Warehouse Management Software – Essential Know-how

Managing warehouse inventory efficiently is a challenge for businesses of all sizes. Inventory management can become complex and error-prone without the right tools, leading to overstocking, stockouts, and operational inefficiencies.

Warehouse inventory management software automates and streamlines inventory tracking, order fulfillment, and warehouse operations, ensuring businesses maintain optimal stock levels and improve overall efficiency.

This comprehensive guide covers everything you need to know about warehouse management software, including its benefits, key features, types, and implementation strategies. It equips you to select and implement the best solution for managing your warehouse inventory and operations effectively.

What is Warehouse Management Software (WMS)?

Warehouse management software is an automated system designed to streamline various business stock control and order management tasks within the warehouse.

It helps companies track and manage inventory items, customer orders, and inbound deliveries to reduce costs and improve efficiency.

The primary purpose of warehouse management software is to provide accurate real-time data on inventory levels, their location, and when they need to be reordered.

This system updates stock levels every time an inventory shipment arrives or leaves the warehouse, offering real-time visibility into inventory status. It also automates tedious manual tasks, reducing human error and improving the accuracy of recorded inventory levels.

What are the Differences Between Warehouse Management Software and General Inventory Management Software?

General inventory management software tracks inventory levels, orders, sales, and deliveries, while warehouse inventory management software coordinates workflows for the entire warehouse.

It manages inventory, order fulfilment, labour, and operational processes, effectively integrating inventory management for comprehensive stock control.

This type of software is particularly beneficial for businesses that operate multiple warehouses or require advanced features such as multi-warehouse inventory tracking, shipment tracking, and RF technology support.

While warehouse and general inventory management software serve similar purposes, they have distinct functionalities tailored to different needs.

What are the Benefits of Warehouse Management Software?

The benefits of warehouse management software are improved inventory visibility and accuracy, reduced carrying costs and stockouts, optimized inventory levels, enhanced order fulfilment, streamlined inventory operations and accurate time tracking.

Here’s a breakdown of each benefit:

Improved Inventory Visibility and Accuracy

Businesses can maintain a precise and up-to-date record of their stock as the tracking of inventory levels, locations, and movements is automated.

This eliminates the errors associated with manual tracking and ensures that inventory data is always accurate.

Real-time visibility into inventory levels helps businesses make informed decisions about purchasing, production, and sales, ultimately leading to better inventory control and reduced discrepancies.

Reduced Carrying Costs and Stockouts

Effective inventory management software helps businesses strike the right balance between carrying costs and stockout costs.

The software optimizes inventory levels, ensuring that businesses hold enough stock, which can lead to high storage and handling costs.

At the same time, it prevents stockouts by maintaining adequate inventory levels to meet customer demand. This balance reduces the financial burden of carrying excess inventory and minimizes the risk of lost sales due to stockouts.

Optimized Inventory Levels

Warehouse management software uses advanced algorithms and data analytics to forecast demand accurately and plan inventory levels accordingly.

This optimization ensures that businesses have the right amount of stock at the right time, reducing the need for emergency orders and minimizing the risk of overstocking or understocking.

Enhanced Order Fulfillment and Customer Service

With warehouse management software, businesses can improve order fulfilment processes and enhance customer service. The software provides real-time information on inventory availability, enabling companies to fulfil orders promptly and accurately.

This reduces the likelihood of backorders and delays, increasing customer satisfaction.

Additionally, the software can integrate with other systems, such as order management and customer relationship management (CRM) systems, to streamline the entire order-to-delivery process.

Streamlined Inventory Operations and Processes

Inventory management software automates inventory-related tasks, such as stock counting, reordering, and reporting.

This automation streamlines inventory operations and reduces the need for manual intervention, saving time and reducing the risk of human error.

The software can also generate detailed reports and analytics, providing valuable insights into inventory performance and helping businesses identify areas for improvement.

Real-Time Tracking and Reporting Capabilities

The software continuously monitors inventory levels and movements, providing real-time updates on stock status. This real-time tracking allows businesses to respond quickly to changes in demand, supply chain disruptions, or other unforeseen events.

Additionally, the software’s reporting capabilities enable businesses to generate comprehensive reports on inventory metrics, such as turnover rates, stock levels, and order fulfilment times, facilitating data-driven decision-making.

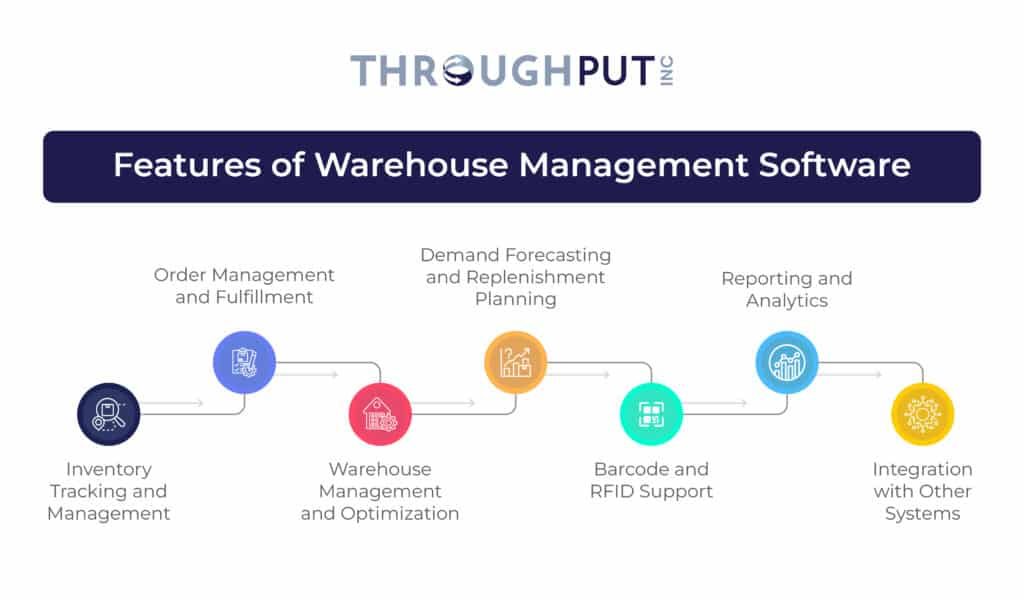

What are the Key Features of Warehouse Management Software?

The key features of warehouse management software are inventory tracking and management, order management and fulfilment, warehouse management and optimization, demand forecasting and replenishment planning, reporting and analytics and integration capabilities.

Here’s a breakdown of the critical features that inventory managers should look for when considering such software:

Inventory Tracking and Management

Inventory tracking allows businesses to monitor inventory levels in real-time, ensuring that stock levels are always accurate and up to date.

It includes functionalities such as tracking inventory across multiple locations, managing stock levels, and setting reorder points to prevent stockouts and overstock situations.

Real-time tracking helps maintain optimal inventory levels and reduces the risk of human error associated with manual monitoring.

Order Management and Fulfillment

Order management and fulfilment capabilities enable businesses to process customer orders from receipt to delivery efficiently.

This feature includes order entry, order processing, and order tracking. It ensures that orders are fulfilled accurately and promptly, improving customer satisfaction.

Additionally, it can automate the order fulfilment process, reducing the time and effort required to manage orders manually.

Warehouse Management and Optimization

Warehouse management features help optimize warehouse space use and improve warehouse operations’ efficiency. This includes functionalities such as layout optimization, picking and packing, and inventory placement strategies.

Demand Forecasting and Replenishment Planning

Demand forecasting and demand driven inventory replenishment are critical for maintaining optimal inventory levels. This feature uses historical sales data and advanced algorithms to predict future demand and plan inventory replenishment accordingly.

Accurate demand forecasting helps businesses avoid stockouts and overstock situations, ensuring they have the right products available at the right time.

Barcode and RFID Support

Barcode and RFID support are essential for automating inventory tracking and management. These technologies enable businesses to capture inventory data quickly and accurately, reducing the risk of human error.

Barcode and RFID systems can be used for various tasks, including receiving, picking, packing, shipping, and streamlining inventory management.

Reporting and Analytics

Reporting and analytics features provide businesses with valuable insights into their inventory performance. These features generate detailed reports on inventory levels, turnover rates, order fulfilment times, and other vital metrics.

Analytics tools can help businesses identify trends, uncover inefficiencies, and make data-driven decisions to improve their inventory management processes.

Integration with Other Systems

Integration capabilities ensure inventory management software works seamlessly with other business systems, such as ERP, accounting, sales, and e-commerce platforms.

This integration allows for the smooth flow of information across different departments, reducing data silos and improving overall operational efficiency. It also ensures that inventory data is consistent and accurate across all systems.

What are the Types of Warehouse Management Software?

The types of warehouse management software are standalone software, ERP-integrated WMS and cloud-based warehouse management software.

Below is a short list of each WMS software type, along with their pros and cons and use cases:

Standalone Software

Standalone warehouse management software is one of the most basic types, focusing on specific management functionalities. Typically, this software is an on-premise system that operates with the business’s existing hardware and network infrastructure.

Standalone systems are often sold without additional supply chain functions, concentrating solely on essential WMS features.The core functionalities of standalone WMS include inventory management and warehouse operations.

Due to its versatility, standalone WMS can also serve as an inventory management system, making it suitable for various applications beyond warehouse management.

Small businesses particularly favour this type of software due to its simplicity and cost-effectiveness.

Key benefits of standalone WMS include:

- Barcode Scanning

- Cycle Counting

- Receiving

- Slotting

- Shipping

- Picking and Packing

ERP Integrated WMS

ERP-integrated warehouse management software is a robust solution combining multiple capabilities in other systems. It is considered one of the top-performing software options, ideal for businesses looking to enhance their software solutions and gain a competitive edge.

This type of WMS integrates seamlessly with Enterprise Resource Planning (ERP) systems, providing a comprehensive suite of functionalities.

ERP-integrated WMS is more expensive due to its extensive capabilities but can replace several other software applications, centralizing and consolidating manufacturing operations management into a single interface.

This integration helps businesses streamline their processes and improve overall efficiency.

Key benefits of ERP-integrated WMS include:

- Supply Chain Planning, Forecasting, and Optimization

- Finance & Accounting

- Customer Relationship Management (CRM)

- Employee Management & Human Resources Activities

Cloud-Based Warehouse Management Software

Cloud-based warehouse management software uses cloud technology to offer a web-based, centralized computing model.

This type of WMS typically operates on a “software-as-a-service” (SaaS) model, known for its scalability, adaptability, and ease of deployment. Cloud-based WMS provides the same benefits as traditional WMS but with faster implementation and lower supply chain costs.

One significant advantage of cloud-based WMS is reduced IT maintenance, as it is hosted on separate or private servers. This setup ensures higher data security protocols, crucial for businesses managing high-value inventory or those requiring enhanced security measures.

Key benefits of cloud-based WMS include:

- Reduced Expenses

- Faster Implementation

- Scalability

- User-Friendly Interface

What to Consider When Choosing Warehouse Management Software?

When choosing warehouse management software, inventory managers should consider scalability, integration capabilities, deployment options, mobile accessibility, reporting features, user-friendliness, and vendor support.

Scalability and Flexibility to Accommodate Business Growth

As your company expands, the software should be able to handle increased inventory volumes, more users, and additional locations without compromising performance.

Flexibility is equally important, allowing the software to adapt to changing business processes and requirements. This ensures that the software remains relevant and valuable as your business evolves.

Integration with Existing Systems

The inventory management software should integrate smoothly with your existing systems, such as ERP, accounting, and e-commerce platforms.

This integration ensures that data flows effortlessly between systems, reducing manual data entry and the risk of errors.

It also provides a unified view of your business operations, enhancing decision-making and operational efficiency.

Cloud-Based or On-Premises Deployment

Another critical consideration is deciding between cloud-based and on-premises deployment. Cloud-based solutions offer several advantages, including lower upfront costs, automatic updates, and remote accessibility.

They are particularly beneficial for businesses with multiple locations or remote teams. On-premises solutions, on the other hand, provide more control over data and may be preferred by companies with specific security or compliance requirements.

Evaluating your business needs and IT infrastructure will help determine the best deployment option.

Mobile Accessibility and Barcode Scanning Capabilities

Inventory management software with mobile capabilities allows staff to access inventory data and perform tasks from anywhere, using smartphones or tablets.

Barcode scanning capabilities further enhance efficiency by enabling quick and accurate data entry. This reduces the likelihood of errors and speeds up stocktaking, receiving, and order fulfilment processes.

Reporting and Analytics Features

The software should provide comprehensive reports on key metrics such as inventory levels, turnover rates, and order fulfilment times.

Advanced analytics can offer insights into trends and patterns, helping you make data-driven decisions to optimize inventory levels, reduce costs, and improve customer satisfaction.

Customizable dashboards and real-time reporting capabilities are also valuable features to look for.

User-Friendliness and Ease of Implementation

The software should have an intuitive interface that is easy to navigate, minimizing the learning curve for users.

Additionally, the implementation process should be straightforward, with clear instructions and support from the vendor. A smooth implementation ensures that your team can start using the software quickly and effectively without significant disruptions to your operations.

Vendor Support and Training

Finally, consider the level of support and training the software vendor provides. Reliable vendor support is crucial for addressing any issues and ensuring the software meets your needs.

Look for vendors that offer comprehensive training programs, ongoing support, and resources such as user manuals and online tutorials. A dedicated account manager can also be beneficial, providing personalized assistance and helping you get the most out of the software.

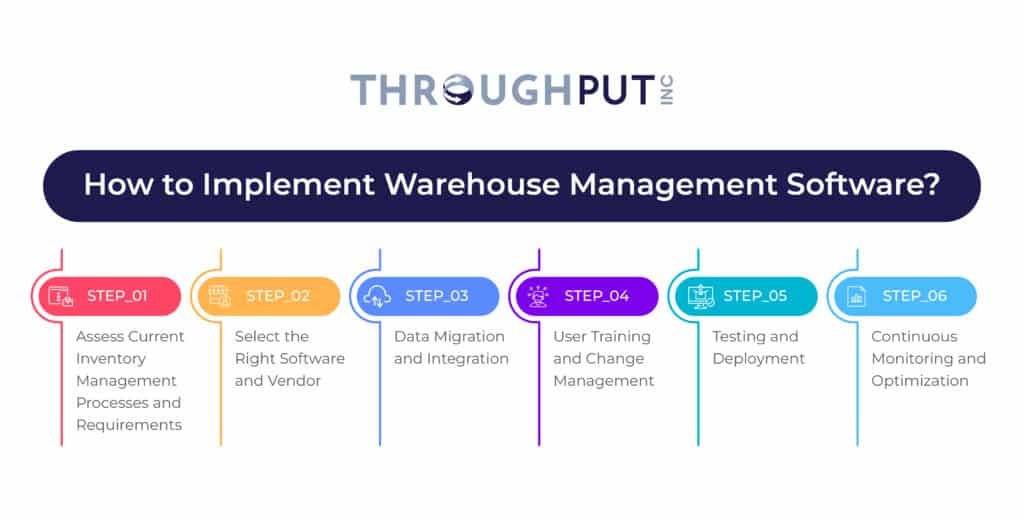

How to Implement Warehouse Management Software?

Implementing warehouse management software requires a structured approach that starts with assessing current processes, selecting the right software and vendor, migrating and integrating data, training users, testing the system, and continuously monitoring and optimizing its performance.

Here’s a detailed step-by-step guide on how to implement inventory management software:

STEP 1: Assess Current Inventory Management Processes and Requirements

The first step in implementing inventory management software is assessing your current requirements thoroughly.

This assessment involves:

- Evaluating Existing Processes – Understand how inventory is currently managed, including tracking, ordering, and fulfilment processes.

- Identifying Pain Points – Pinpoint inefficiencies, bottlenecks, and areas where errors frequently occur.

- Defining Requirements – Determine the features and functionalities necessary to address the identified issues and support your business goals. The requirements may include real-time tracking, automated reordering, and integration with other systems.

STEP 2: Select the Right Software and Vendor

When choosing the right inventory management software and vendor, consider the following:

- Software Features

Ensure the software includes essential features such as inventory tracking, order management, and reporting capabilities. - Scalability

Select software that can grow with your business and handle increased inventory volumes and additional locations. - Vendor Reputation

Research potential vendors, read reviews, and consider their experience and expertise in your industry. - Integration Capabilities

Verify that the software can integrate seamlessly with your existing systems, such as ERP, accounting, and e-commerce platforms.

STEP 3: Data Migration and Integration

Data migration and integration are critical steps that require careful planning and execution:

- Data Cleansing

Clean and organize your inventory data to ensure accuracy and consistency before migration. - Data Mapping

Map your current data fields to the new software’s data structure to ensure a smooth transition. - Integration

Set up integrations with other business systems to enable seamless data flow and avoid data silos. This may involve working with IT professionals or the software vendor to configure APIs and other integration tools.

STEP 4: User Training and Change Management

Practical user training and change management are needed for successful software adoption:

- Training Programs

Develop comprehensive training programs for all users, including hands-on sessions, user manuals, and online tutorials. - Change Management

Communicate the benefits of the new software to your team and address any concerns they may have. Encourage a positive attitude towards the change and provide ongoing support. - User Feedback

Collect feedback from users during the training phase and make necessary adjustments to the training materials and processes.

STEP 5: Testing and Deployment

Before fully deploying the software, thorough testing is necessary to ensure it functions correctly:

- Pilot Testing

Conduct a pilot test with a small group of users to identify any issues and gather feedback. - System Testing

Perform comprehensive system testing to ensure all features and integrations work as expected. - Deployment Plan

Develop a detailed deployment plan that includes timelines, responsibilities, and contingency plans for potential issues.

STEP 6: Continuous Monitoring and Optimization

After deployment, continuous monitoring and optimization are crucial to ensure the software continues to meet your needs:

- Performance Monitoring

Regularly monitor the software’s performance and address any issues promptly. - User Support

Provide ongoing support to users, including troubleshooting assistance and additional training. - Optimization

Continuously evaluate the software’s effectiveness and look for opportunities to optimize processes and improve efficiency. This may involve updating the software, adding new features, or refining workflows.

What’s the Role of AI in Warehouse Management Software?

Artificial Intelligence (AI) is enhancing the capabilities of warehouse management software by providing advanced tools that improve efficiency, accuracy, and decision-making.

AI-powered demand forecasting uses machine learning algorithms to analyze historical sales data, customer trends, and external factors and accurately predict future demand.

These algorithms continuously learn and adapt, improving their predictions over time, which helps businesses maintain optimal inventory levels and reduce the risk of overstocking or stockouts.

Additionally, AI enhances inventory optimization as it analyzes vast amounts of data to determine the most efficient stock levels and reorder points, considering factors such as lead times, supplier reliability, and demand patterns to generate optimal replenishment orders.

AI also automates routine inventory tasks such as order placement, processing, and fulfilment, reducing manual intervention, minimizing errors, and speeding up order fulfilment.

This automation allows employees to focus on more strategic activities, improving overall operational efficiency.

Managing Inventory with Throughput

Throughput provides real-time tracking and accurate data capture, reducing errors and improving inventory visibility. It helps maintain optimal stock levels, prevent overstocking and stockouts, and streamline order fulfilment processes.

Throughput software also supports better collaboration with suppliers and stakeholders by providing real-time inventory data, which enhances coordination and reduces delays.

Additionally, it offers scalability and flexibility, allowing warehouses to handle increased volumes and complex operations efficiently.

Book a free demo to find out how to manage inventory with Throughtput.