As businesses globally focus on reducing lost productivity, costly downtime, and rising inventory expenses, effective spare parts management has become a top priority—especially for asset-intensive industries.

Poor spare parts management and planning can significantly impact the bottom line, leading to inventory failures. This often results in part shortages when they are most needed or an excess of the wrong parts due to over-ordering, both of which drive up costs.

Therefore, optimizing spare parts management software is crucial for the success of supply chain, manufacturing and maintenance operations.

In this blog, let’s dive deeper into the challenges of spare parts management, the solution that ThroughPut AI provides, the features of spare parts management software and how it works.

Let’s get started.

Top Challenges of Spare Parts Management Software

There are multiple challenges that come in the way of effective spare parts management. Some of them are:

- Planning

A common challenge is the need for coordination between demand forecasting and inventory planning across the entire organization. Without proper alignment, businesses end up overstocking or running out of critical parts, affecting overall efficiency.

- Sourcing

Procurement of spare parts is complex, requiring careful consideration of factors such as customer demand, supplier risks, compliance, and delivery times. Any misstep in evaluating supplier availability and readiness can delay operations and disrupt the supply chain.

- Business Continuity

Ensuring uninterrupted operations requires sourcing the right parts at the right time and place. Delays or errors in securing parts can lead to missed maintenance schedules, impacting asset performance and operational continuity.

- Manufacturing

Planning production schedules and maintenance becomes easier with accurate forecasting and resource optimization. This can lead to inefficient operations, unexpected asset failures, and costly downtime, affecting overall manufacturing productivity.

The Effective Solution: Spare Parts Management Software

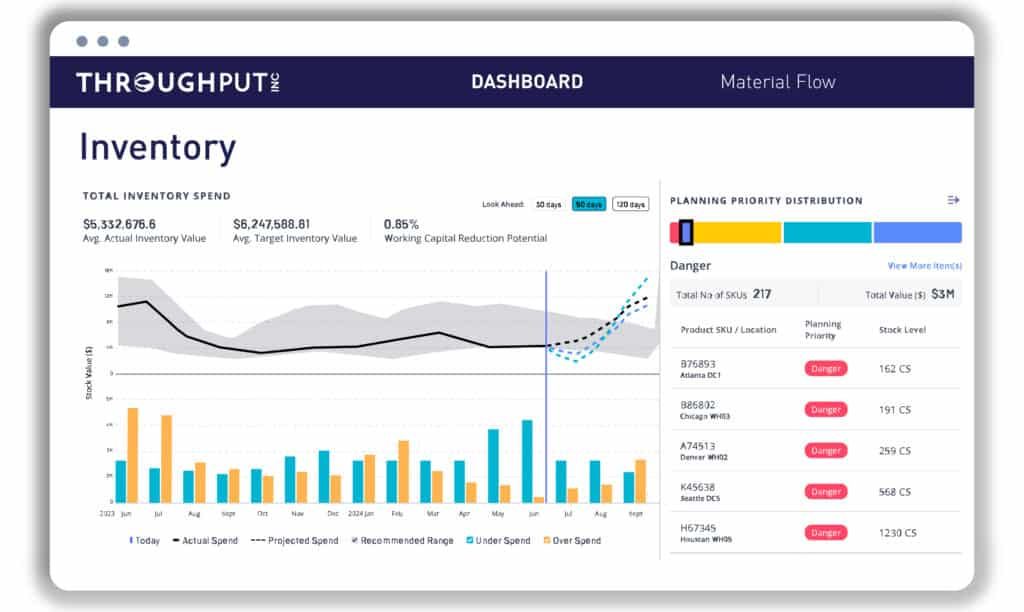

Tools like ThroughPut AI, a Supply Chain Decision Intelligence platform, pulls together different parts of the inventory chain and meshes them to standardize the logic for how businesses manage their inventory.

These tools empower businesses to enhance their market responsiveness by tracking and categorizing real-time usage and expected supply lead times, both current and historical, of millions of products across thousands of locations. Thus the availability of the right parts and kits in the right quantities at the right time in the best place is ensured.

Organizations can proactively and dynamically rebalance inventory levels allowing them to significantly unlock working capital while also avoiding overstocking or understocking their inventories.

For instance, ThroughPut AI highlights opportunities to cancel unnecessary planned orders, directly ship to inventory staging locations, and move existing spare stock faster internally, effectively rebalancing and optimizing supply chain processes end-to-end, from existing suppliers to individual staging and end-points.

Most effective spare parts management software also have patented AI and ML algorithms, and processes for inventory flow management around bottlenecks to help improve product availability while at the same time reducing material waste and unnecessary spending.

Top Key Features of a Good Spare Parts Management Software

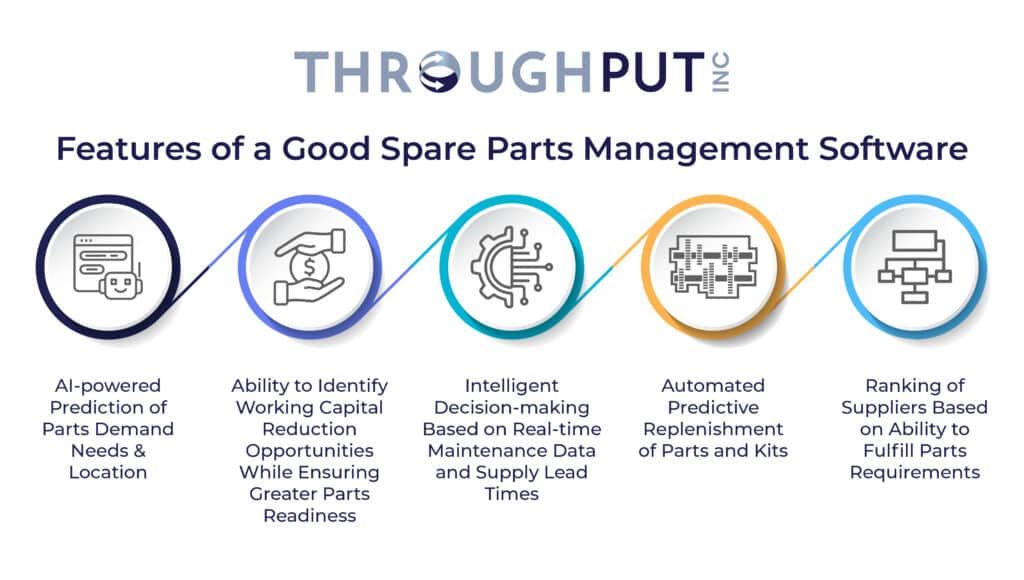

A good enterprise-level spare parts management software will have the following features: AI-driven prediction of parts demand, ability to identify working capital reduction opportunities, intelligent decision-making based on real-time maintenance data and supply lead times, automated predictive replenishment and more.

1. AI-powered Prediction of Parts Demand Needs & Location

The spare parts management software equipped with AI can accurately forecast parts demand by analyzing historical data, equipment usage, and failure rates. It also identifies the best locations for stocking these parts, ensuring availability when and where they are needed most.

2. Ability to Identify Working Capital Reduction Opportunities While Ensuring Greater Parts Readiness

The software helps businesses optimize their working capital by identifying areas where inventory can be minimized without compromising operational readiness. This balance ensures that spare parts are always available for critical needs while reducing unnecessary inventory costs.

3. Intelligent Decision-making Based on Real-time Maintenance Data and Supply Lead Times

With real-time access to maintenance logs and supply chain data, the software enables precise decision-making at the local level. It factors in lead times and part availability, allowing for more efficient planning and reducing the risk of downtime due to delayed parts.

4. Automated Predictive Replenishment of Parts and Kits

The software automates the replenishment process by predicting when parts and kits will be required based on usage trends and equipment performance. This automation ensures that critical parts are reordered just in time, reducing manual effort and preventing stockouts.

5. Ranking of Suppliers Based on Ability to Fulfill Parts Requirements

The software evaluates suppliers based on their reliability, ability to deliver parts on time, pricing, and other important criteria. This ranking system helps businesses choose the most efficient and cost-effective suppliers to meet their parts requirements, improving overall supply chain efficiency.

How Spare Parts Management Software Works?

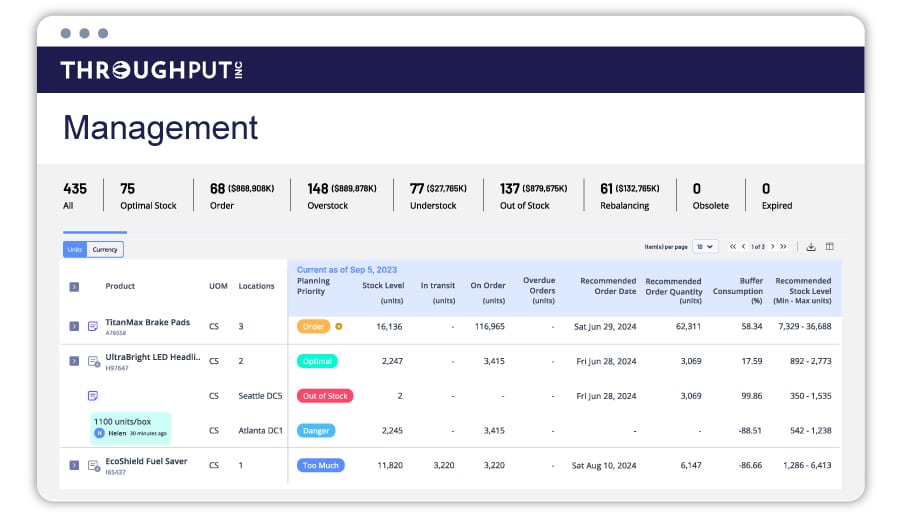

Spare parts management software like ThroughPut AI follows a three-step approach as below.

Step 1: Visualize Global Parts Orders by Expected Lead Times

In the first step, the tool gathers data from disparate systems – inventory, and purchase orders. requisition data, transactions, and more to rebuild a common operating picture that visualizes parts orders at a global level by expected lead time.

Step 2: Recommend Parts Prioritization by Location-based Usage, Stock Levels, and Lead Times Offline or in Real-Time

Next, the tool recommends parts prioritization not just based on existing stock levels, but based on actual maintenance usage at individual locations, as well as real lead times of parts and kits

Step 3: Reduce Working Capital Spend (Up to 60%+)

Finally, it predicts maintenance requirements and recommends optimized schedules to maximize productivity and uptime without wearing down assets. This helps extend asset life and health, thus reducing working capital spending both in the near and long term.

Top Benefits of Spare Parts Management Software

Spare parts management software can greatly enhance your business operations. Here’s how it helps.

- Maximized Output with Optimized Inventory Levels

The tool helps maximize operational efficiency while minimizing excess inventory and associated costs. The tool helps ensure that you maintain the ideal balance of spare parts, preventing overstocking or understocking.

- Improved Planning Reliability

By providing real-time data and forecasting tools, the software enables more accurate planning for spare parts demand. This leads to better resource allocation and smoother operations.

- Reduction of Part Shortages and Costs

The tool helps identify and eliminate unreliable suppliers and inefficient delivery options, reducing the chances of part shortages and lowering procurement costs. It streamlines supplier selection for optimal performance.

- Reduced Working Capital Expenditure

Optimized inventory management and improved supplier reliability reduce the need to tie up working capital in excess inventory, allowing you to allocate financial resources more effectively.

- Prevention of Maintenance Bottlenecks and Downtime

By ensuring that the right parts are available when needed, the software reduces maintenance delays and asset downtime. This minimizes opportunity losses and keeps operations running smoothly.

- Smart Recommendations for Safety Stock and Replenishment

The software uses intelligent algorithms to recommend ideal safety stock levels and reorder points for each part and location. This ensures that critical parts are available without overstocking less essential ones.

- Categorization and Prioritization of Parts

Spare parts management software categorizes parts based on criticality and usage, allowing businesses to prioritize vital components and streamline the maintenance process for essential assets.

- Improved Parts Availability and Reduced Waste

With better demand forecasting and inventory control, the software helps ensure that parts are available when needed, reducing instances of over-ordering or parts becoming obsolete, thereby minimizing waste.

- Simultaneous Optimization of Profitability and Working Capital

The tool balances inventory levels and costs, helping businesses improve profitability while efficiently managing working capital. This maximizes financial returns without sacrificing operational efficiency.

How AI Transforms Spare Parts Management to Eliminate Downtime?

Artificial Intelligence is driving change in spare parts management to significantly reduce downtime. Some of the ways AI is transforming the space are:

- Predictive Maintenance

AI processes data from equipment sensors and maintenance records to forecast when parts are likely to fail, allowing for proactive replacements before any breakdowns occur, thereby avoiding unexpected downtime.

- Accurate Demand Forecasting

By analyzing historical trends, seasonality, and equipment usage, machine learning algorithms provide more accurate predictions for spare parts demand, ensuring essential parts are readily available when required.

- Optimized Inventory Management

AI helps determine the ideal stock levels and reorder points for each spare part by considering demand trends, lead times, costs, and criticality, ensuring a balance between availability and cost control.

- Critical Parts Prioritization

AI assesses the importance of various spare parts by evaluating factors like downtime risks, replacement costs, and lead times, enabling businesses to prioritize inventory investment based on criticality.

- Supplier Evaluation

AI assesses supplier performance and analyzes reliability, lead times, quality, and cost efficiency, to make informed decisions about supplier management and improve the spare parts procurement process.

- Distribution Network Optimization

AI enhances the efficiency of spare parts distribution by determining the best stocking locations and transport modes, ensuring faster delivery and availability.

- Managing Obsolescence

AI identifies obsolete or slow-moving parts, helping businesses minimize excess inventory of outdated items and reduce unnecessary costs.

- Digital Twins

AI-powered digital replicas of physical assets allow businesses to simulate equipment performance, enabling predictive maintenance and better planning for spare parts requirements.

Optimize and Enhance Spare Parts Planning with ThroughPut AI

ThroughPut AI’s advanced capabilities provide businesses with a pioneering solution to optimize spare parts management using AI and predictive analytics. This cutting-edge platform enables companies to accurately forecast spare parts demand, streamline inventory management, and significantly reduce associated costs. By leveraging AI-driven insights, businesses can anticipate equipment needs, proactively manage spare parts replenishment, and ensure that critical parts are always available.

ThroughPut AI not only helps in reducing operational inefficiencies but also boosts equipment reliability and uptime, minimizing the risk of unexpected downtime. By adopting this solution, organizations can revolutionize their spare parts planning and maintenance processes, ensuring smoother operations and higher profitability across the board.

To learn more about how ThroughPut AI can be customized for your business needs, book a no-obligation demo with us.

FAQ:

Q1: How can AI-driven spare parts management help maintenance leaders minimize unplanned downtime?

A. AI-powered spare parts management continuously monitors usage patterns, lead times, and equipment failure trends to predict which parts are likely to fail and when. This allows maintenance leaders to proactively stock the right critical spares, reducing unplanned downtime by up to 30–40% while ensuring higher equipment reliability.

Q2: How does ThroughPut.AI’s solution help supply heads reduce excess and obsolete spare parts inventory?

A. ThroughPut.AI automatically identifies underutilized or obsolete inventory by analyzing multi-year usage, supplier performance, and demand signals across plants. Supply heads can rationalize SKUs, rebalance stock between facilities, and release working capital—often realizing 15–25% reduction in spare parts holding costs within the first 90 days.

Q3: How quickly can industrial organizations deploy ThroughPut.AI’s spare parts optimization solution?

A. Deployment typically takes under 90 days, with full visibility into spare parts across systems achieved in weeks. The solution integrates seamlessly with existing ERP, CMMS, or EAM systems (like SAP, Oracle, Maximo, or Infor), ensuring minimal disruption to ongoing maintenance or sourcing operations.

Q4: How does AI-driven spare parts management support sourcing leaders in supplier negotiation and lead time optimization?

A. By providing supplier performance analytics—such as average lead time, order accuracy, and cost variability—sourcing leaders gain objective data to negotiate better contracts and dual-source critical components. This data-backed approach ensures supply continuity while cutting procurement cycle times and costs.

Q5: What kind of ROI can we expect from implementing ThroughPut.AI’s spare parts management software?

A. Customers typically achieve ROI within 3–6 months. Savings come from reduced working capital tied in inventory, fewer production halts due to parts shortages, and improved maintenance productivity. Additionally, automated insights free up analysts’ and planners’ time for higher-value strategic work.

Q6: How does the solution enhance collaboration between maintenance, supply, and sourcing teams?

A. Through a unified AI-powered dashboard, all stakeholders—maintenance, supply, and sourcing—gain real-time visibility into spare part health, availability, and demand. This shared intelligence ensures synchronized decisions on replenishment, reordering, and redistribution, eliminating siloed planning.

Q7: Can ThroughPut.AI integrate with existing ERP, CMMS, or warehouse systems without disrupting workflows?

A. Yes. The platform is system-agnostic and uses secure APIs to integrate with existing systems like SAP PM, IBM Maximo, Oracle EBS, or Infor EAM. This allows teams to leverage current data infrastructure while adding an AI-driven optimization layer—no need for complex re-platforming.

Q8: What makes ThroughPut.AI different from traditional spare parts management or inventory planning tools?

A. Unlike static, rule-based tools, ThroughPut.AI continuously learns from real operational data—predicting failure patterns, usage shifts, and supply risks. It connects production, maintenance, and supply signals end-to-end to optimize spare part availability and cost, ensuring you have the right part, at the right time, at the lowest cost