Supply Chain Optimization Software the Essential 2024 Guide

Whether you want to streamline your operations, reduce costs, or stay ahead of market trends, supply chain optimization software is a game-changer in today’s competitive business landscape. Selecting the right supply chain optimization software can be as daunting as critical.

As a supply chain professional, you understand that optimizing your supply chain is not just about cutting costs or increasing efficiency; it’s about creating a symphony of operations that resonates with the rhythm of the market and the melody of customer demand.

This article, crafted for supply chain aficionados like yourself, managers, and executives, is your compass for the ideal supply chain optimization software.

We’ll first identify your challenges, stir the desire for a solution, and then illuminate the path to the software that can transform your supply chain into a competitive weapon.

What is Supply Chain Optimization Software?

Supply chain optimization software is a strategic tool that can completely transform business operations. Consider it as a linchpin that holds the potential to revolutionize and revamp your business operations from the ground up.

With its roots deeply embedded in advanced algorithms and artificial intelligence, this software is adept at predicting market trends and dissecting vast amounts of data to bolster informed decision-making.

Its prowess extends to seamless integration with other business systems, offering a panoramic view of the supply chain and ensuring fluid data exchange across departments.

This integration feature ensures that all stakeholders have access to the same data, cultivating a collaborative culture and propelling the entire organization toward a shared vision.

Customization is another forte of supply chain optimization software, allowing it to be meticulously tailored to the unique contours of your business landscape.

Whether it’s industry-specific challenges, distinctive business models, or the nuances of operational processes, this software can be fine-tuned to resonate with your strategic objectives and the ever-shifting market dynamics.

What are the Types of Supply Chain Optimization Software?

The supply chain optimization software spectrum is as varied as the businesses it serves. There are 4 types of supply chain optimization software, each offering unique capabilities that enhance the supply chain.

For instance, Lean Supply Chain Software focuses on eliminating non-value-adding activities, reducing costs, and amplifying operational efficiency. Look at it as a scalpel that excises waste, streamlining operations to enhance efficiency and trim costs.

In contrast, Agile Supply Chain Software is the chameleon, championing flexibility and swift adaptation to the unpredictable ebbs and flows of the market. Agile Supply Chain Software ensures customer demands are met with unwavering precision without compromising efficiency or cost.

Hybrid Supply Chain Software combines the best of both worlds, blending the lean and agile philosophies to forge a solution perfect for businesses navigating the tumultuous waters of volatile markets.

This software is ideal for companies operating in uneasy markets where efficiency and responsiveness are crucial. Material Requirements Planning (MRP) Software and Transaction Cost Analysis (TCA) Software are more specialized tools, focusing on the supply chain’s planning and cost analysis aspects, respectively.

These instruments are pivotal in optimizing resource distribution, curtailing expenses, and propelling profitability to new heights.

What are the benefits of Using Supply Chain Optimization Software?

The advantages of wielding supply chain optimization software are manifold and extend beyond operational efficiency and cost reduction.

Using supply chain optimization software grants real-time visibility into the supply chain, empowering businesses to proactively manage risks and disruptions, such as supplier delays or sudden spikes in demand.

This foresight ensures a seamless operational continuum and upholds customer satisfaction at its zenith. With the ability to anticipate and respond to these challenges, businesses can ensure operational continuity and maintain high levels of customer satisfaction.

Additionally, supply chain optimization software can contribute to sustainability efforts. Companies can reduce their environmental footprint by optimizing resource usage and minimizing waste.

Consumers and stakeholders demand greater ecological responsibility in today’s business world. With proper supply chain optimization software, businesses enhance their bottom line and contribute to a more sustainable future.

What are the Key Features of Supply Chain Optimization Software?

The arsenal of features that supply chain optimization software brings is designed to fortify various facets of supply chain management. Supply chain optimization software offers a variety of features designed to improve multiple aspects of supply chain management.

The key features of supply chain optimization software are:

- Demand Forecasting harnesses the power of historical data and predictive analytics to anticipate future demand, enabling businesses to craft inventory and production strategies with precision.

- Inventory Management assists businesses in tracking and managing their inventory levels, ensuring they have the right amount of stock at the right time.

- Supplier Management enables businesses to manage their relationships with suppliers, including contract management, performance tracking, and communication.

- Order Management streamlines the order management process, from order placement to delivery, ensuring a smooth customer experience.

- Analytics and Reporting provides valuable insights into supply chain performance, unveiling new opportunities for improvement and guiding data-driven decision-making throughout the supply chain.

What to Consider When Choosing Supply Chain Optimization Software?

The quest for the ideal supply chain optimization software demands careful contemplation. It must resonate with your business’s heartbeat—its needs, aspirations, and challenges.

When selecting supply chain optimization software, several factors should be considered. First and foremost, the software should align with your business needs and objectives. Consider factors such as the size of your business, the complexity of your supply chain, and your specific operational challenges.

The software should also be scalable, able to grow and adapt as your business evolves. Another crucial consideration is the software’s integration capabilities. The software should integrate seamlessly with your existing business systems, ensuring a smooth data flow across different departments.

What’s the role of AI in Supply Chain Optimization Software?

In the intricate world of supply chain management, artificial intelligence (AI) stands as a beacon of transformation. By 2023, AI is anticipated to be an integral or enhanced component in a quarter of all supply chain technology solutions.

The fusion of AI, machine learning, and data science into supply chain planning and optimization processes yields a more streamlined and efficient supply chain, adept at tackling challenges like inventory optimization, demand forecasting and planning, and supply chain cost reduction and resource utilization.

Inventory Optimization

Inventory optimization is a cornerstone of supply chain management, influencing procurement, order fulfillment, and production planning.

AI-driven supply chain optimization software empowers businesses to forecast demand accurately, mitigating the risks associated with inventory imbalances and the financial burdens of excess stock or unmet demand.

Demand Forecasting and Planning

An optimized supply chain system enables planners to harness precise demand planning and forecasting.

Understanding the nuances of market demand and supply fluctuations ensures optimal inventory levels, leading to cost savings, efficient production and delivery plans, and significantly reduced lead times.

Supply Chain Cost Reduction and Resource Utilization

Achieving peak supply chain efficiency allows organizations to scrutinize supplier performance, outputs, and processes, unveiling cost-saving opportunities.

This proactive stance enables businesses to identify and rectify inefficiencies within the supply chain, resulting in more streamlined operations and enhanced business results.

How to Implement Supply Chain Optimization Software?

Implementing supply chain optimization software is a strategic maneuver that can substantially uplift your business operations.

This guide outlines a systematic approach to effectively deploy such software, powered by advanced algorithms and AI, to predict market trends, analyze data, and facilitate informed decisions.

Here’s a step-by-step guide on implementing supply chain optimization software to ensure a smooth and effective implementation, improving operational efficiency, cost reduction, and overall business performance.

Step 1: Define Your Objectives

The first step in implementing supply chain optimization software is to define your objectives. What do you hope to achieve with the software? Business objectives range from improving operational efficiency to enhancing customer service.

Clear goals will steer the implementation and enable you to gauge the software’s impact.

Step 2: Choose the Right Software

The next step is to choose the right software. Start by evaluating different options based on their features, capabilities, and alignment with your objectives. Each type of supply chain optimization software offers distinct capabilities.

For example, Lean Supply Chain Software focuses on eliminating non-value-adding activities, reducing costs, and enhancing operational efficiency.

In contrast, Agile Supply Chain Software emphasizes responsiveness and adaptability, enabling businesses to swiftly adjust their supply chain operations in response to market changes and meet customer demands without compromising efficiency or cost.

Step 3: Plan the Implementation Process

With the right software in hand, meticulously plan the implementation. Set a timeline, assign responsibilities, and prepare your team for the change.

The implementation process itself involves:

- Configuring the software to suit your business processes.

- Integrating it with your existing systems.

- Training your team to use it.

It’s essential to monitor the process closely and address any issues that arise promptly.

Step 4: Regularly Review Performance and Make Adjustments

After the implementation, it’s vital to regularly evaluate the software’s performance and make necessary adjustments to ensure it continues to fulfill your needs.

Leverage the software’s analytics and reporting features to gain valuable insights into supply chain performance, helping businesses identify areas for improvement and make data-driven decisions.

ThroughPut – The future of Supply Chain Optimization with Artificial Intelligence

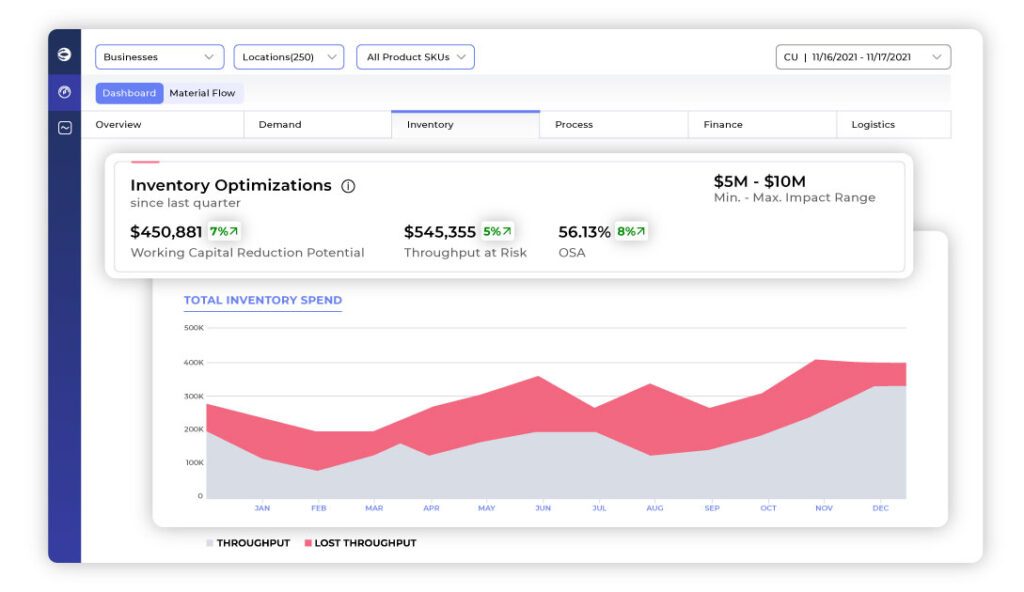

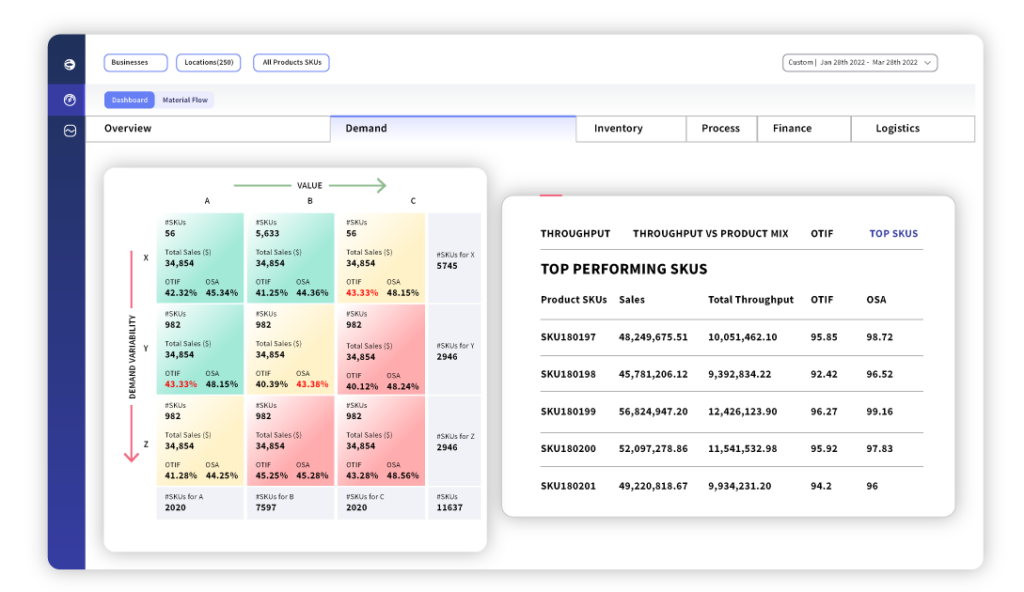

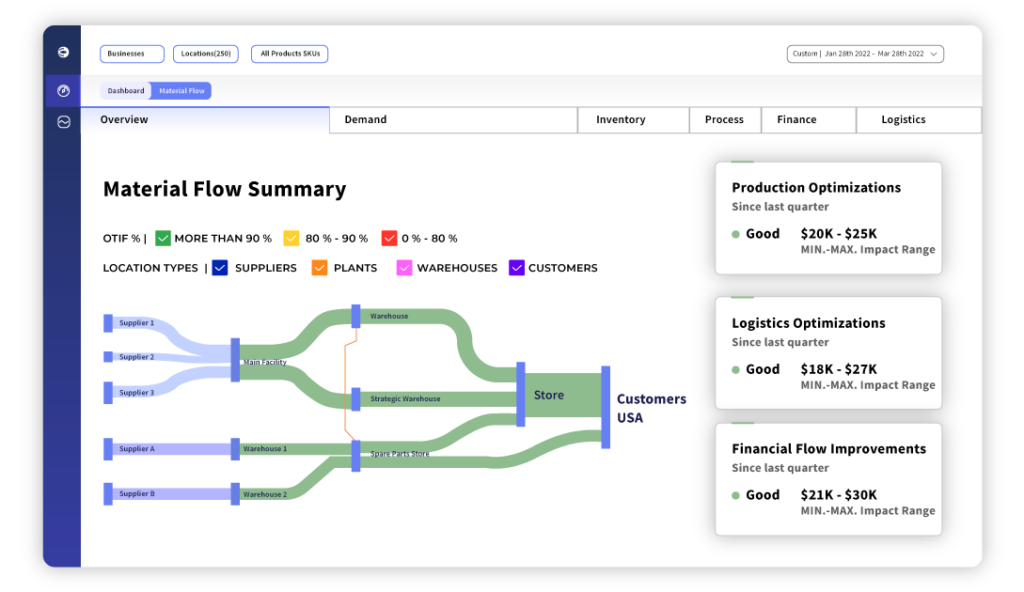

ThroughPut’s AI-powered supply chain planning solution is a testament to the transformative power of technology in the realm of supply chain management.

Designed to dissect and analyze vast quantities of data, it empowers organizations with predictive replenishment capabilities and real-time operational insights, thereby catalyzing swift and precise decision-making.

Organizations that have embraced ThroughPut have witnessed a multitude of strategic benefits, including:

- Enhanced forecast accuracy that dovetails with existing sales and operations planning goals.

- Effective management of real-time demand shifts, ensuring agility in response to market fluctuations.

- Amplified material flow and inventory optimization, guaranteeing on-time, in-full (OTIF) performance.

- Refined product and customer mix, tailored to profit margins, to bolster free cash flow and financial health.

These outcomes are not just incremental improvements but pivotal milestones in achieving holistic supply chain optimization, demonstrating ThroughPut’s pivotal role in elevating businesses to new echelons of operational excellence.

To access ThroughPut’s AI expertise, book a demo here.