Manufacturing Capacity Planning Software: Optimizing Operations with ThroughPut AI

We’ve come a long way since COVID-19 first hit. But let’s be real, “planning for the future” still doesn’t feel like a walk in the park. Our world is full of surprises – and not always the pleasant kind. Plans can go topsy-turvy overnight.

For those of us in production/manufacturing capacity planning, this roller coaster has taught us a few things:

- Demand is likely to keep fluctuating dramatically

- Allocating resources for unforeseen circumstances has become critical

- The flexibility of working capital in response to customer demand is now a crucial consideration

- Understanding the full potential of utilizing spare capacity to drive new sales is essential for maximizing throughput

The terms of manufacturing capacity planning have changed dramatically, exposing the inefficiencies in using spreadsheets and manual processes.

Nowadays, getting your hands on a solid manufacturing capacity planning software isn’t just nice to have – it’s a must-have.

Let’s dive in and explore what a modern manufacturing capacity planning software should achieve when it integrates technologies like AI, analytics, and machine learning.

The Irreplaceable Benefits of Manufacturing Capacity Planning Software

Post the COVID-19 pandemic, geopolitical tensions and fluctuating market demands have consistently acted as disruptors for supply chains.

It is imperative, given all these unpredictable circumstances, that organizations take proactive steps to make themselves resilient against future shocks. Optimizing manufacturing capacity is one of the keys to getting there.

So, what can the optimization of manufacturing capacity translate into?

Can your capacity be reconfigured swiftly in response to market changes?

How complex or simple is it to free up your capacity to handle contingencies?

Can your working capital be adjusted dynamically based on customer demand?

What is the potential for leveraging excess capacity to drive new sales?

Strategic capacity planning can guide you in determining the necessary raw materials, equipment, labor, and facilities over time to meet future demand accurately.

The irreplaceable benefits of an advanced manufacturing capacity planning software system are:

- A well-executed capacity planning strategy can ensure efficient allocation of manufacturing resources

- Excess capacity indicators can prevent inefficient expenditure, diverting the funds to be profitably invested elsewhere

- Insufficient spare capacity scenarios can be avoided that can easily hamper the ability to meet customer demand promptly

Key Features of Manufacturing Capacity Planning Software

The key features of an advanced manufacturing capacity planning software include Scenario Planning, Asset Performance Tracking, Inventory Optimization, Demand and Supply Performance Analysis, and Material and Financial Flow.

The software will give you the strategic advantage to help free up existing manufacturing capacity and adequately meet market demand on time.

It will also ensure sufficient working capital while providing additional throughput potential consistently across various demand-supply scenarios.

Feature #1: Demand and Supply Performance Analysis

The software should be able to efficiently select the best machines for each product while maintaining optimal machine load to mitigate output issues due to variation.

For example, ThroughPut AI’s Capacity Planning module provides detailed capacity insights, including actual used capacity, suggested capacity, underutilized, well-utilized, and overutilized capacity.

Additionally, it delivers demand insights, detailing demand quantity, quantity produced, potential quantity, actual demand, unmet demand, and excess inventory.

Together, these capacity and demand insights help balance supply with demand, ensuring that you are always prepared to meet customer needs without overextension.

Feature #2: Asset Performance Tracking

Any advanced manufacturing capacity planning tool should mitigate throughput losses by aligning real-time demand with resource utilization, keeping it within the set capacity limits. This strategy can significantly reduce operational expenses related to the acquisition of extra capacity.

Furthermore, ThroughPut AI enhances this capability by providing crucial insights into overall asset utilization.

This analysis reveals how long assets spend in various states—underutilized, well-utilized, overutilized, or in overtime. The tool also offers actionable suggestions for effective machine-product pairings throughout the planning horizon.

These recommendations help shift the utilization rate to a more balanced and controlled state, which can then be repurposed for additional productive activities.

Feature #3: Inventory Management

Inventory management is crucial for staying ahead in your industry by maintaining updated information on inventory levels, despite market fluctuations that might affect your inventory and production. An effective manufacturing capacity planning platform should provide essential insights into actual inventory levels, recommended stock levels, and replenishment strategies.

With ThroughPut AI, in particular, you can:

- Measure, track, and trace inventory, with recommendations on when and where reallocation is feasible.

- Balance resource availability with demand, offering deep insights for both mid-term and near-term planning.

- Consider inventory availability across the company, incorporating necessary buffer levels to manage uncertainty in demand fluctuations and production lead time, ensuring reliability in meeting sales targets on time and in full.

- Align inventory availability and demand dynamics with working capital to recommend actions based on priority.

Feature #4: Scenario Planning

An effective manufacturing capacity planning software should be able to anticipate potential changes in demand, supply chain disruptions, or resource availability, and enable you to prepare accordingly.

ThroughPut AI, for instance, lets you create and compare multiple “what-if” scenarios. This could include varying levels of product demand, changes in supply chain logistics, or different staffing models. By simulating these scenarios, decision-makers can visualize the impacts on production capacity and resource utilization.

Integrating real-time data allows the scenarios to be as realistic and informative as possible.

By assessing different scenarios, ThroughPut can recommend optimal resource allocation. This ensures that resources are not underutilized or overextended in any given scenario, balancing efficiency and cost-effectiveness.

How a Manufacturing Capacity Planning Software Works?

ThroughPut’s AI-driven Capacity Planning module is built in the context of the current world we live in.

Its real-time capabilities ensures you’re planning your capacity by considering the constant demand fluctuations, the possibility of disruptions whilst keeping the financial impact in full view.

The ultimate aim is to maximize throughput using your existing capacity and demonstrate significant financial improvements.

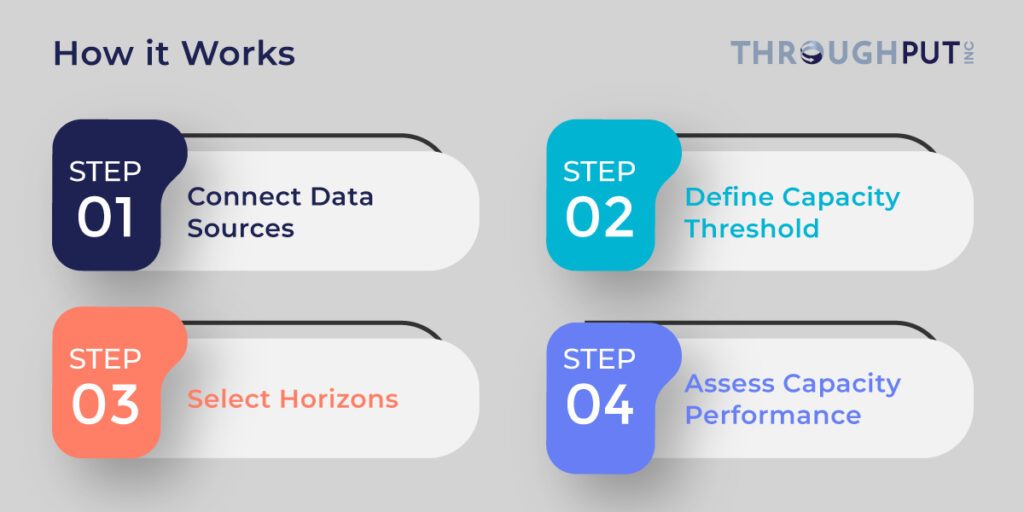

The optimization process with ThroughPut AI is rather methodical. It starts by integrating various existing data sources (ThroughPut AI works with what you already have!), laying the foundation for a comprehensive operational overview.

Next, precise capacity thresholds are set, delineating operational limits and potentials. Planning horizons are then selected to define the strategic time frame for capacity assessment. The process culminates in a detailed assessment of production capacity performance, leveraging data to shape future strategies.

With the ThroughPut Capacity Planning Tool, organizations can meet the below capacity utilization goals:

- Evaluate the actual capacity against realized demand, scheduled production load of processes over time, inventory build up and lost sales opportunities.

- Assess the ability to meet future demand, highlight risks and propose mitigation strategies.

- Expose which products are affected by internal and external constraints.

- Propose the priority to schedule limited resources against the product mix optimized for the highest throughput potential.

Benefits of Manufacturing Capacity Planning With ThroughPut AI

Boost Asset Performance Management

With ThroughPut AI’s capacity planning module, you can nail down exactly how much workload each of your assets can handle. This means you’re using your equipment to its maximum potential without pushing it too hard.

You can also plan for both your regular maintenance and those sudden, out-of-the-blue fixes. This keeps your equipment running smoothly, cutting down unexpected downtime.

Plus, you get a bird’s-eye view of all your sites and plants, making it super easy to manage work orders. You can assign tasks to the right place at the right time, without being blinded by siloed operations.

And lastly, ThroughPut AI’s smart scheduling feature gives you a crystal-clear view of your production schedules, weekly and monthly. This lets you make smart calls on how to use your assets most efficiently, boosting your overall productivity game.

Better Inventory Management

ThroughPut AI’s manufacturing capacity planning gives you precise control over your inventory. It accurately measures, tracks, and suggests when to reallocate your stock. This ensures your inventory levels are always aligned with demand, keeping you well-prepared and efficient.

You’ll have access to detailed insights for both immediate and future inventory needs using the tool. This helps you maintain the right amount of stock at all times, preventing shortages or excesses.

ThroughPut AI also considers your overall inventory availability and required buffer levels. This is crucial for dealing with unpredictable demand and production timelines, ensuring you consistently meet your sales targets.

Moreover, you can align your inventory with market demands and your financial capabilities, with access to action recommendations based on priority. This approach makes sure your inventory levels are not just sufficient but also financially sound, enhancing your business efficiency.

Effective Product Allocation

Identify which machines are best for each product, ensuring they are used efficiently. ThroughPut AI maintains the ideal workload on each machine, preventing production issues due to overuse or underuse. This method improves your overall efficiency and leads to a more consistent and reliable production flow.

Higher Throughput

Ramp up your asset use, getting more out of your production process. ThroughPut AI shows you exactly how your assets are doing – are they underworked, just right, overworked, or burning the midnight oil? This clear picture lets you really get how efficient each asset is.

Plus, ThroughPut AI is all about making room for more productivity. It guides you on which machines should work on what products, balancing their workload. This way, your machines are used just right, and you’ve got space to take on more work without missing a beat.

Superior Service Levels

Sync up your production with what the market wants. ThroughPut Ai helps you set the perfect stock levels to match customer demand. This means your production is always on point with what’s needed out there, making sure you’re using resources wisely and keeping products available.

Plus, ThroughPut AI gives you a clear view of how your machines are performing on the shop floor. You can see how they’re doing compared to what you planned and what the software suggests. This kind of insight is key to know if you’re using your assets effectively and following the best strategies.

And the best part? You can make real-time tweaks and improvements, keeping your production not just efficient, but also super responsive to market changes.

Key Questions Addressed By ThroughPut AI’s Manufacturing Capacity Planning Module

Key questions addressed by this manufacturing capacity planning software at the strategic, mid-level, and tactical levels include:

| Strategic | Mid-level | Tactical |

COO and Chief Supply Chain Officers | Demand Planners and Capacity Planners | Operations Managers |

How can you work towards an effective demand segmentation strategy? | Can you drive timely bottleneck detection across production schedules? | How does capacity utilization impact the plant floor’s actual capacity? |

| Can capacity utilization decisions help meet future demand with accurate assessment of production capacity? | How do you enhance asset performance and reliability? | How can you reallocate day-to-day production schedules based on actual capacity needs for specific resources? |

How can operations strategy help prevent loss of sales or even recover lost sales? | How can you recover lost yield across the supply chain? | How can capacity bottlenecks be identified in a timely manner? |

| How can you overcome operational constraints and identify the need for CAPEX investments in a timely manner? | How does effective capacity planning drive mid-term operational decisions? | Can production limitations be corrected before they adversely affect utilization? |

| How can inventory be optimized to avoid over or under stocking products? | What is the normal performance you can expect based on your current utilization? | How can the overall throughput (gross margin) be increased? |

Maximizing Efficiency with ThroughPut’s Manufacturing Capacity Planning Software

There you have it.

Navigating production capacity planning in 2024 is a whole new ball game, and ThroughPut AI’s got you covered.

From squeezing the most out of every machine and piece of equipment to aligning your inventory with the ever-changing market demands, you’re set to stay ahead of the curve. It’s about being smart with your resources, proactive with your maintenance, and always one step ahead in meeting customer needs.

With ThroughPut AI’s Capacity Planning module, you’re not just keeping up; you’re setting the pace in a world where adaptability and efficiency aren’t just nice-to-haves, they’re must-haves.

Welcome to the future of capacity planning – streamlined, savvy, and always on point.