What is ABC inventory control system? Supply Chain Explained

ABC inventory control is a method for classifying inventory into three categories—A, B, and C—based on its value and importance to the business.

This system is grounded in the idea that not all inventory items have an equal financial impact on a company’s operations.

The ABC classification is based on the Pareto principle, commonly known as the 80/20 rule, which asserts that 80% of the effects come from 20% of the causes.

In inventory control, a small percentage of items significantly influences total inventory costs, guiding businesses to focus their efforts and resources more efficiently.

What is the ABC Inventory Matrix?

The ABC Inventory Matrix is an inventory management technique for organizing inventory items into three distinct categories (A, B, and C), each defined by their value and turnover rate.

This matrix helps businesses prioritize their resources and focus on areas that will provide the most significant impact on inventory optimization. The ABC matrix implementation results in return on investment, preventing overstock of low-impact items and shortages of critical ones.

The most valuable items in the inventory typically represent about 20% of the total items but account for around 80% of the inventory value.

A items require the tightest controls and more frequent reviews because their financial impact is significant. For example, in a technology company, A items might include high-cost electronic components essential for production.

B items strike a balance in the inventory matrix. They are less critical than A items but more important than C items, usually representing about 30% of inventory items and contributing to 15% of the inventory value.

These items require moderately stringent controls. In a retail clothing store, B items might include important but less costly seasonal fashion accessories.

C items are the largest portion of the inventory by number; C items typically account for about 50% of the total items but only 5% of the value.

Because they have the smallest impact on financial resources, C items can be managed with more lenient controls. An example could be office supplies in a corporate setting—necessary but inexpensive on a per-item basis.

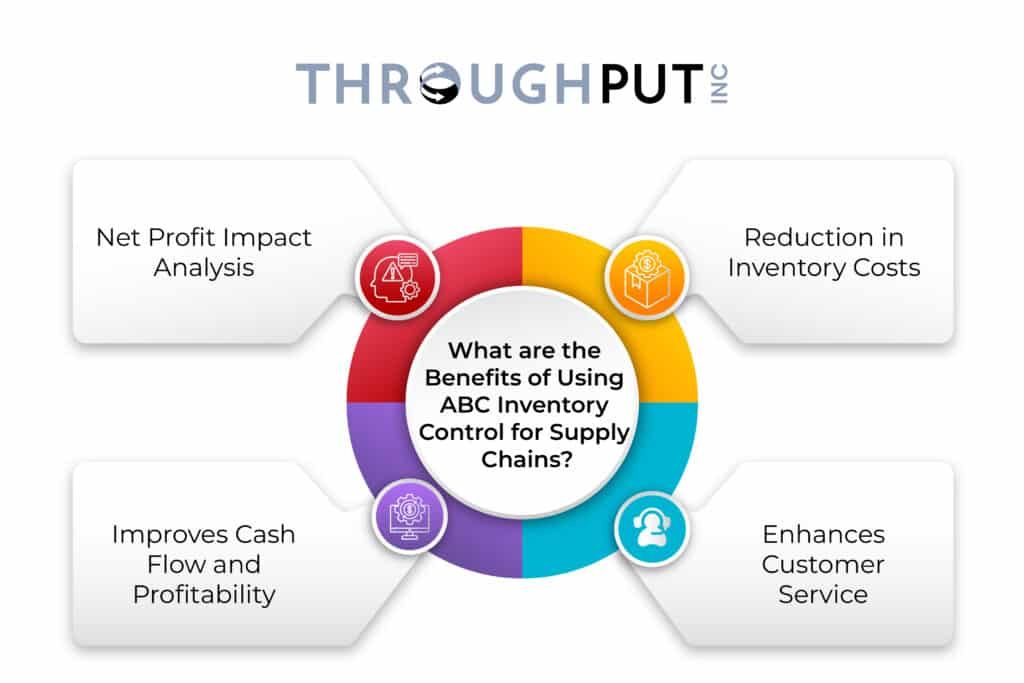

What are the Benefits of Using ABC Inventory Control for Supply Chains?

The benefits of using ABC inventory control for supply chains are reduced inventory costs, improved cash flow and profitability, enhanced customer service, and improved focus on key inventory. The ABC inventory control also impact SKU optimization and rationalization.

This approach not only optimizes inventory management but also supports broader strategic objectives.

Here’s a breakdown of each benefit:/

Focus on Critical Inventory

ABC Inventory Control enables companies to concentrate resources and management efforts on “A” items, which are crucial for the business’s success.

This targeted focus helps in maintaining optimal stock levels, preventing expensive stockouts, and ensuring that high-value items are always available when needed.

Reduction in Inventory Costs

Supply chains can tailor purchasing and storage strategies when differentiating between high and low-value items.

This results in significant cost savings, as less capital is invested in overstocked low-value items, and storage space is utilized more efficiently.

Improves Cash Flow and Profitability

Effective inventory management through ABC analysis helps reduce unnecessary spending on less critical inventory. This better allocation of resources improves cash flow and, consequently, the overall profitability of the business.

Enhances Customer Service

When stockouts of critical items are prevented, businesses can improve their service levels. This reliability can lead to higher customer satisfaction and loyalty, as customers can consistently rely on the availability of essential products.

These benefits collectively contribute to a more streamlined, efficient, and economically sound inventory management system, supporting the broader goals of enhancing operational efficiency and customer satisfaction.

What are the advantages and disadvantages of ABC analysis?

The advantages of ABC analysis are focused efficiency, cost efficiency, and improved decision-making.

ABC analysis provides a more detailed oversight that can be maintained over significant items, guaranteeing that crucial inventory is constantly monitored and sufficiently restocked.

It also lessens storage expenses by pinpointing less profitable items that need not be watched and accumulated with abundance.

ABC analysis promotes better choices by presenting precise descriptions of the stock value distribution. It helps shape long-term planning measures and allocate budget among them.

What are the disadvantages of ABC analysis?

The disadvantages of ABC analysis are potential overemphasis on high-value items, implementation complexity, and significant setup investments.

The implementation of this system is often challenging, especially in companies holding vast amounts of stock.

ABC analysis also requires considerable resources (funds and manpower) during setup and maintenance to support precise inventory categorization and valuation.

The last drawback of ABC analysis is the common neglect of low-priced items. This drawback can jeopardize operations without careful consideration, as prioritizing expensive articles poses a higher risk.

ABC is particularly effective in environments where inventory items vary significantly in value and demand variability. It is most appropriate for businesses looking to focus on value-based inventory management rather than just-in-time inventory or minimal inventory holding.

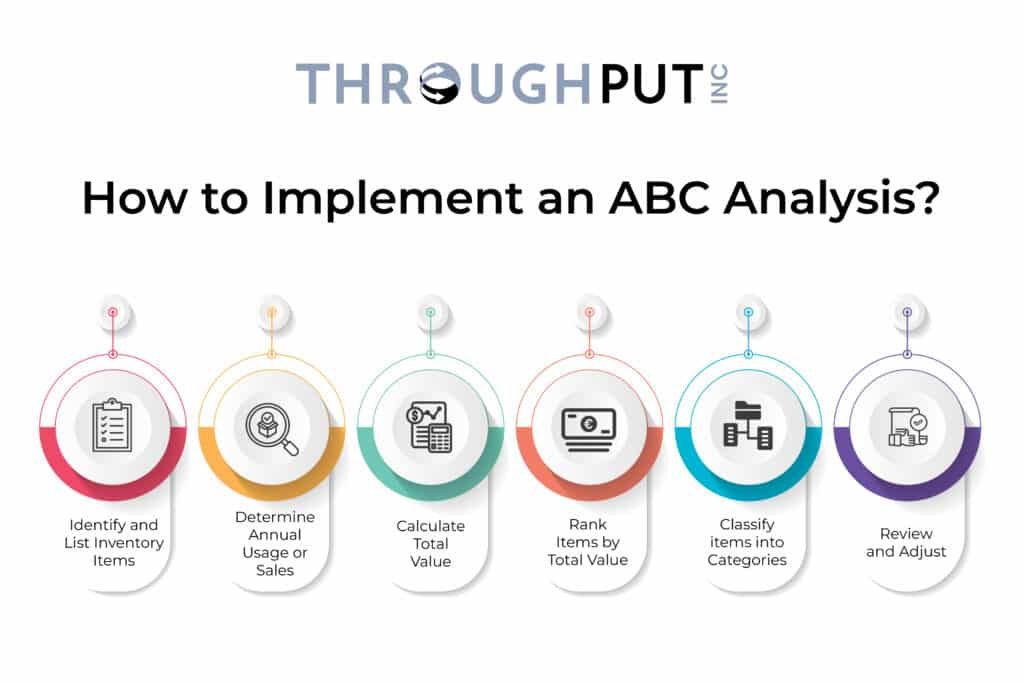

How to Conduct an ABC Analysis?

Conducting an ABC analysis involves six steps, each critical to accurately categorizing inventory based on its value and turnover rate.

Here’s how businesses can effectively implement this analysis:

STEP 1: Identify and List Inventory Items

Begin by compiling a complete list of all inventory items. This comprehensive list is the foundation of the ABC analysis.

STEP 2: Determine Annual Usage or Sales

Calculate the annual usage in quantity and the total cost associated with each item. This step helps you understand the financial impact of each item on the company’s operations.

STEP 3: Calculate Total Value

Multiply the annual usage quantity by the cost per unit for each item to determine the total value. This value is crucial for categorizing the items into A, B, or C classes.

STEP 4: Rank Items by Total Value

Order the items from highest to lowest based on their total value. This ranking will highlight which items contribute most to the company’s inventory costs.

STEP 5: Classify items into Categories

Apply the 80/20 rule to classify items into A, B, and C categories. Typically, the top 20% of items by value are classified as A, the next 30% as B, and the remaining 50% as C.

STEP 6: Review and Adjust

It’s important to regularly review and adjust the classifications as sales patterns and costs change to ensure the accuracy of the ABC analysis.

Example Calculation:

Imagine a business that stocks 100 different products. Here’s an example calculation for one product:

- Annual usage: 100 units

- Cost per unit: $50

- Total value: 100 units x $50 = $5,000

Depending on its total value, this product might be classified as an A, B, or C item.

How does ABC Compare to Just-In-Time (JIT) and Economic Order Quantity (EOQ) Inventory Control Methods?

ABC focuses on categorizing inventory based on importance and profitability, JIT emphasizes minimizing inventory to reduce costs, and EOQ seeks to find a balance that minimizes overall inventory management costs.

Just-In-Time (JIT) operates by synchronizing orders for raw materials with production schedules, aiming to enhance efficiency and minimize waste.

This method allows businesses to receive goods precisely when needed for production, cutting down on inventory costs. However, JIT demands accurate scheduling and carries risks in scenarios where supply chain disruptions occur.

On the other hand, Economic Order Quantity (EOQ) employs a formula to identify the ideal order quantity that reduces the total inventory management costs, including ordering and holding expenses.

EOQ is particularly effective for products with steady demand and supply chains that are relatively stable and predictable.

What are Real-life Examples of ABC analysis?

Real-life examples of ABC analysis are Countdown NZ, Gap Inc., and Samsung. To provide additional context on the problems, implementation, and results, we wrote a breakdown of each example:

Example 1: Countdown NZ

Countdown NZ, a leading grocery chain in New Zealand, faced challenges in managing inventory for a wide range of products across its supermarkets.

The company needed to ensure that high-demand grocery items were always available while minimizing excess inventory of less critical items.

Implementation:

Countdown NZ used ABC analysis to classify inventory into A-items (high-value, high-demand grocery items), B-items (moderate value and demand items), and C-items (low-value, high-quantity items).

This classification helped Countdown prioritize inventory management efforts on A-items, ensuring they were always in stock while managing B and C-items with less stringent controls.

Results:

The application of ABC analysis resulted in better inventory turnover, reduced stockouts of high-demand grocery items, and improved customer satisfaction.

Countdown was able to optimize its inventory levels, reduce carrying costs, and ensure that popular products were always available.

Example 2: Gap Inc.

Gap Inc. faced challenges in managing inventory for its extensive network of retail stores and e-commerce operations.

The company needed to ensure that popular clothing items were always available while minimizing excess inventory of less popular items.

Implementation:

Gap Inc. applied ABC analysis to categorize inventory into A-items (high-value, high-demand clothing items), B-items (moderate value and demand items), and C-items (low-value, high-quantity itemsms).

This categorization allowed Gap to focus on A-items for frequent stock reviews and tighter controls, while B and C-items were managed with less frequent reviews and controls.

Results:

The implementation of ABC analysis led to improved inventory turnover and reduced stockouts of popular clothing items.

Gap optimized its inventory levels, reduced carrying costs, and improved customer satisfaction by ensuring that popular products were always available.

Example 3: Samsung

Samsung, one of the world’s largest manufacturers, faced the challenge of managing an enormous and complex inventory of electronic components and finished products.

The company needed to ensure that critical components were always available to avoid production delays.

Implementation:

Samsung used ABC analysis to classify inventory into A-items (critical components with high value), B-items (moderate value components), and C-items (low-value consumables).

This classification helped Samsung prioritize inventory management efforts on A-items, ensuring they were always in stock while managing B and C-items with less stringent controls.

Results:

The application of ABC analysis resulted in better resource allocation, reduced stockouts of critical components, and improved production efficiency. Samsung maintained a steady supply of essential elements, reducing the risk of production delays and improving overall operational performance.

How to implement ABC Inventory Control?

Implementing ABC inventory control starts with training your team on ABC principles and processes, as well as using inventory software or custom tools for categorization.

Regular review and adjustment protocols must be established, and the system’s importance must be communicated across the organization for compliance and support.

Remember that ABC inventory control requires a thoughtful approach before implementing existing processes.

Here’s a list of key considerations for successfully implementing and maintaining ABC inventory control in your business:

Regular Review and Updating

Inventory dynamics can change due to new products, customer demands, or external market conditions.

Regularly reviewing and updating ABC classifications ensures that the inventory management strategy remains aligned with current business realities.

Cycle Counting and Auditing

Periodic cycle counts should be conducted, especially for items in the A category, to maintain inventory data integrity.

This helps verify the accuracy of inventory records and reduces discrepancies between physical stock and recorded amounts.

Integration with Other Inventory Strategies

ABC inventory control should not operate in isolation. Integrating it with other inventory management practices, such as demand forecasting and reorder point calculations, can enhance its effectiveness.

This holistic approach ensures that all aspects of inventory management work together cohesively.

Here are the practical steps for implementation:

- Step 1: Train your team on the principles of ABC inventory control and the specific processes you will use.

- Step 2: Use inventory software that supports ABC analysis or develop custom tools to assist in categorization and ongoing inventory management.

- Step 3: Establish clear protocols for regularly reviewing and adjusting inventory categories.

- Step 4: Communicate the system’s importance across all levels of the organization to ensure compliance and support.

How does the ABC inventory control system help in inventory optimization?

The ABC inventory control system optimizes inventory by enabling businesses to prioritize their management efforts based on the value and turnover of items.

Focusing resources on the most important items through this method helps businesses reduce excessive investment in less vital inventory, resulting in fewer costly stockouts and overinvestment in less impactful C items. In essence, managing key A items can improve a company’s inventory levels across the board and maximize available resources.

FAQs for ABC Inventory Control System

Question 1. How can an ABC Inventory Control System help reduce working capital without increasing stockouts?

Answer:

An ABC system ensures your highest-value and fastest-moving items (A-class) receive tighter controls—such as more frequent reviews, optimized reorder points, and smaller lot sizes.

When integrated with analytics or AI-based demand sensing platforms like ThroughPut.ai, it becomes possible to dynamically adjust safety stocks based on real-time consumption, supplier variability, and lead-time fluctuations.

This enables major working-capital reduction while maintaining >95–99% service levels.

Question 2. What measurable operational KPIs improve after implementing an advanced ABC inventory control system?

Answer:

Typical improvements industrial leaders see include:

- 15–30% reduction in excess inventory

- 20–40% improvement in service levels for A-class items

- 25% fewer emergency purchase orders

- 10–20% reduction in maintenance downtime from parts unavailability

- Faster PO approval cycles for high-value SKUs

These KPIs directly support strategic goals of cost control, risk reduction, and reliability improvement.

Question 3. How does ABC inventory control support maintenance teams in preventing equipment downtime?

Answer:

ABC analysis helps classify critical spares as priority A-items even if they are low-movement but high-impact.

With AI-enhanced ABC:

- Criticality scores

- Supplier reliability

- MTTR (Mean Time to Repair)

- Failure probability are combined to prioritize stocking decisions.

This ensures critical spares are always available, eliminating unplanned downtime and emergency procurement delays.

Question 4. Is ABC inventory control still relevant when companies already use ERP or SAP?

Answer:

Yes. Most ERP systems offer static ABC categorization based on yearly consumption values.

However, modern manufacturing environments need dynamic ABC, where categories shift automatically based on:

- demand volatility,

- cost impact,

- consumption patterns,

- maintenance criticality,

- supplier risk.

Platforms like ThroughPut.ai enhance ERP instead of replacing it, acting as a real-time intelligence layer above SAP/Oracle/IFS/Infor.

Question 5. How often should ABC classifications be updated for industrial and spare parts inventory?

Answer:

For operational inventory, quarterly updates are common.

For MRO/spare parts, classification should be recalculated monthly because:

- equipment wear patterns change,

- procurement delays occur,

- service levels fluctuate,

- stock value accumulates silently.

AI-driven tools adjust ABC classes in real time, removing manual rework for large SKU catalogs (10,000+).

Question 6. Can an ABC inventory system reduce emergency procurement costs for sourcing teams?

Answer:

Yes. Emergency orders often cost 2–5× more due to expedited shipping and last-minute supplier charges.

An effective ABC system ensures proper stocking of high-value and long-lead items.

When integrated with predictive analytics, sourcing teams get proactive alerts for:

- potential stockouts,

- supplier delays,

- usage rate spikes.

This eliminates firefighting and reduces urgent procurement dependency.

Question 7. How can ABC analysis help manage long-tail inventory in industrial companies?

Answer:

For long-tail or slow-moving SKUs, ABC systems identify:

- obsolete items

- excess stock

- low-impact SKUs

- supplier consolidation opportunities

With AI-driven analysis, you can identify which C-class parts can be: - stocked minimally

- moved to VMI (Vendor-Managed Inventory)

- sourced on-demand

This improves warehouse space, reduces dead stock, and cuts carrying cost significantly.

Question 8. What advanced ABC methods should enterprise supply chain leaders adopt beyond basic classification?

Answer:

Modern leaders apply:

- ABC-XYZ analysis (value + demand variability)

- Criticality scoring for MRO (downtime impact)

- FMEA-based ABC (failure mode prioritization)

- AI-driven probabilistic safety stock

- Multi-criteria ABC (lead time, risk, cost-to-serve)

These advanced methods give a holistic and risk-sensitive inventory strategy.

Question 9. What are the biggest pitfalls industrial companies face when implementing ABC inventory control?

Answer:

Common issues include:

- Using only annual consumption value for classification

- Treating all slow-moving parts as low priority

- Not linking ABC to procurement strategy

- Not considering supplier reliability

- Outdated or inaccurate master data

- Manual spreadsheets for large SKU catalogs

Adopting automated platforms that directly connect to ERP eliminates these issues.

Question 10. How does AI improve the accuracy of ABC inventory classification?

Answer:

AI systems incorporate variables beyond value and consumption, including:

- seasonality patterns

- machine operating behavior

- breakdown frequency

- supply chain disruptions

- cost-to-serve

- logistics bottlenecks

This results in dynamic, accurate, and automated ABC classifications that better align with business outcomes.

Question 11. Does ABC inventory control help with ESG or sustainability goals?

Answer:

Yes. Maintaining optimal stock reduces:

- waste from expired or obsolete items

- unnecessary manufacturing

- overproduction

- additional transport emissions

Better inventory planning aligns with ESG commitments and operational sustainability goals.

Question 12. How quickly can ABC inventory control show ROI in industrial environments?

Answer:

Most companies see ROI in 8–16 weeks due to:

- immediate excess stock reduction

- improved OTIF (On-Time-In-Full)

- reduced expedited freight

- better maintenance uptime

- lower carrying costs

ROI accelerates when used with real-time optimization tools that automate classification.