Retail Inventory Software: How ThroughPut AI’s Decision Intelligence Helped Two Global Retailers Right Size Inventory

As a retail inventory planner, you strive to deliver precise replenishment plans—ensuring the right quantity of stock is available at the right time and place with the help of retail inventory software.

Yet, managing inventory through multiple spreadsheets linked by complex formulas, or using disparate point solutions that don’t integrate, complicates your task.

According to Gartner Digital Markets, about 41% of inventory planners still rely on manual methods, 26% use spreadsheets, and another 26% use third-party software for inventory management.

Many planners find themselves caught between the slow pace of digital transformation in their companies and an over-reliance on spreadsheets, leading to frequent challenges with their current inventory processes.

Inaccurate data can also result in mismanaged stock and poor decision-making, such as incorrect replenishment quantities, lead time errors, or delayed insights due to siloed software systems.

Despite high expectations, you might feel limited by the functionalities of your current system, which lacks decision intelligence and scalability.

Consider the impact on the bottom line: not only is your organization’s profitability at risk, but you are struggling to keep up with fluctuating demand, supplier risk, and market disruptions. Under these conditions, what are your options?

You are not alone in these struggles. Inventory planners globally face similar issues across various industries.

To address these challenges, consider advocating for the adoption of advanced technologies like AI-powered retail inventory software.

Such systems can provide automated alerts for SKU inventories, generate timely overstock reports with real-time data for strategic decision-making, and offer real-time buffer management that accounts for seasonality and demand fluctuations.

For example, two global retail brands we collaborated with faced similar challenges. They successfully navigated these issues by implementing cutting-edge inventory management software for retail and adopting best practices for inventory optimization. Here’s how.

Demand-driven Replenishment Planning for Individual SKU: European Retail Chain

In the retail industry, particularly where margins are low, managing the right stock level is crucial. As an inventory planner, you face ongoing pressure to handle replenishment—determining when and how much to reorder, considering lead times, demand, and numerous other variables.

This task becomes particularly daunting when managing nearly 15,000+ SKUs.

A leading European retail chain operational for about 65 years, was one of the region’s pioneers in adopting organic products and online shopping. Operating with margins between 1% and 3%, the chain needed to accurately gauge demand shifts and prioritize effectively to maximize sales, operational efficiency, and customer experience while minimizing costs.

Previously, without a data-driven approach for its 15,000+ SKUs, the retailer struggled to maintain optimal inventory. Managing products uniformly or relying on fragmented data from Excel was ineffective—they were overstocking low-value, low-demand SKUs and depleting high-value, high-demand inventory too quickly.

The Result?

Inventory planners were trapped in a vicious cycle of making last-minute orders, leading to increased operational and logistics costs, and a planning cycle spiraling out of control.

The Solution

Using ThroughPut’s AI-enabled retail inventory planning, the chain segmented thousands of SKUs to optimize its product mix and enhance profit margins.

After years relying on siloed data systems and manual spreadsheet calculations, the retail group could now accurately sense, analyze, and predict demand in real-time, both short-term and long-term. ThroughPut’s custom AI enabled the company to analyze historical sales data along with external factors like seasonality to monitor and adapt to shifting demand patterns at an SKU level in real-time.

The retail chain identified high-profit and low-profit products. Low-value SKUs with minimal demand were eliminated, freeing resources for more strategic use. Other SKUs were assessed and prioritized in a demand-value matrix to maximize margins.

With SKU optimization, logistics management also improved. The planning of allocation, packaging, and distribution of SKUs became far more streamlined, enhancing operations across the value chain.

The Impact

The European retail business significantly increased sales, profits, and turnover while avoiding both dead stock and stockouts. The AI-enabled inventory management software helped:

- Maximize and improve margins by up to €30 million

- Reduce operating expenses by €2 million through better allocation of the top 150 SKUs

- Identify opportunities to drive a bottom-line impact of up to €10 million per facility

Dynamic Lead Time Management for Stock Availability: Coffee Retailer

In the food and beverage (F&B) retail segment, such as cafes, it’s crucial to source raw materials, and semi-finished and finished products ahead of time. This strategy prevents stock shortages during peak times while ensuring that stock levels are balanced so that product freshness is not compromised.

As an inventory planner, your biggest challenge in this case is to pin down the correct lead time for each product, while keeping in mind that the requirements for these products can fluctuate based on different factors – like, demand variability, production capacity, etc.

Your biggest goal is to maintain the right stocks while ensuring that your products don’t perish while they are still on the shelf. This is exactly where advanced retail inventory software will help you save time, costs, and effort.

Of course, without skipping the basics that need to be taken care of as well.

The right inventory management software for retail with decision intelligence capabilities helps in multi-echelon inventory optimization.

A boutique coffee chain, initially struggled with limited visibility into which menu items were performing well. This lack of insight hindered their ability to quickly identify and adapt to changing tastes and trends, leading to operational disruptions and financial losses.

Common industry challenges such as inventory pile-ups, food wastage, or stockouts were significant issues. Additionally, the coffee retailer faced logistical challenges, needing SKU-level insights into product performance and material movement across their value chain. Accurate demand sensing and planning became critical.

The Solution

The coffee chain sought to address these issues by adopting an intelligent, agile, and cognitive approach to optimizing its product mix, based on precise demand sensing, planning, and fulfillment. Implementing ThroughPut’s advanced retail inventory management capabilities provided them with comprehensive visibility into inventory turnover frequency, customer reorder rates, shipping costs, and lead times for premium products at an individual SKU level.

With this information, the café could adapt its menu in response to anticipated changes in customer tastes and preferences, backed by real-time visibility into current and near-term customer demands.

The Impact

The client was able to continuously optimize its product mix, enhancing customer experiences without interruption.

By utilizing the tool’s demand-value matrix, the client effectively eliminated inventory pile-ups and reduced food wastage, achieving a 15% reduction in inventory and a 5% increase in labor productivity.

Get More From Your Retail Inventory Software

You may be using an ERP system, POS, or an accounting software system that doubles up as inventory management software for retail.

These are function-specific systems.

Yes, these tools are crucial for certain business functions. However, in most circumstances, they are not designed or developed to help you manage your inventory in real-time.

Additionally, the dependence on multi-point and disparate solutions can only make things chaotic, creating data silos.

Viewing your inventory holistically and managing it comprehensively can be much tougher with such systems even though they can, to a certain extent, individually or wholly help you track inventory, manage suppliers, and enable reordering.

A better alternative would be tools that can do much more than the basics.

So, what are the must-have capabilities of new-age retail inventory software? Let’s find out.

1. Demand-driven Inventory Replenishment Planning for Individual SKUs

Both the retailers in the above case studies derived SKU-level clarity of their demand with ThroughPut AI that helped them drive inventory optimization at a granular level.

Demand-driven replenishment allows you to optimize stock levels accurately by aligning inventory orders with real-time market demand.

It requires the retail inventory software to conduct thorough analysis and tracking of sales data, consumer behaviors, and market trends to forecast future needs effectively.

In response, high-performing SKUs can be identified and prioritized; low-performing ones eliminated. And real-time replenishment alerts on reordering SKUs, down to location-wise ordering can be achieved.

2. Intelligent Alerts and Dynamic Recommendations

A robust retail inventory management system should be an active participant in your daily operations and strategic decision-making, not just a passive tool.

Advanced systems like ThroughPut AI provide intelligent alerts for replenishment and urgent stockouts and offer proactive, dynamic recommendations to ensure optimal stock levels are maintained.

3. Dynamic Lead Time Management

An effective retail inventory software built for the current times should aid in dynamically managing lead times, predicting potential delays, and identifying cancellation opportunities.

ThroughPut AI, for instance, in the retailer cafe case study mentioned earlier, enhanced lead time management for premium products at an individual SKU level, minimizing disruptions and smoothing operations.

4. Real-time Buffer Management

For dynamic retail environments, static buffer levels are inadequate. Real-time data-driven adjustments are essential for managing safety stocks based on current needs.

For example, buffer stocks for red-colored apparel might increase during Christmas and Valentine’s Day due to higher demand, while being reduced when demand wanes.

Going back to the above case studies, ThroughPut AI enabled both retailers to maintain dynamic buffers that wouldn’t tied up working capital or lead to wastage.

5. Supplier Risk Management

An advanced retail inventory system assesses and monitors supplier performance, identifying potential risks well in advance. This allows you to take preemptive actions to mitigate risks before they affect your inventory.

ThroughPut AI goes a step further by also identifying the preemptive actions that you could take under such circumstances.

6. Optimizing Operational Capital Spend

Effective inventory management directly influences the financial health of your business. Managing inventory efficiently helps avoid excess stock, which ties up working capital, and prevents stockouts, which can lead to lost sales opportunities.

An advanced inventory system not only manages these aspects but also provides financial insights into inventory operations, showcasing the impact on the bottom line through improved cash flows, reduced carrying costs, and enhanced profitability.

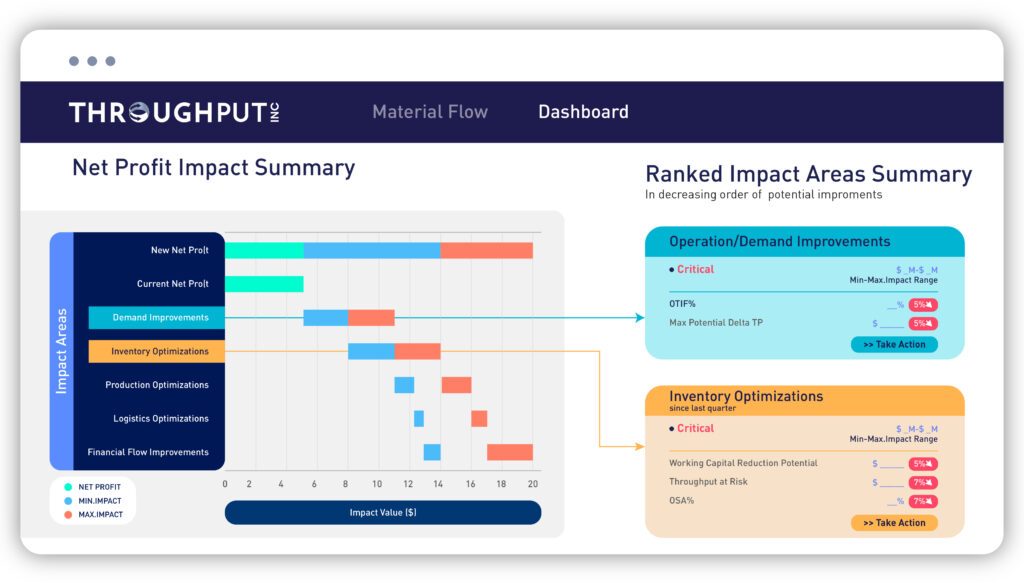

ThroughPut AI’s net profit impact summary is a view that shows the financial potential in each decision made within the supply chain.

Add ThroughPut Inventory Management to Your Existing Supply Chain Software Ecosystem

One of the standout features of ThroughPut AI is that its algorithms act as an additional layer of benefit, enhancing your existing systems and processes to deliver tangible results in less than 90 days. This swift impact is achieved by optimizing current operations instead of overhauling them entirely.

A major advantage of ThroughPut AI is its compatibility with your current systems. It integrates seamlessly, requiring no reconfiguration or displacement of existing systems. This integration enriches your existing infrastructure with advanced capabilities, allowing you to leverage the full potential of ThroughPut AI without major disruptions.

ThroughPut AI efficiently utilizes existing data from various sources—whether it’s POS data, ERP data, cloud-based systems, spreadsheets, material movement data, stock transfer data, OTIF data, or stock overview data. This is done without the need for data migration or system overhauls, offering AI-driven insights right where they are needed.

Equipped with predictive analytics, machine learning, and advanced algorithms, the platform enhances demand forecasting and predicts stock needs with high precision. It provides real-time insights into inventory requirements and delivers accurate projections of inventory needs, ensuring that your supply chain remains efficient and responsive to market demands at all times.

Have questions? Talk to our product experts today.