AI in the Food Industry: Case Studies, Challenges & Future Trends

Integrating Artificial Intelligence (AI) in supply chains within different segments of the Food Industry, including transportation and logistics, production planning, quality control, and others has kicked off revolutionary transformations.

Whether it is optimizing supply chains to reduce waste or adopting smart agriculture practices to improve yield, AI impacts efficiency, personalization and sustainability.

The market size of AI in the food industry, including the beverages sector is set to cross USD 9.68 billion in 2025. It is growing at 38.30% CAGR and is expected to touch USD 48.99 billion by 2029. As per a recent study, AI can help reduce production costs by almost 20% in the agriculture sector! That’s definitely good news.

By the way things are progressing, AI is and can further impact the industry in multiple ways. All for the good. Let’s find out more about this in this article.

Overview of AI in the Food Industry

1. Food Production

AI tools can drive advanced predictive analytics with precision forecasting for weather and crop yield predictions. Analyzing huge amounts of data can help monitor nutrient levels in the soil, and detect signs of pest infestation or diseases, resulting in healthier crops.

Detection of nutritional constituents and allergens in food, optimizing routes and schedules of food delivery, and inventory management are some of the other ways AI is helping the food production industry.

2. Supply Chain Administration

Supply chains are the backbone of the food industry. Artificial Intelligence in supply chain helps track products from harvest to distribution channels and manage inventories with greater accuracy.

The technology also helps set better food standards surveillance, testing products at every level, and ensuring food hygiene setups in different operational scenarios.

3. Optimize Yield for Farmers

AI is helping farmers detect pest infestations and plant diseases proactively. The technology also helps detect environmental conditions like temperature, humidity, soil fertility and nutritional properties. This is called smart farming. Data collected from drones, sensors, and satellites can be analyzed by farmers to save time, and costs related to field trials, food inspections, and more.

4. Food Retail

In the food retail sector, AI has been helping reduce wastage as the tools can more accurately predict the demand for products. Predictive Analytics in supply chain is one of the most powerful features of AI tools that help identify patterns and new trends much before they happen.

5. Enhance Food Safety & Quality

AI is helping food companies become compliant and transparent. It is also bringing in an increased sense of accountability in the food supply chain.

AI-enabled cameras can detect safety issues in case the staff on the shop floors are not wearing food protection gear or following the rules. Production is being tracked in real-time; therefore, issues related to food contamination and other safety issues are getting detected faster and effectively.

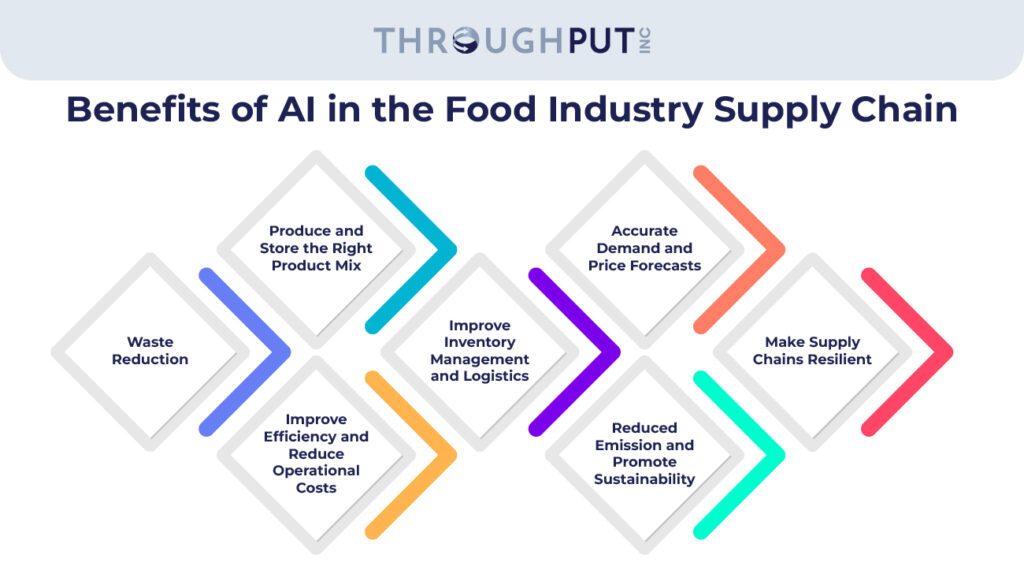

Benefits of AI in the Food Industry’s Supply Chain and Logistics

Waste Reduction

Estimates from the Food and Agriculture Organization point out that nearly one-third of food is wasted every year leaving millions starved and at least one in nine people undernourished. Almost 8% to 10% of all greenhouse gas emissions on the globe today are linked to unconsumed food. Food losses and waste mean economic losses amounting to almost $940 billion each year.

Accurate demand forecasting, demand sensing, improved food storage practices and optimized supply chain management with the help of AI can make a difference when it comes to reducing waste, especially for perishable food products.

Produce and Store the Right Product Mix

One of the biggest challenges that AI helps tackle in the food industry is related to understanding consumer demands. AI powers predictive analytics where trends, preferences and purchasing behaviors are analyzed in-depth that help companies store the right product mix. This gives businesses the flexibility to adjust product offerings with optimized varieties and freshness.

Improve Efficiency and Reduce Operational Costs

AI in the food industry impacts efficiency and operational costs too. From predictive maintenance of equipment to optimizing delivery routes and reducing wastes, AI automation helps streamline production, minimizes downtime and enables precise resource allocation.

Such processes lower energy consumption and boost profitability.

Improve Inventory Management and Logistics

In the context of inventory management and logistics handling in the food industry, AI offers tracking and forecasts demand in real-time that enables companies optimize stock levels. Using predictive analytics, businesses move away from overstocking or understocking, while ensuring timely delivery of fresh products. This boosts customer confidence and satisfaction levels while reducing wastes.

Accurate Demand & Price Forecasts

AI facilitates precision in demand and price forecasting with the help of historical data and market trends. Food companies, especially dealing in perishable products can adjust their production and drive efficient inventory management with AI. Besides, such companies can price their products competitively and take advantage of consumer behavior and market fluctuations.

Reduced Emissions & Promotes Sustainability

AI in the food industry contributes towards reducing emissions as supply chains get optimized and food waste gets minimized. With predictive analysis, crop yield increases, agriculture precision is achieved, and carbon footprint of companies reduces. Energy-efficient processing and distribution have minimal environmental impact.

Make Supply Chains Resilient

Real-time data analysis offers predictive insights of the market demands. AI can help identify potential disruptions and facilitate proactive adjustments, be it in sourcing, operations, or distribution. Supply chains become robust and stabilize even in the face of challenges.

Case Studies of Successful AI Integration in Food Supply Chain

Church Brothers Farms

Church Brothers Farms, a family-owned vegetable business with a vast cultivation area of 40,000 acres, faced significant challenges due to product perishability, volatile market conditions and logistical issues, among others.

Shipping 50 million cartons annually across the US, the company sought to optimize its supply chain to reduce waste and increase profitability.

They turned to Throughput.ai for a solution, which leveraged historical data across 60 commodities and numerous products to enable accurate demand forecasting and supply chain optimization.

Throughput.ai’s tool allowed for a transformation in the supply chain management of Church Brothers Farms by providing advanced forecasting and identifying optimal timelines, workflows, and routes for order fulfillment. This AI-driven approach helped the company minimize disruptions, reduce wastage, and adapt to fluctuating consumer tastes by implementing a make-to-order strategy instead of the traditional make-to-stock approach. This shift was supported by granular visibility into sales volumes, enabling the identification of best-sellers and underperforming products.

The collaboration with Throughput.ai led to substantial improvements for Church Brothers Farms, including a 40% increase in short-term forecasting accuracy and a more efficient management of inventory and production capacity. By achieving the 5 R’s—having the right stock in the right quantity, at the right cost, time, and location—the company not only maximized profitability but also enhanced customer satisfaction through its optimized supply chain.

A Fast-Growing Coffee Retail Chain

A 10-year-old coffee retail company with ambitions to expand as a boutique chain focused on locally sourced, fair-trade and organic products made significant strides with the help of Throughput.ai. Specializing in a variety of coffee brews, fresh juices and smoothies, the company faced challenges related to inventory management such as pile-ups and wastage as well as inefficiencies in shipping and a need for better alignment of its menu with evolving market tastes.

Throughput’s Supply Chain Intelligence software suite offered solutions that allowed the coffee chain to intelligently optimize its product offerings, sense near-term demand more accurately, and adjust its menu dynamically to enhance profit margins while minimizing waste.

The tool provided comprehensive insights into inventory turnover, customer reorder frequencies and the performance of every premium SKU, including shipping costs and lead times. This enabled the chain to prioritize its products more effectively, using Throughput’s demand-value matrix based on demand sensitivity.

As a result of the partnership with Throughput, the coffee chain achieved significant operational improvements, including a 15% reduction in inventory levels and a 5% increase in labor productivity.

These advancements allowed the chain to adapt to market demands more dynamically, maintain fresher stock and avoid overstocking or shortages, ultimately, securing a competitive advantage.

By gaining detailed visibility into SKU-level performance and optimizing its entire supply chain, the company could ensure timely availability of the right products, enhancing customer satisfaction and reducing resource wastage.

Fast Food Companies

Many fast food companies like Chipotle, McDonald’s and Yum Brands are using the power of artificial intelligence to revolutionize the industry.

- Chipotle is using AI-driven cooking methods and robotics to make the kitchen more efficient and reduce food wastage. New-age technology helps enhance customer service with seamless ordering experience and analyze customer feedback to offer personalized dining experience.

- Yum Brands has already integrated artificial intelligence and related technologies into all its retail stores in the US. Other than chatbot systems, AI is helping each outlet predict demand, helping it reduce waste and manage its inventory more efficiently.

Agriculture Companies

We have already spoken about how Church Brothers have benefitted by using Throughput.ai’s platform. Another excellent example is that of Beyond Meat. The plant-based food company uses artificial intelligence and machine learning to make its meat alternatives more flavorsome and rich in texture.

Using sensory data of customers and feedback of its users, the technology analyzes plant proteins at the molecular level, and the profiles of different ingredients to replicate the flavor, texture, and nutrition of animal meat. Consequently, the brand is able to offer sustainable and healthier dietary options to people who want to relish meat-like flavors and textures.

Challenges and Considerations of AI in Food Industry

Technical and Financial Barriers to AI Adoption

Unlike big tech companies that have tons of voluminous data with them, players in the food industry are usually hesitant to try AI because they lack data. Not just that, customizing AI tools that are usually designed to handle large data quantities can be an expensive affair.

Data Privacy and Security Concerns

As food companies collect and analyze vast datasets of customers and operations, the risks of data breaches and unauthorized access increases. With the help of powerful AI tools, the issues related to cybersecurity can be addressed to a great extent.

Need for Skilled Personnel to Manage AI Technologies

Another common challenge for food businesses when implementing AI technologies is about hiring skilled professionals with a background in the industry. Substantial investment is required to educate, train and develop existing employees as well as onboard experts.

Throughput AI’s Value-Added Proposition for AI in Food Industry Supply Chain

1. Predict Near-term Demand

Throughput works with a data-centered approach and facilitates demand sensing not just for the long-term but near-term too. It benefits food producers and retailers, especially if you are in the perishable markets and constantly need to battle issues like seasonality changes, low shelf life, time sensitivity, lost chances of sales and earning revenues.

2. Work With Small Data Quantities

The platform can robustly handle smaller amounts of real-time data, one of the biggest concerns for small players in the industry that do not have huge data with them for analysis.

3. User-Centric Features

With user-friendly features, handling the platform and interpreting the results is quite convenient, even for users who are not experts in AI.

4. Flexible, Customizable and Scalable

Since Throughput can offer tailored solutions to the food industry depending upon the unique needs of your business, you can always start small, experiment and explore use cases, and once it produces results, scale up to fit your operational range. Consequently, you can have a pocket-friendly approach with Throughput.

Future Trends and Predictions of AI in the Food Industry

New-age AI technologies in the food industry have started a revolution in how food is produced, processed and distributed. AI-powered tools in supply chains like Throughput are making accurate demand forecasting reducing overproduction and underproduction.

Additionally, Artificial Intelligence has taken food safety to another level. Be it consumer health, detection of contaminants, or offering personalized nutrition plans, the scope of AI and futuristic technologies have unlocked potential that can make the industry sustainable, healthier and secure.

Further, AI-driven logistics solutions will make route planning for deliveries precise and more effective as these solutions work with real-time traffic conditions, weather forecasts and delivery windows.

Consequently, fuel usage will be more efficient and delivery times reduced. Combined with blockchain technology, AI is set to enhance product traceability from farm to table while ensuring compliance with food safety protocols.

Conclusion

Technological adoptions in the F&B industry are helping companies ace key areas of operation. For example, Throughput’s predictive analytics feature has transformed the supply chain landscape and the logistics workflow for many players, Church Brothers Farmer and the Retail Cafe chain being two great examples as we have seen here.

AI in the food industry is not just about adding another layer of innovative technology to your operations. It has the potential to revolutionize your business, be it food safety, sustainability, improving operational efficiency, reducing waste, saving money, or strengthening customer relationships.

Come, let’s choose to be a part of this agile and smart revolution that can transform your business in an environmentally conscious manner.

FAQ – AI in the Food Industry

Q1: How can AI help a VP of Maintenance reduce downtime in food manufacturing?

AI-driven predictive maintenance tools analyze equipment data to detect early signs of wear, potential failures, or process inefficiencies. This enables maintenance leaders to schedule interventions proactively, reducing unplanned downtime by up to 40% and extending equipment lifespan — all while maintaining compliance with food safety standards.

Q2: How does AI improve supplier reliability and raw material availability?

AI models can analyze supplier performance, delivery patterns, and external risk factors to predict potential disruptions before they occur. For Heads of Supply, this means building a more resilient supplier network and ensuring consistent ingredient availability — even during demand volatility or logistics disruptions.

Q3: Can AI optimize sourcing strategies for cost and quality simultaneously?

Yes. AI algorithms evaluate multiple supplier and market variables — including cost trends, lead times, and historical quality metrics — to recommend optimal sourcing mixes. Sourcing leaders can negotiate better terms, reduce material costs, and ensure supplier compliance without compromising quality or sustainability goals.

Q4: How fast can food manufacturers see ROI from AI-driven optimization?

Most organizations see measurable results within 8–12 weeks of deployment. Early wins often include improved OEE (Overall Equipment Effectiveness), reduced wastage, optimized procurement spend, and faster decision-making cycles driven by unified, AI-analyzed data streams.

Q5: What differentiates ThroughPut.AI’s solutions for maintenance, supply, and sourcing leaders?

ThroughPut.AI’s Supply Chain Decision Intelligence platform connects maintenance, supply, and sourcing data to identify the true operational bottlenecks impacting margins. Unlike traditional analytics tools, it prioritizes actions by business impact — empowering leaders to cut costs, boost uptime, and ensure supply continuity with precision.

Q6: How can AI-driven predictive maintenance reduce unplanned downtime and costs in food industry operations?

AI-powered predictive maintenance systems leverage real-time data from equipment sensors to forecast component failures before they occur, allowing maintenance teams to schedule interventions more effectively and minimize costly downtime. This technology can lead to a reduction in unplanned outages by 20-40%, which not only lowers direct maintenance costs but also ensures production schedules are not disrupted. Enhanced equipment reliability supports sustained output and higher plant profitability.

Q7: What are the key benefits of AI-enabled supply management for VPs and Heads of Supply (not supply chain) in food companies?

By using AI to analyze supply data, companies can identify optimal sourcing opportunities, track critical inventory in real time, and streamline procurement processes. AI-driven systems provide dynamic forecasts and risk assessments for supplier reliability, pricing trends, and material availability, enabling supply leaders to make faster decisions and mitigate risks from market fluctuations or supply disruptions. This results in improved material availability, reduced excess inventory, and better resource allocation.

Q8: Can AI help Heads of Sourcing improve supplier evaluation and contract outcomes in industrial food enterprises?

AI-based sourcing tools can process vast datasets on suppliers, measuring performance using KPIs like on-time delivery, quality defect rates, and risk profiles. Predictive analytics also highlight potential disruptions, enabling contingency planning and more resilient supply contracts. VPs and Heads of Sourcing gain deeper visibility into supplier capabilities and can negotiate terms that maximize reliability and minimize costs.

Q9: How does AI help optimize yield and minimize waste, supporting sustainability goals for food companies?

Smart farming systems powered by AI analyze data from drones, sensors, and satellites to predict crop yield and detect issues like pest infestations early. In processing and distribution, AI markets accurate demand forecasts and inventory optimization, which reduces overproduction and waste, directly supporting both cost savings and sustainability targets. Such systems typically deliver significant reductions in food loss and greenhouse gas emissions.

Q10: hat is required to successfully implement AI solutions for maintenance, supply, and sourcing teams in food manufacturing?

Successful adoption calls for a combination of industry data readiness, selection of scalable and user-friendly AI platforms, pilot programs with measurable KPIs, and strong internal training for both maintenance and supply/sourcing teams. Choosing platforms that can handle smaller real-time datasets and that offer customizable solutions allows food companies to start small, prove value, and scale up as operational needs grow.