18 Best Supply Chain Analytics Software Solutions to Improve Business Efficiency

Supply chain analytics software combines powerful algorithms, data, and the latest technologies like Artificial Intelligence and Machine Learning to address the most elusive challenges in the supply chain right now – visibility and control.

Think of supply chain analytics as your strategic advantage, like catching that perfect wave early in the surfing game. In the ever-changing business landscape, those who get in on the action before the crowd can claim a competitive edge. And that’s precisely what’s on the horizon for supply chain analytics. Given that the supply chain is an industry characterized by constant flux, surprises, and an intricate web of moving parts – supply chain analytics steps in as the all-powerful enabler.

By 2032, the supply chain analytics market is expected to reach USD 38.78 billion. Today, we are at USD 7.41 billion. The 18% estimated Compound Annual Growth Rate (CAGR) comes as no surprise, given the game-changing potential of supply chain analytics.

From leaders to the dedicated folks on the front, supply chain analytics equips everyone to meet their performance goals (those famous KPIs) and get business revenues and growth into high gear.

So, what’s the game plan here? This piece will unveil the top 18 supply chain analytics solutions currently shaking up the market. These aren’t just tools but potential game-changers for your bottom line in the long run. But remember, your choice depends on your specific puzzle, supply chain strategy, and what you’re already packing in your toolkit.

Ready to dive in?

What is Supply Chain Analytics Software?

In the simplest terms, supply chain analytics empowers you to make intelligent decisions based on facts, not gut feelings. Supply chain analytics integrates and evaluates data from across your supply chain to draw actionable insights that can help you optimize your supply chain operations.

Considering your supply chain has large volumes of data lying in siloed systems, supply chain analytics software is like a supercharged information engine that gathers and dissects data from every nook and cranny of your supply chain, which may otherwise not be humanly possible.

Let’s face it – your supply chain is a treasure trove of data scattered across various systems like pieces of a puzzle waiting to be pieced together. This is where supply chain analytics software steps in, conjuring insights faster and with greater precision than human capabilities can muster. It often conjures up those nuggets of wisdom that might have slipped past even the sharpest human eye.

This magic isn’t confined to just one corner of your business. Supply chain analytics software is a versatile tool that stretches its influence across the entire spectrum. From keeping tabs on inventory levels and production schedules to orchestrating order fulfillment, managing transportation, and evaluating supplier performance – it’s your one-stop shop for tracking many events and activities.

So, what features should you look for in your supply chain analytics tool?

What are the Key Features and Functionalities of Modern Supply Chain Analytics Tools?

Supply chain analytics tools offer a wide range of features and functionalities to support effective supply chain management, but there are some non-negotiable ones to look out for:

- Data visualization: Supply chain analytics software must provide interactive visualizations and dashboards, making it easier to understand complex data and identify patterns, trends, and outliers.

- Real-time monitoring: Supply chain analytics software must provide real-time data, alerts, and notifications to enable proactive decision-making and response to unexpected events.

- Data integration capabilities: Your supply chain generates data from various sources – inventory systems, production lines, transportation networks, etc. Top-tier analytics software should seamlessly integrate data from these disparate sources, offering a unified view of your entire supply chain.

- Integration of external data: An effective supply chain analytics software must also be able to access and analyze data from external sources like weather forecasts, social media trends, etc.

- Latest analytics: Supply chain analytics software must have predictive and prescriptive analytics capabilities to help you predict the future and provide actionable recommendations to manage future scenarios.

- Machine Learning and AI integration: Machine Learning and Artificial Intelligence enhance the software’s analytical capabilities. These technologies can uncover patterns, anomalies, and correlations within the data that might not be apparent through traditional analysis methods.

What are the Best Supply Chain Analytics Software Solutions?

Many excellent supply chain analytics software or tools in the market differ in features, focus areas, visualizations, and other vital elements. What you need for your business will depend on the problem you are trying to solve, your existing capabilities, and your budgets.

Based on our experience, here are the top supply chain analytics software solutions you can evaluate in the market today.

- ThroughPut AI

- Palantir Foundry

- SAP Supply Chain Analytics Software

- Oracle Fusion SCM Analytics

- Blue Yonder

- Manhattan Associates

- Tableau

- GMDH Streamline

- IBM Supply Chain Analytics

- Supply Chain Guru X by Coupa

- Kinaxis RapidResponse

- O9 Solutions

- Anaplan

- Qlik

- SAS Supply Chain Analytics

- Aera Technology

- Conversight

- Tredence

Let’s have a closer look at each one.

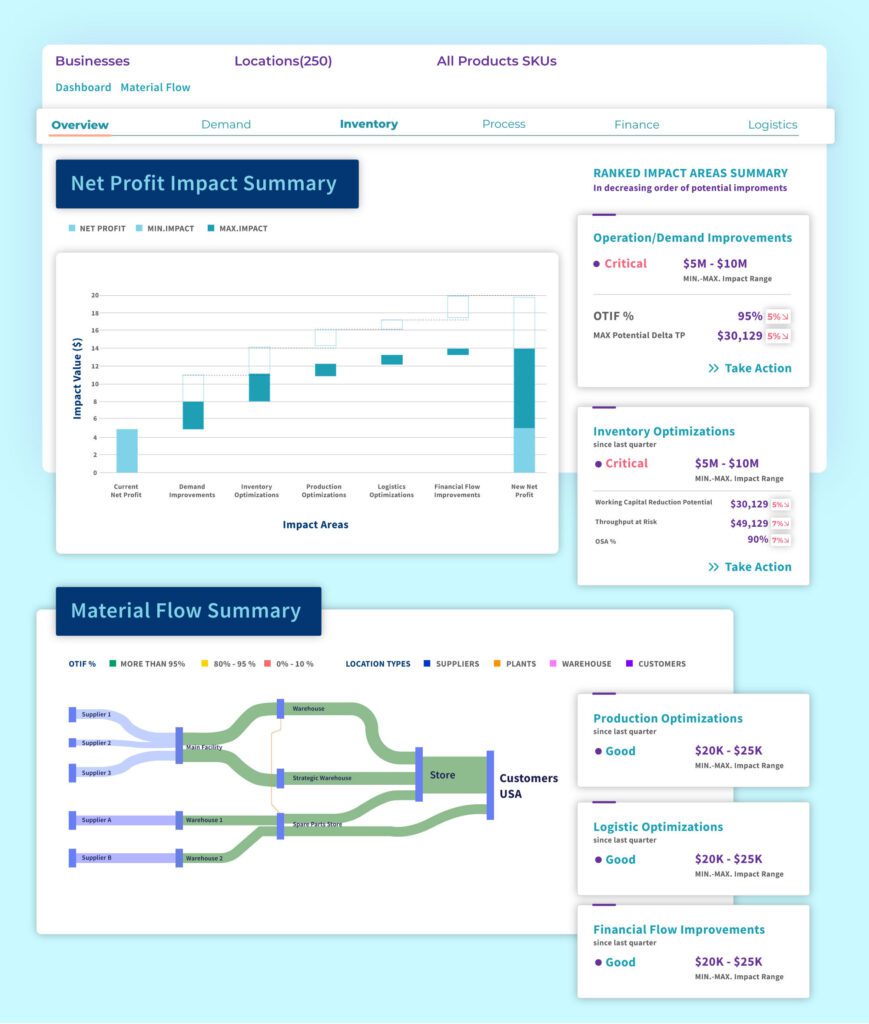

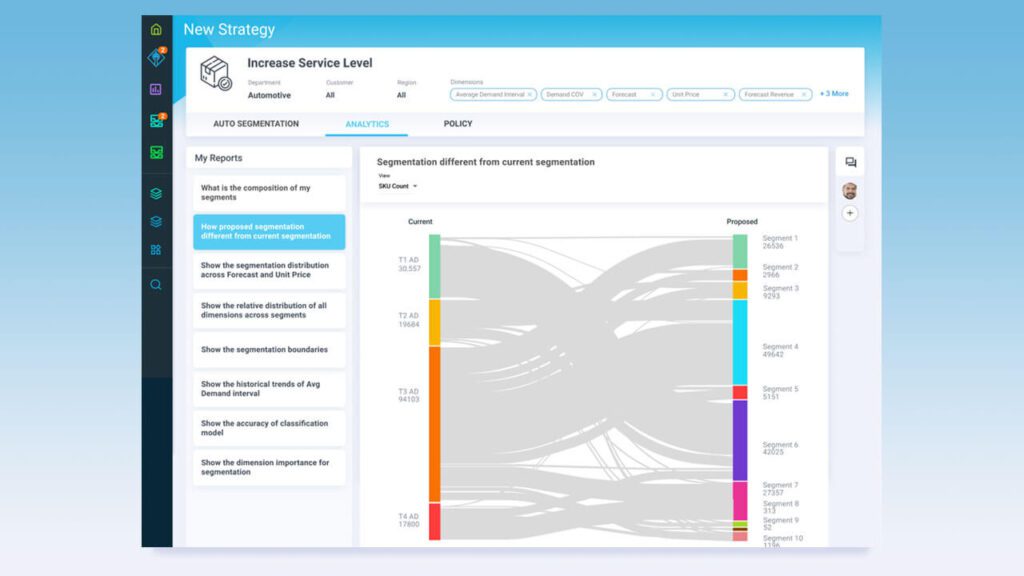

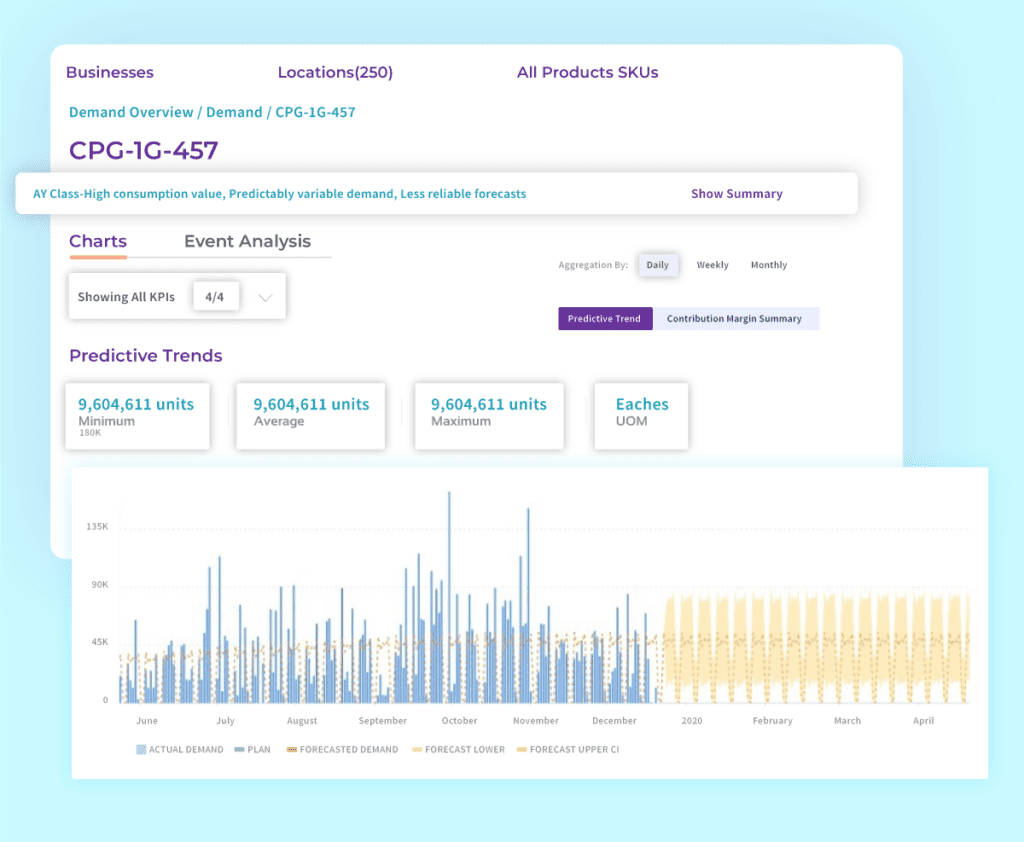

1. ThroughPut

Overview: ThroughPut is an AI-powered supply chain intelligence software that leverages your existing data to diagnose improvements within your supply chain with the fastest and highest ROI. From demand to capacity, product, customer, and logistics, ThroughPut studies your entire supply chain ecosystem to recommend the best and most impactful solutions. Its AI-powered capabilities make it a tool that can be used in real-time to accommodate real-time shifts, fluctuations and disruptions.

Main Features:

- Net profit summary view that helps businesses connect the dots between finance and supply chain operations

- Quick diagnostic capabilities to identify improvements with the fastest ROI

- Customizable visualizations with real-time simulations for root cause analysis

- End-to-end visibility with holistic system optimization

- Single source of truth for data-driven decisions

Main Benefits:

- Recognized as a top-rated supply chain optimization solution

- Fast implementation cycle (5-30 days)

- Ability to report on free cash flow, revenue and working capital

- Adaptable to any business environment

- Trusted by multiple government agencies, defense institutes, retail megacorps, building material manufacturers and agribusinesses

2. Palantir Foundry

Overview: Palantir Foundry is a data integration and analytics platform that offers end-to-end capabilities, data lineage, virtualization tools, and scalability. It is designed to help organizations manage and analyze data from various sources, providing insights for better decision-making.

Main Features:

- Data lineage

- Virtualization tool

- Scalability

Main Benefits:

- Excellent security with granular control

- Data lineage and virtualization tools

3. SAP Supply Chain Analytics Software

Overview: Part of SAP’s broader suite, SAP Supply Chain Analytics Software, is a comprehensive solution for supply chain planning, logistics, manufacturing, lifecycle management, and asset management. It helps businesses optimize costs, achieve revenue growth, and improve supply chain efficiency through advanced planning and optimization features.

Main Features:

- AI-powered demand forecasting

- Advanced planning and optimization (APO)

- Predictive maintenance

Main Benefits:

- Widely used among supply chain professionals and a 19% global market share

- Easy integrations for those already using SAP solutions

- Upgradability and multiple forecast modeling techniques

4. Oracle Fusion SCM Analytics

Overview: A module within Oracle’s Cloud SCM, Oracle Fusion Supply Chain Management Analytics, can detect, understand and resolve supply chain problems faster using a pre-built analytics model.

Main Features:

- Pre-built KPI library

- Add third-party data sources

- Self-service tools for report creation

Main Benefits:

- Rapid implementation in the Oracle SCM ecosystem

- Visibility into cost-saving opportunities

- Correlate supply chain operations with business outcomes

5. Blue Yonder

Overview: Blue Yonder is a suite of integrated solutions for supply chain planning, inventory optimization, and demand forecasting built for manufacturers and retailers. It helps businesses optimize their supply chain operations, reduce costs, and improve customer satisfaction.

Main Features:

- Generative AI

- Unified data model

- Domain-enriched UI component library

Main Benefits:

- Comprehensive suite of integrated solutions

- Advanced analytics capabilities

6. Manhattan Associates

Overview: Manhattan Associates is a supply chain software that engages analytics to provide insights to improve customer experience. From inventory management, order management, subledger, and financial process features to store inventory and fulfillment, Manhattan Associates brings planning and execution together on a single platform.

Main Features:

- Customizable dashboards for supply chain performance

- Delivery alerts for customer satisfaction

- Order management

Main Benefits:

- Supports omnichannel commerce

- Low-code tool

- Focus on customer service

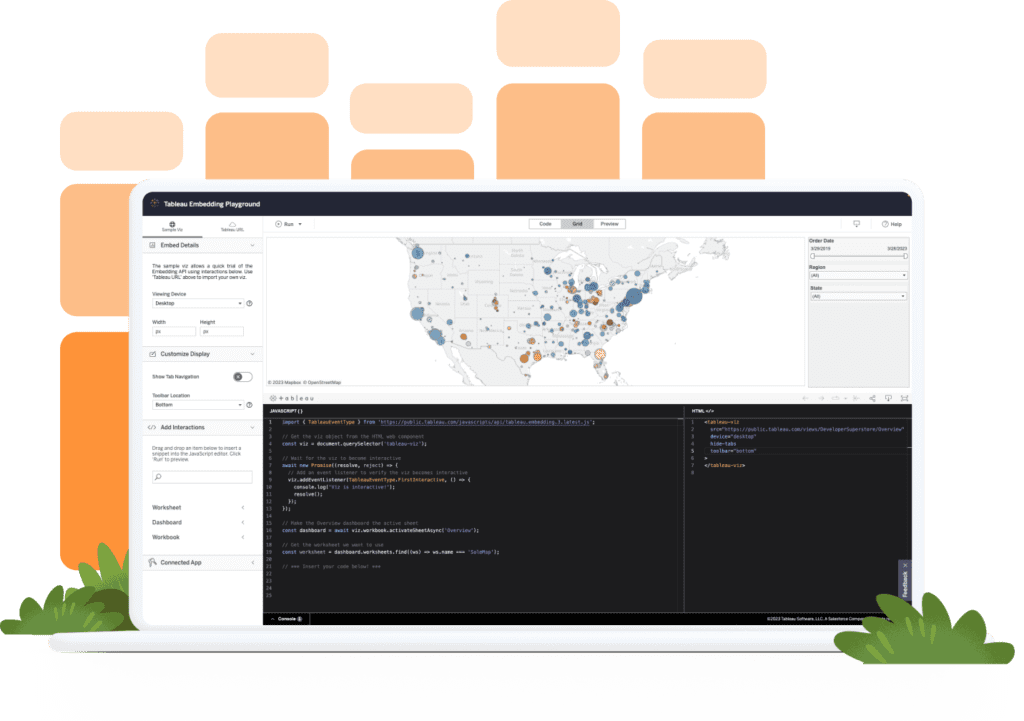

7. Tableau

Overview: Tableau is a data visualization and analytics tool built focusing on manufacturing, production, and logistics. It provides insights for better decision-making and improved capacity planning, inventory management, and delivery.

Main Features:

- Data visualization

- Integration with other systems

Main Benefits:

- Intuitive interface

- Wide range of data visualization options

- Strong community support

8. GMDH Streamline

Overview: GMDH Streamline is a supply chain planning software that engages predictive analytics and is designed primarily for manufacturers, distributors, retailers, and ecommerce brands. It offers visibility to manufacturers to manage day-to-day production, distributors to maintain inventory levels, and retailers to avoid stockouts.

Main Features:

- Integrates with multiple ERPs

- Multi-echelon planning

- Visibility into operations

Main Benefits:

- Replaces Excel sheet

- Designed for day-to-day operational management

- Faster planning

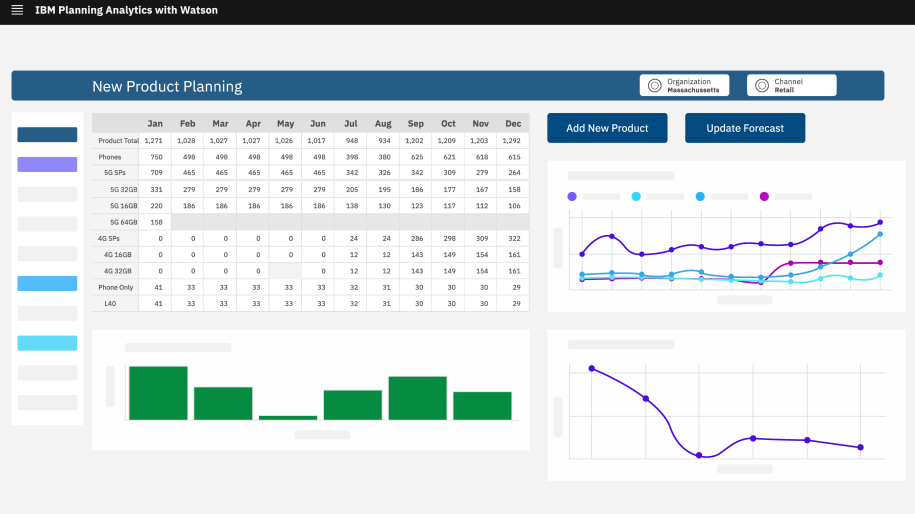

9. IBM Supply Chain Analytics

Overview: IBM Supply Chain Analytics is an AI-enabled supply chain planning software that uses analytics to help businesses make data-driven decisions and improve their supply chain operations. It offers demand forecasting, inventory optimization, and logistics planning features.

Main Features:

- Single centralized platform

- Use of real-time internal and external data

- Multiple business partner solutions

Main Benefits:

- Enterprise-wide collaboration

- More accurate sales and operations plans

- Cut downtime for data analysis

10. Supply Chain Guru X by Coupa

Overview: Supply Chain Guru X by Coupa is a cloud-based supply chain analytics solution that visualizes, optimizes, simulates, and analyzes supply chains for risk mitigation, sustainability and cost improvements.

Main Features:

- Supply chain simulation

- Scenario analysis

Main Benefits:

- Risk management

- Better adaptability

- Product evolution

11. Kinaxis RapidResponse

Overview: Kinaxis RapidResponse is a supply chain planning and analytics solution that empowers businesses with real-time insights and scenario-based planning capabilities.

Main Features:

- Scenario simulation

- End-to-end synchronization

- AI-driven insights

Main Benefits:

- Risk mitigation

- Resilience

- Optimized operations

12. O9 Solutions

Overview: O9 Solutions is a digital platform that provides end-to-end visibility and actionable insights across supply chains. With advanced AI and machine learning capabilities, O9 Solutions enables demand forecasting, inventory optimization, and scenario analysis.

Main Features:

- Integrated planning

- Scenario simulation

- Patented graph-based technology

Main Benefits:

- Better collaboration with business teams

- High security and encryption services

- Scalability

13. Anaplan

Overview: Anaplan is a cloud-based supply chain planning and analytics platform that empowers businesses to connect data, people, and plans across the supply chain for enhanced visibility and agility. Anaplan PlanIQ is integrated with Artificial Intelligence and Machine Learning for better results.

Main Features:

- Intuitive user interface

- Advanced analytics functions

- What-if analysis

Main Benefits:

- Enterprise-wide intelligence

- Recommendations for complicated use cases

14. Qlik

Overview: Qlik is a data analytics and visualization platform that empowers supply chain professionals with insights to drive informed decisions. Qlik enables users to analyze supply chain data from various sources, uncover patterns, and gain actionable insights through its intuitive data discovery and visualization capabilities.

Main Features:

- Data visualization

- Self-service analytics

Main Benefits:

- Insightful decision making

- Better inter-functional collaboration

15. SAS Viya Supply Chain Analytics

Overview: SAS Viya is an analytics platform that empowers supply chain professionals to harness the power of advanced analytics and artificial intelligence for optimizing supply chain operations. With its cloud-native architecture, SAS Viya offers real-time insights, predictive modeling, and machine learning capabilities.

Main Features:

- Advanced analytics

- Model deployment

Main Benefits:

- Scalable

- Faster decisions

16. AERA Technology

Overview: The AERA Decision Cloud digitizes, augments, and automates complex decision-making in the supply chain using advanced analytics.

Main Features:

- Dynamic cognitive processes

- Pre-packaged algorithms

Main Benefits:

- Self-service platform

- Scalable

17. Conversight

Overview:

Conversight is a company that aims to humanize the interaction between people and data, focusing on providing conversational insights and analytics through its AI platform. Their AI assistant, Athena, understands user behavior, context, and intent to offer personalized insights and actions.

Main Features:

- Data democratization

- Embedded analytics

Main Benefits:

- real-time insights

- predictive analytics

- advanced reporting capabilities

- personalized insights and actions to optimize supply chain management, planning, and execution

18. Tredence

Overview: Tredence is a data science and analytics company that partners with organizations to drive data-driven decision-making in their supply chain operations. Through their expertise in analytics, Tredence offers tailored solutions that enhance supply chain visibility, optimize processes, and facilitate proactive strategic planning.

Main Features:

- Data visualization

- Advanced analytics

Main Benefits:

- Strategic planning

- Agile operations

What are the Benefits of Using Supply Chain Analytics Tools for Businesses?

Supply chain analytics is so much more than a simple data overview. Supply chain analytics tools can improve every aspect of your supply chain, including capacity planning, inventory levels, demand sensing, and your business’s net profits.

Some of the key benefits of using a supply chain analytics tool include:

- Data-driven decision-making: By consolidating and analyzing data from various sources, supply chain analytics tools can enable you to make informed decisions based on accurate and reliable information.

- Increased visibility: Supply chain analytics tools can provide a comprehensive view of your entire supply chain, allowing businesses to identify bottlenecks, inefficiencies, and areas for improvement from a larger and more informed perspective.

- Improved efficiency: A well-oiled supply chain is an efficient one. When analytics software identifies bottlenecks, inefficiencies, and redundancies, it allows you to optimize processes. Whether trimming excess inventory or streamlining production schedules, efficiency is a definite by-product.

- Cost savings: Efficiency leads to savings. Supply chain analytics software helps you cut unnecessary costs by identifying areas where resources are wasted. This could mean reducing inventory holding costs, minimizing transportation expenses, or identifying alternative suppliers.

- Swift problem resolution: Disruptions are the reality of supply chains. With supply chain analytics software, you’re not just reacting to problems but proactively tackling them. Real-time monitoring and alerts ensure you’re the first to know about any deviations, giving you a head start in finding solutions.

- Strategic insights: Analytics software doesn’t just deal with the present; it’s a crystal ball into the future. Identifying trends and patterns provides strategic insights that guide long-term planning and goal setting.

- In a world where speed and efficiency are vital differentiators, supply chain analytics software gives you an edge. You stay ahead of the curve by making informed decisions faster, adapting to market changes swiftly, and optimizing your processes.

What are Data Visualization Techniques for Effective Decision-making in Supply Chain?

Data visualization makes the insights drawn from data accessible to one and all. Visualization is an essential feature in any supply chain analytics tool. Some effective data visualization techniques include:

- Charts and graphs: Visual representations such as line graphs, bar charts, and pie charts provide a clear overview of key performance indicators (KPIs) and trends, enabling stakeholders to identify areas for improvement.

- Heatmaps: Heatmaps visually depict data density and patterns. Stakeholders can quickly pinpoint operational bottlenecks and take necessary actions by identifying hotspots and outliers.

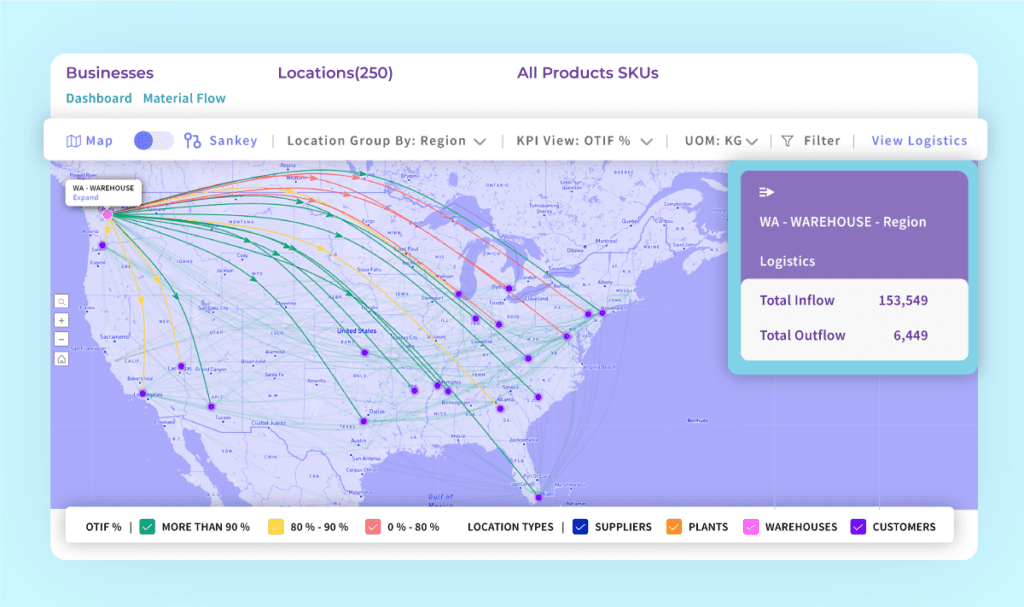

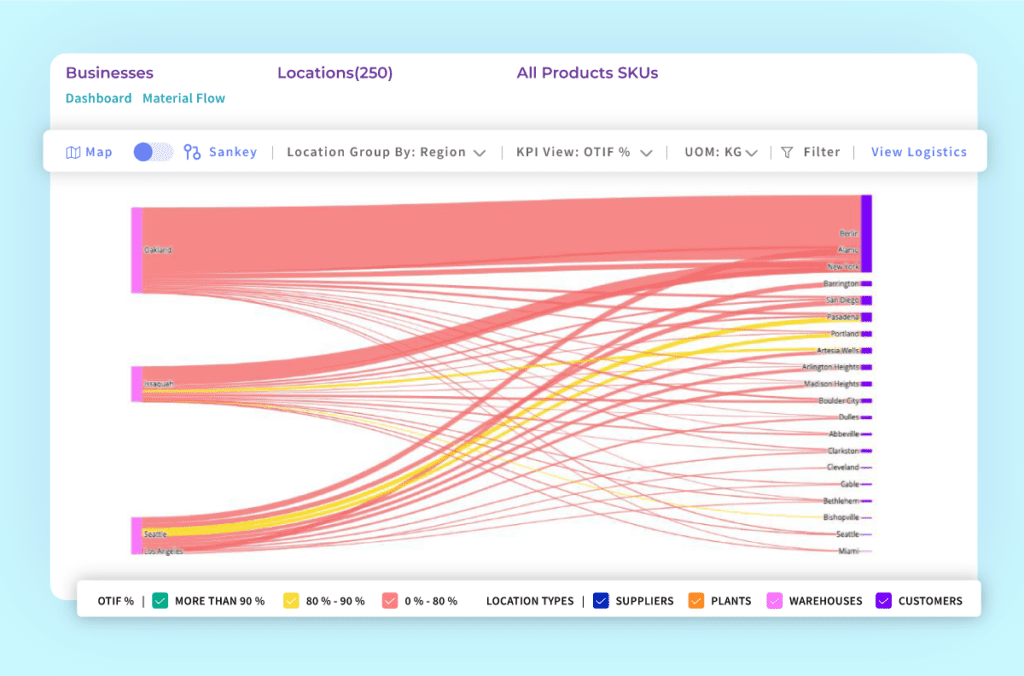

- Geospatial mapping: Mapping supply chain data on geographic maps allows for visualizing distribution networks, identifying regional performance variations, and optimizing logistics and transportation routes.

- Sankey diagrams: Sankey diagrams are valuable tools in supply chain analytics for visualizing the flow of resources, materials, or information within a complex supply chain network. They help illustrate the movement and distribution of various components and resources at different supply chain stages.

With proper data visualization techniques, supply chain analytics software empowers every stakeholder to interpret complex datasets, gain insights, and make data-driven decisions.

How to Run Expense Management and Cost Optimization Using Supply Chain Analytics Software?

If there’s anything that businesses expect from supply chain leaders right now, it is to optimize costs and boost revenue. A good supply chain analytics software plays a crucial role in identifying cost-saving opportunities and improving the overall efficiency of the supply chain.

Role of supply chain analytics software in identifying cost-saving opportunities

A good supply chain analytics software can enable businesses to analyze vast amounts of data and identify areas where costs can be reduced. Businesses can gain valuable insights into cost-saving opportunities by integrating data from various sources such as transportation, procurement, and inventory.

For example, by analyzing historical transportation data, businesses can identify routes or carriers that are more cost-effective. They can also optimize inventory levels to reduce carrying costs while minimizing stock-outs. These insights enable businesses to make informed decisions that result in significant cost savings.

Analyzing and optimizing transportation, distribution, and warehouse costs

A smart supply chain analytics software allows businesses to analyze and optimize transportation, distribution, and warehouse costs. Companies can identify inefficiencies and implement corrective measures by collecting and analyzing data related to transportation routes, fuel prices, and carrier performance.

Additionally, the software can help optimize distribution and warehouse costs by analyzing factors such as order fulfillment time, storage utilization, and labor productivity. Companies with complex supply chains can enhance their profitability and competitiveness by identifying areas where costs can be reduced and operations can be optimized.

What is the Role of Performance Tracking and Metrics in Supply Chain Analytics Software?

Performance tracking and metrics play a crucial role in the success of any supply chain. With the help of supply chain analytics software, businesses can now effectively measure and monitor their performance to make data-driven decisions.

Key performance indicators (KPIs) for measuring supply chain success

Supply chain analytics software provides a comprehensive set of key performance indicators (KPIs) that help businesses evaluate their supply chain performance. These KPIs include:

- On-time delivery: Measures the percentage of orders delivered on time.

- Order fulfillment cycle time: Calculates the time taken to fulfill an order.

- Inventory turnover: Evaluates how quickly inventory is sold and replenished.

- Supplier performance: Assesses the performance of suppliers in meeting quality and delivery standards.

- Cash-to-cash cycle time: Measures the time it takes for cash to flow from purchasing raw materials to collecting funds from customers.

Real-time visibility and tracking of metrics through analytics dashboards

Supply chain analytics software offers real-time visibility and tracking of metrics through interactive supply chain analytics dashboards. These dashboards provide a clear and concise overview of key metrics, allowing businesses to monitor their performance anytime.

With customizable views and real-time updates, decision-makers can quickly identify trends, spot bottlenecks, and track progress toward goals.

Using analytics to identify potential bottlenecks and improve performance

By leveraging the power of analytics, supply chain analytics software helps businesses identify potential bottlenecks and inefficiencies within their supply chain. Advanced analytics algorithms analyze large datasets to uncover patterns, trends, and anomalies.

C-suite staff can then use these insights to optimize their supply chain operations, improve efficiency, and enhance overall performance.

What are the Best Practices for Implementing Supply Chain Analytics Software?

Here’s what you already know: Implementing supply chain analytics software can provide you with valuable insights and a competitive edge. However, successful implementation and integration require careful planning and consideration.

Here are some steps, challenges, and best practices to guide you.

Steps for successful implementation and integration

While these steps are not mandatory, following them will make your life easier.

- Define your goals: Identify what you aim to achieve with the supply chain analytics software. Outline specific objectives and key performance indicators (KPIs) immediately.

- Assess your data infrastructure: Evaluate your existing data infrastructure and capabilities. Ensure it can handle the volume and complexity of data required for effective analytics.

- Data cleansing and integration: Cleanse and integrate your data from various sources into a comprehensive database. Ensure data accuracy and consistency.

- Select the right software: Research and select a supply chain analytics software solution that aligns with your needs and goals. Consider factors such as functionality, scalability, and ease of use.

- Pilot test and validate: Conduct a pilot test before full implementation to assess the software’s effectiveness and identify any potential issues. Validate the results and make necessary adjustments.

- Train your staff: Provide thorough training on effectively using the software. Ensure the staff understands its capabilities and how it can support their decision-making processes.

- Phased implementation: Roll out the software in phases rather than a single, large-scale deployment. This approach allows for easier troubleshooting and reduces disruption to ongoing operations.

- Monitor and refine: Continuously monitor the software’s performance and make refinements as needed. Regularly review and update your analytics strategies to align with your evolving business goals.

Addressing challenges and overcoming resistance during software adoption

You’re bound to face some resistance while implementing any tool. There are budgets involved, changes in familiar ways of working and a steep learning curve for multiple stakeholders. Some of the things you might expect to happen include:

- Resistance to change can come from current employees. Here’s how you can deal with it: address the benefits through effective change management strategies. Communicate the benefits of the software and involve employees in the decision-making process.

- Integration with existing legacy systems can be complex. Collaborate with IT professionals to ensure seamless integration and minimize disruption.

- Develop robust data security measures to protect sensitive information. Adhere to data privacy regulations and industry best practices.

- Involve key stakeholders throughout the implementation process to gain support and meet their needs.

Best practices for training, user adoption, and ongoing support

With all being said, some best practices will ensure a higher probability of software adoption:

- Provide comprehensive training: Offer training sessions covering software functionality and how it can be practically applied in daily operations.

- Foster a culture of analytics: Encourage employees to embrace analytics as part of their decision-making process. Provide ongoing support and encourage knowledge sharing.

- Establish a support system: Create a support team or help desk to promptly address user queries and provide technical assistance.

- Stay updated with software upgrades: Regularly update the software to benefit from new features and enhancements. Maintain a clear roadmap for future improvements.

Following these steps and best practices will help you successfully integrate supply chain analytics software into your operations, unlocking valuable insights and driving performance improvements.

What are the Future Trends in Supply Chain Analytics Tools?

The field of supply chain analytics software is constantly evolving, driven by the advancements in technology and the changing needs of businesses.

Here are some future trends that will shape the landscape of supply chain analytics software:

Exploration of emerging technologies shaping the future of supply chain analytics

As technology advances, new and emerging technologies such as blockchain, Internet of Things (IoT), and advanced analytics will play a significant role in shaping the future of supply chain analytics software.

These technologies have the potential to provide real-time visibility, enhance data accuracy, and improve collaboration among different stakeholders in the supply chain while providing the opportunity to automate decisions in the supply chain.

Potential implications of artificial intelligence and machine learning on analytics

Artificial intelligence (AI) and machine learning (ML) have already started making their mark in supply chain analytics software. AI and ML algorithms can process large volumes of data faster, identify patterns, and generate actionable insights. In the future, AI and ML will become even more sophisticated, enabling advanced cognitive analytics and automation in supply chain decision-making processes.

Predictive analytics and prescriptive insights for proactive decision-making

Supply chain analytics software will increasingly focus on predictive and prescriptive analytics, leveraging historical data and algorithms to forecast future demand, optimize inventory levels and improve planning processes.

Additionally, prescriptive insights will enable businesses to proactively identify and act on potential risks, bottlenecks, and inefficiencies in the supply chain and take proactive measures to mitigate them.

As supply chains become more complex and dynamic, the demand for advanced supply chain analytics software will continue to grow.

Enterprises harnessing these emerging trends’ power will gain a competitive advantage, improve operational efficiency, and make informed decisions to drive their supply chain performance to new heights.

Final Thoughts

Improved decision-making is a crucial priority for supply chain leaders. Undoubtedly, more and more leaders will turn to supply chain analytics software to support, augment, and automate their decisions. It’s like having a trusted compass guiding you through the complexities.

This software will open doors to precious insights, steering you toward data-backed choices that fine-tune your supply chain dynamics.

Embracing supply chain analytics tools is more than a suggestion; it’s wise. The results are like an orchestra playing in harmony when woven into your supply chain strategies. Analytics becomes your conductor, orchestrating processes, trimming costs, elevating performance, and taming uncertainties.

So, as you embark on this journey, remember to explore the cream-of-the-crop solutions we’ve laid out above. The significance of supply chain analytics software will only escalate in the future, and we firmly believe that ThroughPut offers the cutting-edge advantage needed by supply chain aficionados today and in the promising times ahead.

FAQs: What Maintenance and Supply Executives Need to Know Before Investing

Question : How can supply chain analytics software help our maintenance team reduce unplanned downtime?

Answer: For a Head of Maintenance, the primary pain is equipment failure, spare-parts shortages and the resulting production halts. A robust supply chain analytics platform can:

- Pull together maintenance logs, parts inventory, supplier lead times and production schedules to identify which assets are likely to fail and when you might run out of critical spares. (As described in your blog: analytics helps identify bottlenecks and inefficiencies).

- Provide predictive insights (via analytics/AI) into when parts should be reordered, rather than simply reacting when stock is zero.

- Visualize the “cash-to-cash” or “asset downtime to asset-up” cycle (which is analogous in your blog as part of tracking KPIs) to help maintenance leaders show value to operations and finance.

- Ultimately, reduce both the frequency and duration of unplanned stoppages by proactively aligning spare-parts supply with asset maintenance schedules.

By highlighting this, you’re speaking directly to their job: “Keep production running, reduce downtime, show maintenance costs declining.

Question : In sourcing/supply (procurement) what capabilities should I demand in an analytics tool to improve supplier performance and availability of critical materials?

Answer: As a Head of Supply (sourcing), your job is ensuring the right materials arrive on time, at the right cost, and with minimal disruption. The right analytics software delivers:

- Supplier-performance dashboards: On-time delivery, quality issues, lead-time variability. Your blog mentions supplier performance is a key KPI.

- Scenario-analysis capability: What happens if Supplier A delays, or lead-time increases by 20 %? The analytics tool should simulate supply risk, cost impact, and suggest alternative sourcing or inventory buffers. Your blog references simulation and what-if analysis.

- End-to-end visibility: Integrating internal data (POs, inventory, production schedule) with external data (supplier data, market disruptions) so you can spot supply risk early. Your blog emphasises data integration as a key feature.

- A unified view of cost to serve, working capital tied up in supply, and the agility to adjust sourcing strategy or inventory levels accordingly. This aligns with “free cash flow, working capital” insight described for your software.

By focusing on these capabilities, you are speaking directly to the sourcing-executive’s priorities: supplier reliability, cost risk, and supply chain resilience.

Question: How quickly can we demonstrate ROI when we deploy a supply chain analytics platform across maintenance and materials sourcing?

Answer: ROI speed is one of the top concerns for VPs/Directors. When both maintenance and supply sourcing functions are involved:

- The software should allow a pilot or fast implementation (as your blog highlights that some solutions can implement in “5-30 days”).

- Define the initial metrics: e.g., # of unplanned downtime events avoided in first 90 days, reduction in emergency parts procurement cost, savings from expedited freight or premium supplier cost due to delays.

- The analytics tool’s strength lies in identifying immediate opportunities for “quick wins” — such as parts reorder timing, stock versus risk tradeoffs, supplier lead-time visibility.

- For example, if your maintenance team can avoid just one high-cost asset failure (say $100 K skid change) by foreseeing a parts shortage, that alone can cover the cost of the analytics deployment.

- Include hard financials: working capital freed-up, inventory holding cost reduction, emergency sourcing premiums avoided. These tangible benefits resonate with the leadership.

Thus by showing ROI in the first quarter through maintenance + sourcing alignment, you reinforce that this is not just a tool, but a business-outcome driver.

Question: What are the most critical data and systems integration points we must get right to succeed with analytics in sourcing and maintenance?

Answer: Increasingly, executives ask: “We already have ERP, CMMS, procurement systems — how do we integrate analytics without disruption?” The key integration points:

- Inventory systems (material stock levels, parts locations) + procurement systems (POs, supplier lead-times, spend history). Without these, sourcing analytics has no feed.

- Maintenance systems / CMMS (asset failure history, maintenance schedules, parts usage). For reliability analytics.

- Production scheduling / operations systems (to align supply & maintenance with production downtime windows).

- Supplier data (delivery performance, quality metrics, external risk indicators).

- External data (market / commodity price signals, transport disruption data, weather or geo-risk) – as referenced in your blog under “integration of external data” feature.

Getting these integrations right ensures that the analytics engine has “single source of truth” and avoids siloed dashboards. As your blog says: “single source of truth for data-driven decisions”.

For both maintenance and sourcing leaders, this answers the question: “Will it work given our legacy systems?” — yes, if you connect these critical nodes.

Question: How can analytics help my sourcing team balance cost reduction with supply-risk mitigation for critical components?

Answer: That balance is a core job for a Head of Supply: drive cost savings while ensuring supply continuity. Analytics platforms support that by:

- Highlighting cost vs risk trade-offs: e.g., cheaper supplier has longer and more variable lead-time — analytics shows the net risk cost of late part delivery.

- Scenario modelling: Shows what happens to production, inventory, cost, if market conditions shift (e.g., raw material price increases or supplier disruption). These features are in your blog under scenario simulation / what-if.

- Continuous monitoring of supplier performance + lead-time variability + quality issues + inventory buffer cost, so sourcing leaders can make informed decisions about buffer strategy, multi-sourcing, or vendor consolidation.

- Dashboard visibility that ties sourcing decisions to business outcomes: e.g., how supplier delays cost X in downtime or production cost increases — tying into the “net profit summary view” your blog mentions in relation to ThroughPut AI.

In summary: analytics doesn’t force you to pick purely lowest cost supplier; it helps you choose the optimal supplier network considering cost, reliability, risk — which is exactly the job of sourcing leadership.

Question: What features should I look for in an analytics tool that supports both maintenance spare-parts management and procurement sourcing workflows?

Answer: Since you’re writing for leaders in maintenance and supply (sourcing), bridging both functions is a differentiator. The features to look for:

- Unified dashboards/work-bench: that show both spare-parts availability and procurement status in one view. The blog mentions “interactive dashboards” and “real-time monitoring.”

- Spare parts inventory optimisation: Ability to model minimum/maximum, multi-echelon inventory levels, and tie those to asset risk.

- Supplier/sourcing analytics: lead-time variability, cost trends, performance risk.

- Scenario planning/simulation: e.g., What if a critical supplier delays? What if a part stockout occurs? The blog mentions scenario simulation.

- Real-time alerts/notifications: e.g., parts stock below threshold, supplier delivery missed, maintenance schedule impacted — maintenance and sourcing teams both benefit.

- Financial linkage: ability to report on working capital (inventory value) and supplier cost impact, as your blog mentions “report on free cash flow, revenue and working capital.”

By looking for these features, you demonstrate to those leaders that the solution is built not just for supply chain planning generically, but with a lens on maintenance + sourcing integration — a high-value joint domain in industrial companies.

Question: How will implementing a supply chain analytics platform change the way my sourcing and maintenance operations – and metrics – are reported to the executive team?

Answer: This is important — executives care about metrics and how they reflect on your function. After implementation you can:

- Move from reactive metrics (e.g., number of breakdowns, emergency purchase spend) to proactive metrics (e.g., predicted risk events avoided, percentage of parts forecasted vs actual).

- Provide a unified “health” dashboard: linking asset uptime, sourcing lead-time performance, inventory carrying cost, cost of expedited supplier orders, working capital.

- Show impact on key executive KPIs: e.g., on-time delivery, cash-to-cash cycle, inventory turnover, supplier performance — all referenced in your blog.

- Leverage real-time data and alerts so the reporting is timely, rather than relying on weekly/monthly spreadsheets. This allows the sourcing and maintenance functions to position themselves as strategic rather than operational.

- By using analytics, you shift the narrative from “cost centre” to “business enabler” — demonstrating how sourcing + maintenance contribute to bottom-line profitability, working capital optimisation, and risk reduction (which executives care about).

Question: What are the common pitfalls when maintenance and sourcing teams adopt analytics tools, and how can we avoid them?

Answer: Both maintenance and sourcing functions face unique hurdles when digitising via analytics; it’s useful to show your audience you understand and have answers. Based on your blog content:

- Pitfall #1: Undefined goals — if you don’t specify what you’re trying to achieve (e.g., reduce downtime by 15 %, cut sourcing spend by 10 %) the analytics project can drift. Your blog lists “Define your goals” as first step.

- Pitfall #2: Poor data integration — silos across CMMS, procurement, inventory lead to “garbage in, garbage out.” The blog emphasises “assess data infrastructure” and “data cleansing”.

- Pitfall #3: Lack of stakeholder buy-in — maintenance teams, sourcing teams, operations all have to align. The blog mentions “resistance to change”.

- Pitfall #4: Trying to deploy big-bang — Trying to roll out across every part of sourcing and maintenance at once can lead to chaos. The blog recommends a “phased implementation”.

- Pitfall #5: Not continuously monitoring and refining — analytics is not “set and forget”. The blog has “monitor & refine” in best-practices.

Advice: For the audience (maintenance or sourcing leaders), position yourself as initiating a pilot for high-risk/high-value parts or suppliers, align sponsors from both maintenance & sourcing, and then scale with lessons learned.

Question: How do we ensure our sourcing strategy is resilient in today’s volatile environment using analytics?

Answer: Resilience (especially given global disruptions) is a major job for sourcing leaders. Analytics helps by:

- Providing real-time visibility into supplier lead-time shifts, transportation disruptions, inventory buffer status — as your blog emphasises real-time monitoring.

- Running scenario-analysis: e.g., what happens if Supplier X faces an embargo, or if freight costs double, or parts are delayed by 30 days. Analytics simulates cost, production impact, sourcing diversion.

- Enabling multi-source comparison: You can identify which suppliers have lower risk (geographic, financial, reliability) and build “risk-weighted” sourcing strategies rather than simply lowest cost.

- Linking sourcing decisions to business outcomes, not only cost: e.g., percentage of critical parts covered by alternative supplier, inventory days buffer for critical items, supplier performance indexed to downtime risk.

- Generating actionable dashboards for leadership: “Here’s our exposure today”, “Here’s the cost of delay if we don’t act”, “Here’s our mitigation plan” — turning risk into action.

By articulating this, you speak directly to the VP/Director sourcing’s role: manage cost and resilience, monitor risk, and turn supply chain analytics into operational risk intelligence.

Question: With so many analytics tools on the market, how do we select the right one for our maintenance-sourcing integrated workflow?

Answer: This is a key question for both maintenance and sourcing executives— they want a decision framework, not just a list of features. You can answer:

- First, clarify the job: Are you solving for maintenance downtime/spare-parts availability or sourcing cost/risk? Or both? The blog emphasises “your choice depends on your specific puzzle”.

- Then, evaluate fit to workflow: does the tool support spare-parts management, supplier lead-time analytics, scenario modelling across both domains?

- Check integration ability: It must integrate with your CMMS, ERP, procurement systems, as well as with external data sources. The blog lists integration capabilities as a key feature.

- Look at speed to value: Can you run a pilot quickly, get actionable insights? Some tools boast implementation in days.

- Review scalability and adoption: Will it be usable by both maintenance and sourcing teams, with dashboards tailored to each? The blog mentions training, user adoption.

- Ensure metrics linkage: Does it allow you to link analytics insights to business metrics (uptime, cost, working capital) so you can justify the investment to the C-suite?

By providing this structured selection framework, you empower the VP/Director of Maintenance or Sourcing to champion the project internally and choose appropriately.