5 Best Capacity Planning Software in the Market Right Now

Capacity planners face the ongoing challenge of balancing production capacity with unpredictable demand fluctuations. You’re not only responsible for ensuring enough capacity to meet demand but also for efficiently scheduling production, managing inventory, and minimizing the risk of lost sales opportunities.

Being able to quickly assess these variables and adjust in real time is crucial for maintaining smooth operations and meeting future demand. Modern capacity planning software is designed to help you identify potential risks, develop actionable strategies, and optimally allocate resources—ensuring you stay ahead in a rapidly changing market.

In this blog, we’ll introduce you to the top best capacity planning software that you can evaluate for your enterprise.

Five Best Capacity Planning Software You Can Choose From

While the market is overcrowded with software and solutions, here are five top recommendations of the best production capacity planning software in the market right now.

1. Spreadsheets!

Spreadsheets are great due to the sense of familiarity, yes! However, if it is about facilitating smart and agile decision-making in the dynamically changing world of capacity planning, spreadsheets are definitely not the right answer.

Microsoft Excel and Google Sheets are excellent for a single-unit business that is small with a few product categories. A word of caution though – if the business goals are growth-related, spreadsheets may not be the answer you are looking at.

Start considering the other best capacity planning software listed here.

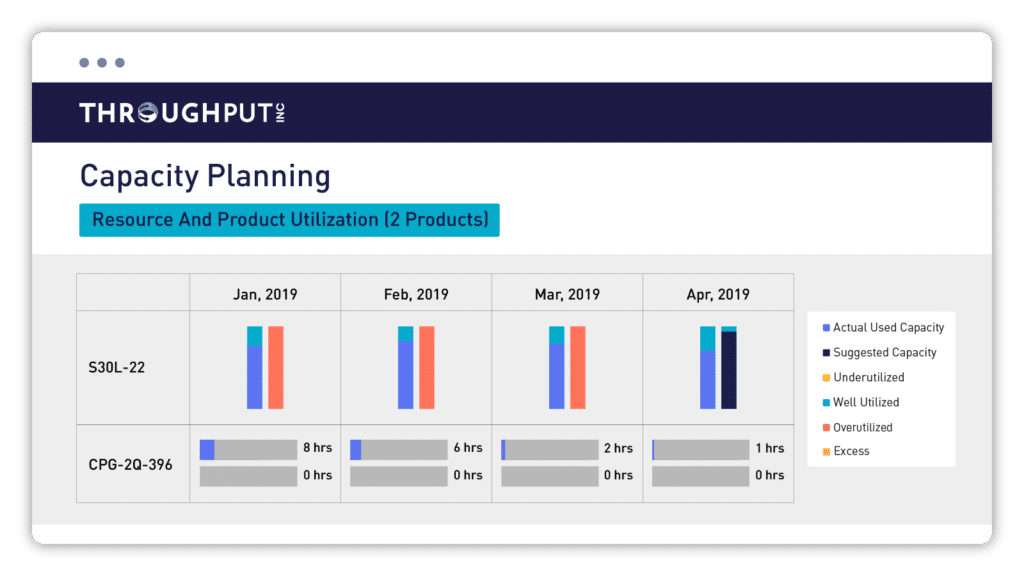

2. ThroughPut AI

As a capacity planner, you need a tool that accurately assesses the actual capacity vis-a-vis realized demand, identifies lost sales opportunities, and schedules production load. That’s where the Capacity & Production Planning module of ThroughPut AI comes into the picture. It empowers you to strategically understand if future demands can be met or not with existing capacity, highlighting risks and offering risk mitigation strategies such that available resources can be optimally scheduled. With ThroughPut AI, you can prioritize product mix optimally, evaluate current capacity, and strategize to meet future demands accurately.

Feature #1: Flow-based Capacity Optimization

Optimize the flow of resources, materials, and tasks across the entire system. Instead of adding extra resources, ThroughPut AI lets you focus first on pinpointing and resolving bottlenecks or inefficiencies that slow down operations, thereby increasing output without the need for additional investments.

Feature #2: Capacity- or Supply- Constrained Demand Forecasts

Accurately predict future demand while factoring in current supply limitations. ThroughPut AI goes beyond traditional demand estimation by integrating a detailed understanding of your production or supply chain’s maximum output, ensuring forecasts are aligned with what can realistically be delivered.

This way, you can set achievable goals, prevent overpromising, and maintain customer satisfaction.

Feature #3: OI/ROA/Net Financial Impact Estimation

Make data-driven decisions, quantify the potential financial outcomes of various supply chain strategies and ensure more informed, profitable business choices.

ThroughPut AI integrates three essential financial metrics—ROI, ROA, and Net Financial Impact Estimation—to evaluate the profitability, efficiency, and financial performance of your investments or supply chain activities.

Feature #4: Equipment Readiness

Ensure your machinery, tools, and technology are always primed for optimal performance. ThroughPut AI reduces downtime and guarantees that equipment is consistently ready to meet production demands, a critical factor for capacity planners aiming to maintain smooth operations.

This feature goes beyond routine maintenance by integrating timely upgrades and implementing more efficient processes to enhance operational readiness.

Benefits of ThroughPut AI

- Work With Existing Data: ThroughPut AI leverages existing client transactional data by extracting targeted information from current data sources through API connectors, direct database access, or data dumps. Once extracted, the data is enriched with relevant internal and external sources, such as promotions, weather trends, commodity prices, and public health indicators. For capacity planners, this approach is critical in developing a comprehensive, data-driven strategy. By integrating diverse data streams, it enhances predictive accuracy and provides deeper insights for more informed decision-making. Additionally, it eliminates the need for substantial upfront investments in data migration or cleaning technologies, making it a cost-effective solution for real-time capacity optimization.

- ROI in 90 Days: The return on investment generated by ThroughPut AI is very fast. As the best capacity planning software, it quickly identifies and eliminates inefficiencies across your production process with advanced AI-driven insights. It helps optimize resource allocation, streamline workflows, and reduce operational costs. Within just 90 days, you get to typically see significant improvements in productivity and profitability, making ThroughPut AI a powerful tool for delivering fast, measurable financial gains.

- Treats Manufacturing as Part of the E2E Value Chain: ThroughPut AI views manufacturing not as an isolated function but as a critical component of the end-to-end value chain. It is designed to integrate manufacturing with supply chain, logistics, and customer demand, ensuring that every aspect of production is aligned with overall business objectives. This comprehensive approach enhances operational efficiency, drives better decision-making, and ensures that manufacturing contributes meaningfully to the entire value chain.

- Finance Integration: ThroughPut AI seamlessly integrates financial data into its operational analytics, enabling a comprehensive view of the business’s financial health. By aligning operational performance with financial outcomes, the platform helps businesses make data-driven decisions that optimize both production efficiency and financial results.

3. Palantir

Palantir features on the list of the best capacity planning software because it offers precision and insights to optimize your operations. Designed for businesses aiming to enhance efficiency and strategic decision-making, Palantir empowers organizations to navigate complex production and supply chain challenges with ease.

Features:

- Integrates data from diverse sources, providing a comprehensive view of your operations.

- Utilizes predictive analytics to forecast demand and align your resources accordingly.

- With an intuitive, user-friendly interface, Palantir makes complex capacity planning accessible

Benefits:

- Scalable platform that adapts to your specific needs, ensuring that you can manage capacity effectively at any scale.

- Treats capacity planning as an integral part of the end-to-end value chain, aligning production with supply chain and financial objectives, and driving overall business efficiency.

4. Logility

Logility offers a single solution to capacity planners for planning manufacturing and capacity optimization. The solution helps in capacity planning and detailed scheduling.

Features:

- Manage forecast consumption across single and multiple periods to enable safety stocking

- Updation of released manufacturing orders to facilitate logical planning beyond shop order sequencing

- What-if simulations to save planning time

Benefits

- Production planning can be optimized to hours and minutes

- Faster response time to meet service targets

- Cycle times get shortened for better ROIs

5. Anaplan

The Anaplan Production Planning software is another platform on the list of the best capacity planning software that’s designed to streamline and optimize your production processes. With its cloud-based architecture, Anaplan enables real-time collaboration and data-driven decision-making across your organization. It can be seamlessly integrated with existing systems, offering advanced analytics and predictive capabilities to align production with demand.

Features

- Customized views for planning at the macro and the micro levels

- Converts attribute-based plans fast into SKU configurations to support flexible business logic

- Faster allocations via transparent models for actual status updates and forecasts

Benefits

- Faster planning determination to plan allocation of materials, employees, and production capacities

- Dynamic and continuous planning by drilling down the root causes with what-if analysis so that production plans can be amended in real time

- Connected planning to drive maximal efficiency across manufacturers, suppliers, and trading partners

- Ensuring budget compliance by converting volumes to values.

Demand-driven Capacity Planning with ThroughPut AI

ThroughPut AI’s Capacity Planning module equips capacity planners to lead in an increasingly complex production landscape. By maximizing asset utilization and optimizing production schedules, it ensures that every machine operates at peak efficiency. Whether managing unexpected maintenance or aligning inventory with market demands, ThroughPut AI provides the precision and insight to handle modern production challenges.

For capacity planners, this means driving continuous improvement and operational excellence. With ThroughPut AI, you can make informed decisions that boost productivity, reduce downtime, and align resources with business goals—ensuring greater efficiency and success.

Frequently Asked Questions (FAQs) on AI-Driven Capacity Planning Software

1: What is the best capacity planning software for large enterprises?

The best capacity planning software for large enterprises is one that combines AI-driven forecasting, real-time capacity visibility, financial impact analysis, and end-to-end value chain alignment. Platforms like ThroughPut AI stand out because they go beyond static planning by identifying bottlenecks, quantifying lost sales, and aligning production capacity with actual market demand—while integrating operational and financial outcomes.

2: How does AI-powered capacity planning differ from traditional tools?

Traditional capacity planning tools rely on historical data and static assumptions, often leading to overproduction or missed demand.

AI-powered capacity planning software, such as ThroughPut AI, continuously analyzes real-time data, detects constraints, runs what-if simulations, and recommends actionable strategies—allowing planners to respond proactively instead of reactively.

3: Can capacity planning software help reduce lost sales and stockouts?

Yes. Advanced capacity planning software identifies capacity-demand mismatches early, enabling planners to adjust production schedules, optimize product mix, and prioritize high-margin or high-demand SKUs. ThroughPut AI specifically highlights lost sales opportunities and recommends mitigation strategies to ensure demand is met without overloading resources.

4: How quickly can businesses see ROI from capacity planning software?

With traditional tools, ROI may take months or even years.

With AI-driven platforms like ThroughPut AI, businesses typically see measurable ROI within 90 days, driven by improved asset utilization, reduced downtime, optimized production flow, and better demand alignment.

5: Does capacity planning software integrate with existing ERP and data systems?

Modern capacity planning software is designed to work with existing systems. ThroughPut AI integrates seamlessly with ERP, MES, supply chain, and financial systems using APIs, direct database connections, or data dumps—eliminating the need for heavy data migration or system replacements.

6: How does capacity planning software support financial decision-making?

Best-in-class capacity planning solutions don’t stop at operational insights. ThroughPut AI connects capacity decisions with financial metrics such as ROI, ROA, and Net Financial Impact. This allows leaders to clearly understand how capacity changes affect profitability, working capital, and overall business performance.

7: Is capacity planning software suitable for complex, multi-site manufacturing environments?

Yes. AI-driven capacity planning platforms are built to handle multi-plant, multi-product, and multi-constraint environments. ThroughPut AI evaluates capacity across locations, identifies system-wide bottlenecks, and recommends optimal production schedules—ensuring global alignment and local efficiency.

8: How does ThroughPut AI support demand-driven capacity planning?

ThroughPut AI enables capacity- or supply-constrained demand forecasting, ensuring that demand plans are realistic and executable. By aligning demand forecasts with actual production and supply constraints, planners can avoid overpromising, improve service levels, and protect customer trust.

9: What should I evaluate before choosing a capacity planning software?

Before selecting a solution, evaluate:

- Ability to identify and resolve bottlenecks

- Real-time capacity and demand alignment

- Financial impact visibility

- Integration with existing systems

- Speed of ROI

- Scalability across the end-to-end value chain

ThroughPut AI addresses all these criteria, making it a strong choice for enterprise capacity planners.

10: Is ThroughPut AI suitable for organizations looking to modernize capacity planning?

Absolutely. ThroughPut AI is designed for organizations moving away from spreadsheets and siloed tools toward AI-driven, demand-aware, financially aligned capacity planning. It enables planners to lead with confidence, agility, and measurable business impact.