Supply chain management in the food industry plays a pivotal role in global stability and sustainability, and also happens to be one of the most complex logistics networks in the world.

Even the smallest disruption can upend entire processes, production schedules, distribution logistics, and ultimately, the customer experience. All these factors have significantly increased the risk of goods in transit, stirring uncertainty, safety and shipment reliability concerns across the industry. Supply chain challenges have become a constant stressor and drag on profitability for F&B businesses, with seemingly no end in sight.

As these challenges pile up, so does the demand for fresh, high-quality food. That’s where the need for smarter solutions comes in, that can help Food & Beverage (F&B) retailers succeed and boost their margins.

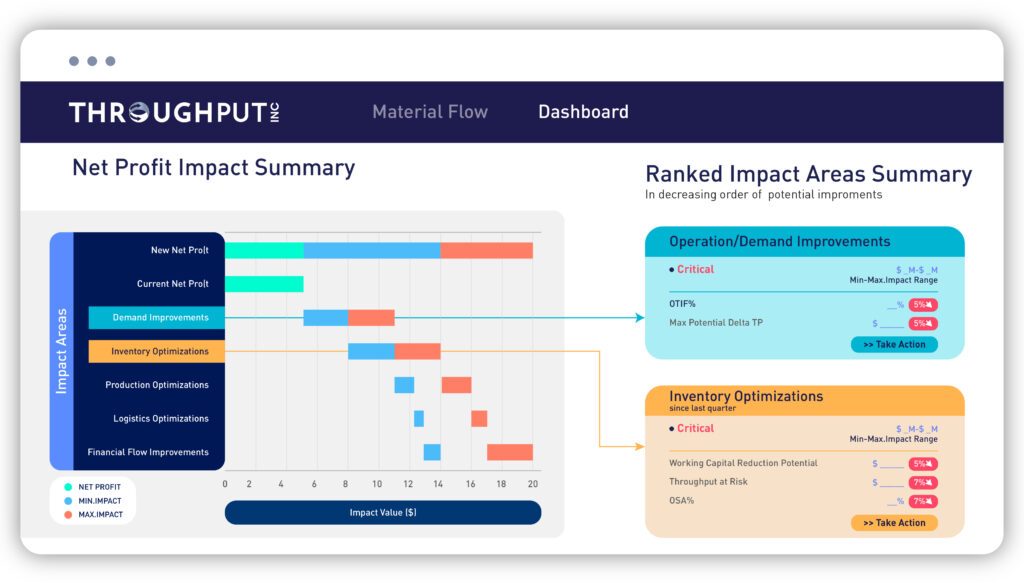

ThroughPut AI uses supply chain analytics and decision intelligence to help food businesses stabilize and improve key variables like safety stock, reorder points, and customer satisfaction. With smart predictions and actionable insights, F&B retailers can get a clear picture of where to focus their efforts and how to maximize cash flow and operational efficiency.

It empowers F&B retailers to proactively respond to the shifts in demand, enabling them to adopt a nuanced approach to managing key variables such as market and global trends, seasonality, holidays, expiration dates, and costs. F&B retailers also optimize their product mix with ThroughPut AI and align it with customer demand in real-time, thus enabling them to affect optimized distribution, maximize margins, and increase market share.

Challenges of Supply Chain Management in the Food Industry

There are several challenges of supply chain management in the food industry that F&B retailers face. Some of them include finite product shelf life, ever-changing demand and consumption trends, constantly changing regulations, scheduling, etc. Let’s look at them in detail below.

Finite Product Shelf Life

In the dynamic landscape of the F&B industry, customer loyalty hinges on the ability to deliver the freshest products on demand consistently. Failure to meet this expectation often results in customer attrition, as discerning patrons readily shift their allegiance to competitors capable of providing a superior and timely offering.

Food retailers must, therefore, balance product availability with the challenges of inventory cost and spoilage. Thus, when dealing with narrow profit margins and products with limited shelf life, inventory control is critical. To keep inventory as fresh as possible, retailers need to keep stock levels optimally balanced dynamically at the individual SKU while still being able to fulfill demand on time and in full.

Ever-changing Demand and Consumption Trends

Within the ever-evolving landscape of the F&B industry, where consumer needs and preferences are in constant flux, retailers must possess the vision and agility to adapt in real time to even the subtlest shifts in market demand. Simultaneously, they must strive to fulfill these demands with optimal efficiency, ensuring cost-effectiveness in their operations. They need to be able to sense current demand and predict future demand, using it as their north star to plan their raw material ordering, finished goods replenishment, promotional campaigns, and distribution logistics effectively to cater to a multitude of market changes.

Constantly Changing – and Increasing – Regulations

Many F&B retailers are realizing that 360°, end-to-end traceability in the food supply chain plays a key role in complying with the growing environmental, social, and corporate governance (ESG) requirements – as well as retaining consumers who are increasingly concerned about sustainability. The pressure to build a sustainable food supply chain is increasing, and questions – such as “Where is it coming from?” And “where is it going?” – are being raised, which places new demands on the supply chain. The answers to these questions can be found only with full supply chain transparency.

Navigating Collaborative Challenges in the Food Supply Chain

A single missed deadline at any point in the food supply chain can trigger a domino effect that simply goes downhill from the point of crisis, leading to significant delays at every stage. When dealing with food, this can translate into spoilage or contamination, which causes expensive product recalls.

While technology has improved communication considerably, the fact remains that there are glaring gaps in the food supply chain. Since there are multiple players, teams, and vendors involved, each with unique operational and logistics strategies, there are high chances for things to simply fall through the cracks at times. There are even cases where different individuals working on the same commodity never interact. This can pose several challenges, such as delays in moving products, food spoilage and wastage.

Scheduling for Exact Timeframes, While Still Accounting For Variability and Perishability

Successful F&B retailers rely on contemporary S&OP functioning to help balance supply and demand and better meet their key business goals. However, reconciling supply & demand is just table stakes. Leading F&B retailers also dynamically adapt to any variance, while remaining within expiration windows, for maximum profit. To be able to achieve that, they need a holistic view of their supply chain to achieve a common operating picture, and a dynamic plan of action that enables effective, efficient, and strategic S&OP aimed at customer satisfaction.

Transform Supply Chain Management in the Food Industry with ThroughPut AI

ThroughPut AI supports F&B retailers across all of the roles and levels of their supply chain networks. You can consolidate your demand sensing, forecasting, planning, capacity planning, S&OP planning, order management, and inventory management efforts on a single platform, making it possible to cohesively work toward revenue generation and higher ROI.

With ThroughPut, you can gain full supply chain actionability and visibility into customer demand, vis-à-vis your available inventory to estimate the expected delivery timelines of raw materials, which enables the creation of feasible production schedules and inventory plans.

Infact, unlike a lot of tools in the market, ThroughPut AI optimizes food production, product mix, and customer demand on a daily basis to:

- Accelerate production and distribution efficiencies

- Reduce supply and distribution wait times

- Maximize margins as well as market share

Key Features

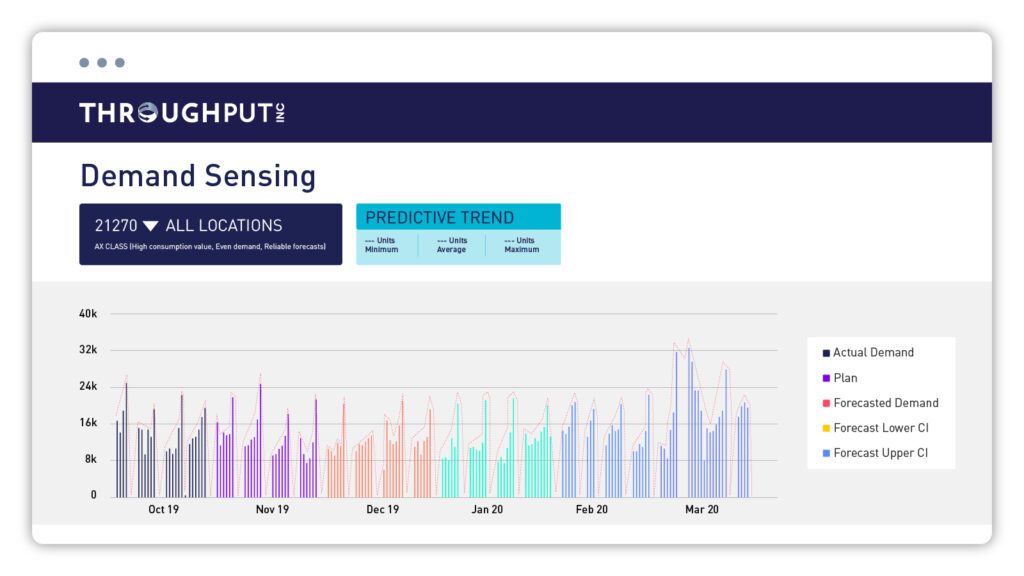

- Data and AI-driven, highly accurate demand sensing, forecasting, and planning

- Daily forecasts and intelligent recommendations that enable efficient order prioritization and fulfillment

- Ability to identify, analyze, and cover up lost sales opportunities

- Holistic and granular views of goods flow, down to a location, or SKU level

Benefits

Powerful Demand Sensing and Forecasting

With ThroughPut AI, you can sense real-time demand across the entire food supply chain network, and provide relevant, highly accurate forecasts as well as actionable intelligence on demand fluctuations, taking into account external influences as well – such as trends, seasonal preferences, and weather changes. With complete visibility into demand, supply chain, and available capacity, F&B manufacturers and distributors benefit from precise planning and agility in real-time, allowing you to effectively and efficiently manage fluctuating order requirements. ThroughPut AI also leverages data on demand versus sales, enabling you to calculate and analyze lost sales.

Intelligent Customer Segmentation

With ThroughPut AI, you can rank, categorize, and prioritize customers based on a range of variables such as order volume, revenue contribution, and profit margins, allowing for more efficient dock appointment bookings, which in turn enable more effective order fulfillment.

The platform’s powerful customer segmentation capabilities empower F&B retailers to incorporate real-time insights and gain an in-depth understanding of trends, drivers, and available market alternatives, allowing demand planners to slice main revenue drivers from multiple perspectives and drive faster, smarter demand fulfillment decisions that optimize cost and effort

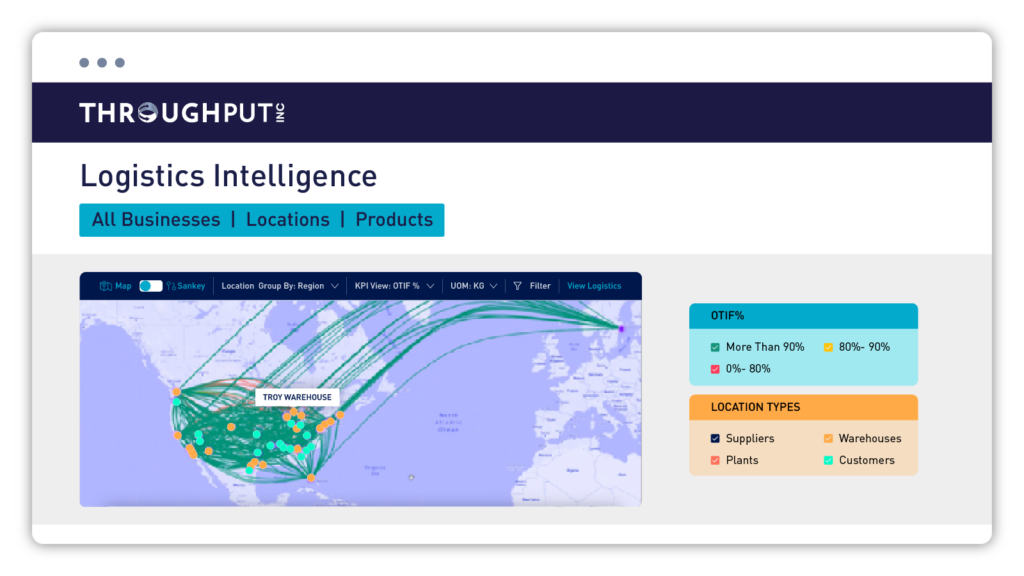

Optimized Logistics

ThroughPut AI provides a centralized, holistic view of all goods across the food supply chain, whether they are stationary, in transit, or delayed, to accelerate the shipping of the right goods at the right time – and in the right quantity – by leveraging a combination of business rule mapping and Machine Learning-based pattern extraction.

You can dynamically prioritize shipments based on logistics costs, lost sales opportunities, and more taking into account existing capacity constraints, rising shipping costs, changing customer priorities, and demand for faster delivery, minimizing cost and risk in real-time.

Case Studies of Effective Food Supply Chain Management

Church Brothers Farms

Church Brothers Farms, a family-owned vegetable producer, supplier, and food processor in the US, owns 40,000 acres of farmland, shipping 50 million cartons every year, utilizing 8 or more pallets per 4,400 trucks The company’s core focus is customer experience and to drive the same, it offers superior quality produce even with increased aggressiveness and volatility market conditions.

Challenges

While on the one hand, the company had to deal with constrained budgets, labor, time, assets, and weather, on the other, it had to continuously deliver value to customers and shareholders. The main challenges for the company were:

- Hostile market conditions meant that the company wanted to predict demand product-wise and product-group-level-wise proactively while identifying and ranking products for on-priority distribution and order fulfillment.

- The seasonality of sales meant that the company needed full transparency into SKU-wise sales, identifying top-selling & under-performing products and categories, with granular visibility and actionability to prevent revenue leaks.

- Inadequacy in inventory control & rising costs were an issue too. Church Brothers Farms wanted to implement a demand-driven, and smart plan to shift from make-to-stock to make-to-order. This way with optimized stock, distribution, and production, unnecessary costs and inventory space could be minimized in the value chain.

Solutions

- Key Insights: ThroughPut AI evaluated current and historical data related to sales and revenues from diverse sources across 490 product groups, 60 commodities, and 25 value-added products. The tool offered valuable recommendations related to sales frequency, sales volume, price and revenue, distribution, and specialty sales.

- Minimizing Disruptions: By analyzing seasonality and various external factors, Church Brothers Farm could address a key challenge in the agriculture industry – disruptions. Common factors that contribute to disruptions like high demand uncertainty, product perishability, volatile commodity prices, safety and quality compliance, weather, innovations, logistics issues, complex production constraints, fluctuating consumer tastes, seasonal promotions, etc. were assessed for meaningful insights.

- Demand Sensing: While demand forecasting in the long-term is essential, the supply chain management in the food industry depends largely on near-term predictions. ThroughPut AI leveraged the real-time data to generate patterns and actionable insights, helping boost short-term forecasting accuracy.

- Inventory Management and Replenishment: The tool helped Church Brothers Farm to identify top-selling and highest-margin-contributing commodities to optimize its supply chain end-to-end. The focus shifted to the 4 R’s – right stock at the right time at the right location at the right cost.

Impact

- 40% enhanced short-term forecasting accuracy.

- Better timelines and workflows

- Route optimization for order fulfillment

- Increased efficiency in inventory management

- Minimized carry costs and excess stock.

Coffee Retail Chain

The company has been fast making its mark as a boutique coffee chain retailer in the past 10 years with the strategic use of locally-grown top-quality organic raw materials. The cafe specializes in hand-brewed, iced, and blended coffees, smoothies and fresh juices.

Challenges

The cafe business space is aggressively competitive. On one hand, customers demand quality, freshness, creative and artful items, on the other, the food industry has its own set of challenges. These include:

- Lack of granular visibility into the great and not-so-great-performing items on the menu to match the market for a competitive edge and minimize operational disruptions.

- Wastages and inventory pile-ups are common problems of supply chain management in the food industry. Consequently, running out of stocks or deadstock can easily become the weakest link in food businesses. The client faced similar issues with overstocking, which led to rotting, and understocking, which meant increasing customer dissatisfaction levels.

- Logistics challenges are plenty in the food industry, the ever-increasing fuel and shipping costs are a cause of concern for retailers all throughout. This further strains an already constricted budget. For the client, it was essential to reach the right permutation and combination of volume of goods and materials with time. It meant accurate demand sensing and forecasting.

Solution

- Dynamic Menu Modification – ThroughPut’s real-time visibility into existing customer demand and in the near term became a possibility, helping in menu modifications aligned with anticipated customer tastes and preferences.

- High OTIFs for Fresh Products – Prioritization of materials and goods for optimized utilization could be done with ThroughPut’s custom AI. This meant access to all the 3 R’s – right materials, right time, and right volume – to meet customer expectations.

Impact

- Dynamic adaptation to demand shifts

- Minimized operational disruptions

- SKU-level visibility across the chain

- Easing of cash flows

- Elimination of stock-out situations and wastages

Results Achieved

- 15% reduction in inventory

- A 5% productivity gain in labor

Fresh Food Supply Chain Management Shouldn’t Involve Compromise

There’s a lot at stake if the food supply chain falters. The pressure to cut costs while squeezing more value from products with limited shelf life is a never-ending battle. But with the right mix of strategic, AI-powered, data-driven supply chain management, even the most strained operations can leap to new levels of efficiency, profitability, and safety.

Curious to see how ThroughPut AI can make that happen for your business? We’d be happy to show you. Let’s set up a quick demo!