Demand planning software is here to stay. Every major supply chain company has demand planners’ toolkits containing it.

However, with numerous features and tools available, supply chain planners and managers often wonder which functionalities are truly essential for their operations.

This uncertainty can lead to significant challenges, as the wrong choice may not only hinder the ability to generate accurate demand forecasts but also complicate data integration and employee training processes.

Without the key features that align with their specific business needs, companies struggle to harness the full potential of demand planning solutions, leading to inefficiencies and missed opportunities in a highly competitive market.

Read on to discover the top demand planning software features that will transform your supply chain operations.

What is Demand Planning Software?

Demand planning software is a specialized tool designed to support and enhance the process of forecasting and managing customer demand across various stages of the supply chain.

This type of software utilizes advanced algorithms, statistical analyses, and data integration capabilities to predict future demand for products and services more accurately.

The primary objective of demand planning software is to ensure that businesses can meet customer demands efficiently without overstocking or understocking inventory.

The software integrates historical sales data, market trends, seasonal fluctuations, and other relevant factors to create detailed demand forecasts.

These forecasts enable companies to optimize inventory levels, align production schedules, manage resources effectively, and improve overall supply chain performance.

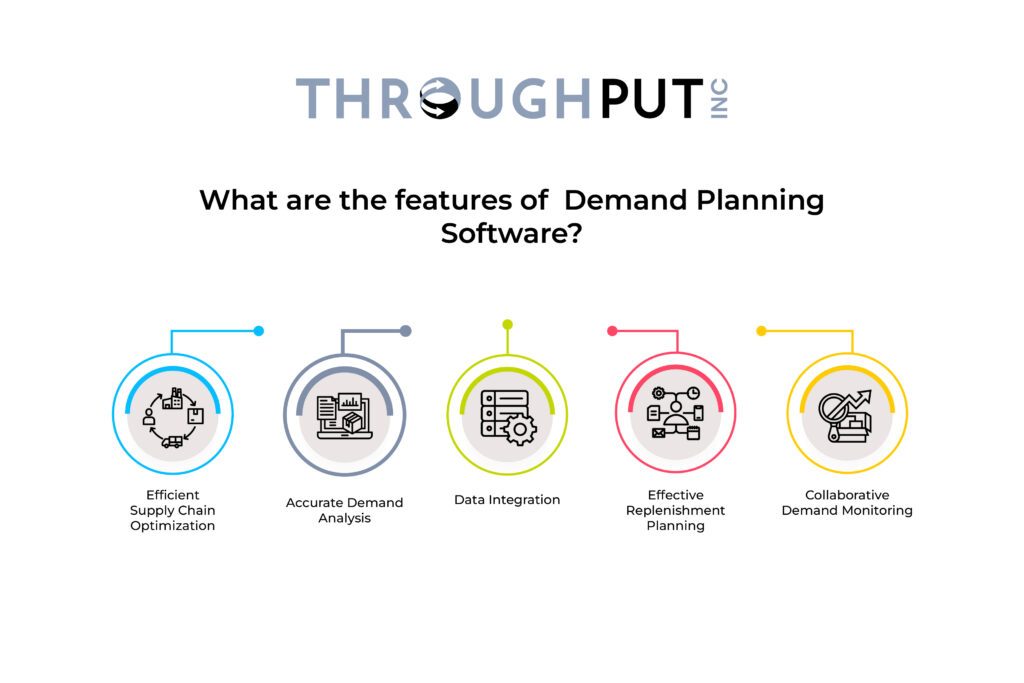

What are the Key Demand Planning Software Features?

The key demand planning software features are data integration, efficient supply chain optimization, replenishment planning, demand analysis, and collaborative demand monitoring.

These features streamline the demand planning process and ensure that businesses can adapt quickly to market changes, optimize inventory levels, and, ultimately, enhance profitability.

Let’s delve deeper into these features, exploring their use cases, importance, and application contexts.

Data Integration

Data integration capability in demand planning software enables the corporation to seamlessly amalgamate this data, providing a unified view critical for accurate demand forecasting.

USE CASE:

A multinational corporation with diverse product lines and global markets must consolidate data from various sources, including ERP systems, CRM platforms, and external market research.

IMPORTANCE OF DATA INTEGRATION:

The importance of data integration lies in its ability to break down silos within an organization, ensuring that all departments work with a single source of truth.

This is particularly crucial in industries such as retail and manufacturing, where real-time data on sales, inventory, and supply chain activities directly influences demand planning accuracy.

Efficient Supply Chain Optimization

This feature supports optimizing inventory levels, production schedules, and distribution strategies. It provides real-time recommendations for optimal inventory and production volumes across multiple locations and aids in identifying potential supply chain disruptions.

USE CASE:

An e-commerce company experiences seasonal spikes in demand, leading to inventory management and distribution challenges.

Efficient supply chain optimization within demand planning software allows the company to adjust inventory levels and distribution strategies dynamically, ensuring products are available where and when customers need them, without overstocking.

IMPORTANCE OF SUPPLY CHAIN OPTIMIZATION:

This feature is vital for businesses operating in fast-paced environments where demand can fluctuate rapidly, such as e-commerce and fast-moving consumer goods (FMCG).

Efficient supply chain optimization software ensures businesses maintain high service levels, minimize costs associated with excess inventory, and avoid lost sales due to stockouts.

It empowers companies to be agile, adapting their supply chain strategies to meet changing market demands efficiently.

Effective Replenishment Planning

Optimal replenishment planning is critical for ensuring inventory is strategically positioned to meet demand. AI-powered demand planning solutions excel in creating accurate demand forecasts based on supply drivers, facilitating demand-driven inventory replenishment.

USE CASE:

A grocery chain needs to maintain optimal stock levels across its stores to ensure customer satisfaction while minimizing waste, especially for perishable goods.

Effective replenishment planning in demand planning software enables the chain to forecast future demand accurately, automate replenishment orders, and adjust inventory levels based on real-time sales data.

IMPORTANCE OF REPLENISHMENT PLANNING:

In industries where product freshness is critical, such as groceries and pharmaceuticals, effective replenishment planning is essential. It ensures that inventory levels align precisely with demand, reducing waste and ensuring product availability.

This feature supports sustainability efforts by minimizing overproduction and waste, contributing to more environmentally friendly operations.

Accurate Demand Analysis

Advanced demand planning solutions leverage AI to offer multi-dimensional sensitivity analysis, evaluating the impact of product features, pricing, availability, and market trends on demand.

This includes analyzing demand shifts and pinpointing the drivers behind these changes.

USE CASE:

A consumer electronics manufacturer launches a new product line and needs to understand how various factors, such as marketing campaigns, competitor actions, and economic trends, will affect demand.

Accurate demand analysis provides multi-dimensional insights, enabling the manufacturer to forecast demand more precisely and plan production accordingly.

IMPORTANCE OF ACCURATE DEMAND ANALYSIS:

Accurate demand analysis is crucial for businesses in sectors characterized by high innovation rates and competitive intensity, such as technology and consumer electronics.

This feature allows companies to dissect the impact of multiple variables on demand, enabling them to strategize effectively, allocate resources efficiently, and gain a competitive edge in the market.

Collaborative Demand Monitoring

A robust demand planning solution offers configurable dashboards for real-time monitoring of the pulse on demand dynamics.

These dashboards track demand across products, sales channels, regions, and promotional events, providing immediate alerts when demand deviates from forecasts.

This feature ensures that businesses respond proactively to demand fluctuations, aligning with planned targets and adjusting strategies as needed.

USE CASE:

A fashion retailer collaborates with its suppliers and logistics partners to ensure the timely availability of its seasonal collections.

Collaborative demand monitoring allows all parties to track real-time demand, inventory levels, and delivery statuses, facilitating seamless coordination and quick adjustments to meet actual demand.

IMPORTANCE OF COLLABORATIVE DEMAND MONITORING:

This feature is particularly important for industries with short product life cycles and high variability in demand, such as fashion and entertainment.

Collaborative demand monitoring fosters transparency and cooperation among all supply chain stakeholders, enhancing responsiveness to market changes and improving overall supply chain efficiency.

ThroughPut’s AI-Powered Demand Planning

ThroughPut AI leverages advanced demand planning with AI, enhancing the accuracy of future demand predictions through sophisticated data analysis.

This shift from traditional, manual methods reduces operational inefficiencies and mistakes. The platform conducts an in-depth analysis of sales data, market trends, and external factors like economic indicators to generate precise demand forecasts.

These forecasts inform ThroughPut AI’s recommendations for inventory, production, and procurement alignment, mitigating the risks of overstocking and understocking to boost operational efficiency and customer satisfaction.

The software’s ability to predict short-term demand and update demand plans in real-time is a standout feature in today’s volatile market. This adaptability allows supply chains to respond to market changes swiftly, preventing losses due to lack of foresight.

Additionally, ThroughPut’s expertise in demand segmentation, SKU optimization, and replenishment planning, all centered around a demand-focused strategy, empowers businesses across various industries to make pivotal decisions impacting their financial performance.

If you would like to learn how to plan demand with ThroughPut efficiently, schedule a demo.