, analyzing large amounts of data, and providing guidance on forecasting supply and demand.

- Internet of Things (IoT) devices enable real-time tracking and authentication of products and shipments using GPS and other technologies. They monitor storage conditions, ensure quality management throughout the supply chain, and provide real-time visibility and tracking of goods and products from production to distribution to end consumers.

- Blockchain technology can improve supply chains by enabling faster and more cost-efficient delivery of products, enhancing traceability, improving coordination between partners, and aiding access to financing. Blockchain can track inventory levels, optimize inventory management processes, and facilitate supply chain finance by providing secure and transparent records of transactions between suppliers, manufacturers, and distributors.

What is a Supply Distribution Network Design?

The supply distribution network design is a framework that determines the flow of goods, the locations of warehouses and distribution centers, and transportation routes.

An effective distribution network design ensures that goods are transported from the point of production to the end of consumption most efficiently and cost-effectively.

What to Consider in Designing an Efficient Supply Distribution Network?

- Geographical coverage of the distribution network should reach a wide geographical area to ensure products can get customers efficiently.

- Customer demand patterns must be understood to determine the number and location of distribution centers to optimize product availability.

- Transportation costs must be considered in the distribution network design, including shipping, fuel, and maintenance, to minimize overall supply chain expenses.

- Lead time requirements of different products

- Inventory positioning within the distribution network must ensure that products are available when and where needed, reducing stockouts and excess inventory.

Techniques for Optimizing Warehouse Locations and Transportation Routes

There are several techniques used for optimizing warehouse locations and transportation routes:

- Network optimization modeling uses mathematical models to evaluate scenarios and identify the optimal locations for warehouses and distribution centers.

- Transportation route optimization uses algorithms that analyze transportation routes, considering factors such as distance, cost, and delivery time to identify the most efficient ways.

- Simulation models test different distribution network designs in a virtual environment, allowing businesses to assess their performance and make data-driven decisions.

The Power of AI-driven Supply Chain Planning

With IoT and artificial intelligence (AI) led technologies rapidly gaining momentum especially in the global logistics and supply chain management industries, supply and demand planners stand to benefit from these in several ways.

The powerful evolution in artificial intelligence, machine learning, and data science has the potential to bring in massive disruption and meaningful innovation across these industries.

With specific reference to supply chain planning, AI can help to a great extent in reducing supply chain costs, managing inventory, and eliminating potential bottlenecks. AI in supply chain can help obtain new insights into several areas to boost productivity and optimize resources as well.

As a result, floor operators and planners are able to create more agile, flexible, and profitable supply chain plans to deliver goods and services as per customer expectations.

One such important application of AI in supply chain planning is the process of eliminating bottlenecks across the supply value chain to ensure supply chain planners and managers can meet their revenue targets easily.

Safer, Smarter and Better Supply Chain Planning with ThroughPut

ThroughPut’s Demand-driven supply chain planning software is a fully automated, scalable, enterprise-ready Kaizen Artificial Intelligence product based on digitalizing the world’s leading continuous improvement operations principles.

It enables your operations managers in effective supply chain planning to achieve unprecedented productivity and operational excellence.

ThroughPut analyzes existing industrial data in real-time to detect, identify, prescribe and prevent potential bottlenecks saving millions in delays and lost revenue.

It helps meet your supply chain goals by nailing down bottlenecks and eliminating inventory waste to achieve end-to-end efficiencies. You ultimately benefit from an efficient and optimal smart supply chain plan along with time, money, and resource savings.