Demand Planning Software – the Essential Software Guide for 2026

Choosing the right demand planning software is critical for businesses that want to streamline their supply chain and manufacturing processes.

With many options, each promising a range of features and benefits, selecting the most suitable software can be daunting. The challenge lies in navigating the technical specifications and understanding which software best aligns with your business objectives.

Making the correct choice could lead to adequate demand forecasting, resulting in inventory mismanagement, lost sales opportunities, and increased operational costs.

This article serves as a guide to demystify the process of selecting demand planning software.

It is tailored for supply chain professionals, demand planners, and C-level executives. It provides insights into the essential aspects of demand planning software, including its key features, implementation strategies, and advantages.

What is Demand Planning Software?

Demand planning software is a digital tool designed to help businesses efficiently predict future demand for their products or services.

This type of software plays a crucial role in supply chain management by facilitating better inventory control.

It analyzes historical sales data, current market trends, and potential influencing factors.

The demand planning software improves forecasting accuracy, optimizes inventory levels, decreases stockouts and overstock incidents, and supports strategic business decisions.

The core components of demand planning software include:

Data Collection

This feature gathers historical sales data, market trends, and other relevant information from various sources, including ERP (Enterprise Resource Planning) systems, CRM (Customer Relationship Management) systems, and external market research.

Data Analysis

Once the data is collected, the software analyzes it to identify patterns, trends, and anomalies. This analysis is crucial for understanding past performance and predicting future demand.

Forecasting Algorithms

Demand planning software uses sophisticated algorithms and statistical models to forecast future demand.

These models can include time series analysis, regression analysis, and machine learning techniques.

The software may also allow for scenario planning, enabling businesses to explore different “what-if” situations and their potential impact on demand.

What are the Types of Demand Planning Software

The main types of demand planning software are cloud-based solutions, on-premise software, and integrated software suites.

Cloud-based solutions are hosted on the provider’s servers and accessed online. Cloud-based demand planning software offers the advantages of scalability, flexibility, and lower upfront costs.

It suits businesses looking for quick deployment and minimal IT infrastructure investment.

On-premise software is installed and runs on the company’s servers. On-premise solutions offer greater control over data security and customization but require a higher initial investment in hardware and IT resources.

Integrated suites are a part of a more extensive integrated suite of supply chain management tools.

These suites offer comprehensive functionality covering various aspects of supply chain management, including inventory management, procurement, and logistics.

Integrated suites are ideal for businesses seeking a holistic approach to supply chain optimization.

Why is Demand Planning Software Important?

Demand planning software is important because it enhances forecasting accuracy, increases supply chain efficiency, and helps companies gain a competitive advantage.

Here’s a short breakdown of each benefit:

Enhancing Forecast Accuracy

Demand planning software significantly enhances the accuracy of demand forecasts by utilizing advanced statistical methods and machine learning algorithms.

This technology analyzes historical data, identifies patterns, and accurately predicts future demand.

Better accuracy helps businesses effectively minimize the risks associated with overproduction or underproduction, reducing the costs associated with excess inventory and stockouts.

Accurate forecasting ensures that companies maintain optimal inventory levels, avoiding the financial strain of unsold stock and emergency restocking.

Benefits to Supply Chain Efficiency

Accurate demand planning is pivotal for achieving overall supply chain efficiency.

Demand planning software provides reliable demand forecasts and enables companies to streamline their operations across various departments, including procurement, production, and distribution.

This synchronization ensures that resources are allocated efficiently, reducing waste and enhancing responsiveness to market changes.

Moreover, the agility afforded by effective demand planning allows businesses to adapt quickly to new opportunities or challenges, maintaining a competitive edge in rapidly changing markets.

Competitive Advantage

In today’s highly competitive business environment, effectively aligning supply with market demand is crucial for sustaining profitability and market share.

Demand planning software facilitates this alignment by providing detailed insights into consumer demand trends.

Companies can leverage this information to make informed decisions about product development, marketing strategies, and sales initiatives.

Furthermore, anticipating market needs and responding appropriately enhances customer satisfaction and loyalty, which are critical drivers of competitive advantage.

Businesses can outperform competitors and capture more significant market share by ensuring product availability and minimizing delays.

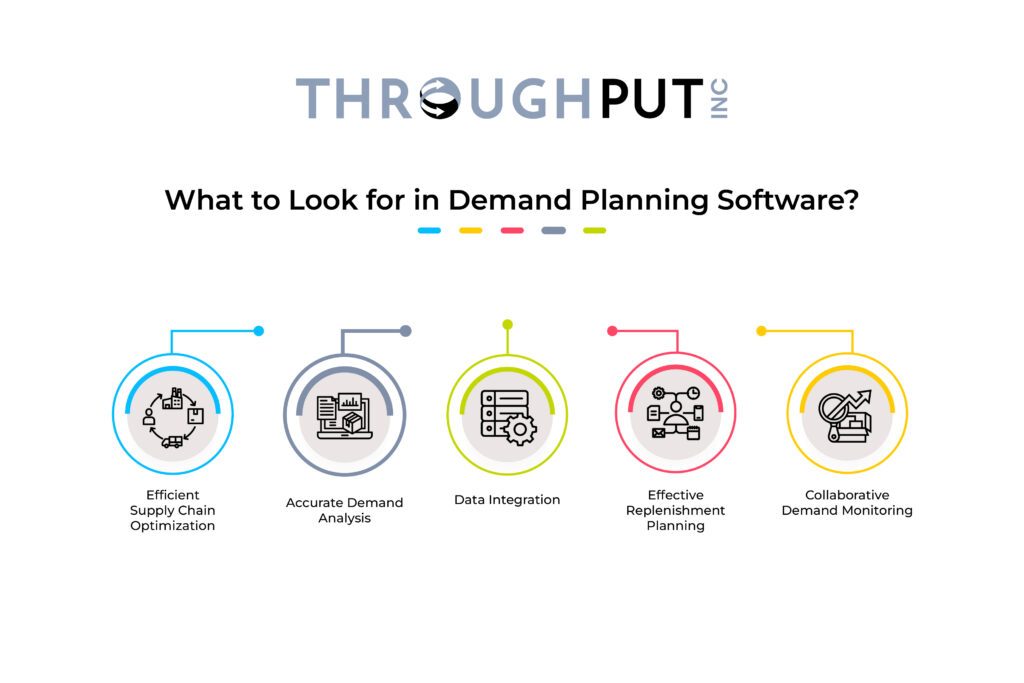

What to Look for in Demand Planning Software?

When evaluating different demand planning software options, consider the software’s data integration capabilities, demand analysis , and supply chain efficiency optimization features.

Data Integration

Data integration plays a crucial role in making a demand planning solution successful because it allows all the desirable data from disparate sources, such as sales history, orders, inventory levels, shipment, and customer feedback, to be consolidated and centralized.

When amassed in a single storage, you can examine and exploit it more skillfully and precisely. Optimally interpreting such data trends can magnificently improve the precision of your demand forecasts retrospectively.

Besides, the capacity for data integration also tirelessly checks for data quality issues proactively, such as missing or inconsistent data from assorted sources.

It even assures collaboration among various teams and departments unified in an organization.

This collated data inflow ensures an all-around association connected with different commerce outgrows, like marketing and sales production. The software’s demand forecasts are based not only on single-market demands but also on buyers’ preferences.

Efficient Supply Chain Optimization

Efficient supply chain optimization software is crucial to effective decision-making when prioritizing demand based on specific criteria such as product type, customer demographics, region, and brand.

Efficient forecasts help businesses to manage inventory levels, production schedules, and product distribution strategies more effectively.

Automating the supply chain planning process can provide real-time recommendations on optimal inventory levels, production volumes, and schedules at multiple locations.

It also facilitates the early recognition of potential supply chain disruptions, such as delivery or production delays, which may hinder meeting demand. When real-time information is factored into supply chain planning, companies can react more quickly and accurately to fluctuations in demand.

Accurate Demand Analysis

An effective AI demand planning solution will present an in-depth and multi-faceted sensitivity analysis. Such an analysis gauges variable impact via product differentiation, pricing, stock delivery, seasonal patterns, and trend fluctuations.

This comprehensive system will also provide knowledge of the evolving needs and focal points driving demand from internal and external sources.

Effective Replenishment Planning

Having the appropriate demand planning tool in place is essential in achieving effortless inventory management, ensuring supplies are distributed in the correct quantities and locations, and accommodating anticipated consumption patterns.

This innovative demand planning solution adopts a demand-leading approach; it enables businesses to undertake efficient organizational operations, delivering significant benefits.

Collaborative Demand Monitoring

A productive demand planning tool delivers adaptable dashboards that allow you to track demand in real-time, drill down according to specific product segments, selling channels, and regions, and respond to promotional events.

This solution seamlessly integrates monitoring actual versus intended demand levels, enabling suitable notifications to be sent promptly so that you can effectively manage overrunning or inadequate demand.

What are the Key Features of Demand Planning Software?

The key features of demand planning software are accurate statistical forecast, demand forecasting, material requirements planning (MRP), forecast approval system, and revenue planning features.

These features handle everything from data analysis to inventory optimization and supply chain planning, ensuring businesses can effectively meet their customers’ demands while maintaining operational efficiency.

Here’s a breakdown of each feature:

Accurate Statistical Forecast

Demand planning software’s core is its ability to generate accurate statistical forecasts. This feature uses historical sales data and advanced statistical algorithms to predict future demand.

The accuracy of these forecasts is crucial for maintaining optimal inventory levels, avoiding overproduction or shortages, and minimizing associated costs.

Demand Forecasting

Demand forecasting employs sophisticated machine learning and artificial intelligence technologies to analyze past sales data and detect trends.

This not only helps in anticipating market demands but also adjusts production schedules and inventory management practices accordingly. This feature’s adaptability ensures that businesses respond swiftly to market changes, maintaining a balance between supply and demand.

Material Requirements Planning (MRP)

Material Requirements Planning is another vital feature that calculates the necessary materials and components required for production based on demand forecasts.

MRP optimizes resource utilization and minimizes waste by aligning production operations with market demand. Integration with ERP systems enhances this feature, ensuring real-time updates and coordination across procurement and inventory management.

Inventory Planning and Optimization

Inventory planning and optimization tools are essential for maintaining the proper stock levels to meet anticipated customer demands without resulting in excess inventory.

Features such as re-order point calculation, safety stock, and economic order quantity are integral to this process, helping businesses avoid the costs of unsold stock and emergency restocking.

Essential Integrations

Demand planning software’s ability to integrate seamlessly with ERP and CRM systems significantly enhances its effectiveness.

This integration allows for efficient data exchange across different business functions, ensuring that all aspects of the supply chain are informed by accurate and up-to-date information.

ROI Factors for Demand Management Software

The return on investment (ROI) from demand planning software manifests in several ways, including cost reduction through optimized inventory levels, increased sales from improved product availability, and efficiency gains from the automation of manual tasks.

These factors collectively contribute to a more robust bottom line and enhanced operational efficiency.

Forecast Approval System

A forecast approval system provides a control mechanism where senior management can review and approve forecasts before they are finalized. This ensures the forecasts align with the business’s strategic goals and provides an audit trail for compliance and reference.

Revenue Planning

Revenue planning features integrate demand and financial planning to forecast revenue based on projected sales volumes.

This integration helps businesses plan their financial strategies more effectively, considering the potential impacts of different market scenarios.

Flexible Manual Adjustments

Making flexible manual adjustments to forecasts allows planners to incorporate the latest market information or insights that may not be reflected in historical data.

This feature ensures that businesses can quickly adapt to changes, maintaining relevance and responsiveness in a dynamic market environment.

New Products Forecasting

Demand planning software for new products without historical sales data uses predictive tools that analyze market trends and competitive data to forecast demand.

This is crucial for launching new products successfully and capturing market interest early on.

Demand and Revenue Planning

This feature combines demand forecasting with revenue planning and aligns supply chain activities with financial goals.

It helps businesses identify the most profitable products and customer segments, focusing efforts where they are most likely to enhance profitability.

How to Implement Demand Planning Software?

The implementation of demand planning software is a 3-step process that starts with preparation and planning, selecting the right software vendor for the supply chain’s needs, and finishing with adoption and training.

This critical process requires careful planning and execution to deliver the intended benefits.

Here’s a practical guide to implementing demand planning software in an organization:

STEP 1: Preparation and Planning

The first step in implementing demand planning software involves thorough preparation and planning. This stage ensures that all necessary prerequisites are addressed, setting the foundation for a successful implementation.

- Data Audit

Conduct a comprehensive audit of existing data to assess its quality, accuracy, and relevance. This involves identifying data sources, evaluating the completeness of the data, and cleansing any outdated or incorrect information. Ensuring accurate data is crucial as it forms the basis of all demand forecasting. - Determining System Requirements

Determine the technical requirements needed to support the demand planning software. This includes assessing current IT infrastructure, hardware, and software capabilities to ensure compatibility with the new system. Considerations should include data storage needs, processing power, and network capabilities. - Process Mapping

Map out current demand planning processes to identify any gaps or inefficiencies that the software should address. This helps customize the software to meet specific organizational needs. - Stakeholder Engagement

Engage key stakeholders from various departments such as sales, marketing, finance, and operations. Their input is invaluable as they can provide insights into the practical needs and challenges that the software should address.

STEP 2: Choosing the Right Vendor

Selecting the right software vendor is crucial as it affects the quality of the software , as well as the support and service you will receive.

- Vendor Evaluation

Create a shortlist of vendors offering demand planning software that meets your needs. Evaluate each vendor based on their market reputation, the robustness of their software, and feedback from existing users. - Customization Capabilities

Assess how the software can be customized to fit your business processes and needs. Customization is critical to ensuring the software can effectively support your unique demand planning processes. - Support and Service

Consider the level of support provided by the vendor. This includes the availability of technical support, the responsiveness of customer service, and the provision of regular updates and maintenance. - Cost Consideration

Analyze the cost of the software, including initial purchase costs, implementation fees, and ongoing maintenance expenses. Ensure that the cost is within your budget and provides good value for money.

STEP 3: Training and Adoption

The final step involves training the users and facilitating software adoption across the organization.

- Comprehensive Training

Develop a comprehensive training program that covers how to use the software effectively. Training should be tailored to different user groups based on their roles and interactions with the software. - Change Management

Implement change management strategies to help staff transition to the new system. This includes communicating the new system’s benefits, addressing any concerns, and providing ongoing support to ensure smooth adoption. - Pilot Testing

Before full-scale implementation, pilot testing with a small group of users is conducted to identify any issues and gather feedback. This allows for adjustments before rolling out the software across the entire organization. - Feedback Loop

Establish a feedback loop where users can report issues, suggest improvements, and provide insights on the software’s performance. This ongoing feedback is crucial for continuous improvement and optimization of the demand planning process.

Demand Planning with Throughput

ThroughPut AI transforms demand planning using sophisticated AI and machine learning technologies to improve data analysis, allowing companies to forecast future demand accurately.

This transition away from conventional, manual techniques minimizes operational inefficiencies and errors.

The software’s thorough sales data analysis, market trends, and external influences, such as economic indicators, result in highly accurate demand forecasts.

Based on these forecasts, ThroughPut AI also suggests optimal strategies for aligning inventory, production, and procurement. These strategies minimize the risks associated with overstocking and understocking, thus enhancing operational efficiency and customer satisfaction.

A key feature of this tool, especially in today’s unpredictable market, is its ability to forecast short-term demand and adjust the demand plan based on real-time data.

This capability gives supply chains the essential flexibility to adapt to fluctuating market conditions and avoid losses due to inadequate foresight.

Moreover, ThroughPut’s capabilities in demand segmentation, SKU optimization, and replenishment planning, all grounded in a demand-centric approach, enable businesses across various sectors to make critical decisions that significantly affect their financial outcomes.

Schedule a demo to discover how to plan demand effectively with ThroughPut AI.

Frequently Asked Questions (FAQs) About Demand Planning Software

1 How do I know if my business needs demand planning software?

If your business struggles with frequent stockouts, excess inventory, inaccurate forecasts, or reactive decision-making, you need demand planning software.

Organizations managing multiple SKUs, locations, or volatile demand patterns especially benefit from AI-driven demand planning, as it replaces manual forecasting with data-backed, real-time insights.

2. What is the difference between traditional demand planning tools and AI-powered demand planning software?

Traditional demand planning tools rely heavily on historical averages and manual adjustments, making them slow to respond to demand volatility.

AI-powered demand planning software, like ThroughPut AI, uses machine learning to:

- Detect demand patterns automatically

- Sense demand changes in near real time

- Continuously improve forecast accuracy

- Recommend actionable decisions, not just predictions

This leads to faster planning cycles, lower inventory risk, and higher service levels.

3. How long does it take to implement demand planning software?

Implementation timelines vary based on data readiness, integrations, and organizational complexity.

On average:

- Cloud-based AI demand planning solutions can go live in 8–16 weeks

- Legacy or heavily customized systems may take longer

Platforms like ThroughPut AI accelerate implementation by integrating quickly with ERP systems and using pre-built AI models.

4. Can demand planning software integrate with ERP systems like SAP or Oracle?

Yes. Modern demand planning software is designed to integrate seamlessly with ERP systems such as SAP, Oracle, Microsoft Dynamics, and other data sources like CRM and POS systems.

Strong ERP integration ensures:

- Real-time data synchronization

- Accurate forecasts

- Faster cross-functional decision-making

ThroughPut AI is built for enterprise-grade ERP and supply chain integrations.

5. How does demand planning software improve inventory performance?

Demand planning software improves inventory performance by:

- Reducing overstock and obsolete inventory

- Preventing stockouts and lost sales

- Optimizing safety stock and reorder points

- Aligning inventory with actual demand signals

AI-driven tools go a step further by recommending optimal inventory actions across SKUs, locations, and time horizons.

6. Is demand planning software suitable for manufacturing businesses?

Absolutely. Demand planning software is especially valuable for manufacturing companies dealing with:

- Long lead times

- Complex BOMs

- Capacity constraints

- Demand variability

By aligning demand forecasts with production and material planning, manufacturers can reduce waste, improve service levels, and increase throughput.

7. How does demand planning software handle new product forecasting?

For new products with no historical data, demand planning software uses:

- Market trends

- Comparable product data

- Pricing and promotion inputs

- AI-based predictive modeling

This enables businesses to launch products with greater confidence and avoid costly inventory mistakes.

8. What ROI can I expect from demand planning software?

Most organizations see ROI in the form of:

- 10–30% reduction in inventory holding costs

- Improved forecast accuracy (up to 95% in stable categories)

- Higher service levels and revenue capture

- Reduced manual planning effort

AI-powered platforms like ThroughPut AI typically deliver measurable ROI within the first few planning cycles.

9. How do I choose the best demand planning software for my business?

The best demand planning software should offer:

- AI-driven forecasting and demand sensing

- Strong ERP and data integrations

- Scenario and what-if planning

- Real-time visibility and alerts

- Proven results in your industry

Evaluating vendors based on outcomes—not just features—is critical at the decision stage.

10. Why choose ThroughPut AI for demand planning?

ThroughPut AI goes beyond forecasting by turning demand insights into actionable supply chain decisions.

Its AI-driven platform helps businesses:

- Sense and respond to demand volatility

- Optimize inventory and replenishment

- Align demand, supply, and financial goals

- Improve service levels while reducing costs

It is designed for organizations that want measurable results, not just reports.