ROI in Supply Chain: Achieving Rapid Value with ThroughPut AI in Just 90 Days

In the aggressively competitive digital era, Artificial Intelligence (AI) is one of the few technologies that has immense potential to revolutionize business operations, outcomes and revenue alike.

However, effective implementation of AI can prove challenging for many businesses – as is evident from the Gartner discovery that a massive 85% of all AI projects fail to deliver the estimated business value.

Naturally, one of the reasons that businesses hesitate to adopt AI is the time it takes to realize ROI. With the constantly evolving, disruption-prone nature of the supply chain space, executives are demanding quick insights, decisions and action.

With time running short, businesses need to build a clear business case for AI with a concrete plan of action that rapidly – and incrementally – achieves ROI.

ThroughPut AI, a Gartner-recognized Supply Chain Decision Intelligence and Analytics Platform, does just that.

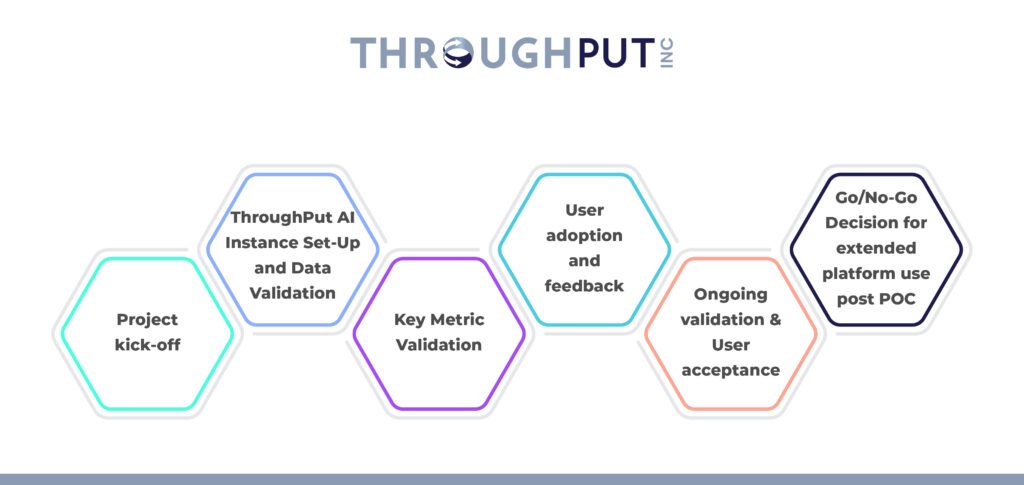

ThroughPut AI: 6 Steps to Rapid Supply Chain ROI and Time to Value

Step 1: Project Kick-off

This stage is when we lay the foundation of the AI project – we clarify and define objectives, establish the project scope, and ensure that all stakeholders are on the same page.

We then work with you to align data requirements and project plans and identify the key participants.

Following this, data sources are identified and shared, and success metrics and business outcomes are defined so that everyone works toward the same goals.

This is a critical stage of the AI project because a well-defined kick-off sets the groundwork for the entire project and ensures that all stakeholders have a proper understanding of expectations, goals and timelines.

Pro Tip: To enable a holistic situational understanding, ThroughPut works with data from both internal and external sources, and aligns functional and financial goals to drive consensus for the expected business outcomes and quantifiable supply chain improvements .

Step 2: ThroughPut AI Instance Set-Up and Data Validation

Over the next few weeks, the ThroughPut instance is set up and connected to your data sources (for example, Snowflake, ERP systems ) to ensure a seamless data integration.

This process is fundamental to the AI project, as it sets the stage for the transition from data to an insight-driven business – it includes configuring data ingestion processes, creating a data dictionary and validating data for relevance, completeness, quality and accuracy.

Pro-tip: Integrations and automation are crucial for utilizing AI in supply chain management. ThroughPut AI offers an extensive suite of APIs and capabilities, enabling businesses to simplify the complexity of supply chain data engineering like never before. This is achieved with unparalleled ease and genuine self-service capabilities, marking a significant advancement in the field.

ThroughPut understands that data is the fuel for AI, and therefore, ThroughPut AI’s patented, Gartner-recognized AI-powered Supply Chain Analytics and Decision Intelligence software ensures that every effort is made to establish a robust data engine for accurate AI-powered forecasting and decision-making.

Such quality validation is crucial, as a seemingly simple mislabeling of a product category could potentially lead to, for example, a 10% inefficiency in demand forecasting.

This thorough preparation prevents costly corrections in the long run and accelerates the path to ROI.

Step 3: Metric Selection

During the next step, we focus on validating key metrics.

Insights from the ThroughPut AI platform are reviewed by the team to ensure that business objectives are being met.

Parameters such as supplier performance, demand forecasts and inventory turnover are analyzed to ensure a responsive supply chain.

Validating these metrics demonstrates AI effectiveness in real time, while also allowing for adjustments to ensure a closer alignment with operational goals.

In a nutshell, metric validation ensures that the impact of the AI implementation is directly proportional to business outcomes.

For example, a 5% improvement in delivery times could in turn affect a 2% increase in customer satisfaction.

Other key metrics that can track the impact of the AI project include order accuracy, warehouse throughput, inventory carrying costs, etc. can provide tangible indicators of success.

This step is key as it ensures that the results of the project are observable and measurable, facilitating clear validation of the benefits of AI implementation.

Step 4: User Adoption and Feedback

Approximately a few weeks into the process, user adoption becomes the focal point of the process, when ThroughPut commences platform training and gathering feedback.

The platform users, who play a critical role in the system’s success, start leveraging ThroughPut and providing feedback – which is invaluable to affect adjustments and further tailoring of the AI model to align with the company’s goals.

This feedback loop, happening within just a few weeks of deployment, is key to ensuring that the AI system not only meets the needs of the business but is also user-friendly – which enhances both the speed and magnitude of ROI.

The feedback stage facilitates a deep dive into the AI system’s functionalities.

ThroughPut enables major use cases such as supply chain visibility and actionability, parts management, supply chain cost reduction, bottleneck detection, sales and operations (S&OP) planning, SKU optimization, inventory planning, demand segmentation and replenishment planning.

Each use case solves key business problems, like, bottleneck detection helps decrease downtime and boost productivity, S&OP planning helps minimize supply and demand variance, SKU optimization helps mitigate supply chain risks while managing demand and market fluctuations, inventory planning enables intelligent, just-in-time demand fulfillment, demand segmentation accelerate profitability while eliminating product shortages, unpredictable lead times, and order backlogs, and replenishment planning automates demand replenishment to minimize inventory costs and lost sales.

Fine-tuning the AI model to achieve these objectives is critical to ensuring project success.

Step 5: Ongoing Validation & User Acceptance

This phase involves launching a continuous process of ongoing validation and user acceptance.

User feedback thus generated is used to inform model adjustments, ensuring that the AI remains aligned with the evolving needs of the business.

For example, did the AI system help achieve a 50% reduction in overstock, or did it enable a 12% decrease in inventory costs?

This step sets the stage for continuous improvement – it ensures that the AI not only works in terms of achieving the long-term goals of the business but also for the people who use it every day.

In other words, ThroughPut ensures that the AI solution is not only technically sound but also fully adopted – a critical step to achieve rapid ROI.

This also enables forward planning, such as expanding the project to other products, product categories, etc., or refining the AI models for better accuracy/to adapt to new business goals.

Step 6: Decision Regarding Extended Platform Use Post POC

The final phase culminates in a decision: whether or not to proceed with full-scale implementation.

This is where the pilot project’s results are analyzed, to decide whether to define expansion and go forward with full-scale deployment of ThroughPut AI.

This decision is based on alignment with partnership agreements and additional functionality requirements that have been identified during the pilot project.

Final results are presented, and model changes are reviewed to arrive at a strategic decision taking into account the payoff (measurable benefits) against the initial investment in AI.

Real-world Examples Proving ThroughPut ROI And Faster Time to Value

ThroughPut enables businesses to achieve financial as well as operational ROI.

Below are a few examples of how we achieved unparalleled financial ROI.

1. Global Cement Manufacturer Achieves $1.5M Working Capital Savings

A leading building materials & cement manufacturer with over a century of industry experience wanted to identify efficiency opportunities across the value chain that could help them maximize working capital savings to reduce hidden and unplanned bottlenecks.

Download this case study to learn how ThroughPut enabled the manufacturer to:

- Enhance product mix and segmentation while reducing excess inventory

- Identify optimal stock levels and reduce working capital

- Drive 17.8% improvement in yield margins

2. Next-Gen Aerospace Sensor Manufacturer Maximizes Capacity Utilization to Achieve $10 Million in Annual Savings

A US-based, highly innovative aerospace manufacturer with over a century of experience and a reputation for building next-gen sensor technology for use in commercial as well as defense navigation applications wanted to perfect their complex production processes and eliminate bottlenecks to increase production output without compromising on quality or production and delivery timelines.

Download this case study to learn how ThroughPut enabled the manufacturer to:

- Accelerate productivity by 20%, leading to annual potential savings of up to $10 million

- Reduce processing time by 10%, leading to a significant positive impact on customer experience

- Anticipate and prevent production inconsistencies

3. European Retail Megacorp Optimizes 15000+ SKU Mix to Boost Profit Margins by €30 Million

A leading European retail giant that had been operating for nearly 65 years and was one of the first retailers in the region to lead the transition to organic products and online shopping wanted to shift to a data-driven approach to demand management, eliminate low-value SKUs and optimize allocation and replenishment of resources, and reduce material, operational, and logistics costs.

Download the case study to learn how ThroughPut enabled the retailer to:

- Implement AI-powered demand sensing to monitor and analyze shifting demand patterns at an SKU level in real time

- Significantly reduce logistics costs

Below are a few examples of how ThroughPut enabled rapid operational ROI.

4. Global Cement Manufacturer Optimizes Truck Yards per Hour Utilization, Minimizing CO2 & Waste

An industry-leading innovator in sustainable building solutions wanted to improve asset utilization of its trucks, while at the same time reducing carbon emissions.

Download the case study to learn how ThroughPut enabled the company to:

- Optimize its logistics network

- Effectively segment customers for optimized truck utilization

- Reduce CO2 emissions and improve asset utilization

5. Church Brothers Farms Leverages Existing Data to Accurately Predict Near-term Demand for Perishable Goods

A leading grower-owned fresh vegetable producer, processor, and shipper was looking to accurately forecast demand and accordingly optimize its product mix to better serve its customers and maximize profitability.

Download this case study to learn how ThroughPut enabled the company to optimize operations by answering a few simple questions about sales frequency and volume, price and revenue, distribution, and specialty sales.

In Conclusion

The transition to AI-enabled decision-making, while urgent, is not something that can be implemented overnight.

It needs to be phased out while ensuring adequate ROI at a reasonable pace.

Partnering with experts like ThroughPut, can help businesses harness the power of AI rapidly while minimizing their exposure to risk.