Over the past few years, the relentless disruptions of the Covid-19 pandemic, natural calamities, geopolitical tensions and economic instability have exposed glaring vulnerabilities in supply chains across the globe. As a result, executives and boards of directors everywhere are upping the pressure on supply chain leaders to de-risk the supply chains.

With a lot of these issues expected to persist or worsen going ahead, Chief Supply Chain Officers (CSCOs) are urgently looking to reinvent business strategies and prioritize agility, resilience, and sustainability in supply chain management. It’s no wonder that a KPMG study has found that 50% of supply chain organizations plan to invest in artificial intelligence (AI) applications and advanced analytics capabilities through 2025.

That said, implementing AI in your supply chain can be a daunting task.

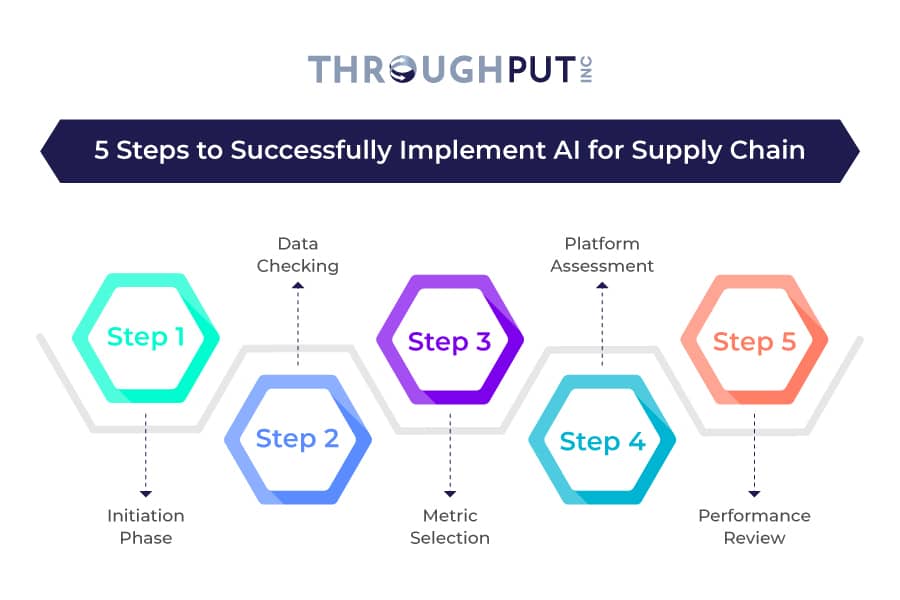

Here are five steps to help you implement AI in your supply chain and logistics to enhance their performance and outcomes.

5 Steps to Successfully Implement AI in Your Supply Chain

Step 1: Initiation Phase

First things first: It is easy to get swayed by the glitz and glam of the latest AI technologies, but don’t start your supply chain AI project by choosing the tool first.

Instead, start by documenting current processes and identify issues.

For example, what is the overall workflow? What are the common challenges, and where are the bottlenecks most frequent? What are the individual variations needed for specific issue resolution?

Every AI project starts with a problem – not a broad problem, like plain automation or augmentation, but a business problem. Are you losing money to inventory mismanagement? Is poor capacity planning tying up working capital? Are you losing sales opportunities to poor forecasting?

Defining the problem/s clearly will give you clarity around what you are trying to achieve – what’s your goal. This will, in turn, help you set the objectives for the AI project, and draft a detailed plan outlining the scope, timeline, and milestones of the project.

Step 2: Data Checking

This step involves preparing the data for the AI system.

The quality of your AI model largely depends on the quality of your data input.

Unfortunately, many organizations commonly face challenges with data being incomplete, irrelevant, or invalid/inaccurate.

Having gaps in data, in turn, trigger inaccuracies even in the best supply chain AI projects.

For example, a mislabeled product category can lead to a 10% inefficiency in demand forecasting.

Therefore, it is essential to perform an exhaustive audit and check for completeness and accuracy to fix data quality before commencing AI modeling. Thorough data cleansing significantly enhances the accuracy of AI’s predictive analytics in supply chains.

Step 3: Metric Selection

Not everything can be improved or enhanced at the same time with AI. From the problem/s you have identified in Step 1, now is the time to narrow the focus to specific processes or products for a pilot.

For example, you can aim to achieve a 5% improvement in the delivery time of a top-selling product that can lead to a 2% increase in revenue due to increased orders, or you can focus on a 3% reduction of inventory that could realize a 4% increase in margins.

Based on the outcome chosen, key metrics can be identified to track the impact of AI, such as “order accuracy” or “warehouse throughput”. This is important to enable tangible measurement of success and to ensure you are on track with what you intend to achieve.

Impact needs to always be observable and measurable to ensure clear validation of the benefits of AI implementation.

Step 4: Platform Assessment

Platform selection only comes in at step 4 while implementing AI in your supply chain.

The platform assessment stage involves a comprehensive analysis of the functionalities of the AI system, based on the outcome you wish to achieve.

It is important, at this stage, to have the right questions defined to ask the supply chain planning and management vendors you’re accessing.

For example, top reasons why ThroughPut.ai is a preferred choice for multiple industries including military and defense, retail, food & beverages, cement and transportation is because:

- ThroughPut achieves faster ROI

By identifying areas within the supply chain with the maximum impact on the bottom line and in the fastest possible time, ThroughPut gets you to the desired ROI faster.

- Works with existing data

ThroughPut works with existing data. Every supply chain has huge volumes of data, though they may be siloed. Integrations with SAP, Microsoft Dynamics 365, project44 and APIs to connect with legacy systems saves time that is often lost in data preparation.

- Customizable to multiple use cases and industries

ThroughPut’s AI is trained to cater to multiple use cases across industries including capacity planning, demand sensing, demand segmentation and logistics planning among others.

Step 5: Outcome Review

This is where the success of the project is measured by reviewing the selected success metrics against defined objectives.

For example, did the implementation of AI in your supply chain help achieve a 50% reduction in overstocking? Or did it improve margins by 7%?

Based on success rates, you can commence forward planning and determine whether to expand the role of AI, or refine its algorithms for more accurate results.

Thus, this stage sets the foundation for a continuous loop of learning from, and improvement of, outcomes – and eventually scaling the project for implementation of AI across other supply chains.

Best Practice Tip: Always Start with a Pilot

It is always advisable to start small and scale fast.

The best advantage of beginning with pilot projects is that you can test theories, validate concepts, and demonstrate tangible value in a safer environment.

Once success has been established, you can rapidly scale up implementation while also leveraging lessons learned and continuously iterating processes to affect improved outcomes.

Start Your AI Project for Supply Chain Optimization Today!

AI is a key driver of competitive advantage in a wide variety of industries today, with use cases ranging from automation and optimization to personalized customer experiences and predictive maintenance. AI-powered supply chains offer unbeatable and innovative ways to differentiate offerings, transcend competition, and deliver undeniable value to customers.

In today’s data-driven world, AI-powered supply chains empower executives to make timely, intelligent decisions based on razor-sharp, real-time insights.

To get started today, reach out to ThroughPut AI.