The Ultimate Buyer’s Guide for Inventory Management Software

Overview

You’ve been there time and again—inventory headaches. No matter what you do, it feels like your inventory is conspiring against you: always too much or too little, and it’s not just by chance that you find yourself in this familiar predicament.

You’re likely here for one of two reasons:

One, your inventory management software strategy desperately needed an upgrade…yesterday.

Or two, your inventory management tools are falling short, despite the cost and effort you and your team put into setting them up and implementing them—failing to deliver the expected ROI.

Nearly all businesses recognize that effective inventory control is critical for maintaining healthy financials. Many try to achieve this through spreadsheets or specialized tools, but mastering inventory control remains a formidable challenge. The balancing act of managing stock levels, avoiding understocking, and freeing up working capital is immensely difficult.

Spreadsheets pose two significant issues: they are manual and don’t scale well. With vast amounts of data pouring in from various assets, sensors, and locations, compiling and extracting valuable insights becomes nearly impossible, and agile responses remain out of reach.

Inventory management tools, on the other hand, don’t face these particular issues. However, many businesses find that these tools still don’t produce sufficient or timely ROI, compounding frustrations. Additionally, these tools often operate in silos, pursuing divergent goals, which further impacts ROI.

Long story short: What you need is a system that considers the entire supply chain and delivers tangible value in terms of inventory control, material flow, and financial impact—without straining your budget or disrupting existing processes. Look for a solution that starts small but can scale quickly as needed.

If this sounds familiar, you’re in the right place.

This buyer’s guide is designed to answer some of your most pressing questions before you invest in inventory management software:

- What features are essential in an advanced inventory management solution?

- What is supply decision intelligence, and how does it enhance inventory management?

- How does supply chain decision intelligence differ from other tools?

- How can you assess the success of inventory management software?

- What considerations about AI should you keep in mind when selecting inventory management software?

- What are the key questions to ask potential software providers before making a purchase?

Here’s Where You Start: Define Your Inventory Management Needs

Believe it or not, the first question is not “what to buy”. It’s not even whether you’ll build a tool in-house, invest in a third-party tool, or fall back on age-old (albeit less reliable) spreadsheets. Before diving into the buying process, it’s crucial to understand why you need an inventory management software. What is your need? More specifically, what problem are you looking to solve? Some of the common problems leading to this point are:

- Frequent stockouts/overstocking

- Inventory cost overruns

- Tied up working capital

- Inability to predict and manage demand

- Inadequate, inefficient, or ineffective inventory tracking and reporting

- Unoptimized order fulfillment

Whatever the problem(s), the idea is to clearly define the “to do tasks” for the tool to help you overcome your inventory challenges. In addition, it should be able to integrate data from a variety of sources to provide you with end-to-end visibility across the length of your supply chain and generate recommendations for real-time inventory adjustments, picking, packing, and shipping decisions, etc. so that you can start optimizing cost, time, and effort every step of the way.

You’re Most Likely Not Looking For An Advanced ERP, POS, or WMS – Here’s Why

Let’s face it—while many ERP, POS, and warehouse management systems today boast an array of extended features beyond the basics, they often fall short in fully addressing inventory management needs. Here’s a closer look at why:

- Lack of Flexibility: These systems are often designed with specific operational scenarios in mind, resulting in a rigid framework that can be difficult to adapt to unique business needs or specialized inventory strategies. For instance, while WMS systems are tailored for warehouse operations, they generally lack the flexibility required for more sophisticated inventory processes.

- High Manual Effort: Despite their technological integration, these tools frequently necessitate considerable manual input in terms of data entry, system configuration, and ongoing maintenance. In contrast, dedicated inventory management software tends to be more streamlined and automated, significantly reducing the manual labor involved in its operation and upkeep.

- Insufficient Optimization: ERP systems are commonly built to support a broad range of business processes, with only basic inventory management functionalities. Similarly, POS systems focus primarily on sales transactions and WMS systems on warehouse operations, often overlooking the need for advanced inventory optimization features that could enhance overall efficiency and effectiveness.

- Limited Forecasting Capabilities: ERP, POS, and warehouse management systems typically rely on static models, making them ill-equipped for dynamic calculations like demand forecasting or reorder quantities that respond to seasonal fluctuations or emerging trends. These systems primarily use historical data, limiting their ability to predict short-term demand. Consequently, inventory management can become outdated and unresponsive to sudden market shifts.

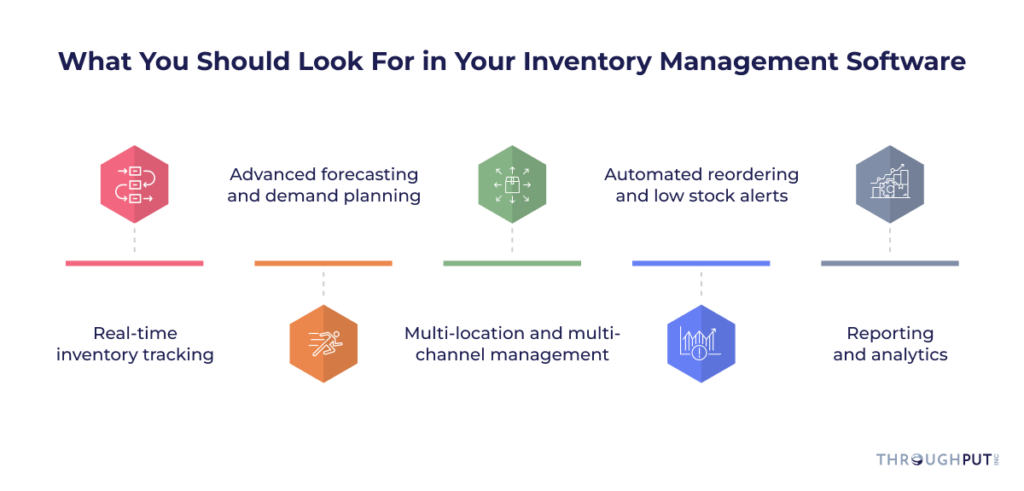

The Basic Capabilities of Any Inventory Management Software

There are plenty of inventory management solutions out there in the market. However, choosing one that is right for your business needs is critical to ensuring that you deliver better value to your customers as well as accelerate profitability – while also cutting unnecessary costs. At a minimum, any inventory management tool you are considering must have the following basic capabilities:

Real-time inventory tracking

Essential for any enterprise-level system, this feature allows for monitoring inventory across all departments, teams, channels, and the supply chain from a centralized dashboard. It supports dynamic inventory management and enhances customer experiences by providing up-to-the-minute data accuracy.

Advanced forecasting and demand planning

Integrating AI-powered forecasting tools is crucial for mitigating the risks associated with demand fluctuations and boosting market responsiveness. These capabilities lay the groundwork for proactive inventory planning, speeding up the time to value and optimizing cost efficiency.

Multi-location and multi-channel management

The software must facilitate the management of inventory across various locations and channels, ensuring the availability of the right products in the correct quantities and at the appropriate places and times. Dynamic replenishment strategies, which adapt to current demand, are key to maintaining constant product availability and maximizing revenue.

Automated reordering and low stock alerts

To effectively manage the high volatility of demand, the software should include automated replenishment systems that respond to even minor shifts in demand while accommodating operational constraints of distribution centers and stores. Additionally, setting up low stock alerts is critical for improving order fulfillment strategies, avoiding sales losses, and maintaining customer satisfaction.

Reporting and analytics

Finally, you need to be able to leverage all your data to identify trends and patterns that help you make better decisions. All data displays should be user-friendly and not require translation by a data scientist. You should be able to view reports in as much or as little detail as relevant to your role and responsibilities, and they should be immediately actionable – meaning that any decision you make should require no more than a couple of clicks.

Choose Supply Chain Decision Intelligence for Inventory Management

Supply chain decision intelligence empowers you to make more effective, efficient, and profitable decisions in real time and at scale, leading to incremental, measurable improvements on your bottom line. This data-driven approach allows you to function rapidly and intelligently in the face of increasingly volatile market conditions, maximizing outcomes while optimizing precious resources.

With enhanced access to actionable intelligence, you can generate millions of decision-making alternatives and evaluate “what if” scenarios, along with their associated trade-offs.

More importantly, by integrating decision intelligence with the operational and regulatory constraints of your supply chains, you can make consistently smarter decisions.

Here are three levels at which supply chain decision intelligence can support your inventory management decisions:

- Decision Support: Machines provide basic features such as alerts to support decision-making carried out by humans.

- Decision Augmentation: Machines play a significant and proactive role in the decision-making process by analyzing data to predict and recommend actions. You can review and validate these recommendations. For instance, if a suggestion is made to purchase 500 units from vendor A twice a year to save $35,000 by year-end, you can accept, reject, or tweak the variables to explore other potential outcomes.

- Decision Automation: Machines autonomously make and execute decisions based on AI-driven rules, predictions, and optimizations. Your role would be to monitor any unusual activity or potential risks and regularly review outcomes to refine the system.

An effective supply chain decision intelligence system should offer all three levels of intelligence—support, augmentation, and automation—to help you develop trust in the system and accelerate further automation.

Another crucial feature of supply chain decision intelligence is optimizing inventory management to ensure just the right amount of stock is in the right place at the right time. Essential aspects of this include:

Dynamic Stock Replenishment

Automated adjustment of inventory levels based on actual, real-time demand variances, lead times, and supplier constraints, ensuring optimal stock levels while minimizing carrying costs.

Mitigation of Procurement Lead Time Risks

Proactive strategies like demand forecasting, safety stock optimization, and supplier collaboration help mitigate lead time impacts, maintaining stock availability and ensuring seamless operations.

Buffer Management

Precise buffer sizing criteria ensure an adequate supply for the next supply chain node at all times, minimizing risk and wastage while monitoring buffer consumption against recommended stock levels.

Financial Alignment

Monitoring historical spend patterns and other metrics to manage operating capital dynamically and maintain robust financial health, identifying opportunities for cost savings without compromising stock optimization.

In essence, supply chain decision intelligence software gives you an advantage over traditional inventory management tools by not only providing end-to-end visibility but also actionable recommendations that positively impact your financial performance. Most importantly, it facilitates decisions that offer the most significant improvement potential in cost, time, or effort savings, swiftly and effectively.

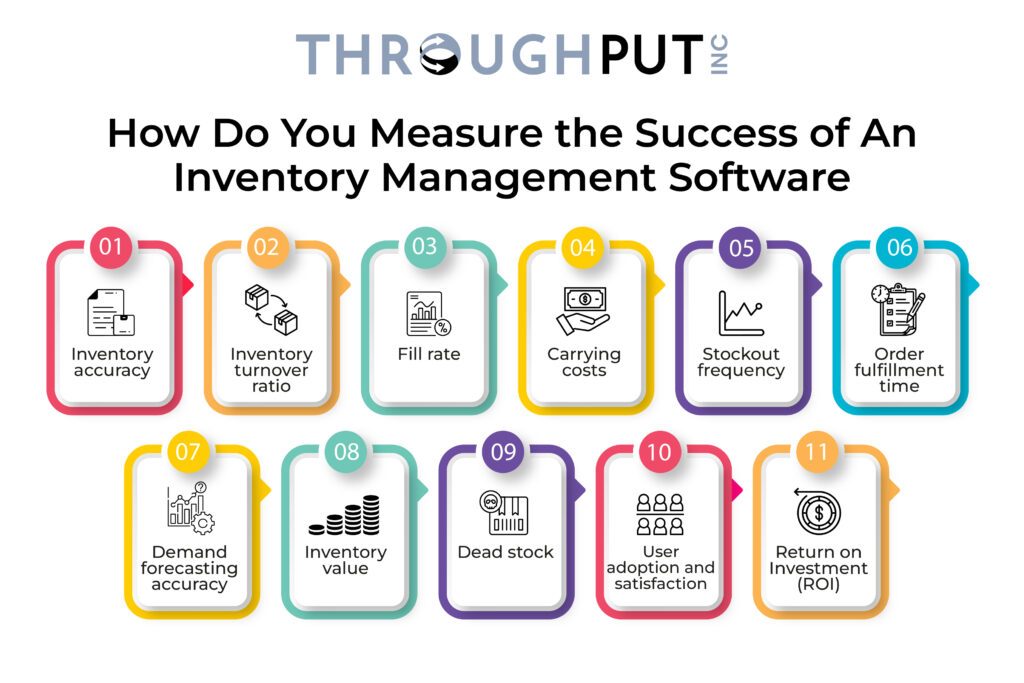

How Do You Measure the Success of An Inventory Management Software?

To measure the success of any inventory management software, you need to analyze the performance of the following key metrics and indicators:

- Inventory accuracy: This measures the accuracy of your stock valuation, or how closely your physical inventory matches the records in your software. A high accuracy rate indicates reliable data and effective inventory control. In addition, it aids better financial reporting and a solid understanding of the true value of inventory, which in turn enables better cost control and profitability analysis.

- Inventory turnover ratio: This is the number of times you sell out all your inventory – and replenish it – during a given time period. The general rule of thumb is, the higher the ratio, the more efficient your inventory management. A low turnover means that you have excess inventory, and is an indicator that it may be time for you to rethink your procurement or production strategy (or both).

- Fill rate: This metric, which has a direct impact on customer satisfaction, measures how often you can fulfill customer orders from available inventory. A high fill rate generally translates into high customer satisfaction – and also indicates sound inventory control.

- Carrying costs: This is the percentage of your inventory value tied up in holding costs. Lower carrying costs usually indicate more efficient inventory management – and higher profitability. A good practice is to keep your carrying costs at about 25% of your overall inventory value, but if you want to reduce this further, the best place to start would be to reduce the size of your inventory.

- Stockout frequency: This is a measure of how often you run out of stock. The fewer the number of stockouts, the better your inventory planning and management. The idea here is to hit the right balance – i.e., to maintain a low frequency of stockouts without tipping over and ending up with excess stock.

- Order fulfillment time: Like the fill rate, this metric directly impacts customer satisfaction. It measures the time you take to process and ship orders. Faster fulfillment times are usually an indicator of high customer satisfaction and efficient inventory management.

- Demand forecasting accuracy: This is a measure of the precision with which your software predicts future inventory needs. More accurate demand forecasts enable better inventory planning and control.

- Inventory value: This tracks the total cost of your inventory over time. Optimizing this value while maintaining adequate stock levels (and a consistent average inventory over the year) is a sign of effective inventory management.

- Dead stock: This is the amount of your inventory that has not moved in a long period of time. In other words, it is stock that cannot be sold. The higher the dead stock a company has, the lower its market competitiveness. Low dead stock indicates better inventory control.

- User adoption and satisfaction: How many employees are using your inventory management software? What are their satisfaction levels with it? High adoption and satisfaction rates mean that your software is user-friendly – and effective.

- Return on Investment (ROI): This calculates the financial benefits of your software in relation to its cost. A positive ROI indicates that the software is generating value for your business.

By consistently tracking these metrics, you can gain valuable insights into the effectiveness of your inventory management software – and identify areas for improvement in your overall inventory management processes in a timely manner.

However, monitoring and analyzing this many metrics is no mean feat. To effectively control your inventory, you need to:

- Set clear, SMART (Specific, Measurable, Achievable, Relevant, Time-bound) objectives

- Regularly collect and analyze your data

- Compare your metrics over time to identify trends and improvements

- Benchmark your performance against industry standards and competitors as applicable

- Regularly review and update your measurements to ensure their relevance to your business goals

What to Keep in Mind About AI When Choosing Your Inventory Management Software

Undeniably, AI in inventory management presents powerful use cases for several functions – whether to reduce costs, streamline operations, or improve efficiencies. The transformative potential of AI-powered inventory management software can enable accurate demand forecasting, real-time tracking of inventory, automation of ordering/reordering stock, and streamline overall inventory operations.

So whether you run a small business or a large one, implementing AI in your inventory management process will enhance your business profitability.

However, many businesses do not appreciate the fact that adopting AI-powered inventory software will not magically solve their problems overnight. Like any AI technology, it needs to be trained to generate results that are meaningful for your business. So you need to look for a solution that will allow you to start small, experiment, and build your way up to a system that works for you.

More importantly, it’s pointless to adopt advanced tools without the right environment for them to succeed – in this case, data being the most important factor. It’s key to know that data transformation is the first step toward healthy inventory management. It’s only then that you can choose a solution that suits your problem – with or without AI.

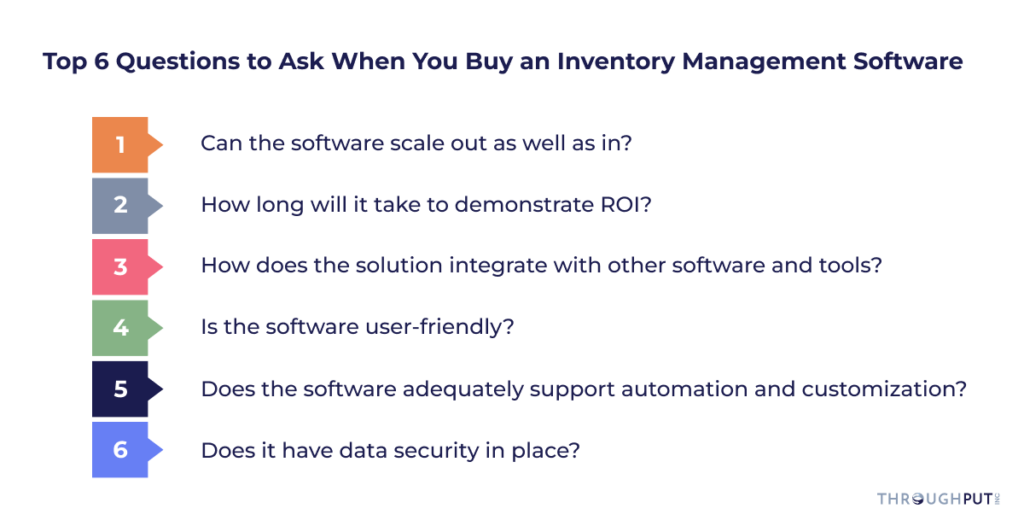

Top 6 Questions to Ask When You Buy an Inventory Management Software

Yes, it’s quite an order. But then inventory management is one of the foundational processes of any business. Naturally, choosing the right software for it will entail careful consideration of several factors. Here are the top questions you should be asking of any vendor you consider:

Can the software scale out as well as in? Your business needs not only the flexibility to grow and expand, but also respond to market dynamics.

How long will it take for the inventory management software to demonstrate ROI? You need definite timelines. Talk months, not years.

How does the solution integrate with other software and tools? Here, too, you need specifics. You need something that can plug and play – something that can rapidly integrate your existing data streams with built-in connectors, and doesn’t require additional third-party APIs to facilitate integration.

Is the software user-friendly? No ease of use, no dice. If you can’t get your employees to use your software, your problems are a lot larger than you think. Let’s not even go there.

Does the software adequately support automation and customization? The whole point of the exercise is to set your inventory management into as autopilot mode as possible. If you can’t achieve a significant level of automation, you’re defeating the purpose – and looking at the wrong solution. Also, this is one case where you can’t go for a one-size-fits-all solution. Your inventory needs are unique to your business. Your solution should treat them that way.

Does it have data security in place? No brainer, but can’t be stated enough. Your data is invaluable. There’s nothing in the world worth risking its security. Don’t shy away from asking what cybersecurity features your solution comes with.

Wrapping Up

To remain competitive under increasingly hostile market conditions, you need to tighten up your inventory management capabilities. This means investing in advanced technologies such as AI, which can generate actionable insights at scale to automate simple processes while enabling data-driven decision-making for more strategic ones.

It is also important to ensure continuous learning and improvement across all inventory processes. This will enable you to build and sustain a competitive edge in the rapidly evolving market. To start your journey to AI-powered inventory management, get in touch with our team today. We’d be happy to chat with you.

Frequently Asked Questions (FAQs) – Inventory Management Software

1: How quickly can inventory management software deliver measurable ROI?

Most modern inventory management and decision intelligence platforms start delivering measurable ROI within 3–6 months when deployed with clear objectives. Early gains typically come from reduced stockouts, lower excess inventory, improved forecast accuracy, and better working capital utilization. Faster ROI depends on data readiness, integration speed, and how quickly teams adopt automated recommendations.

2: Can inventory management software work with our existing ERP, WMS, or POS systems?

Yes. Leading inventory management software is designed to integrate seamlessly with existing ERPs, WMS, POS, and planning tools through prebuilt connectors and APIs. Instead of replacing your core systems, it sits on top of them, unifying data and enabling smarter, cross-functional inventory decisions without disrupting daily operations.

3: How is AI-driven inventory management different from traditional rule-based systems?

Traditional systems rely on static rules and historical averages, while AI-driven inventory management continuously learns from real-time demand signals, lead-time variability, supplier constraints, and market changes. This allows AI to recommend or automate optimal reorder quantities, safety stock levels, and replenishment decisions dynamically—reducing both risk and manual intervention.

4: Is inventory management software suitable for multi-location and multi-channel businesses?

Absolutely. Advanced inventory management solutions are built for complex, distributed supply chains, enabling centralized visibility across warehouses, stores, distribution centers, and sales channels. They optimize inventory placement across locations to improve service levels, reduce inter-location transfers, and ensure the right stock is available where demand actually occurs.

5: How much customization is required to fit our business processes?

Modern solutions are configurable rather than heavily customized. This means you can adapt replenishment logic, service-level targets, constraints, and workflows without lengthy development cycles. The best platforms allow you to start small—focusing on high-impact SKUs or locations—and scale gradually as confidence and value increase.

6: What data is required to get started with inventory management software?

At a minimum, you’ll need historical sales data, inventory levels, lead times, and basic product master data. However, leading platforms are designed to work even with imperfect data and improve accuracy over time. As data quality improves, the system’s recommendations and automation capabilities become increasingly powerful.

7: How do we ensure user adoption across teams?

High adoption depends on ease of use, explainable recommendations, and clear business impact. Inventory management software should provide intuitive dashboards, role-based views, and transparent “why” behind every recommendation. When planners and operations teams can see how decisions improve KPIs, adoption naturally follows.

8: What KPIs should improve first after implementation?

Typically, businesses see early improvements in:

- Inventory accuracy

- Stockout frequency

- Fill rate

- Inventory turnover

- Carrying costs

These early wins build confidence and justify expanding automation and decision intelligence across more inventory processes.

9: Is inventory management software secure and compliant?

Yes. Enterprise-grade inventory management platforms implement robust data security protocols, including encryption, access controls, audit logs, and compliance with industry standards. Always confirm security certifications and data governance policies before finalizing a vendor.

10: How do we know if we’re choosing the right inventory management software?

The right solution will:

- Show ROI in months, not years

- Integrate easily with your existing systems

- Scale as your business grows

- Support decision support, augmentation, and automation

- Clearly link inventory decisions to financial outcomes

If a vendor cannot demonstrate this clearly during evaluations or pilots, it’s a red flag.