AI-based Demand Forecasting – Everything You Need to Know

Anticipating consumer demand is an essential aspect of successful business operations, making demand forecasting a crucial process of any supply chain.

Quicker decisions, faster activities and efficient continuous improvements became inevitable for a contemporary supply chain environment – all of it made possible through leveraging groundbreaking AI algorithms.

Since the use of artificial intelligence (AI) in supply chain is here to stay and will make huge waves in the years to come (especially in demand forecasting), we wanted to cover all the essentials about the impactful topic in a concise, but informative content piece.

What is AI-based Demand Forecasting?

AI-based demand forecasting is the use of AI software that performs predictive analytics to generate estimates of customer demand, taking into account pertinent economic indicators.

Efficient AI demand forecasting supports profitable outcomes by enabling effective AI supply chain management. The two primary categories of demand forecasting methods are qualitative and quantitative strategies, with qualitative methods relying on expert input and on-site information and quantitative ones leveraging existing data and analytical techniques to generate predictions.

How Does AI-based Demand Forecasting Work?

AI demand forecasting works through application of complex mathematical algorithms to automatically recognize patterns, capture demand signals, and spot complicated relationships in large datasets.

AI software analyzes vast volumes of information, enabling intelligent systems to retrain models and adapt them to changing conditions continuously. These systems are leveraged to directly address volatility and produce more accurate and reliable forecasts in complex scenarios.

Imagine a company that produces a popular product that experiences seasonal demand fluctuations. With traditional forecasting methods, it can be difficult to predict demand during peak seasons accurately.

However, with ML (machine learning) and AI, the system can analyze historical data, identify patterns, and predict future demand with greater accuracy, as well as identify trends and potential issues before they become significant problems.

Due to AI’s help, the company can plan production better and avoid over or under-producing, costly delays or stockouts – ultimately leading to increased profits.

What are the Benefits of AI Demand Forecasting?

The benefits of AI demand forecasting are reduced costs of inventory, higher precision of demand forecasts, planned price changes, reliable internal and external data, time and resource savings.

The full list of AI-based forecasting benefits can be broken down in two major groups:

Automation benefits that enhance your demand forecasting process

AI-driven demand forecasting enhances the accuracy of the planning process. The supply chain can maintain optimal profitability by closely monitoring historical and present product demand.

The effects of price fluctuations on specific supply chain segments can be anticipated and managed accordingly.

AI automates the laborious and time-consuming demand planning procedures, resulting in substantial savings of time and resources. AI solutions can consistently adjust demand and supply by continuously analyzing all relevant data and limitations, effectively reducing excess inventory and stockouts.

The AI utilizes automatic demand analysis to address unexpected demands and facilitate swift, proactive planning.

Real-time supply chain data processing perks

Reliable data from both internal and external sources facilitate accurate predictions, making it easier to identify seasonal changes.

When companies analyze data in real-time, they can improve their ability to forecast future demand more precisely. This enables them to optimize inventory levels, streamline supply chain processes, and minimize the risk of stockouts or overstocking.

AI technology consolidates and organizes data from various departments, providing planners with a comprehensive view of analysis and demand forecasting.

Additionally, AI can identify the causal relationships between demand patterns and external factors, automatically incorporating the corresponding data into the forecast creation process.

The AI system also detects outliers in demand planning, enabling early detection of fluctuations and prompt action initiation.

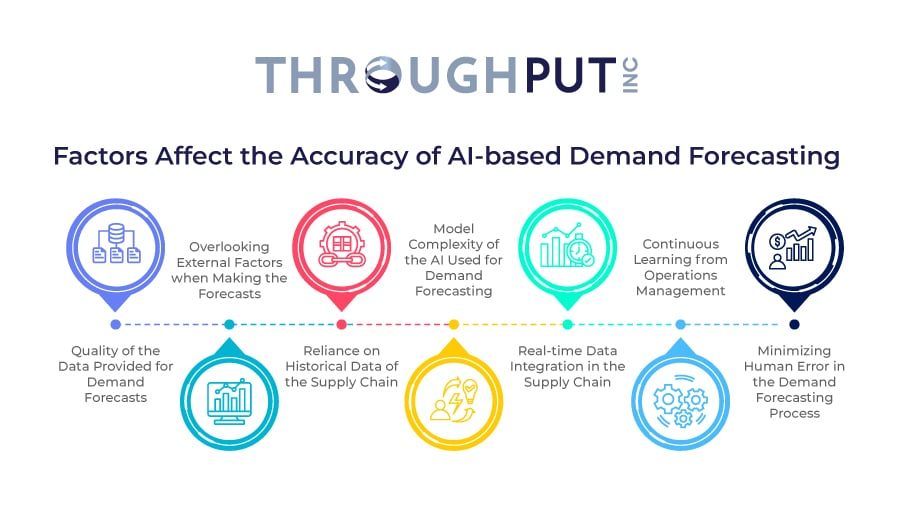

What Factors Affect the Accuracy of AI-based Demand Forecasting?

Factors that affect the accuracy of AI-based demand forecasting are the quality of data provided for demand forecasts, overlooking external factors, reliance on historical data, model complexity of the AI used and real-time data integration.

AI-powered demand forecasting systems rely on a variety of data sets that may vary depending on the system being used. However, there are some “universal” factors that can impact the precision of these algorithms.

Here’s an overview of the major factors to consider when working with AI for demand forecasting.

Factor 1: Quality of the Data Provided for Demand Forecasts

The accuracy of AI demand forecasting heavily depends on the data quality used for training the machine learning models. Inaccurate, outdated, or flawed data can lead AI systems astray, resulting in incorrect predictions that can severely impact inventory control and supply chain operations.

Factor 2: Overlooking External Factors when Making the Forecasts

Neglecting external factors such as socioeconomic influences or market trends can result in misinterpreted theories affecting demand forecasting accuracy. AI models need to incorporate these external factors to make accurate predictions.

Factor 3: Reliance on Historical Data of the Supply Chain

AI-based demand forecasting systems are trained on historical data. While this allows them to recognize existing patterns, they may need to work on account for unexpected scenarios or disruptive changes if supplemented with relevant data.

A system trained purely on historical data will always be limited to recognizing existing patterns.

Factor 4: Model Complexity of the AI Used for Demand Forecasting

The complexity of the AI model can also affect the accuracy of demand forecasting. If the model is too simple, it may capture only some of the relevant patterns in the data. Conversely, if the model is simple enough, it may overfit the training data and perform poorly on new, unseen data.

Factor 5: Real-time Data Integration in the Supply Chain

AI platforms like Throughput are equipped with advanced technology capable of effectively processing vast amounts of data in real time.

They analyze complex variables such as consumption patterns, industry trends, and socioeconomic factors that affect demand much faster than traditional systems, enabling immediate adjustments to forecasts based on recent developments or changes in conditions.

Factor 6: Continuous Learning from Operations Management

An inherent strength of machine learning models lies in their ability to self-improve over time through repeated iterations. As these models continue working on forecast operations management tasks, they refine their predictions based on historical data sets combined with new data inputs.

Factor 7: Minimizing Human Error in the Demand Forecasting Process

Automation in AI-based demand forecasting mitigates human error—a common culprit behind poor forecasting accuracy rates. By replacing manual processes fraught with bias, unaccountable assumptions, and inconsistencies with automated routines upheld by stringent rules defined by AI, there is a marked improvement in overall efficiency and precision.

How to Implement AI Demand Forecasting in Supply Chains?

The implementation of AI demand forecasting starts with identifying the specific forecasting needs of the supply chain, then research is needed to choose the right demand forecasting software. After the software solution is chosen, supply chain data needs to be prepared for analysis and specialists need to be trained to properly use the demand forecasting solution.

Implementing AI-based forecasting software in supply chains is done in several steps:

- Identify the specific forecasting needs of your supply chain. Both short-term demand prediction, long-term planning, and dealing with volatile demand patterns.

- Do the research or hire a consultant to choose the right demand forecasting software.

Many vendors of demand forecasting software offer out-of-the-box integrations with the most popular ERP providers, Excel, and other business tools. Choose a provider that can assist you with system connections.

- Prepare the data for analysis. The more data you have, the more impacting factors will be considered, and the more accurate your forecasts will be.

- Take your time with implementation and training.

Engage with ML engineers, data scientists, and other specialists to make the transition smoother. Implement the chosen software and train your team to use it effectively.

- Bonus alternative – use ThroughPut to easily predict near-future demand trends and quickly identify & expose patterns across past events, historical data and various external factors (economic, geographical, climate, etc.)

How does AI-based Demand Forecasting Compare to Traditional Demand Forecasting Methods?

AI-based demand forecasting provides more accurate and efficient forecasts compared to traditional forecasting methods.

Traditional methods rely heavily on historical data and manual calculations, AI-based forecasting utilizes machine learning algorithms to analyze vast amounts of data and generate accurate predictions in real time.

This approach offers several advantages over traditional methods, including increased accuracy, speed, scalability, and efficiency.

Accuracy of the Predicted Demand

AI-based demand forecasting can significantly improve the accuracy of predictions. Traditional methods often need help with large volumes of complex information, while AI systems thrive on substantial datasets.

Machine learning algorithms, a field within artificial intelligence, are trained with past sales data, incorporating factors such as seasonality, price variations, and promotional events.

The more diverse and comprehensive this training dataset is, the greater the algorithm’s ability to discern patterns and make accurate forecasts.

AI models can uncover complex patterns and correlations within data, leading to more accurate predictions than traditional forecasting methods relying on more straightforward statistical techniques.

Speed of Decision-making

AI-based demand forecasting enables an expedited decision-making process. Traditional demand forecasting methods often involve time-consuming steps, complex data analysis, and long processing time to generate insights.

However, with AI’s computing power, the immense volume of data can be processed in seconds or minutes. This speed allows companies to make agile adjustments to their operations and respond promptly to market changes.

Scalability of Analyzing Large Data Volumes

AI-based demand forecasting can handle large and complex datasets, incorporating numerous variables and factors influencing demand, such as historical sales, seasonality, promotions, economic indicators, and external events.

This scalability allows organizations to improve their forecasts and adjust strategies accordingly continuously.

Higher Demand Forecasting Efficiency

AI-based demand forecasting can drastically reduce errors within supply chain networks.

Numerous companies that have adopted these advanced systems report a notable drop in inaccuracies. With an artificial intelligence-driven approach, businesses can reduce their mistakes in predicting market demands by up to 50%.

AI models can continuously learn and adapt to changing patterns and market dynamics by incorporating new data, enabling organizations to refine their forecasts over time. Traditional methods require manual adjustments and updates to account for changing conditions.

AI-based demand forecasting revolutionizes supply chain management by offering a more precise, efficient, and scalable method of interpreting data trends.

As we move further into the age where data reigns supreme, the usage and refinement of tools like AI demand forecasting will inevitably become indispensable.

How will AI Change Demand Forecasting in the Supply Chain?

AI will change demand forecasting in the supply chain by empowering managers to make better decisions and execute optimal purchasing plans by constantly rebalancing demand and supply.

Let’s face it. The power of Artificial Intelligence (AI) is revolutionizing the supply chain industry, providing companies with practical solutions to tackle their challenges.

With AI’s unparalleled ability to analyze vast amounts of data, comprehend complex relationships, and offer valuable insights, it’s no wonder that it’s quickly becoming a game-changing tool.

Companies using this cutting-edge technology can confidently take on any challenge and achieve unprecedented success.

What are Good Real-Life Examples of AI Used in Demand Forecasting?

Good real-life examaples of AI used in demand forecasting are Zara, Walmart and Danone group.

Numerous examples demonstrate the excellent results of the effective implementation of AI-based demand forecasting solutions.

Here”s a breakdown of our 3 real-life examples of supply chain companies in the retail sector that use AI-based software for demand forecasting:

Example 1: Walmart

Walmart uses AI to predict customer demand for products, optimize inventory management, and enhance overall operational efficiency.

The company leverages AI algorithms to analyze vast amounts of historical sales data, customer behavior, and external factors to predict future demand with high precision.

As a result, Walmart adjusted to customers’ increased usage of e-commerce and significantly improved its supply chain operations.

Example 2: Zara

Zara, a leading fashion retailer, uses AI-based demand forecasting to adjust its production schedules and quantities in its supply chain. The company’s AI algorithms analyze historical sales data, customer behavior, and market trends to generate accurate demand forecasts.

This approach to demand forecasting enabled Zara to optimize its inventory levels, reduce stockouts, and improve overall supply chain efficiency.

Example 3: Danone Group

Danone Group, a French manufacturer of food products, implemented a machine learning system to make better demand forecasts. The company required more accurate and secure demand forecasts due to the short shelf-life of its fresh products and volatile demand.

The AI algorithms used by Danone analyzed various sources of data, such as weather data, financial data, and third-party data (e.g. social media, historical sales data, and macroeconomic data) to make predictions on how event combinations in the past affected demand for future consumer demand.

The implemented AI system improved forecasts, planning between different departments (such as sales, supply chain, finance, and marketing), efficiency, and inventory balance, allowing Danone to achieve its target service levels for channel or store-level inventories.

Leverage Throughput AI for an Accurate Demand Forecast

ThroughPut is a software solution fueled by artificial intelligence that offers outstanding supply chain planning capabilities specifically for demand forecasting and demand sensing.

The platform is packed with robust planning features like its Demand Sensing Module, which uses advanced algorithms and machine learning techniques to generate accurate forecast plans in the near-term and recommend optimal inventory levels, and operations plans that align with market sentiments at any given point in time.

The software draws from more than just historical information, taking into account a range of external factors such as economic trends, geographic influences, and climate impacts.

These influences are evaluated in real-time alongside demand-based insights, and the resulting data is presented in a convenient, digestive format.

With the Demand Sensing Module at your fingertips, you can easily predict near-future demand patterns and have access to actionable recommendations that realign the supply source to avoid unnecessary waste and accordingly streamline the flow of materials, processes, output, and ultimately free up the cash flow across your entire supply chain.