Which is the Best Supply Chain Optimization Software Right Now?

Optimizing supply chain operations for better efficiency and cost effectiveness is a key focus of supply chain leaders.

It’s not surprising, therefore, that you are always on the lookout for the best supply chain optimization software that can let you better manage material and cash flow.

But finding the right technology can be tricky. Not all tools out there deliver what they promise. Sometimes, even the most advanced software can end up creating more problems than it solves, like causing departments to work in silos.

When departments make decisions on their own, without coordinating, it’s easy to miss out on making the most impactful changes. This kind of fragmented approach can really drag down productivity. It leads to inefficiencies, spiraling costs, and lost revenue.

Sound familiar? If it does, you don’t have to keep dealing with these issues. Luckily, it’s 2025, and there are some great tools designed to make your supply chain operations more optimized. These tools not only streamline processes but also improve decision-making across departments, ensuring everyone is aligned.

Let’s take a look at what these tools are.

Best Supply Chain Optimization Software in the Market Right Now

Following is the list of best supply chain optimization software:

- Spreadsheets (Don’t draw any conclusions before you read our perspective below)

- ThroughPut AI

- SAP Integrated Planning

- Anaplan

- O9 Solutions

- GmDH Streamline

- SAS

- Coupa

- IBM Planning Analytics

- Blue Ridge

- Oracle Supply Chain Management

- Logility

- Blue Yonder

- Manhattan Associates

- Arkieva

- Palantir

- RELEX

- Kinaxis

- AWS

Let’s look at each of them in detail below.

1. Spreadsheets?!

Okay, this might be a surprise. But we had to call your attention to spreadsheets.

Supply chain professionals love spreadsheets.

And it works as long as your business has limited (very few) product lines and restricted locations. Beyond that, if you are still using spreadsheets, your team is most likely stuck in the comfort zone of a familiar tool – which is fair. But if you are aiming to grow aggressively, we urge you to look at other tools on this list. Spreadsheets have limitations that can become significant barriers as your business expands.

The only other reason why you’d use spreadsheets is because you don’t mind taking the risk of falling behind, especially in the age where Artificial Intelligence and analytics are ruling the world. From limited scalability to erroneous outputs, there are a lot of chances that you are taking by sticking to the familiarity of spreadsheets.

2. ThroughPut AI

Watch On-demand Demo

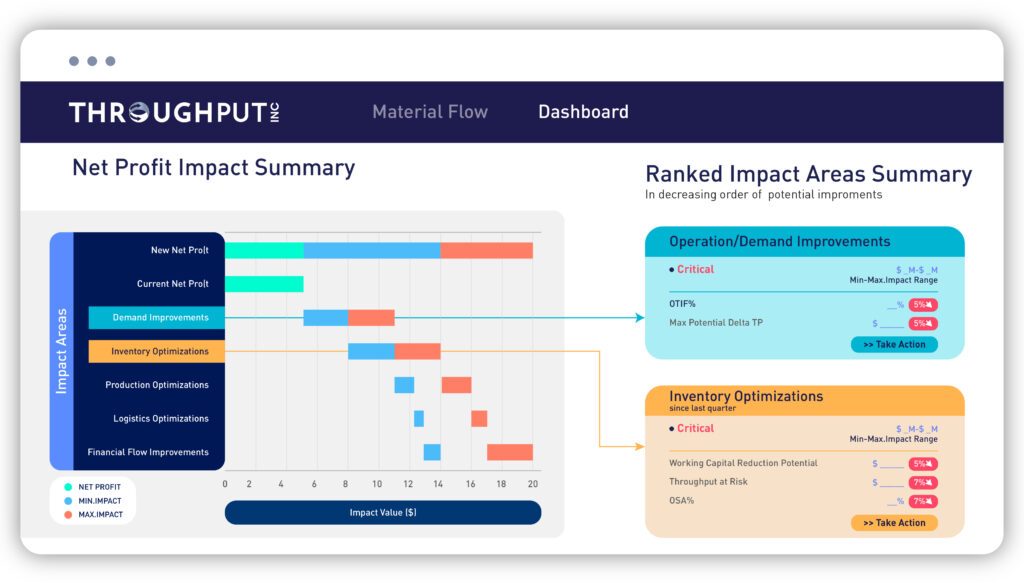

Now to some real tools, much different from spreadsheets. ThroughPut AI is a supply chain analytics and decision intelligence tool recognized by Gartner as a “Leading Vendor in the Prestigious 2023 Gartner Market Guide for Analytics and Decision Intelligence Platforms in Supply Chain.”

The tool is used across enterprises in multiple sectors, helping organizations with cost reduction, operational efficiency, and revenue creation. Using advanced AI and machine learning technologies, the tool helps predict demand accurately, optimize inventory, and streamline operations.

Key Features

- Financial insights and working capital optimization

- Uses patented AI algorithms for advanced analytics

- Provides actionable real-time recommendations across the value chain

- What-if scenario analysis

- Near-term demand sensing

- Dynamic replenishment recommendations

Main Benefits

- Rapid time-to-value (ROI in 90 days)

- Works with existing data sources without requiring major infrastructure changes

- Customizable for different industries and use cases

3. SAP Integrated Planning

SAP IBP or SAP Integrated Planning is a cloud-based solution created for end-to-end supply chain management and planning processes. It uses real-time data, machine learning, and advanced analytics to seamlessly integrate the different components of your business processes, viz sales, supply, inventory, and demand planning.

Key Features

- Provides actionable insights with real-time data

- Facilitates what-if analysis to evaluate potential impacts and outcomes

- Enhances cross-functional collaboration

Main Benefits

- Streamlines planning processes

- Enhances demand forecasting accuracy

- Empowers businesses with data-driven insights

4. Anaplan

This is another cloud-based platform for best supply chain optimization software. It facilitates agile and accurate business planning, performance management, and decision-making across multiple functionalities, including finance, sales, HR, and supply chain.

Key Features

- Enables seamless collaboration across departments

- Allows users to create and compare multiple scenarios

- Leverages advanced analytics to forecast trends

Main Benefits

- Empower businesses to respond swiftly to market changes and operational challenges

- Reduces errors and enhances the accuracy of forecasts and plans

- Streamlines planning processes

- Provides a comprehensive view of business performance

5. O9 Solutions

As an AI-driven platform, the software helps integrate various units for smoother business planning and decision-making. It also offers real-time insights and end-to-end visibility with its machine learning and advanced analytics features.

Key Features

- Utilizes AI and machine learning to predict demand, optimize supply chains, and enhance decision-making

- Offers comprehensive visibility across the entire business

- Enables robust what-if analysis

Main Benefits

- Streamlines processes and improves operational efficiency

- Increases accuracy in demand forecasting and inventory management

- Empowers strategic decisions

6. GMdH Streamline

A robust software that helps in accurate demand forecasting and inventory optimization. It supports businesses of all kinds and sizes, assisting them in streamlining their supply chain operations. Using machine learning and advanced algorithms, the tool helps optimize inventory levels and accurate forecasts.

Key Features

- Leverages statistical models and machine learning for precise demand predictions

- Facilitates what-if analysis

- Easily integrates with ERP systems, spreadsheets, and other data sources

Main Benefits

- Enhances demand planning accuracy

- Optimizes inventory levels

- Streamlines supply chain processes

7. SAS

Helping with accurate demand forecasting, sensing, and shaping, SAS is a supply chain optimization tool that helps align the supply chain with near-real-time plans.

Key Features

- Demand-driven planning for precise forecasts at every stage with sophisticated algorithms

- Multi-echelon inventory optimization for production and logistics management

- A visual approach to demand analysis and meaningful insights

Main Benefits

- Supports Integrated Business Planning process

- Minimizes risks of over or under-stocking

8. Coupa

Coupa Supply Chain Design is another supply chain optimization software that helps businesses with powerful scenario modeling and network design tools.

Key Features

- Scenario modeling

- Advanced network design tools

- Real-time visibility into supply chain disruptions

Main Benefits

- Easily optimize costs and minimize risks

- Cloud collaboration

- Real-time monitoring

9. IBM Planning Analytics

IBM Planning Analytics leverages AI to offer sophisticated demand forecasting, business planning, and predictive models.

Key Features

- AI-driven forecasting and analytics

- Integrated business planning (IBP)

- In-memory data processing

- Predictive models for demand planning

Main Benefits

- More accurate forecasting, minimizing stockouts and excess inventory

- Integrated planning across departments

- Agile responses to demand fluctuations

10. Blue Ridge

Blue Ridge offers precise demand sensing and inventory optimization solutions that help businesses maintain balanced stock levels and maximize profitability.

Key Features

- Demand sensing and forecasting tools

- Inventory optimization algorithms

- Supply chain analytics dashboard

- Supplier collaboration capabilities

Main Benefits

- Reduce overstocking and lost sales opportunities

- Improve profitability with inventory optimization

- Speed up procurement processes

11. Oracle Supply Chain Management

Oracle Supply Chain Management provides an end-to-end solution that integrates logistics, procurement, and AI-driven forecasting for holistic supply chain control.

Key Features

- End-to-end supply chain visibility

- Integrated logistics and procurement management

- AI-based demand forecasting

- Cloud-native infrastructure

Main Benefits

- Total visibility and control from procurement to delivery

- Scalability and integration with other enterprise systems

- Minimizes risk and enhances inventory accuracy

12. Logility

Logility combines machine learning with automated procurement processes and multi-echelon planning to deliver a comprehensive supply chain management solution.

Key Features

- Machine learning enhanced demand planning

- Advanced inventory optimization tools

- Multi-echelon supply chain planning

- Automated procurement processes

Main Benefits

- Continuous improvements in demand forecasts

- Enhances inventory control across different supply levels

- Streamlines purchasing workflows

13. Blue Yonder

Blue Yonder is an AI-powered supply chain solution designed to optimize inventory management and synchronize supply and demand in real time.

Key Features

- AI-powered supply chain optimization

- Dynamic inventory management

- Real-time demand and supply synchronization

- Cloud-native control tower

Main Benefits

- Precision in supply chain operations

- Minimizes waste and stockouts

- Quick adjustments to supply chain changes.

14. Manhattan Associates

Manhattan Associates specializes in omnichannel supply chain management with tools for optimizing warehouse operations and labor management.

Key Features

- Omnichannel supply chain management

- Warehouse and distribution optimization

- Labor management tools

- AI-powered demand forecasting

Main Benefits

- Optimizes complex omnichannel operations

- Reduces inefficiencies and improves speed to market

15. Arkieva

Arkieva offers flexible, customizable solutions for demand and inventory planning, supply chain optimization, and risk management.

Key Features

- Demand and inventory planning

- Customizable dashboards

- Scenario planning and risk management

Main Benefits

- Customizable solutions tailored to unique business challenges

- Prepares you for different market conditions, minimizing risk

- Instant insights into supply chain performance

16. Palantir

Palantir uses advanced AI-driven predictive analytics to empower businesses with real-time supply chain insights and collaborative planning tools.

Key Features

- Predictive analytics and AI-driven decision-making

- Advanced data integration tools

- Real-time supply chain monitoring

- Collaborative planning features

Main Benefits

- Smarter decision-making, reducing uncertainties in demand and supply

- Seamlessly integrates with other systems, providing a holistic view of your supply chain

- Collaborative tools promote better communication and planning across teams

17. RELEX

RELEX Solutions focuses on AI-enhanced demand forecasting, inventory optimization, and automated replenishment to streamline retail and supply chain operations.

Key Features

- AI-enhanced demand forecasting

- Inventory and space optimization

- Unified retail planning platform

- Automated replenishment

Main Benefits

- Improves demand planning accuracy, reducing stock issues

- Seamless integration of inventory, logistics, and retail operations

- Saves time and reduces human errors in replenishment

18. Kinaxis

Kinaxis’ RapidResponse platform offers real-time supply chain visibility, concurrent planning, and AI-powered demand forecasting.

Key Features

- Real-time visibility

- Concurrent supply chain planning

- AI-powered demand forecasting

- Agile decision-making tools

Main Benefits

- Immediate issue resolution

- Enhances agility, allowing businesses to adjust quickly

- Reduces inventory costs and improves service levels

19. AWS

AWS Supply Chain is a cloud-native solution that uses machine learning for demand forecasting and provides real-time visibility across supply chain networks.

Key Features

- Cloud-native infrastructure

- Machine learning for demand forecasting

- Real-time supply chain visibility

- Secure, scalable solutions

Main Benefits

- Scalable, secure solutions suitable for businesses of all sizes

- Minimizes errors in demand predictions.

- Ensures seamless integration with other AWS services

Each platform has unique strengths, making it essential to choose one that aligns with your specific needs.

Now that you’ve gone through the list of top supply chain optimization software, here are some additional good-to-know information for you.

What is Supply Chain Optimization Software, After All?

A Supply chain optimization software system is a powerful strategic tool designed to streamline and enhance business operations. Acting as a critical enabler, it can reshape and elevate the way companies manage their supply chains, driving efficiency end-to-end.

Powered by advanced algorithms and artificial intelligence, this software excels in analyzing large datasets and forecasting market trends, enabling businesses to make data-driven decisions with precision.

One of its key strengths lies in its ability to seamlessly integrate with existing business systems, providing a comprehensive view of the entire supply chain. This interconnectedness ensures consistent and transparent data sharing across departments, fostering collaboration and aligning all stakeholders toward common goals.

The software’s flexibility is another significant advantage, as it can be customized to address the specific challenges and needs of different industries and business models. Whether adapting to unique operational processes or shifting market conditions, supply chain optimization software can be tailored to support your organization’s strategic vision and enhance its competitive edge.

Why is Supply Chain Optimization Software Essential for Modern Businesses?

Supply chain optimization software is essential for maintaining competitiveness, reducing operational costs, and delivering superior business outcomes.

The complex supply chain landscape calls for advanced technology. It is no longer a choice — it’s a necessity. Artificial intelligence (AI), machine learning, and data science have become integral to transforming supply chain management.

The integration of these technologies into supply chain planning and optimization drives significant improvements in areas like inventory management, demand forecasting, cost reduction, and resource utilization.

Inventory Optimization

Effective inventory management is crucial for balancing procurement, order fulfillment, and production planning. AI-powered supply chain optimization software enables you to predict demand with greater accuracy, reducing the risk of overstocking or stockouts. This capability minimizes the financial strain caused by excess inventory and ensures that customer demand is consistently met.

Demand Forecasting and Planning

Supply chain optimization software offers advanced tools for precise demand forecasting and planning. By understanding market dynamics and supply variations, you can maintain optimal inventory levels, reduce lead times, and develop efficient production and delivery schedules. The result is a more agile and cost-effective supply chain.

Supply Chain Cost Reduction and Resource Utilization

A well-optimized supply chain provides organizations with the ability to analyze supplier performance, identify inefficiencies, and discover cost-saving opportunities. By taking a proactive approach to managing operations, you can streamline processes, maximize resource utilization, and ultimately improve your bottom line.

What Features Should You Look for in Supply Chain Optimization Software?

When choosing supply chain optimization software, selecting a solution with the right features is critical to ensuring it meets your business’s specific operational needs.

Here are the essential features to look for:

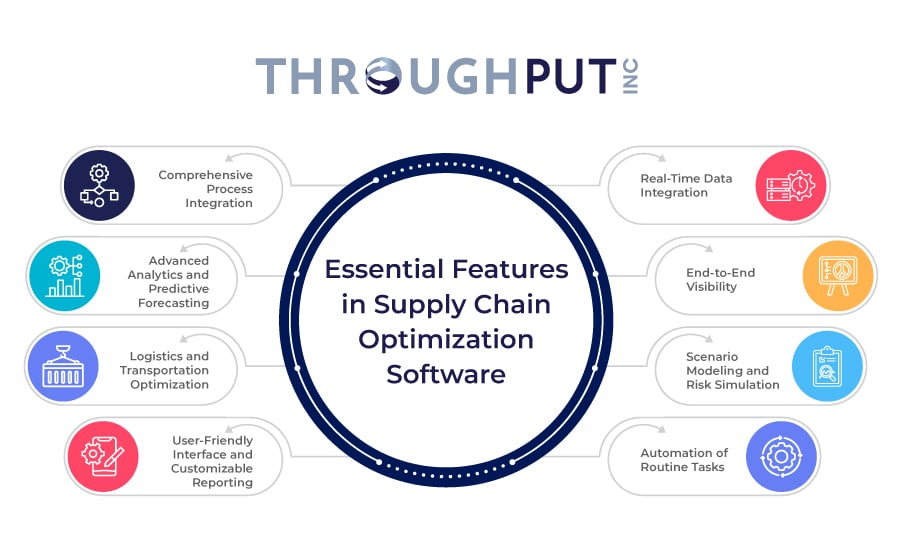

Comprehensive Process Integration

The software should cover all critical aspects of supply chain management, including inventory control, demand forecasting, logistics, and supplier relationship management. A fully integrated system ensures that each component of the supply chain functions cohesively, driving overall efficiency and performance.

Advanced Analytics and Predictive Forecasting

Robust analytics are crucial for driving actionable insights. Look for software that includes predictive analytics for accurate demand forecasting and inventory management. Collaborative forecasting features are particularly valuable, as they allow inputs from multiple stakeholders—such as sales teams, suppliers, and customers—resulting in more accurate projections and better decision-making.

Logistics and Transportation Optimization

Efficient logistics management is key to reducing operational costs and improving delivery times. The software should offer tools for route optimization, warehouse management, and reverse logistics. Features that enable transportation mode selection and optimized storage layouts can significantly enhance logistics efficiency and minimize costs.

User-Friendly Interface and Customizable Reporting

A well-designed, intuitive user interface is essential for smooth adoption across your organization. Employees should be able to easily navigate the software and access critical functions. Additionally, real-time reporting tools that provide up-to-date insights into supply chain performance are indispensable for informed, data-driven decisions.

Real-Time Data Integration

Ensure the software can process real-time data from multiple sources, such as ERP, CRM, and WMS systems, as well as third-party providers. Continuous, real-time data flow enables visibility into your entire supply chain and ensures quick, responsive decision-making.

End-to-End Visibility

Complete visibility from procurement through delivery is a must-have. With this feature, businesses can monitor supply chain performance, track key metrics like OTIF (On-Time In-Full) deliveries, and swiftly address bottlenecks. This ensures consistent service levels and improved customer satisfaction.

Scenario Modeling and Risk Simulation

Software that supports scenario modeling allows businesses to simulate different strategies and operational changes. This helps assess risks and build contingency plans for supply chain disruptions, ensuring resilience and continuity.

Automation of Routine Tasks

Automation is a key driver of efficiency. Look for software that automates repetitive tasks such as order processing, replenishment planning, and transportation management. Automation reduces the likelihood of human error, speeds up processes, and frees up valuable resources for higher-priority activities.

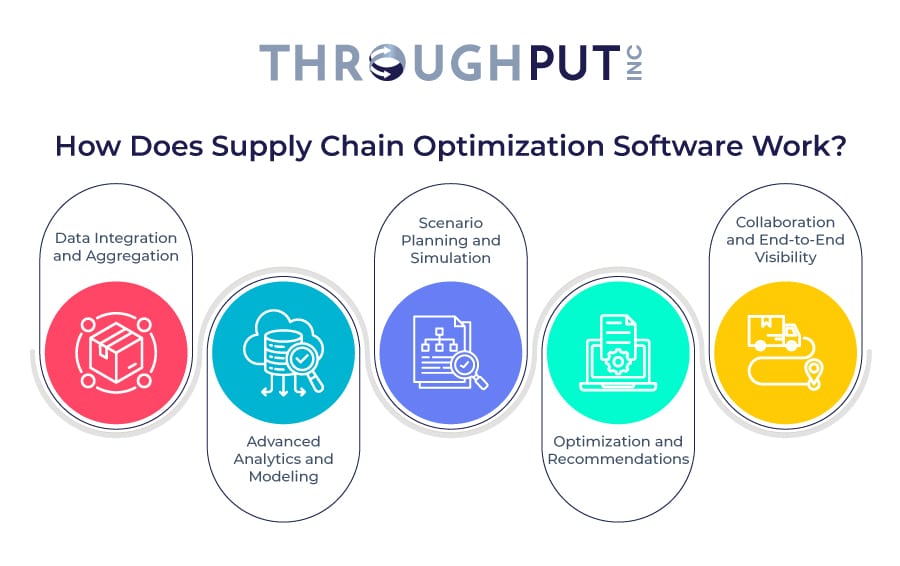

How Does Supply Chain Optimization Software Work?

Supply chain optimization software operates by leveraging advanced analytics, data integration, and sophisticated algorithms to streamline and enhance various aspects of supply chain operations.

Here’s an overview of how these solutions work:

1. Data Integration and Aggregation

Data is aggregated from multiple sources, including ERP systems, warehouse management systems (WMS), transportation management systems (TMS), and third-party providers. This data could be related to critical metrics such as inventory levels, demand forecasts, supplier performance, and transportation costs, providing a comprehensive view of the entire supply chain.

2. Advanced Analytics and Modeling

Utilizing machine learning algorithms and optimization techniques, the software processes and analyzes this integrated data. It identifies patterns, trends, and inefficiencies, and can execute tasks such as:

- Demand Forecasting: Predicting future sales to optimize inventory levels and reduce excess stock

- Network Optimization: Determining the best locations for facilities and transportation routes to minimize costs

- Supplier Risk Analysis: Evaluating potential risks and vulnerabilities to prevent supply chain disruptions

These insights enable businesses to anticipate challenges and seize opportunities for improvement.

3. Scenario Planning and Simulation

The software enables users to create various scenarios, simulating changes in demand, lead times, or transportation costs. By assessing the impact of these scenarios on key performance indicators (KPIs) like cost efficiency, service levels, and sustainability, companies can make data-driven, proactive decisions. For example, if transportation costs rise unexpectedly, businesses can pick alternative routes to maintain profitability.

4. Optimization and Recommendations

Based on the analysis and scenario evaluations, the software generates optimized strategies for different supply chain functions, such as:

- Inventory Replenishment: Crafting strategies that reduce stock outs while avoiding excess inventory.

- Production Scheduling: Aligning manufacturing schedules with demand forecasts and supplier lead times for optimal efficiency.

- Transportation Planning: Suggesting the most cost-effective routes and transportation modes that meet delivery deadlines.

These actionable insights empower organizations to improve efficiency, cut costs, and meet customer expectations more effectively.

5. Collaboration and End-to-End Visibility

A key feature of supply chain optimization software is the ability to enhance collaboration across the supply chain. It often includes:

- Shared Dashboards and Real-Time Reports: Providing visibility into KPIs and live data, enabling all stakeholders to stay aligned.

- Workflow Tools: Facilitating task coordination and approval processes across multiple organizations.

- Alerts and Notifications: Automatically notifying users of potential disruptions or new opportunities, ensuring rapid response times.

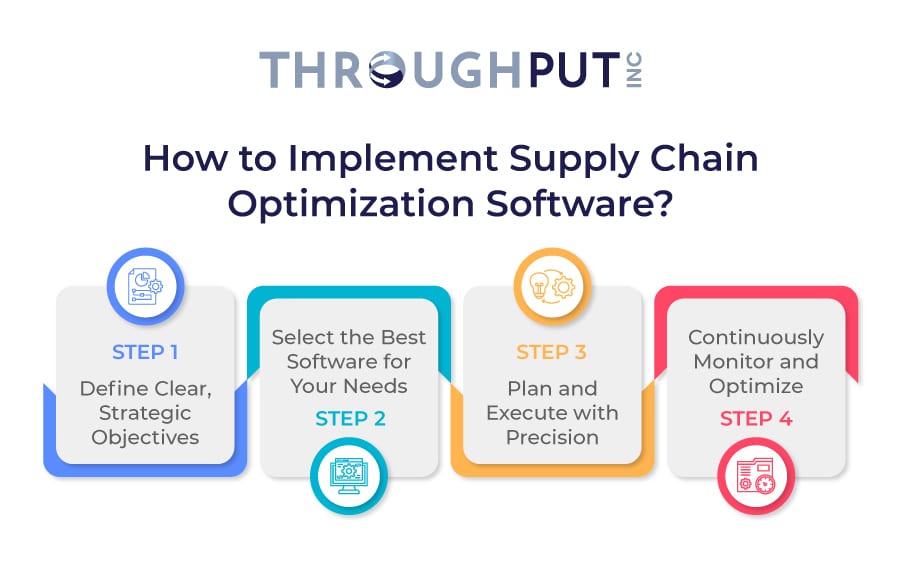

How to Successfully Implement Supply Chain Optimization Software in Your Business?

Implementing supply chain optimization software can elevate your business operations to new levels of efficiency, agility, and profitability. With the right approach, this technology, powered by AI and advanced algorithms, can unlock valuable insights, streamline processes, and drive smarter decision-making.

Here’s a step-by-step guide to ensure a seamless, impactful deployment that maximizes operational efficiency, reduces costs, and enhances overall business performance.

Step 1: Define Clear, Strategic Objectives

Start by identifying what you want to achieve with the software. Is your goal to enhance efficiency, reduce costs, or improve customer service? Clear, measurable objectives will guide the implementation, ensuring the software delivers tangible results that align with your business goals.

Step 2: Select the Best Software for Your Needs

Choosing the right software is crucial. Evaluate options based on their specific features and how they align with your objectives. For instance, Lean Supply Chain Software focuses on cutting waste and driving efficiency, while Agile Supply Chain Software enables rapid adaptation to market shifts. Select the platform that best matches your operational needs and business strategy.

Step 3: Plan and Execute with Precision

Once you’ve selected the right solution, meticulous planning is essential. Establish a detailed roadmap with clear timelines, roles, and expectations. This phase includes:

- Customizing the software to your business processes

- Integrating it seamlessly with existing systems

- Providing comprehensive training to your team to ensure effective use

Careful execution and close monitoring will prevent delays and ensure a smoother transition.

Step 4: Continuously Monitor and Optimize

After deployment, regular performance reviews are critical. Leverage the software’s analytics tools to assess its impact and identify opportunities for improvement. Continuous optimization ensures the software evolves alongside your business, delivering sustained efficiency gains and supporting informed, data-driven decisions.

How Businesses Saved Millions with Supply Chain Optimization Software: Case Studies

Case Study 1: A Global Lime Manufacturer Saves $16 Million in Inventory Optimization and Distribution

The global cement and lime manufacturer, producing thousands of tons of hydrated lime daily, sought to boost sustainability and competitiveness.

The key challenges included:

- Identifying underperforming On-Time In-Full (OTIF) deliveries

- Streamlining inefficient product flow streams

- Eliminating non-profitable orders and,

- Optimizing inventory to manage operational costs

ThroughPut’s AI-driven solutions helped the company address these issues by optimizing OTIF performance, refining product mix, and improving inventory management. They mapped top-performing SKUs, reducing unnecessary costs related to taxes and deliveries, and optimized their overall product distribution.

As a result, the company achieved $16 million in annual savings, improved performance by 13.5%, and unlocked $50,000 in working capital reduction opportunities.

Case Study 2: A European Retail Behemoth Saves €3.5 Million Annually in Logistics Costs

A leading European retail chain faced escalating logistics costs due to increased operational complexity and inefficient DC shipment management. The rise of e-commerce forced the retailer to handle a wide range of products and meet expedited delivery demands, resulting in high shipping and holding costs. Without proper demand forecasting, inventory levels were poorly managed, further driving up expenses.

ThroughPut’s AI-powered solution enabled the retailer to optimize shipment processes by revising allocation practices, prioritizing 150 top-selling SKUs, and dynamically adjusting distribution across DCs. This resulted in a 20% reduction in SKU volumes, a 33% decrease in transportation costs, and an OTIF rate of over 90%. Ultimately, the company saved €3.5 million annually in logistics costs.

What is the Future of Supply Chain Optimization Software with AI and Machine Learning?

The domain of supply chain optimization software is undergoing a dramatic evolution, driven by the integration of AI and Machine Learning (ML). These technologies are set to revolutionize decision-making, boost efficiency, and foster innovation across supply chain management processes.

Precision in Predictive Analytics

AI and ML will bring a new level of accuracy to predictive analytics, allowing businesses to forecast demand with unprecedented precision. By analyzing historical data and spotting trends, AI-powered tools can help companies optimize inventory, avoid stockouts, and minimize excess stock. For example, AI-driven systems constantly refine demand forecasts, ensuring products are available just in time to meet customer needs while cutting warehousing costs.

Automation and Real-Time Decisions

AI-driven automation will streamline supply chain operations, reducing human error and increasing speed. Machine learning algorithms can rapidly process real-time data, enabling instant, data-driven decisions such as optimizing delivery routes or adjusting production schedules based on fluctuating demand. For instance, Tesla’s supply chain leverages AI to adjust parts orders dynamically, keeping pace with the latest production demands.

How to Get Started With Supply Chain Optimization Software for Immediate Impact?

To ensure a smooth and impactful start with Supply Chain Optimization Software, follow these key steps:

1. Define Clear Objectives

Identify the specific goals you aim to achieve, such as reducing operational costs, improving delivery efficiency, optimizing inventory, or enhancing customer satisfaction. Well-defined objectives will serve as the foundation for selecting and implementing the right solution.

2. Assess Current Processes

Conduct a thorough evaluation of your existing supply chain processes to pinpoint inefficiencies and areas for improvement. Analyze key performance indicators (KPIs) like lead times, inventory turnover, and order fulfillment accuracy. This will help focus your optimization efforts on areas that offer the highest potential for improvement.

3. Choose the Right Software

Select a supply chain optimization solution that aligns with your objectives and current processes. Look for essential features like real-time data integration, advanced analytics, demand forecasting, and logistics optimization. Ensure seamless integration with your existing systems to avoid disruptions during implementation.

4. Implement in Phases

Start with a pilot project focused on a specific area, such as demand forecasting or inventory management. This allows you to test the software’s capabilities and make adjustments before expanding to other areas of your supply chain.

5. Train Your Team

Comprehensive training is essential for successful adoption. Ensure that your team understands how to effectively use the software and is equipped with resources for ongoing support. Proper training will maximize the software’s potential and drive faster results.

6. Monitor and Adjust

After implementation, continuously track performance metrics to evaluate the impact of optimization efforts. Use this data to refine strategies and make informed decisions, ensuring that the software evolves with your business needs.

By following these steps, your organization can quickly leverage supply chain optimization software to drive immediate improvements in efficiency, cost savings, and overall supply chain performance.

FAQs

- Why is real-time data analytics essential in supply chain software?

Real-time data analytics is a must-have feature in supply chain software because it empowers organizations to make timely, data-driven decisions. With up-to-the-minute insights, businesses can quickly adapt to market changes, customer demands, and operational disruptions. This capability helps optimize inventory management, improve demand forecasting accuracy, and enhance overall operational efficiency. Moreover, real-time data fosters seamless collaboration among supply chain partners, ensuring all stakeholders are informed and aligned, which leads to better customer satisfaction and cost reductions.

- What makes AI-Powered supply chain solutions better than traditional approaches?

AI-powered supply chain solutions surpass traditional methods as the former use advanced algorithms and machine learning to process and analyze vast datasets. AI can uncover patterns and trends that are often missed through manual analysis, enabling businesses to make proactive, data-driven decisions. Additionally, AI-driven automation reduces human error and boosts operational efficiency, leading to greater cost savings and enhanced competitiveness in today’s fast-paced market.

- How does demand forecasting Improve with supply chain optimization software?

Demand forecasting becomes significantly more accurate with supply chain optimization software, which uses advanced analytics and collaborative forecasting methods. By analyzing historical data alongside real-time market trends, businesses can better predict demand and adjust their strategies accordingly. Incorporating insights from multiple stakeholders, such as sales teams and suppliers, helps create forecasts that truly reflect market conditions. This demand-driven approach enables businesses to optimize production and inventory levels, minimizing stockouts and excess inventory, resulting in higher service levels and lower operational costs.