Supplier Risk Management: How to Manage Procurement Lead Time With ThroughPut AI

The global semiconductor chip shortage has starkly demonstrated the importance and challenges of supplier risk management. When automakers couldn’t get the chips they needed, production lines halted, profits took a hit, and the global economy was impacted.

If you’re a supply planner or procurement professional, you’re all too familiar with the challenge of coordinating multiple suppliers, each with different lead times. It’s a demanding role, but essential for keeping operations flowing smoothly.

In this article, let’s explore how to use supply chain analytics and intelligence tools for effective supplier risk management and keep your operations on track.

But before that…

What is Supplier Risk Management?

Supplier risk management is the process of identifying, assessing, and managing risks that could arise from working with third-party suppliers. It’s about creating a safety net for your supply chain, ensuring potential issues don’t disrupt your operations.

The main goals of supplier risk management are straightforward. First, you want to keep your operations running smoothly without any unexpected hiccups.

Second, protecting your company’s reputation is crucial because no one wants lost sales and missed opportunities due to supplier issues.

Lastly, you aim to avoid financial losses from supplier-related problems.

Before you achieve these goals, you need to understand the key components of supplier risk management:

- Risk Identification involves spotting potential problems before they become real issues. Think of it as proactive problem-solving.

- Risk Assessment is a process where you evaluate how likely these issues are to occur and the potential damage they could cause.

- Risk Mitigation is about devising strategies to avoid or minimize these risks. For example, it could involve diversifying your suppliers or having backup plans.

- Continuous Monitoring never stops. As a supply planner you must continuously keep an eye on deliveries and inventory levels to catch any new risks early.

How Can Supply Planners Assess Supplier Reliability? What Criteria Should They Use?

Supply planners assess supplier reliability by evaluating several key criteria that provide a comprehensive view of a supplier’s performance and capabilities.

Here’s what you should look for in your assessment:

On-Time Delivery Performance

Track the percentage of orders your supplier delivers on or before the agreed-upon date. This metric will identify and address any patterns of delays.

Order Fill Rate

Monitor how often your supplier delivers the total quantity of products ordered without shortages or backorders. A high fill rate indicates a reliable supplier who consistently meets your demand.

Quality Metrics

Monitor defect rates, returns, and adherence to specifications to ensure consistent quality.

Lead Time Consistency

Compare actual delivery times against promised lead times to assess how reliably your supplier meets their quoted lead times.

Communication and Responsiveness

Track how quickly and effectively your supplier responds to inquiries, issues, and change requests.

How to Identify Supplier Risk?

A systematic approach helps you spot potential issues before they disrupt your supply chain. Here’s how to effectively identify supplier risks and keep your supply chain resilient and free of delays.

Define Risk Categories

Define the different types of risks your suppliers may pose. Common categories include financial risk, operational risk, quality risk, compliance risk, reputational risk, cybersecurity risk, and geopolitical risk. Clearly categorize these risks to help you focus your assessment efforts.

Monitor Supplier Performance

Track key performance indicators (KPIs) to measure supplier performance over time. Common KPIs include on-time delivery rate, defect rate, fill rate, and cycle time. Monitoring these metrics helps you identify patterns and address issues before they escalate.

Use Supplier Risk Assessment Tools

Use tools and templates to conduct comprehensive risk assessments. Collect detailed information from suppliers about their operations, financial health, compliance, and risk management practices through questionnaires and surveys.

Assign scores to suppliers based on various risk factors using risk scoring models, helping you prioritize which suppliers need closer monitoring.

More on this in the next chapter.

Leverage Technology and Data Analytics

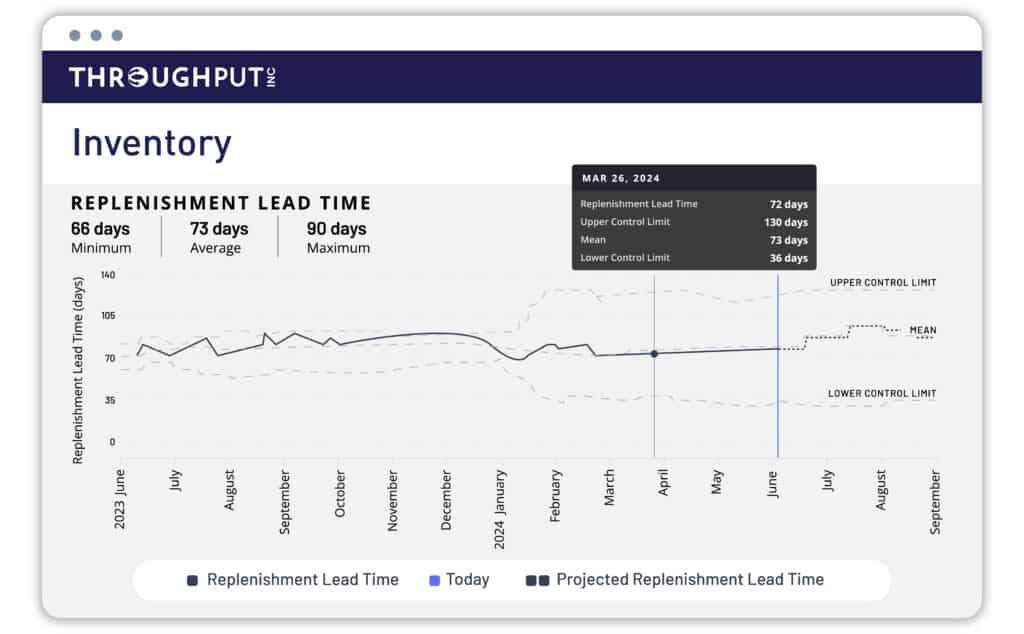

Use advanced data analytics to enhance visibility and predict potential risks. ThroughPut AI, for example, provides real-time insights into supplier performance and risk factors using artificial intelligence and machine learning.

Its predictive analytics and multi-source data integration offer a unified platform to analyze supplier data and make informed decisions.

Implement Continuous Monitoring

Adopt continuous monitoring solutions to keep track of emerging risks. Regularly update risk assessments and stay informed about changes in your suppliers’ operations, financial health, and external environment. Continuous monitoring ensures you can respond swiftly to new risks.

Use Scenario Planning and What-If Analysis

Conduct scenario planning and what-if analysis to understand the potential impact of various risk events. This approach helps you prepare contingency plans and prioritize risk mitigation efforts based on the estimated effects of disruptions.

The next chapter brings us to technology and the specific features that safeguard your supply chain.

How Can Technology and Supply Chain Analytics Mitigate Supplier Risks?

Technology and ThroughPut AI supply chain analytics can mitigate supplier risks by providing tools and insights that help you manage and anticipate potential issues.

Here’s how specific features of ThroughPut AI, for example, help identify and mitigate risks early on:

Real-time Performance Tracking

Monitor supplier activities in real-time to quickly identify and address any deviations from expected performance. Always keep this proactive approach, it’s your warning signal to address issues before they escalate.

With ThroughPut AI, you can keep a constant eye on key metrics like delivery times and order accuracy, so you get the agility and breathing space to respond promptly to any disruptions.

Predictive Analytics

Forecast future outcomes using historical data and machine learning algorithms with predictive analytics. This allows you to anticipate potential disruptions and take proactive measures to mitigate them.

ThroughPut AI’s predictive analytics can forecast demand fluctuations and identify potential supply chain bottlenecks, helping you stay ahead of problems and maintain smooth operations.

Multi-source Data Integration

Consolidate information from various systems and sources into a single, coherent view with multi-source data integration. This feature allows you to identify patterns and correlations that might not be visible when looking at data in isolation.

ThroughPut AI integrates data from multiple sources, giving you a unified platform to analyze supplier performance and make informed decisions.

Automated Supplier Scorecards

Automated supplier scorecards evaluate and rank suppliers based on predefined criteria: delivery performance, quality, and responsiveness. These scorecards help you objectively assess supplier reliability and identify areas for improvement.

ThroughPut AI automates this process, providing you with up-to-date performance evaluations that help you manage supplier relationships more effectively.

Risk Analysis

Risk analysis involves identifying and assessing potential risks in your supply chain. This feature helps you understand the likelihood and impact of various risks, enabling you to prioritize and address them accordingly.

ThroughPut AI’s risk analysis tools highlight vulnerabilities in your supply chain and suggest mitigation strategies, ensuring you’re prepared for any eventualities.

Pattern Recognition

Pattern recognition identifies trends and anomalies in your supply chain data. This feature helps you detect early warning signs of potential issues, allowing you to take corrective action before problems become critical.

ThroughPut AI’s pattern recognition capabilities empower you to spot these trends quickly, ensuring you stay ahead of potential disruptions.

Supplier Risk Management with ThroughPut AI

Managing supplier risk is fundamental for a resilient and efficient supply chain.

Understand typical supplier risks and assess supplier reliability using criteria such as on-time delivery, order fill rate, and financial stability.

ThroughPut AI equips you with real-time performance tracking, predictive analytics, multi-source data integration, automated supplier scorecards, risk analysis, and pattern recognition. These features provide actionable insights and proactive measures, helping you enhance supplier reliability, ensure business continuity, and drive more efficient and profitable operations.

FAQs for a Supplier Risk Management

Question: How can supplier risk management directly reduce unplanned downtime for industrial facilities?

Answer: Proactive supplier risk management helps identify early warning signals like delayed shipments, inconsistent lead times, or quality slippage. For maintenance leaders, this reduces the risk of critical spare parts not arriving on time.

Using platforms like ThroughPut AI, teams get real-time visibility into supplier performance, predictive alerts on high-risk vendors, and automated scoring. This enables preventive maintenance timelines to be aligned with reliable supply availability—cutting unplanned downtime and ensuring continuous operations.

Question: What supplier risk indicators should maintenance and operations heads monitor to avoid production stoppages?

Answer: Industrial maintenance leaders should track:

- Lead time variability

- Order fill rate

- Defect rates for critical spare parts

- Supplier communication responsiveness

- Financial and geopolitical risk exposure

With predictive analytics, ThroughPut AI aggregates these metrics and flags deviations early, allowing organizations to reroute orders, shift loads, or activate backup suppliers before operations are impacted.

Question: How does advanced supply chain analytics help identify failures in single-source or high-dependency suppliers?

Answer: Single-source suppliers expose operations to high risk. Advanced analytics identifies risks by:

- Detecting volatility in historical lead times

- Flagging performance degradation over time

- Predicting capacity shortfalls and delivery failures

- Identifying upstream supplier issues

ThroughPut AI integrates multi-source data (ERP, WMS, MES, procurement) to build a transparent view of hidden dependencies, helping leaders diversify or build contingency plans before a disruption hits.

Question: What is the ROI of implementing an AI-powered supplier risk management system in manufacturing?

Answer: Companies typically see ROI in:

- 15–25% lower supplier-related disruptions

- 20–35% reduction in expediting and premium freight costs

- 10–20% lower safety stock due to reliable supply visibility

- 5–10% higher OEE due to fewer production pauses

- Faster sourcing cycles and more accurate supplier selection

AI systems like ThroughPut AI accelerate decision-making, reduce risk exposure, and ensure consistent material flow—contributing directly to EBITDA improvement.

Question: How can supplier risk analytics improve maintenance planning and spare parts availability?

Answer: Demand variability and delayed shipments can disrupt maintenance schedules. Using predictive analytics:

- Maintenance teams can forecast part availability with higher accuracy

- Procurement can preemptively secure stock for planned shutdowns

- Risks in critical suppliers are flagged weeks in advance

- Spare part lifecycle reliability becomes transparent

This results in more precise maintenance planning and fewer emergency breakdowns.

Question: How can sourcing leaders compare suppliers objectively when making time-sensitive procurement decisions?

Answer: AI-powered supplier scorecards evaluate suppliers across:

- Delivery performance

- Lead time consistency

- Quality metrics

- Pricing stability

- Responsiveness

- Risk factors (financial, geopolitical, ESG)

This allows sourcing heads to quickly select the best-fit supplier under risk constraints, without manual spreadsheet work. ThroughPut AI provides automated, real-time scorecards for every supplier.

Question: How does predictive supplier risk management support business continuity planning (BCP)?

Answer: Predictive systems simulate disruptions like:

- Supplier shutdowns

- Port congestion

- Geopolitical instability

- Raw material scarcity

ThroughPut AI performs what-if simulations, recommends fallback suppliers, and visualizes impact on production, allowing leaders to redesign contingency plans with real data instead of assumptions.

Question: Can supplier risk analytics help reduce reliance on safety stock without increasing risk?

Answer: Yes. With real-time supplier tracking and predictive risk scoring, safety stock can be optimized.

Instead of holding excess inventory “just in case,” companies can:

- Trust reliable suppliers

- Forecast risks

- Calculate exact buffers needed

- Reduce working capital locked in inventory

This creates a leaner yet more resilient supply chain.

Question: How does multi-source data integration improve supplier risk monitoring for industrial manufacturers?

Answer: Manufacturers usually store supplier data in many systems (ERP, MES, QMS, procurement tools).

ThroughPut AI unifies this data to reveal hidden risks such as:

- Declining quality trends

- Rising cycle times

- Shipment delays from upstream tiers

- Capacity mismatches

This gives executives a 360° view of supplier health—something spreadsheets or siloed systems cannot achieve.

Question: How can ThroughPut AI help teams detect supply disruptions earlier than traditional procurement workflows?

Answer: ThroughPut AI leverages:

- Pattern recognition

- Predictive alerts

- Machine learning

- Real-time data feeds

It identifies anomalies weeks before they become failures—such as longer processing times, inconsistent lead times, or quality drops.

This enables teams to take action (expedite orders, switch suppliers, adjust schedules) before disruptions affect production or maintenance operations.

Question: Which supplier risks are most critical for heavy industries like automotive, aerospace, machinery, and oil & gas?

Answer: The most severe risks usually include:

- Long-lead-time component shortages

- Defective or non-compliant critical parts

- Financial instability in niche or Tier 2 suppliers

- Overdependence on single-source vendors

- Capacity limitations and labor shortages

- High logistics and geopolitical risks

Predictive platforms help classify these risks by severity and probability, ensuring executives focus resources where it matters most.