Inventory Control With Supply Chain Intelligence: How Planners Can Avoid Overstocking and Understocking

Balancing inventory levels to avoid the costly pitfalls of overstocking and understocking is already a complex task for inventory planners.

In an enterprise setup, this complexity further increases. Multiple locations, thousands of product lines, and millions of data sources make it even harder to keep up with market changes and consumer demands.

Using outdated spreadsheets and disconnected systems doesn’t enable real-time decision-making and agile operations – both of which are essential to keep up with the pace and scale of the unpredictable changes we are seeing today.

This guide will explore how leveraging supply chain decision intelligence and AI-based solutions like ThroughPut AI can help you overcome these challenges and optimize inventory control.

What is Inventory Control?

Inventory control, also known as stock control, is the process of managing and regulating inventory levels within a business.

This process involves tracking stock levels and monitoring the movement and storage of goods while ensuring that the right amount of supply is available to meet customer demand while minimizing costs.

Sounds straightforward but…

Managing Thousands of SKUs Gets (Pretty) Complex!

As Inventory Analysts in an enterprise, you often deal with hundreds and thousands of Stock Keeping Units (SKUs), each with unique characteristics and demand patterns.

One of the main goals of inventory control in large-scale setups is to manage the inventory levels of all these complex SKUs at a granular level, because then you can:

- Track and Manage Diverse Products

With various products, each with different demand cycles, inventory control helps accurately track and manage stock levels for each SKU.

- Optimize Stock Levels

Understanding the demand patterns of different SKUs enables you to optimize stock levels, so that high-demand items are always available while excess stock of slower-moving items is minimized.

- Improve Forecasting Accuracy

Inventory control systems can integrate with demand forecasting tools to provide more accurate predictions for each SKU, helping you plan better and reduce the risk of stockouts or overstocking.

- Enhance Supplier Management

Effective SKU-level inventory control involves monitoring supplier performance and lead times, ensuring timely replenishment, and meeting quality standards.

Why is Inventory Control Important?

To reiterate, inventory control is important because it helps businesses avoid the costly pitfalls of overstocking and understocking. It ensures that capital isn’t tied up in excess inventory and that stockouts do not lead to lost sales.

This balance of optimal inventory is what improves cash flow.

Additionally, inventory control provides valuable insights for better decision-making, supports quality control, and ensures that inventory is well-organized and in good condition, ultimately, contributing to the overall efficiency and profitability of the business.

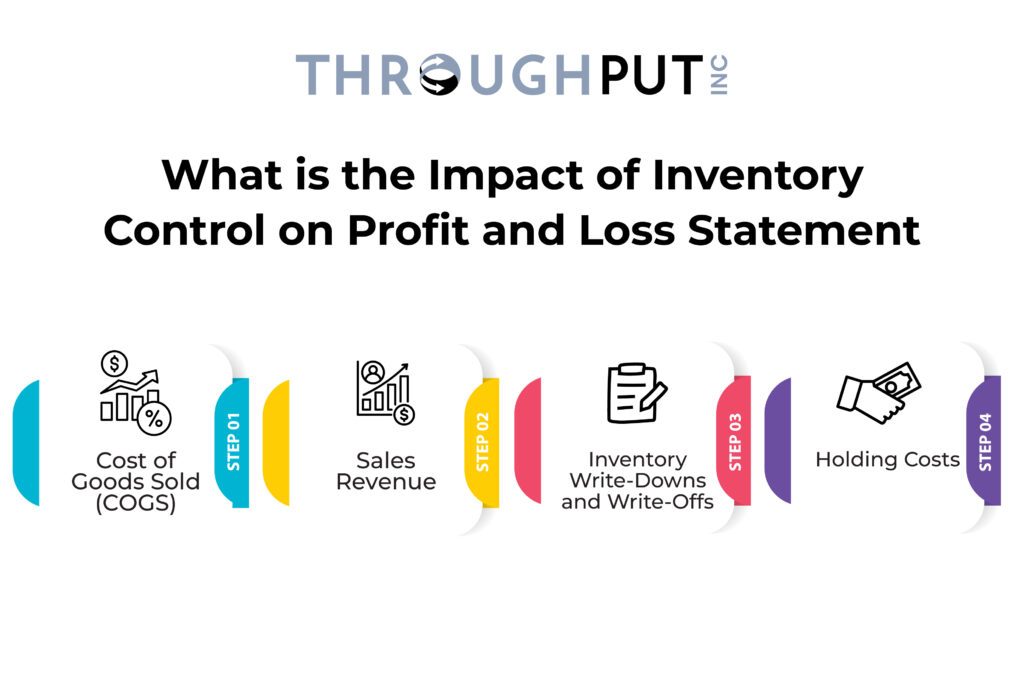

Impact of Inventory Control on Profit and Loss Statement

Inventory control has a significant impact on a company’s profit and loss statement and it is imperative for the modern inventory planner to have a view of this relationship. And, also to be able to report on it.

Here are a few good reasons:

Cost of Goods Sold (COGS)

When you sell inventory, you transfer its cost from the inventory account to the COGS account. This action affects the gross profit, calculated as sales revenue minus COGS. Efficient inventory management helps reduce COGS as it minimizes waste and optimizes purchasing.

Sales Revenue

Inventory levels directly impact sales revenue. Adequate inventory ensures that customer demand is met, leading to higher sales. Conversely, understocking can result in lost sales opportunities and dissatisfied customers, negatively affecting revenue.

Inventory Write-Downs and Write-Offs

Obsolete or unsellable inventory must be written down or written off, which directly impacts the P&L statement by increasing expenses. Effective inventory management helps minimize these occurrences by ensuring inventory levels are aligned with demand forecasts.

Holding Costs

Holding costs, including warehousing, insurance, and spoilage, are part of operating expenses. Overstocking increases these costs, reducing net profit. Efficient inventory management aims to balance inventory levels to minimize holding costs.

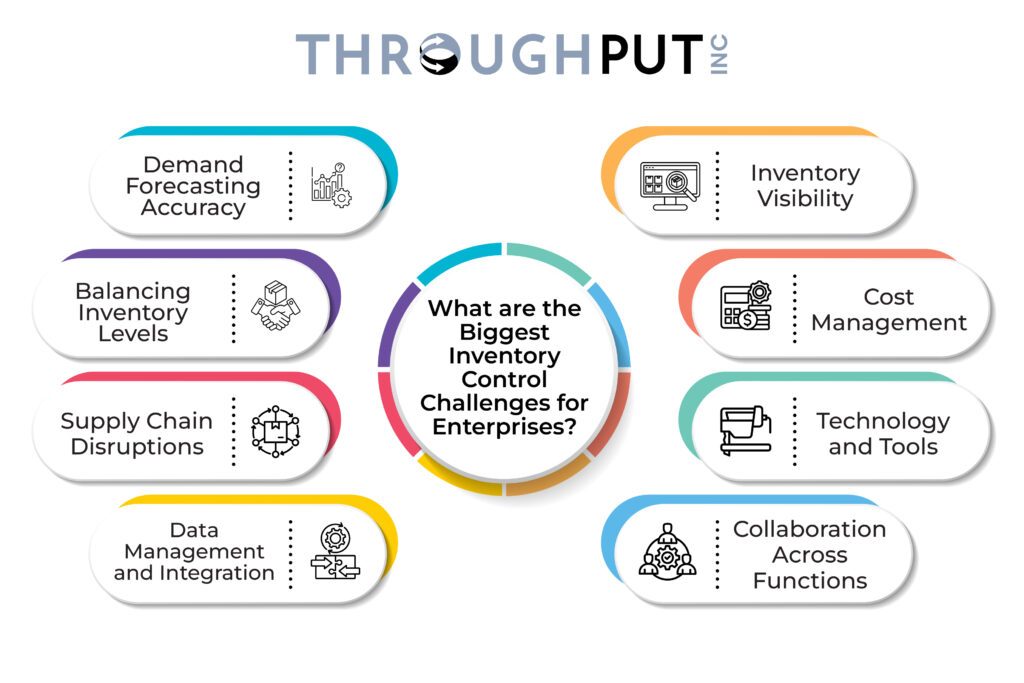

What are the Biggest Inventory Control Challenges for Enterprises?

The biggest challenges that inventory planners face in their daily work are balancing inventory levels despite inaccurate demand forecasts, supply chain disruptions, inadequate data management practices, lack of inventory visibility, and insufficient collaboration across different functions.

The following challenges can impact the effectiveness of inventory control:

Demand Forecasting Accuracy

Predicting customer demand accurately is one of inventory planners’ most critical and challenging tasks. Inaccurate forecasts lead to either overstocking or understocking, which have negative financial implications.

The dynamic nature of market demand, influenced by factors such as seasonality, economic conditions, and consumer trends, makes demand forecasting a complex and ongoing challenge.

We’ll talk more about solving overstocking and understocking in the following chapter.

Balancing Inventory Levels

Maintaining the right balance between too much and too little inventory is a constant struggle.

Inventory planners must continuously monitor and adjust inventory levels to align with fluctuating demand, which requires precise planning and real-time data.

Supply Chain Disruptions

Supplier delays, transportation issues, and unexpected demand spikes can severely impact inventory levels.

Planners must be agile and responsive to mitigate these disruptions.

Data Management and Integration

Managing and integrating data from various sources (suppliers, warehouses, sales channels) to get a real-time view of inventory levels is complex. Inconsistent or inaccurate data can lead to poor decision-making.

Effective inventory control requires seamless data integration and real-time analytics to provide accurate and actionable insights.

Inventory Visibility

Lack of visibility often results in inefficiencies and increased costs.

Advanced inventory management systems and technologies are necessary to get a bird’s eye view of inventory levels and movements.

Cost Management

Controlling inventory costs, such as holding, ordering, and shortage costs, requires careful planning and continuous monitoring. Inventory planners must balance these costs to optimize profitability while ensuring inventory levels meet customer demand.

Technology and Tools

Implementing and maintaining advanced inventory management systems and tools can be resource-intensive.

Planners must effectively use these tools to get accurate and actionable insights.

Integrating AI and machine learning technologies can enhance inventory control by providing predictive analytics and real-time decision support.

Collaboration Across Functions

Effective inventory management requires collaboration across different functions, such as procurement, sales, and logistics. Misalignment between these functions can lead to inefficiencies and increased costs.

Cross-functional cooperation and communication are key components that ensure inventory strategies align with overall business goals and customer needs.

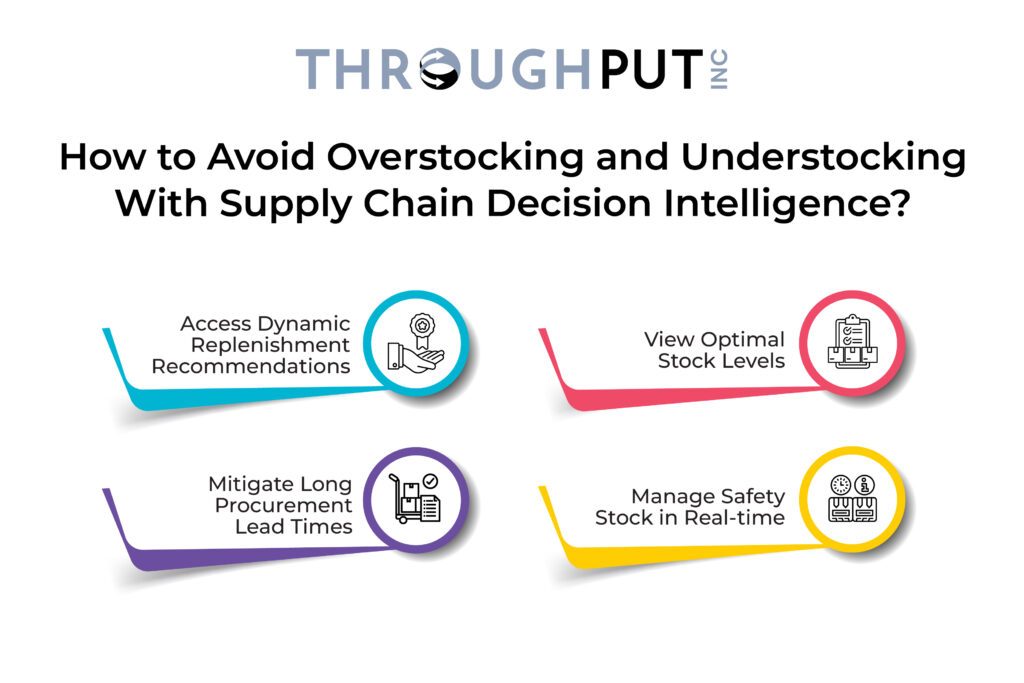

How to Avoid Overstocking and Understocking With Supply Chain Decision Intelligence?

Supply chain decision intelligence is a data-driven approach to optimizing supply chain operations that leverages advanced analytics, machine learning, and artificial intelligence (AI).

This approach includes predictive and cognitive analytics techniques, which help businesses make smarter, faster, and more informed decisions across their supply chain networks.

Using supply chain intelligence tools like ThroughPut AI, enterprises can optimize their inventory in the following ways:

Access Dynamic Replenishment Recommendations

Traditional inventory management often relies on manual reorder points and fixed order quantities, which can be inflexible and inefficient.

Supply Chain Intelligence software like ThroughPut AI moves away from these static methods with its dynamic replenishment recommendations.

The software intelligently adjusts inventory levels based on real-time demand fluctuations, actual lead times, and supplier constraints.

This adaptive approach optimizes stock levels, reducing carrying costs and preventing excess inventory.

Mitigate Long Procurement Lead Times

Long procurement lead times can disrupt stock availability and compromise operational efficiency. ThroughPut AI employs proactive strategies to mitigate the impact of lead times on stock availability.

These strategies include advanced forecasting, safety stock optimization, and supplier collaboration tools.

Identifying potential delays early on and implementing contingency plans minimizes disruptions and maintains uninterrupted operations.

For example, the system can recommend higher safety stock levels or alternative suppliers to ensure continuous supply when a primary supplier is delayed.

View Optimal Stock Levels

ThroughPut AI provides allocation and distribution recommendations to create a perfect pull system.

This approach helps remove unnecessary moves to get the product to where it is needed, on time and in full (OTIF), ensuring you never miss a sale.

The system continuously updates target service levels based on product mix priorities for each period and ensures that inventory levels align with current demand.

Manage Safety Stock in Real-time

ThroughPut AI uses correct buffer sizing criteria to ensure that you can always supply the next node in your supply chain to the desired level of service.

This feature involves monitoring buffer consumption to translate performance against recommended stock level targets over time.

When system risks and waste are exposed and minimized, you can maintain optimal inventory levels and improve overall supply chain efficiency.

ThroughPut AI Versus Other Inventory Management Software

In the crowded inventory management software market, ThroughPut AI distinguishes itself with advanced decision intelligence capabilities that surpass traditional solutions.

ThroughPut AI is a supply chain decision intelligence tool that offers a comprehensive, data-driven approach to real-time, agile inventory management.

It enables inventory planners to optimize operations, reduce costs, and enhance service levels.

Here’s a short overview of more features that make ThroughPut AI a preferred choice among enterprises.

Common Operating Picture

ThroughPut AI consolidates existing stakeholder data sets into a comprehensive view of the supply chain.

This integrated perspective empowers you to make informed decisions at strategic, operational, and tactical levels.

By adopting this holistic approach, you can ensure that inventory decisions align with broader business goals and enhance operational efficiency, providing a unified perspective for inventory planners, managers, and the C-suite.

Out-of-the-box Data Integration and Transformation

One of ThroughPut AI’s main advantages is its data integration and transformation excellence.

It seamlessly connects with existing data sources such as ERP systems, POS data, spreadsheets and material movement data.

This out-of-the-box integration capability ensures you can quickly and efficiently leverage your existing data without extensive modifications.

The platform’s real-time ability to transform and analyze data gives you the insights to make informed decisions and swiftly respond to market changes.

5X Faster ROI

ThroughPut AI delivers ROI in 90 days. How?

- It works with your existing data, systems, and resources cutting down on the implementation time,

- And, the tool is built to identify and recommend areas with the most improvement potential in the shortest time.

Alignment of Supply Chain, Inventory, and Financial Impact

ThroughPut AI aligns supply chain operations with inventory management and financial impact to provide inventory planners with a comprehensive view of how your inventory decisions affect the overall business.

The platform’s decision intelligence capabilities enable enterprises to prioritize actions based on their potential impact on profitability and operational efficiency.

Inventory Control Optimization for Enterprises

What makes supply chain intelligence tools a smarter choice for inventory management and control is that it goes beyond traditional solutions with its advanced AI-driven capabilities.

ThroughPut AI especially integrates with existing data seamlessly, providing a unified view of inventory that helps businesses understand lead times and optimize stock management in real time.

ThroughPut AI also offers dynamic replenishment recommendations, real-time analytics, and actionable insights to avoid overstocking or understocking.

The software aligns supply chain operations with financial impacts to help inventory planners ensure that inventory strategies are operationally efficient and financially sound.

Don’t just take our word for it.

ThroughPut was recognized as one of the leading vendors in Gartner’s 2024 Market Guide for Analytics and Decision Intelligence Platforms.

Try out ThroughPut and book a free demo here.